Neo Pro PTA07 Reference guide

PTA07

Powder Spray

Customer Product Manual Part

Issued 12/10

Table of Contents

Safety 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Qualified Personnel 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Use 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Personal Safety 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fire Safety 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Action in the Event of a Malfunction 1-3 . . . . . . . . . . . . . . . . . . . . . . . .

Disposal 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Label 1-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation and Maintenance 3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Daily Maintenance 3-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PTAG07 Automatic Gun 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diffuser 6-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Injector 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PTAU07Control Module Electrical Parts 6-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PTAU07Control Module Pneumatic Parts 6-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 1

Safety

Introduction

Read and follow these safety instructions. Task- and equipment-specific

warnings, cautions, and instructions are included in equipment

documentation where appropriate.

Make sure all equipment documentation, including these instructions, is

accessible to all persons operating or servicing equipment.

Qualified Personnel

Equipment owners are responsible for making sure that Promaks equipment

is installed, operated, and serviced by qualified personnel. Qualified

personnel are those employees or contractors who are trained to safely

perform their assigned tasks. They are familiar with all relevant safety rules

and regulations and are physically capable of performing their assigned

tasks.

Intended Use

Use of Promaks equipment in ways other than those described in the

documentation supplied with the equipment may result in injury to persons

or damage to property.

Some examples of unintended use of equipment include

_

using incompatible materials

_

making unauthorized modifications

_

removing or bypassing safety guards or interlocks

_

using incompatible or damaged parts

_

using unapproved auxiliary equipment

_

operating equipment in excess of maximum ratings

Personal Safety

To prevent injury follow these instructions.

_

Do not operate or service equipment unless you are qualified.

_

Do not operate equipment unless safety guards, doors, or covers are

intact and automatic interlocks are operating properly. Do not bypass or

disarm any safety devices.

_

Keep clear of moving equipment. Before adjusting or servicing any

moving equipment, shut off the power supply and wait until the

equipment comes to a complete stop. Lock out power and secure the

equipment to prevent unexpected movement.

_

Relieve (bleed off) hydraulic and pneumatic pressure before adjusting or

servicing pressurized systems or components. Disconnect, lock out,

and tag switches before servicing electrical equipment.

_

Obtain and read Material Safety Data Sheets (MSDS) for all materials

used. Follow the manufacturer.s instructions for safe handling and use

of materials, and use recommended personal protection devices.

_

To prevent injury, be aware of less-obvious dangers in the workplace

that often cannot be completely eliminated, such as hot surfaces, sharp

edges, energized electrical circuits, and moving parts that cannot be

enclosed or otherwise guarded for practical reasons.

Fire Safety

To avoid a fire or explosion, follow these instructions.

_

Do not smoke, weld, grind, or use open flames where flammable

materials are being used or stored.

_

Provide adequate ventilation to prevent dangerous concentrations of

volatile materials or vapors. Refer to local codes or your material MSDS

for guidance.

_

Do not disconnect live electrical circuits while working with flammable

materials. Shut off power at a disconnect switch first to prevent

sparking.

_

Know where emergency stop buttons, shutoff valves, and fire

extinguishers are located. If a fire starts in a spray booth, immediately

shut off the spray system and exhaust fans.

_

Clean, maintain, test, and repair equipment according to the instructions

in your equipment documentation.

_

Use only replacement parts that are designed for use with original

equipment. Contact your Promaks representative for parts information

and advice.

Grounding

WARNING: Operating faulty electrostatic equipment is hazardous and can

cause electrocution, fire, or explosion. Make resistance checks part of your

periodic maintenance program. If you receive even a slight electrical shock

or notice static sparking or arcing, shut down all electrical or electrostatic

equipment immediately. Do not restart the equipment until the problem has

been identified and corrected.

All electrically conductive objects in the spray areas shall be electrically

connected to ground with a resistance of not more than 1 megohm as

measured with an instrument that applies at least 500 volts to the circuit

being evaluated.

_

Equipment to be grounded includes, but is not limited to, the floor of the

spray area, operator platforms, hoppers, photoeye supports, and

blow-off nozzles. Personnel working in the spray area must be

grounded.

_

There is a possible ignition potential from the charged human body.

Personnel standing on a painted surface, such as an operator platform,

or wearing non-conductive shoes, are not grounded. Personnel must

wear shoes with conductive soles or use a ground strap to maintain a

connection to ground when working with or around electrostatic

equipment.

_

Operators must maintain skin-to-handle contact between their hand and

the gun handle to prevent shocks while operating manual electrostatic

spray guns. If gloves must be worn, cut away the palm or fingers, wear

electrically conductive gloves, or wear a grounding strap connected to

the gun handle or other true earth ground.

_

Shut off electrostatic power supplies and ground gun electrodes before

making adjustments or cleaning powder spray guns.

_

Connect all disconnected equipment, ground cables, and wires after

servicing equipment.

Action in the Event of a Malfunction

If a system or any equipment in a system malfunctions, shut off the system

immediately and perform the following steps:

_

Disconnect and lock out electrical power. Close pneumatic shutoff

valves and relieve pressures.

_

Identify the reason for the malfunction and correct it before restarting the

equipment.

Disposal

Dispose of equipment and materials used in operation and servicing

according to local codes.

Safety

1-4

Safety Labels

Table 1-1 contains the text of the safety label on this equipment. The safety

label is provided to help you operate and maintain your equipment safely.

Table 1-1 Safety Label Shipped With Powder Spray Guns

WARNING: The following procedures MUST be followed when working with

this electrostatic spray equipment. Failure to follow these instructions may

result in a fire and/or serious personal injury. Display this warning on the

spray booth.

1. NO SMOKING. Keep open flames, hot surfaces, and sparks from torches

or grinding away from booth.

2. Turn the electrostatic power unit off when the spray gun is not in use.

3. Shut down immediately in event of fire.

4. Maintain ground circuit on all conductive objects below 1 meg ohm to

prevent sparking.

5. Shut down operation and correct grounds if sparking occurs.

6. Install fixed fire suppression system before operating with combustible powder.

7. Install automatic flame detectors before operating automatic guns.

8. Examine all equipment at the beginning of each work period and repair or

replace any damaged, loose, or missing parts.

9. Before cleaning or performing any maintenance on the electrostatic spray

gun, turn off the power unit and ground the nozzle. Maintain electrostatic

spray equipment in accordance with instruction manual. Do not deviate.

Do not substitute parts from other manufacturers.

10. Operator must be grounded to prevent shocks from static electricity.

Floor surface must be conductive. Footwear and gloves must be static

Dissipative.

11. Air velocity through all booth openings must meet local requirements and

contain powder within the booth. If powder escapes from the booth, shut

down operation and correct the malfunction.

12. Powder may be toxic or be a nuisance dust hazard. Refer to supplier.s

MSDS. If exposed to dust during operation, maintenance, or clean up,

operators must use appropriate personal protective equipment.

13. Do not use compressed air or organic solvents for removal of powder

from skin or clothing. Do use soap and water. Wash hands before eating

or smoking.

14. Guns, feeders, booths, etc., may be cleaned with clean dry air at 1.7 bar

(25 psig). If you have any questions concerning this electrostatic spray equipment, call

+90 216 362 10 34, and ask to speak with the Powder Systems Group Technical Service Department.

Section 2

Description

The Promaks Tribo PTAG07 automatic powder spray gun uses friction

(the tribo effect) to electrostatically charge powder coating particles as they

are forced through the spray gun by compressed air. The spray gun is used

with a PTAU07 controller and powder pump.

The gun mount is used with a 5/8-in. diameter mounting bar to mount the

spray gun to a reciprocator or oscillator, or to a fixed gun stand. An optional

gun holder adapter allows existing PTAG07 gun holders to be used with

gun mounting bars.

The spray gun uses the same wide variety of optional nozzles and

sprayheads available for use with the original PTAG07 automatic spray

gun

WARNING: Make sure the spray gun is grounded before spraying powder

or cleaning the spray gun with compressed air. Without a ground

connection the spray gun will become electrostatically charged. Personnel

touching the spray gun could receive a shock.

Flow rate air pumps powder out of the feed hopper and forces it through the

feed hose to the diffuser. Diffuser air mixes with the powder and increases

its speed. The powder and air mixture then passes between the inner and

outer wear sleeves inside the charge module. The collision of the powder

particles with the walls of the sleeves electrostatically charges both the

powder particles and the sleeves.

The sleeves are grounded through the spray gun body, ground wire, and

control unit. The charge picked up by the sleeves is displayed in

microamperes at the control unit. The display indicates how well the

powder is charging (the higher the number, the stronger the charge the

powder is receiving). The strength of the charge the powder receives will

vary depending on many factors, including the powder type and its speed

through the spray gun.

Section 3

Operation and Maintenance

WARNING: Allow only qualified personnel to perform the following tasks.

Follow the safety instructions in this document and all other related

documentation.

WARNING: All electrically conductive equipment in the spray area must be

grounded. Ungrounded or poorly grounded equipment can store an

electrostatic charge which can give personnel a severe shock or arc and

cause a fire or explosion.

WARNING: Make sure the spray gun is grounded before spraying powder

or cleaning the spray gun with compressed air. Without a ground

connection the spray gun will become electrostatically charged. Personnel

touching the spray gun could receive a shock.

Operation

Each automatic spray gun is controlled by one gun control unit which

houses electrical controls, a bar led display, and regulators and gauges for

flow rate and diffuser air. Refer to the control unit manual for operation

instructions.

Powder volume, velocity, and atomization are controlled by the flow rate and

diffuser air pressure settings. As a starting point, set air pressures to:

Flow rate (ejector) air pressure 1.8 bar (26 psi)

Diffuser (atomizing) air pressure 2.5 bar (36 psi)

Keep the flow rate air pressure as low as possible. Maintain the same ratio

of diffuser air-to-flow rate air without reducing the charging level. Reduce

the diffuser air pressure if powder is being blown out of recesses. Build

coating thicknesses slowly. Reduce air pressures to keep overspray to a

minimum.

Experiment with the part hanger configuration and part density. Reduce the

space between parts to keep overspray to a minimum. Keep the air velocity

through the booth as close to the minimum required by law as practical

without violating safety.

Operation and Maintenance

Operation

Use different sprayheads for different part shapes. Select the appropriate

nozzle for the parts being coated.

_

Pinpoint nozzles for penetration

_

Eight-orifice nozzles for flat surfaces

_

Cylindrical nozzles for general purpose coating

Angle the nozzles to meet and follow the parts as they move through the

booth. Typical nozzle-to-part distance is 32,5 cm. Coat the

inside surfaces and recessed areas first, then coat the outside surfaces and

open areas.

Daily Maintenance

WARNING: Make sure the spray gun is grounded before spraying powder

or cleaning the spray gun with compressed air. Without a ground

connection the spray gun will become electrostatically charged. Personnel

touching the spray gun could receive a shock.

1. Remove the powder feed hose from the pump and the air tubing from

the pump and diffuser. Use air gun to clean the hose, diffuser, and charge

module with compressed air.

NOTE: Never blow powder through the feed hose back into the pump.

Turn on the booth exhaust fan, disconnect the hose from the pump, and

blow out the hose from the pump end into the booth.

2. Remove the diffuser from the gun body. Disassemble the diffuser and

clean the parts with compressed air and a clean, soft cloth. Check the

powder contact parts for wear and replace worn parts.

3. Blow out the charge module and sprayheads. Disassemble and clean

the charge module. Check the powder contact parts for wear and

replace worn parts.

NOTE: Never use a knife or other sharp object to clean plastic parts.

Powder will build up on scratches on the powder contact surfaces. The

powder particles can fuse on impact and clog the spray gun.

WARNING: All electrically conductive equipment in the spray area must be

grounded. Ungrounded or poorly grounded equipment can store an

electrostatic charge which can give personnel a severe shock or arc and

cause a fire or explosion.

4. Make sure all conductive equipment in the spray area, including the

spray guns, are connected to a true earth ground. The resistance from

part to ground, through the hangers and conveyor, must not exceed one

megohm. For best results, the resistance should be less than 500 &.

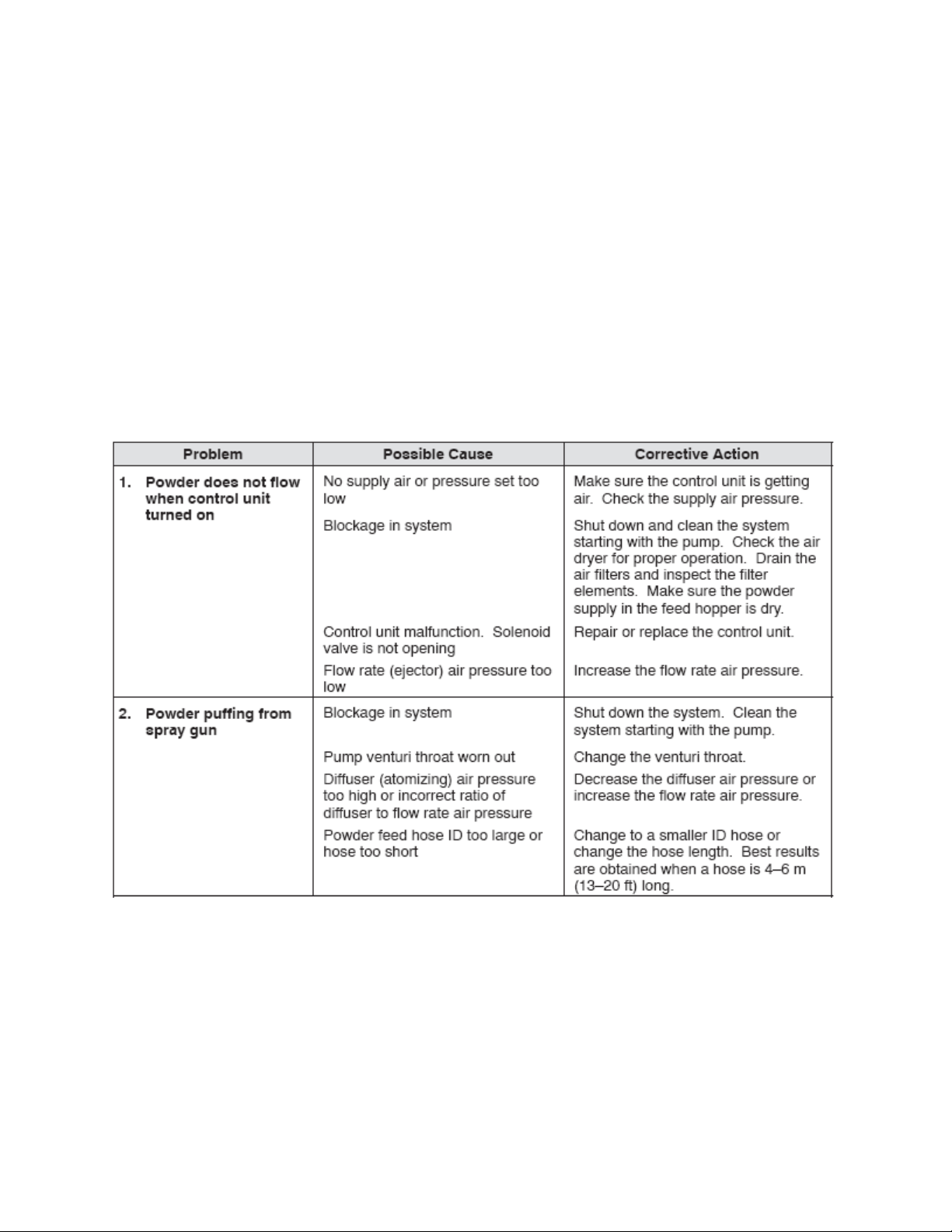

Troubleshooting

4-1

Section 4

Troubleshooting

WARNING: Allow only qualified personnel to perform the following tasks.

Follow the safety instructions in this document and all other related

documentation.

This section contains troubleshooting procedures. These procedures cover

only the most common problems that you may encounter. If you cannot

solve the problem with the information given here, contact your local

Promaks representative for help.

Section 5

Repair

WARNING: Allow only qualified personnel to perform the following tasks.

Follow the safety instructions in this document and all other related

documentation.

Section 6

Parts

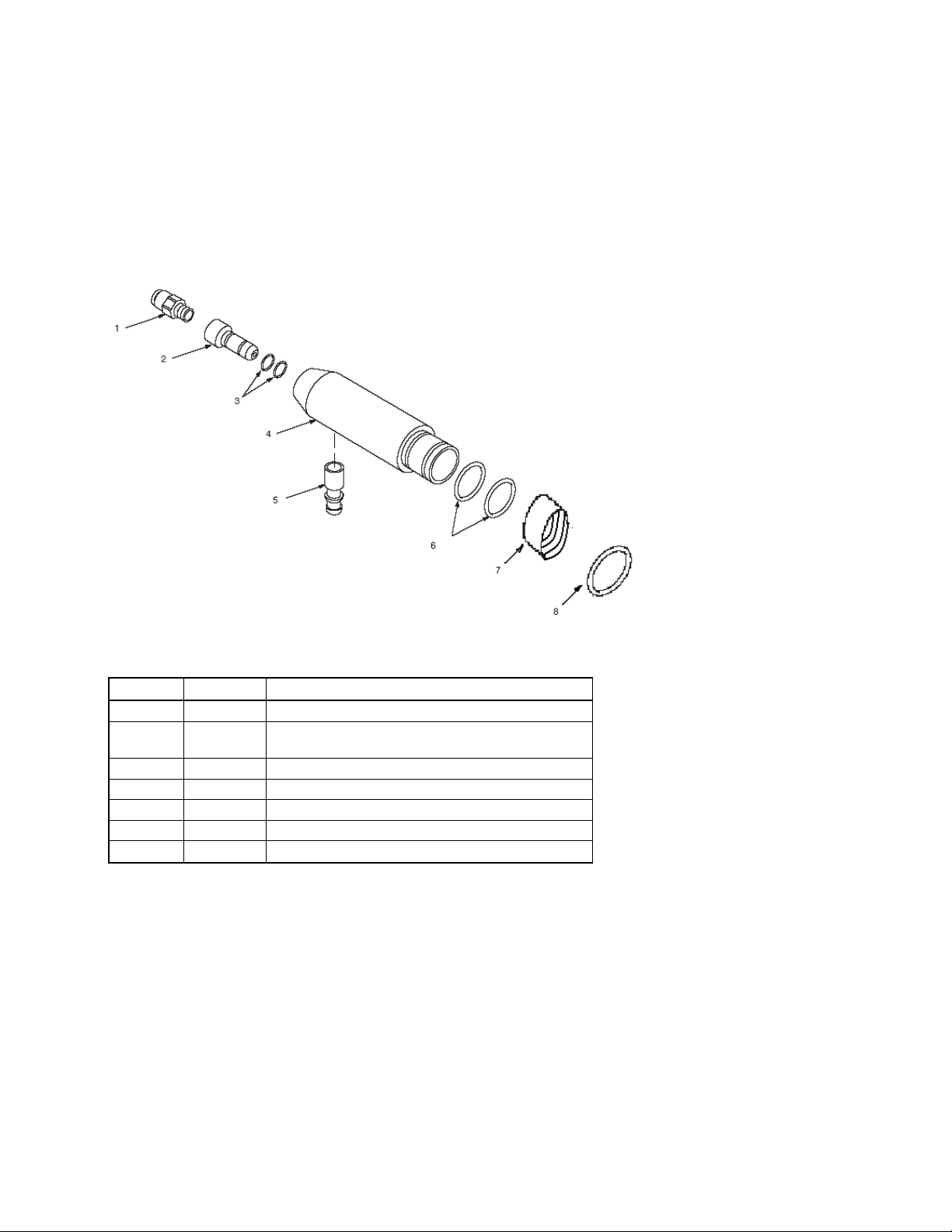

PTAG07 Automatic Gun

Item Part Description

1 PT631225

EXTENSION Body

2 PT631221

SLEEVE, wear,outlet, assembly, teflon

3 PT940224

O-RING, silicone, 1.000*1.125*0.0063 in

4 PT361222

SPRING, silicone, 1.25*1.50 in

5 ********** SLEEVE,wear,outlet , teflon

6 PT631220

RING, spacing

7 PT631212

SLEEVE, wear,outlet, teflon

8 PT940284

O-RING, silicone, 1.375*1.500*0.0063 in

9 PT631224

DISTRIBUTOR, outlet, teflon

10 PT631216

SLEEVE, wear, inner, teflon

11 PT631210

RING, positioning

12 PT631211

STUD, M8*9.65 long

13 PT631234

DISTRIBUTOR, inlet, teflon

14 PT631232

SLEEVE, wear, inlet, assembly, teflon

15 PT631228

BODY, autogun, assembly

16 PT630088

STUD, ground,with nut

17 PT630073

KNOB, M5 X 08

18 PT631229

EXTENSION Knob

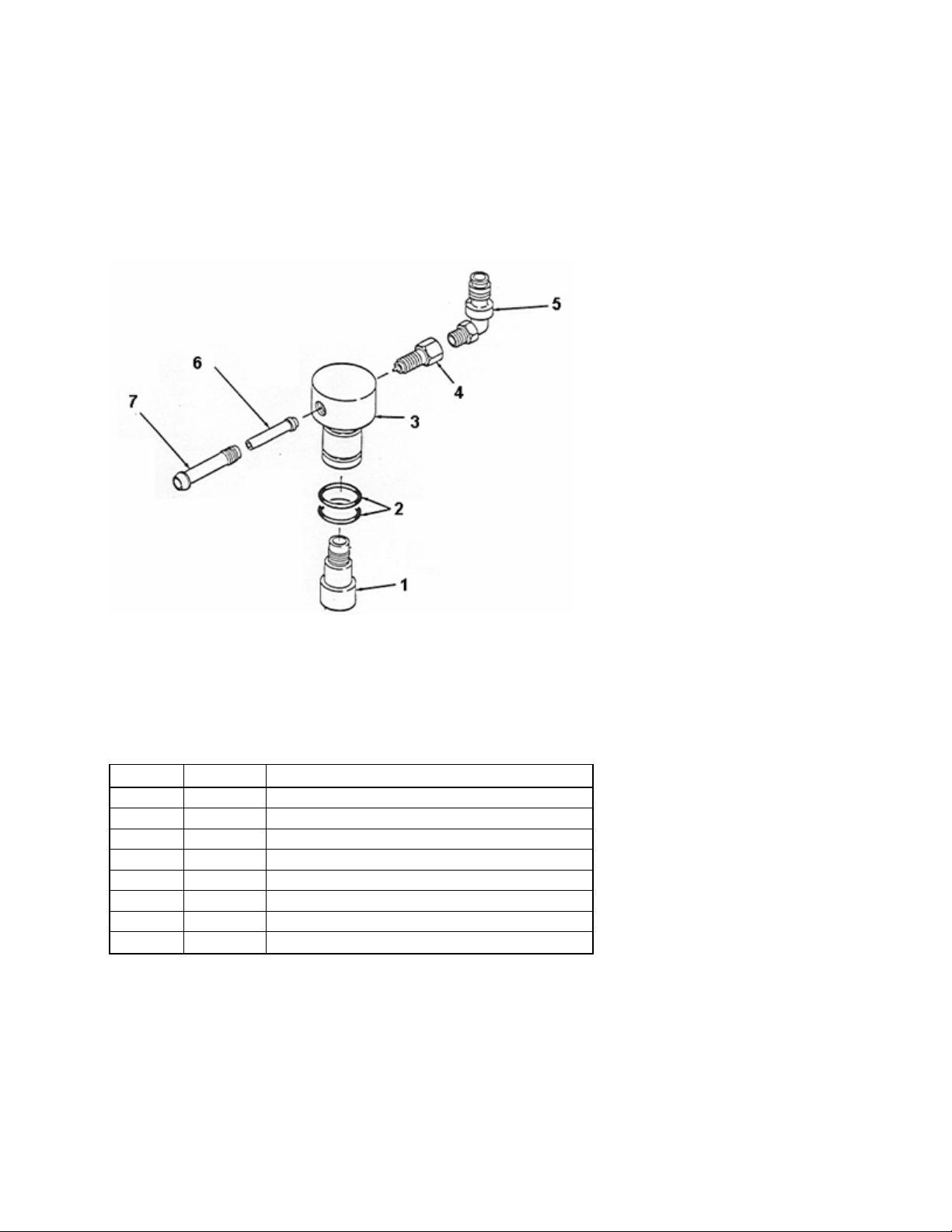

DIFFUSER

Item Part Description

PT631271

DIFFUSER

1 PT630035

CONNECTOR,MALE,1/8-in NPTF x1/4-in

tube

2 PT635007

NOZZLE,diffuser

3 PT940117

O-RING, silicone,0.312*0.438*0.063 in

4 PT635008

HOUSING, diffuser

5 PT631275

CLAMP,hose,0.781-0.875 in

6 PT940224

O-RING, silicone,1.00*1.125*0.063 in

INJECTOR

Item Part Description

PT630034

INJECTOR COMPLETE

1 PT630043

VENTING HOSE ADAPTER

2 PT630025

O-RING, silicone, 1.000*1.125*0.0063 in

3 PT630037

INJECTOR BODY

4 PT630036

INJECTOR NOZZLE

5 PT630035

CONNECTOR,male,1/8-in NPTF*1/4-in tube

6 PT630038

INSERT SLEEVE

7 PT630041

INSERT SLEEVE NUT

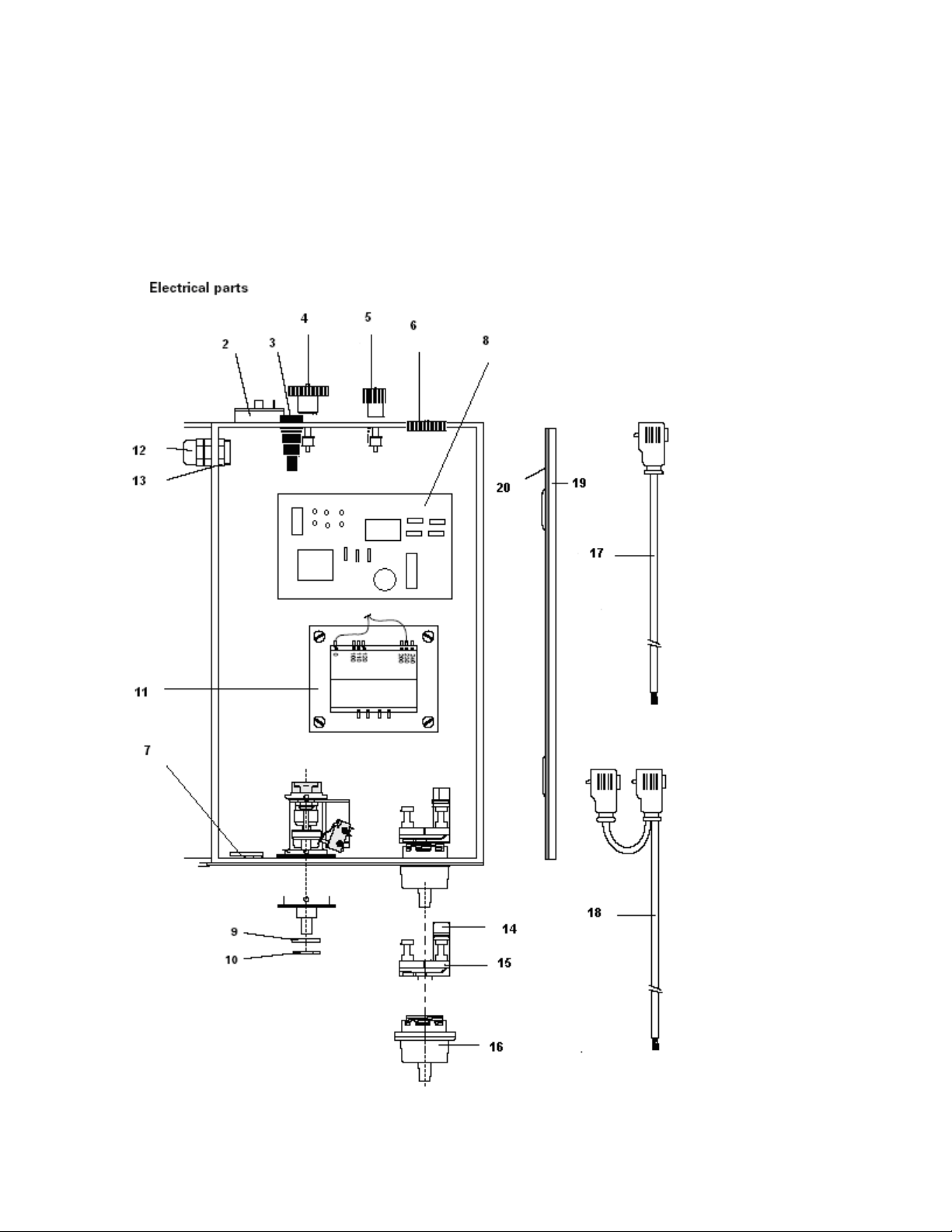

PTAU07 Control module

Electrical Parts

1 GOLD SERİES Control module (complete) PTAU07

2 Fixed plug, with gasket (for Mains connection) PG200 409

3 Fuse holder - F1 PG200 131

4 Knurled grounding nut - M6 PG200 433

5 Grounding Nut PT512 244

6 Control Box Air Fitler PNM100131

7 Bar Led PT526 320

8 Printed circuit board - CB1 PT526 319

9 Washer PG200 271

10 Clamp nut - M 12 x 1 mm PG200 700

11 Transformer PT526 318

12 Clamp nut - PG 7 PG230 537

13 Lead-through - PG 7 PG235 989

14 Contact unit PG235 938

15 Adapter fixture PG235 920

16 Switch PG235 911

17 Mains cable connection (single plug) PG303 607

18 Mains cable connection (two plugs) PG343 366

Mains cable connection (four plugs - not shown) PG343 374

Mains cable connection (eight plugs - not shown) PG343 382

19 Cover plate PG352 128

20 Sealing strip - 9 x 6 mm PG100 269

PTAU07 Control module

PTAU07 Control module

Pneumatic parts

1 Screw coupling - ø 8 mm PNM100102

2 Screw connector - ø 8 mm ……………

3 Screw coupling - ø 6 mm PNM100105

4 Screw connector - ø 6 mm ……………

5 Solenoid valve (24 VAC - 3/8" B.S.P. thread) PG235 865

5.1 Solenoid valve coil - 24 VAC PG243 930

6 T-connector (3/8"- ø 8 mm) PG235 873

7 Hose - ø 6 / 4 mm PG103 144

8 Hose - ø 8 / 6 mm PG103 756

9 Pressure reducing valve PG235 822

10 Control knob PG200 069

11 Clamp nut - M14 x 1 mm PG302 163

12 Pressure gauge (0-4 bar) PG235 814

13 Quick-release connector (1/8"- ø 6 mm) PG233 412

14 Check valve PT368 746

PTAU07 Control module

Table of contents