1-2

SAFETY PRECAUTIONS

During servicing carefully observe the following.

1. OBSERVE ALL PRECAUTIONS

Items and locations that require special care during

serv-icing, such as the cabinet, chassis, and parts are

labelled with individual safety instructions. Carefully

comply with these instructions and all precautions in

the instruction manual.

2. BE CAREFUL OF ELECTRIC SHOCK

The chassis carries an AC voltage. If you touch the

chassis while it is still alive, you will get a severe

shock. If you think the chassis is alive, use an isolating

transformer or gloves, or pull out the plug before

replacing any parts.

3. USE SPECIFIED PARTS

The components have been chosen for minimum

ammability and for specic levels of resistance value

and withstand voltage. Replacement parts must

match these original specifications. Parts whose

specifications are particularly vital to safe use and

maintenance of the set are marked on the circuit

diagrams and parts list.

Substitution of these parts can be dangerous for you

and the customer, so use only specied parts.

4. REMOUNT ALL PARTS AND RECONNECT ALL

WIRES AS ORIGINALLY INSTALLED

For safety, insulating tape and tubes are used

throughout, but some lift-off parts on the printed wiring

board require special attention.

All wires are positioned away from high-temperature

and high-voltage parts, and, if removed for servicing,

they must be retuned precisely to their original

positions.

5. LAMP

Be very careful of the lamp because it generates high

heat while it is used at high voltage. When replacing

the bulb, make sure it is cool enough.

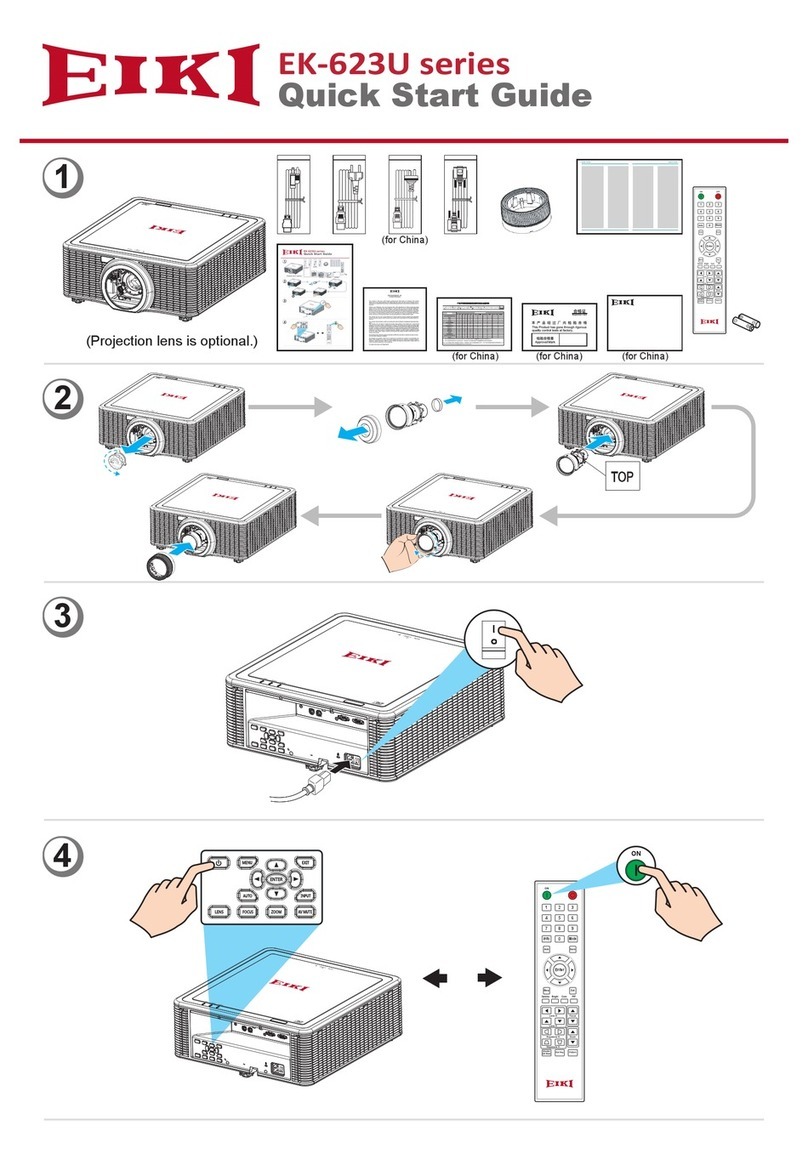

6. LENS

Do not look into the lens during projection. This

important to avoid damage to the eyes.

7. SERVICING

At the time of repair or inspection services, use an

earth band (wrist band), without fail.

8. RUN A COMPLETE SAFETY CHECK AT THE

COMPLETION OF SERVICING

After comp le ti on o f se rvicing , co nf ir m th at a ll

screws, parts, and wiring, removed or disconnected

for servicing, have been returned to their original

positions. Also examine if the serviced sections and

peripheral areas have suffered from any deterioration

as a result of servicing. In addition, check insulation

between external metallic parts and blades of wall-

outlet plugs. This examination is indispensable in

conrming complete establishment of safety.

(Insulation check)

Pull out a plug from a wall outlet to disconnect the

connection cable. Then turn on the POWER switch.

Use a 500V megger (Note 2) and confirm that the

insulation resistance is 1MΩ or more between each

terminal of the plug and exposed external metal (Note

1). If the measured value is below the specied level,

then it is necessary to inspect and x the set.

(Note 1)

Exposed external metal....RGB input terminals, control

terminals, etc.

(Note 2)

If a 500V megger is not available for an unavoidable

reason, then use a circuit tester or the like for inspection.