8

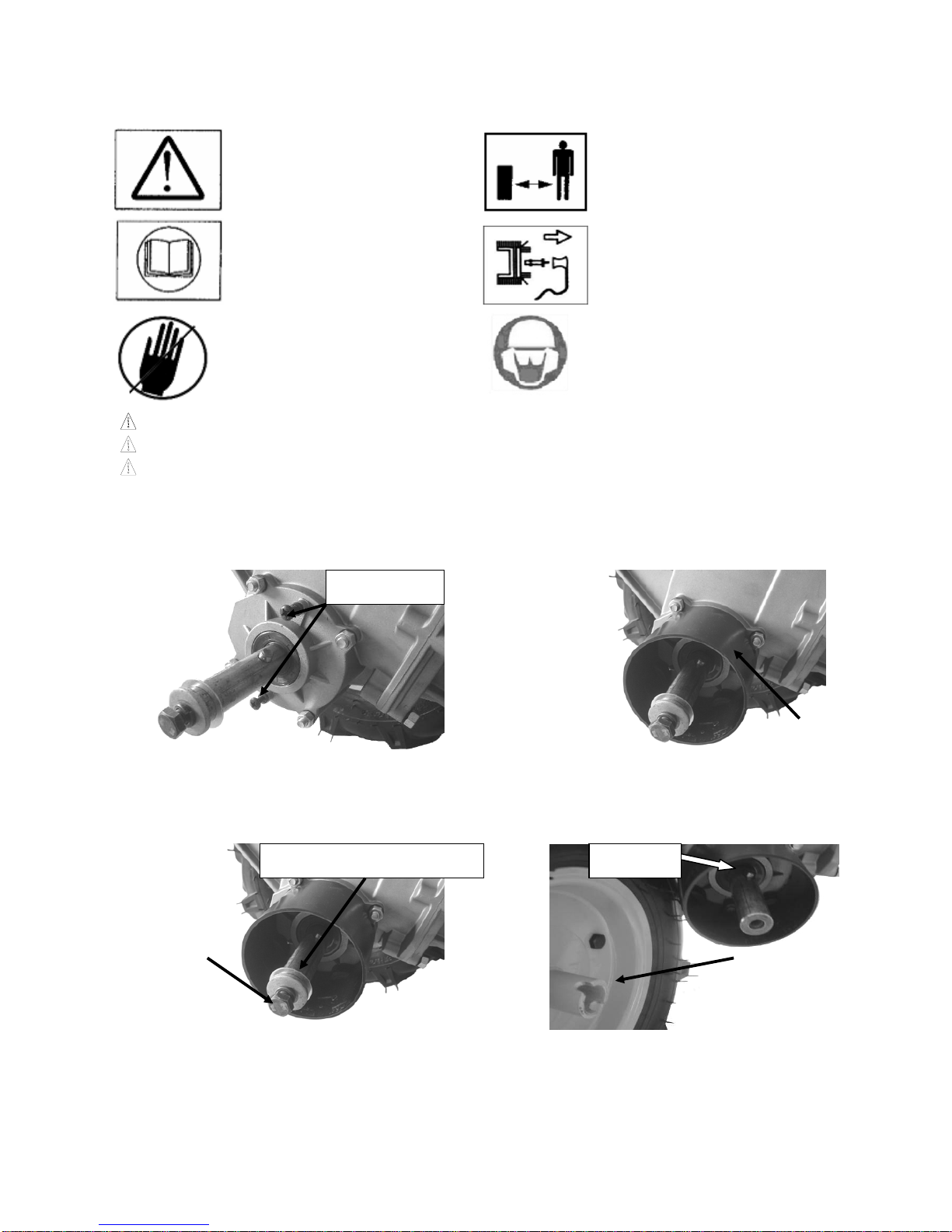

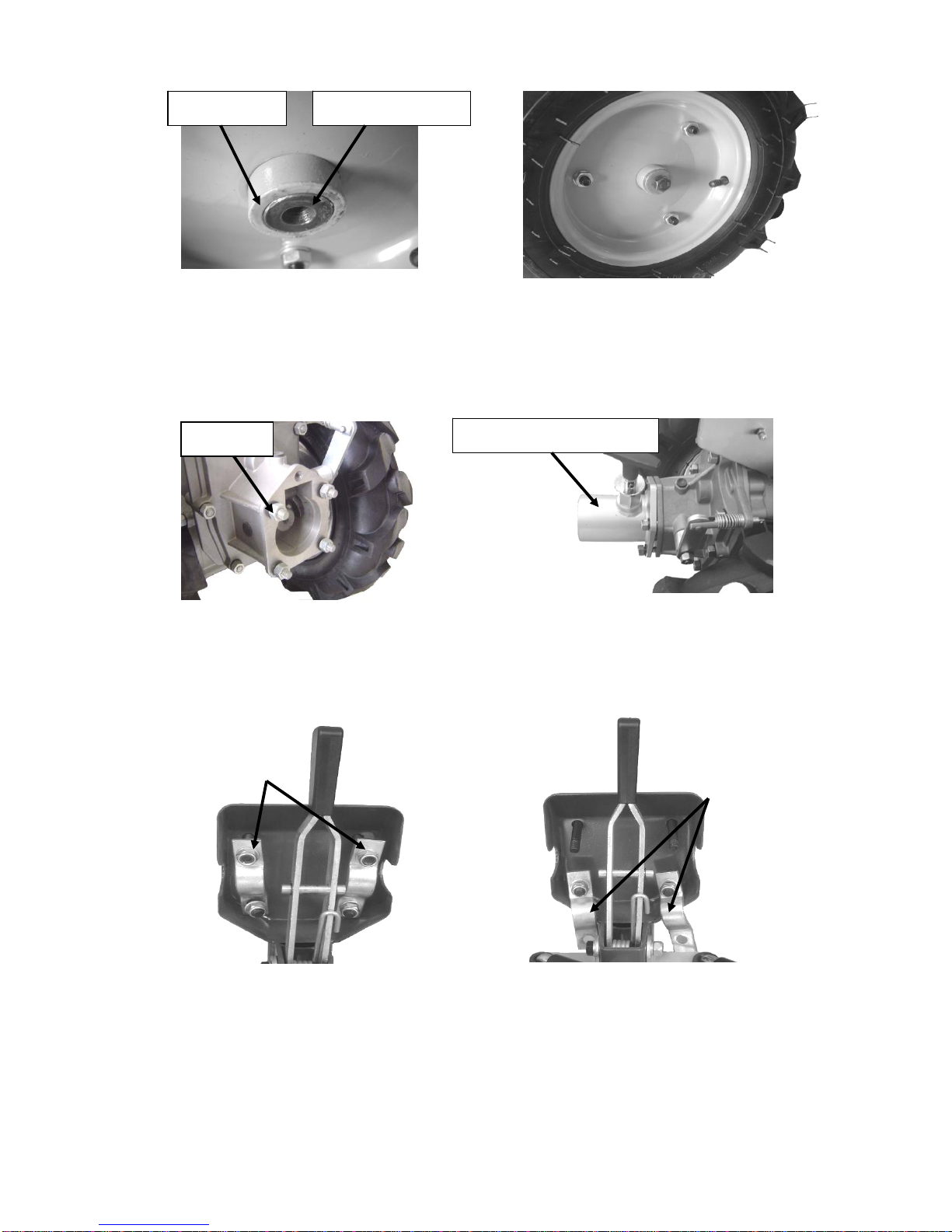

●Pull the cotter pin and the gear lever. See the diagram 20.

●Pull the steering hand lever and rotate it in accordance with instruction to suitable position and then

disengage it. See the diagram 21.

●Finally assemble the gear lever and cotter pin and arrange all the assemblies.

2. Height Control Hand Lever

●Customers could adjust the height to a suitable position by pushing down the height control hand lever. See

the diagram 22.

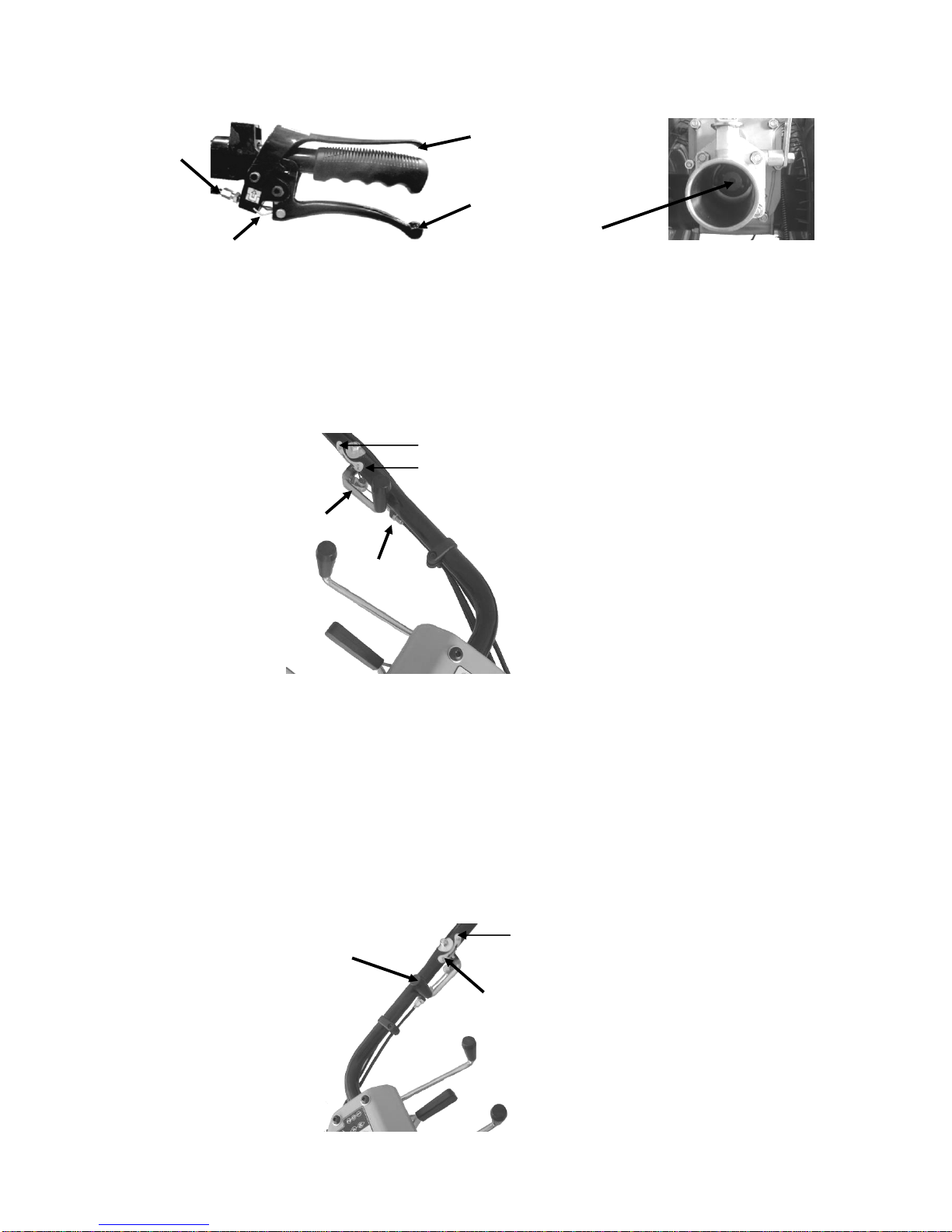

3. Input clutch handlebar and emergence shut-down handlebar

●Input clutch handlebar is meant to control the travel of gearbox. Under normal circumstance, it must be

disengaged. While when the engine starts or shifts the gear, it is necessary to hold the handlebar to protect the

gears from damage. See the diagram 23.

●Emergence shut-down handlebar is used to control gasoline flameout. Under working condition, the

handlebar must be held. If you don’t, the engine will stop. See the diagram 23.

●It is very important to learn to use input clutch handlebar and emergence shut-down handlebar. You must first

pull the latter and then the former. When disengaging the handlebar, we must bear against the input clutch

handlebar with guard ring. See the diagram 23.

●If you want to disengage the input clutch handlebar, open the guard ring and then the it will be disengaged

automatically.

●The Debugging of Input Clutch: Debug it without starting up. Release the handle of input clutch and lightly

tug the gasoline engine, then the output shaft should be rotating. If not, please turn the adjusting bolt

towards inner side. Seize the handle of input clutch; prop it with the guard ring and lightly tug the gasoline

engine, then the output shaft should not be rotating. If not, please turn the adjusting bolt towards the

outward side. See the diagram 23 and 24.

Diagram 20

Cotter lever

Gear lever

Steering hand lever

Diagram 21

Height control hand lever

Diagram 22