Nelco NBHP 18V Manual

Table of contents

Popular Water Pump manuals by other brands

Zoeller

Zoeller X161 owner's manual

Pentair

Pentair Sta-Rite WhisperfloXF Installation and user guide

Spinera

Spinera SUP2 operating instructions

ARO

ARO Ingersoll-Rand PX10P-FKS Series Operator's manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS PA Series Installation, operation, and maintenance manual with parts list

Titan

Titan 0528900D owner's manual

SAMES KREMLIN

SAMES KREMLIN AIRMIX 16C240 manual

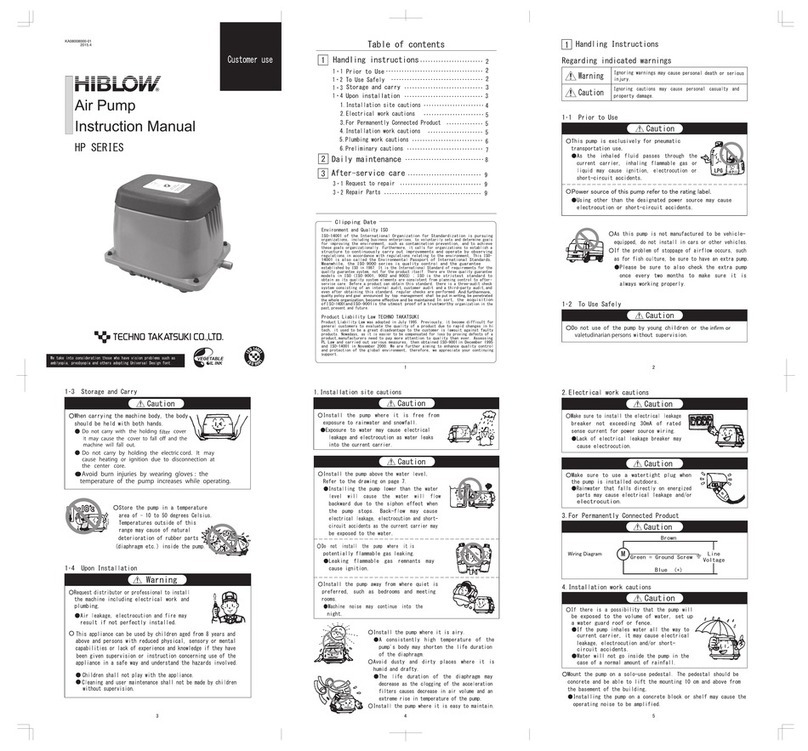

TECHNO TAKATSUKI

TECHNO TAKATSUKI HIBLOW HP Series instruction manual

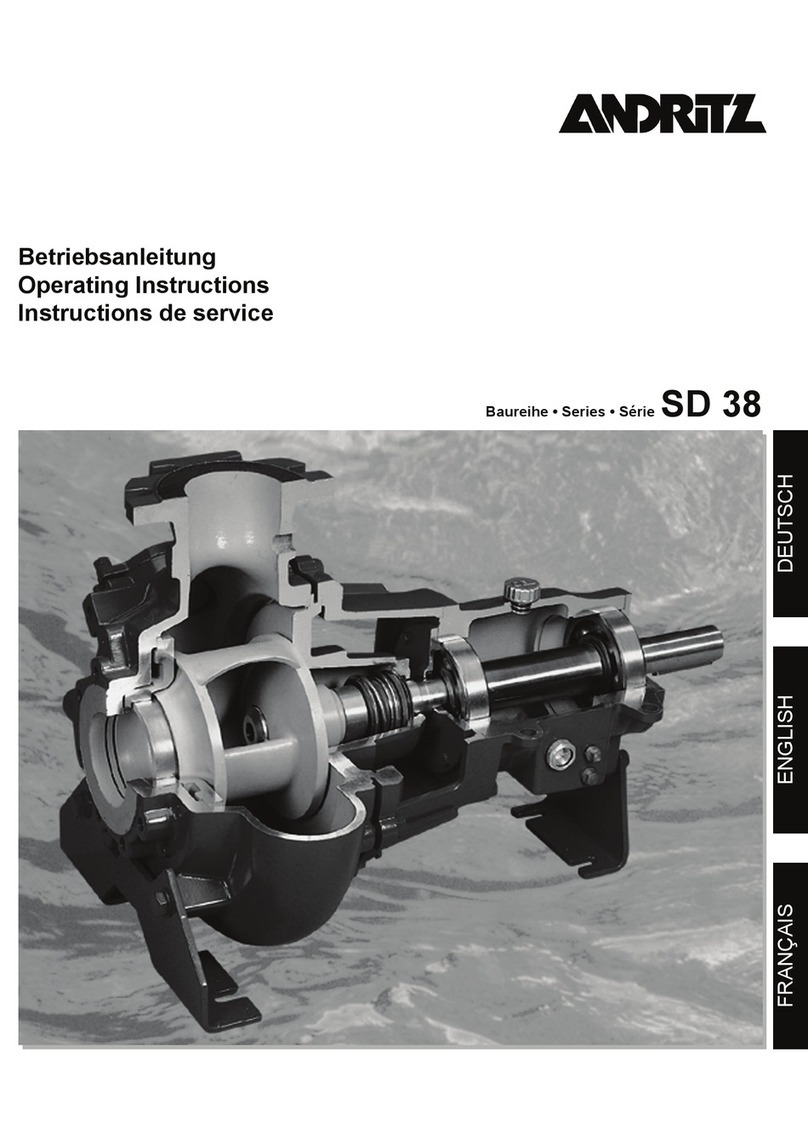

Andritz

Andritz SD 38 Series operating instructions

SFA

SFA SFA SANISPEED quick start guide

HP

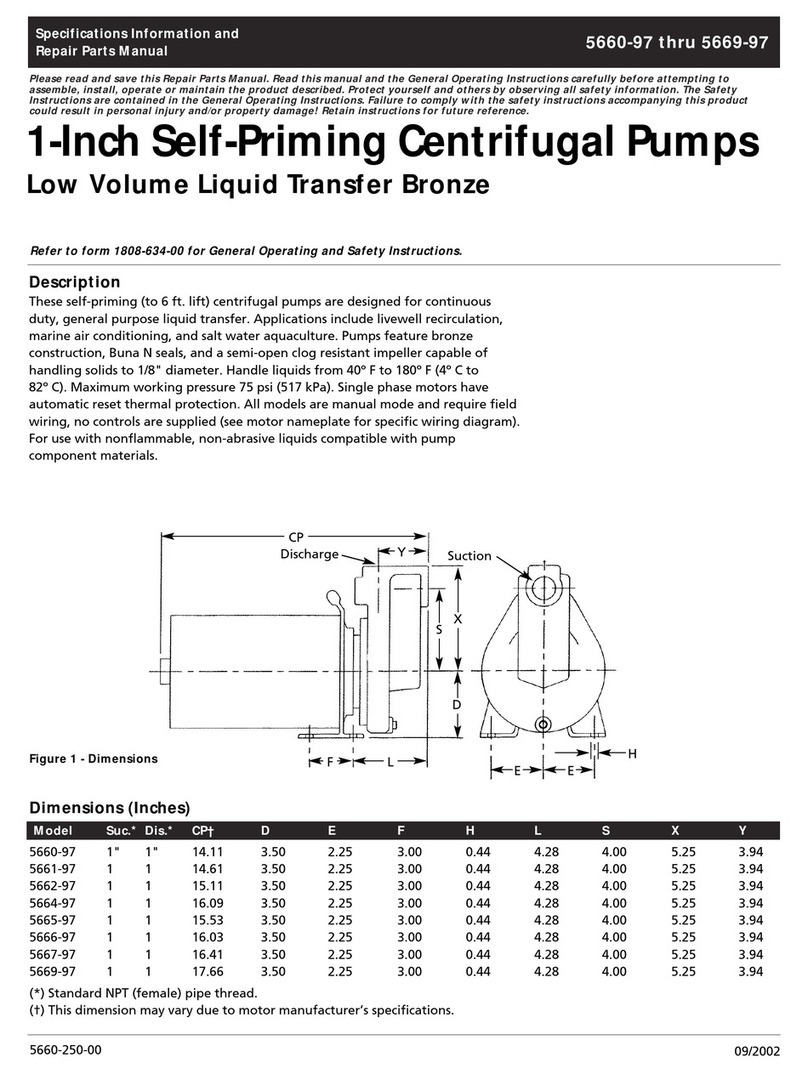

HP 5660-97 Specifications information and repair parts manual

Davey

Davey Dynapond 7000 Installation and operating instructions

BUSCH

BUSCH COBRA NC 0200 B Installation and maintenance instructions

Lutz-Jesco

Lutz-Jesco MEMDOS SMART LD operating instructions

Medela

Medela Clario toni Instructions for use

Graco

Graco SaniForce 1040e user manual

Arcomed

Arcomed Volumed uVP7000 Premium Maintenance manual

Ribimex

Ribimex Ribiland PRRBK200 User and maintenance manual