Bareknuckle Welterweight APS Instruction Manual

WELTERWEIGHT

AIRLESSPAINT

SPRAYER

ImportantSafetyInstructions:

Carefullyreadallsafetywarningsand

operatinginstructionspriortouse.Savethese

instructionsforfuturereference.

Mustbegroundedwhenusingthispump:ReadGrounding

instructions.Onlyusewithgroundedelectricaloutlets

protectedbyaresidualcurrentdevice.

Personswithanyheartconditionorhavingapacemaker

shouldnotusethismachine.

Whenunpackingthiscarton,ifanypartsaremissingorbroken,

immediatelyreturntotheplacethatyoupurchasedthisproductfrom.

BareknuckleOperatingInstructions

andSafetyManual

Forportablesprayapplicationof

paintsandcoatings

COMPLIES WITH

AS/NZ 60204.1:2005/Amend 1:2006

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL | 1

Important safety instructions 1 - 2

Technical Data 2

Warning 3 - 5

Installation 6 - 9

Pressure Relief Procedure 9

Operating Instructions 10 - 13

Airless Sprayer Cleaning Procedure 14 - 15

Long Term Storage 16

Grounding and Electric Requirements 17 - 18

Daily Maintenance 18

General Repair Information 19

Troubleshooting 20

Airless Sprayer Electrical Installation Drawing 21

Parts List 22 - 23

Project Sheet 24

Warranty 25

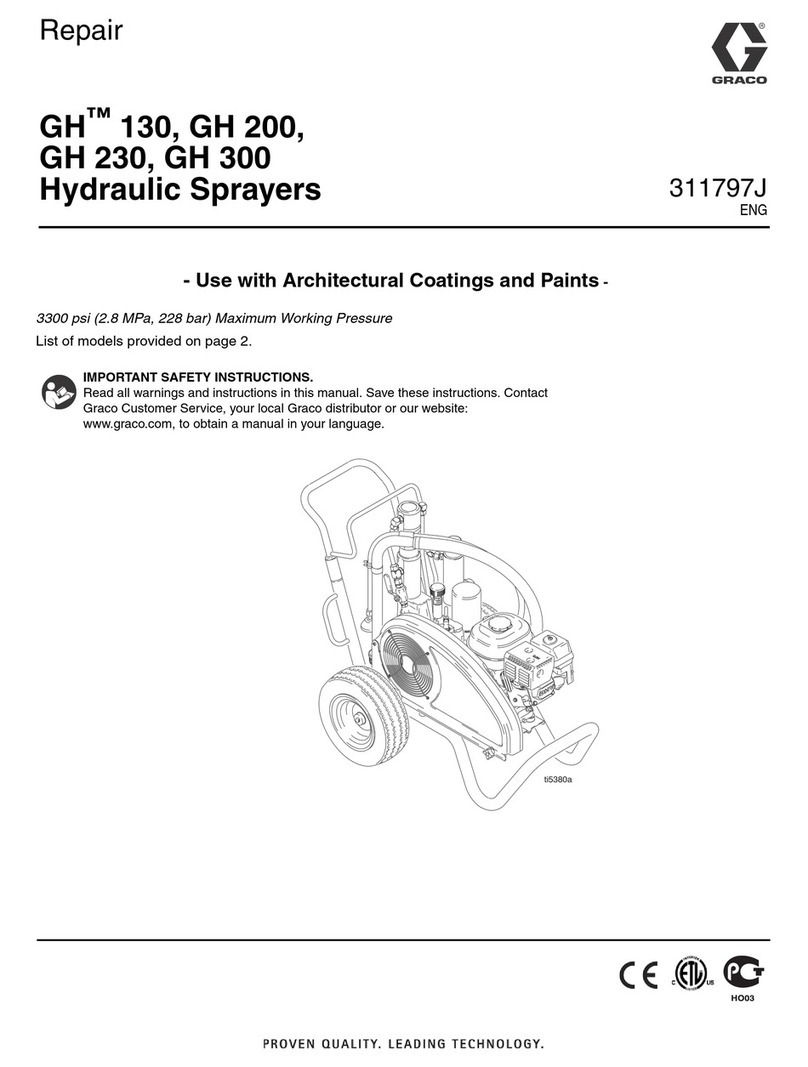

INSTRUCTIONS PERTAINING TO A RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS

WARNING – When using this machine, basic precautions

should always be followed, including the following:

a) SAVE THESE INSTRUCTIONS - To reduce the risks of fire

or explosion, electrical shock and injury to persons, read

and understand all instructions included in this manual.

Be familiar with the controls and the proper usage of the

equipment.

b) WARNING - To reduce the risk of fire or explosion:

1) Do not spray flammable or combustible materials near

an open flame or sources of ignition such as cigarettes,

motors, and electrical equipment.

2) For units intended for use with only water-based

materials-Do not spray or clean with flammable liquids.

Use water based liquid only.

3) For units intended for use with only water-based or

mineral spirit-type materials with a minimum flash

point of 21C°(69.8 F°) Do not spray on clean with

liquids having a flash point less than 21C°(69.8 F°)

4) Paint or solvent flowing through the equipment is able

to result in static electricity. Static electricity creates

a risk of fire or explosion in the presence of paint or

solvent fumes. All parts of the spray system, including

the pump, hose assemble, spray gun, and objects in

and around the spray area shall be properly grounded

to protect against static discharge and sparks. Use

only conductive or grounded high-pressure airless

paint sprayer hoses specified by the manufacturer.

5) Verify that all containers and collection systems are

grounded to prevent static discharge.

6) Connect to a grounded outlet and use grounded

extension cords. Do not use a 3 to 2 adapter.

7) Do not use a paint or a solvent containing halogenated

hydrocarbons. See operating instructions for examples

of these types of materials.

8) Keep spray area well ventilated. Keep a good supply

of fresh air moving through the area. Keep pump

assembly in a well ventilated area. Do not spray pump

assembly.

9) Do not smoke in the spray area.

10) Do not operate light switches, engines, or similar spark

producing products in the spray area.

11) Keep area clean and free of paint or solvent

containers, rags, and other flammable materials.

12) Know the contents of the paints and solvents being

sprayed. Read all Material safety Data Sheets (MSDS)

and container labels provided with the paints and

solvents. Follow the paint and solvent manufacturer’s

safety instructions.

13) Fire extinguisher equipment shall be present and

operational.

c) WARNING - To reduce the risk of skin injection.

1) Do not aim the gun at, or spray any person or animal.

2) Keep hands and other body parts away from the

discharge. For example, do not try to stop leaks with

any part of the body.

3) Always use the nozzle tip guard. Do not spray without

nozzle tip guard in place.

4) Only use a nozzle tip specified by the manufacturer.

5) Use caution when cleaning and changing nozzle tips.

In the case where the nozzle tip clogs while spraying,

follow the manufacturer’s instructions for turning off

the unit and relieving the pressure before removing the

nozzle tip to clean.

6) Do not leave the unit energized or under pressure while

unattended. When the unit is not in use, turn off the

unit and relieve the pressure in accordance with the

manufacturer’s instructions.

7) High-pressure spray is able to inject toxins into the

body and cause serious bodily injury. In the event that

injection occurs, seek medical attention immediately.

8) Prior to use, thoroughly check the spray machine, hose

and parts for any signs of visible damage. If there is

any signs of damage or wear and tear, do not use the

machine.

9) This system is capable or producing 20.7Mpa. Only use

replacement parts or accessories that are specified

by the manufacturer and that are rated a minimum of

22.8Mpa.

10) Always engage the trigger lock when not spraying.

Verify the trigger lock is functioning properly.

11) Verify that all connections are secure before operating

the unit.

12) Know how to stop the unit and bleed pressure quickly.

Familiarise yourself with the controls of the machine

before use.

d) WARNING - To reduce the risk of injury.

1) Always wear appropriate gloves, eye protection, and a

respirator or mask when painting.

2) Do not operate or spray near children. Keep children

away from equipment at all times.

CONTENTS

Operating Instructions and Safety Manual

IMPORTANT SAFETY INSTRUCTIONS

Important Information

The Bareknuckle Welterwieght Airless Spray Machine is a lightweight and portable

airless spray machine designed to be used for a wide range of DIY / household

projects including painting walls, ceilings, fences, garage doors, outdoor furniture.

This spray machine is not intended for commercial use and large painting projects.

Commercial use of this machine will void the warranty. A 12 month limited warranty

is provided with this machine. The warranty does not cover normal wear and tear of

consumable items. Refer to Important Warranty Information in this manual.

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL |2 | 3

3) Do not overreach or stand on an unstable support.

Wear safety footwear and keep well balanced at all

times.

4) Stay alert and watch what you are doing.

5) Do not operate the unit when fatigued or under the

influence of drugs or alcohol.

6) Do not kink or over-bend the hose.

7) Do not expose the hose to temperatures or to pressures

in excess of those specified by the manufacturer.

8) Do not use the hose as a strength member to pull or

lift the equipment.

9) The maximum pressure for the air hose is 22.8 Mpa, the

normal pressure is 20.7Mpa

10) The paint can be compatible: phenol aldehyde paint

series, nitryl paint series, alkyd paint series, epoxy

resin paint series, oxidized rubber paint series, latex

paint series, water soluble paint series. The paint

should be kept in the shade and dry location.

11) Be aware of any hazards presented by the material

being sprayed and consult the markings on the

container or information supplied by the manufacturer

of the material to be sprayed, including requirements

for the use of personal protective equipment.

12) Do not spray any material where the hazard

is not known.

The following warnings are for the setup, use,

grounding, maintenance and repair of this

equipment. The exclamation point symbol alerts

you to a general warning and the hazard symbol

refers to procedure-specific risks. Refer back

to these warnings. Additional, product-specific

warnings may be found throughout the body of

this manual where applicable.

Flammable fumes, such as solvent and paint

fumes, in work areas can ignite or explode. To

help prevent fire and explosion:

• Use equipment only in well ventilated areas.

• Eliminate all ignition sources; such as pilot

lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static arc charge).

• Sprayer generates sparks. When flammable

liquid is used in or near the sprayer or for

flushing or cleaning, keep sprayer at least 20

feet (6 m) away from explosive vapors.

• Keep work area free of debris, including

solvent, rags and gasoline.

• Do not plug or unplug power cords or turn

lights on or off when flammable fumes are

present.

• Ground equipment and conductive objects in

work area. Read Grounding instructions.

• If there is static sparking or you feel a shock,

stop operation immediately. Do not use

equipment until you identify and correct the

problem.

• Keep a working fire extinguisher in the work

area.

Improper grounding, setup, or usage of the

system can cause electric shock.

• Turn off and disconnect power cord before

servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure the power outlet is protected by a

residual current device.

• Do not expose the equipment to rain.

Store indoors.

High-pressure fluid from gun, hose leaks, or

ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that

can result in amputation. Get immediate medical

treatment.

• Do not point gun at anyone or at any part of

the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand,

body, glove, or rag.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this

manual, when you stop spraying and before

cleaning, checking, or servicing equipment.

DO NOT USE THE BAREKNUCKLE WELTERWEIGHT AIRLESS SPRAY MACHINE WITH A GENERATOR

OR UNREGULATED POWER SUPPLY. THE MACHINE REQUIRES CONSISTENT REGULATED POWER.

POWER SPIKES OR SURGES MAY LEAD TO DAMAGE TO THE MACHINE, COSTLY REPAIR OR

PERMANENT DAMAGE.

TECHNICAL DATA

TYPE: Bareknuckle Welterweight

Power requirements 230±10%Vac, 50±1Hz

Input power 650 - 750W

Rated current 2.0~4.5A

Maximum working pressure 3000PSI

Sound pressure level: 89 db

Vibration value: 0.715 m/s²

Maximum delivery gpm (lpm) 1.1

Working environment temperature requirement: 5oC - 40oC

Working environment humidity requirement: 30% - 95%

Standard nozzle 517

Transportation and storage temperature requirement: 25oC - 55oC

Paint hose: 7.6m

Paint outlet connector: 1/4-18-NPSM

Dimensions Weight 9.7kg

FIRE AND EXPLOSION HAZARD

SKIN INJECTION HAZARD

WARNING

ELECTRIC SHOCK HAZARD

WARNING

!

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL |4 | 5

WARNING

Equipment surfaces can become very hot during

operation. To avoid severe burns, do not touch hot equipment. Wait until equipment has cooled

completely.

BURN HAZARD

Moving parts can pinch or amputate fingers and

other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective

guards or covers removed.

• Pressurized equipment can start without

warning. Before checking, moving, or servicing

equipment, follow the Pressure Relief Procedure

in this manual. Disconnect power or air supply.

MOVING PARTS HAZARD

Toxic fluids or fumes can cause serious injury or

death if splashed in the eyes or on skin, inhaled,

or swallowed.

• Read warnings to know the specific hazards of

the fluids you are using.

• Store hazardous fluid in approved containers,

and dispose of it according to applicable

guidelines.

TOXIC FLUID OR FUMES HAZARD

You must wear appropriate personal protective

equipment (PPE) when operating, servicing, or

when in the operating area of the equipment to

help protect you from serious injury, including

eye injury, inhalation of toxic fumes, burns, and

hearing loss. This equipment includes but is not

limited to:

• Protective eye wear

• Clothing and respirator as recommended by the

fluid and solvent manufacturer

• Gloves

• Hearing protection

• Protective footware

PERSONAL PROTECTIVE EQUIPMENT

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure

or temperature rating of the lowest rated

system component. Read Technical data.

Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with

equipment wetted parts. Read Technical Data in

all equipment manuals.

Read fluid and solvent manufacturer’s warnings.

For complete information about your material,

request MSDS from the distributor or retailer.

• Check equipment daily. Repair or replace

worn or damaged parts immediately with

manufacturers replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose.

Call your Retailer for information.

• Route hoses and cables away from traffic areas,

sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to

pull equipment.

• Comply with all applicable safety regulations.

• Keep children and animals away from work area.

• Do not operate the equipment when fatigued or

under the influence of drugs or alcohol.

EQUIPMENT MISUSE HAZARD

Do not use 1, 1, 1-trichloroethane, ethylene

chloride, other halogenated hydrocarbon solvents

or fluids containing such solvents in pressurized

aluminum equipment.

Such use can cause serious chemical reaction and

equipment rupture, and result in death, serious

injury, and property damage.

PRESSURIZED ALUMINUM PARTS HAZARD

A) The machine is not designed for use in potentially

explosive atmospheres;

B) Use of electrostatic atomizing and spraying equipment

with machines not specially designed for this

equipment, may result in serious harm and/or hazard

for the operators

C) Hazards resulting from contact with and/or breathing

of toxic materials, gases, mists and vapours which

may be created by operation of the machine. Such

warnings shall also include the use of personal

protective equipment and reminding the user to be

aware of the recommendations of the coating material

manufacturer;

D) Surface temperatures of any part of the machine,

reachable during normal operation, maintenance and

servicing but not normally in contact with the human

body, which can exceed 48oC or be less than 0oC.

E) Pressured coating material and /or compressed air not

to be directed towards persons or animals;

F) Relating to training for the safe operation, adjustment,

cleaning and maintenance of the machine;

G) Regarding any special earthing measures;

H) Stating that a list of the materials used in the

construction of the machine will be made available on

request to validate the compatibility with the coating

materials being used;

I) Regarding the requirements of using the machine only

in a well ventilated area with regards to health, fire and

explosion risks;

J) Regarding the visual inspection for damage on hoses

which may be subjected to friction

K) Requirements for environmental protection to be

observed

L) Reduce the quantity of coating and/or auxiliary

materials at workplaces to a minimum

a) Maximum allowable pressure for the coating

material……… 20.7 Mpa (3000psi)

b) Typical coating material flow rate for sample

conditions: 1.1L/Min

c) Type and use of any safety devices in the machine:

1. Temperature control device

2. Maximum pressure control device

3. Maximum electrical current control device

4. Creepage protect control device

5. Hand-hurt protect device

SPECIAL FOCUS

SPECIAL ATTENTION:

!

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL |6 | 7

Clean Sprayer immediately to prevent permanent damage. Clean Sprayer immediately to prevent permanent damage.

7

INSTALLATION:

8

8

8

8

8

8

8

BEFORE YOU BEGIN

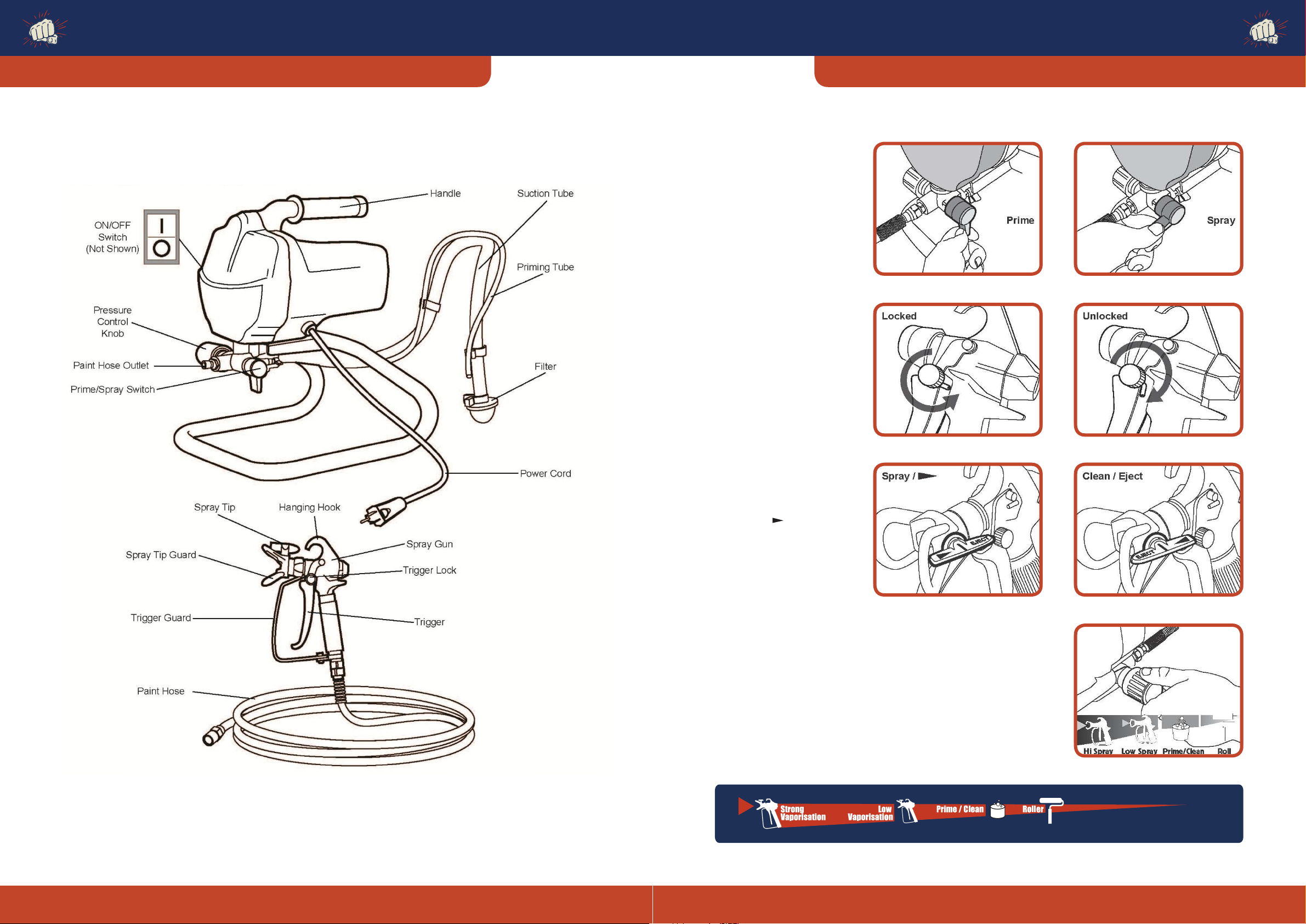

Familiarise yourself with the Paint Sprayer and it’s functions. Prime/Spray Switch

This switch toggles the unit between

priming mode and spraying mode.

Trigger Lock

When engaged, this mechanism

prevents the trigger from being

pulled accidentally such as if the

gun is dropped.

Lock whenever not in use.

Nozzle

The nozzle is reversible and

removable to make cleaning and

unclogging easier.

Turn to Spray ( ) position to use

the spray gun.

Turn to Clean (Eject) position to

clean the nozzle.

Pressure Control Knob

The Pressure Control Knob can be adjusted for High Pressure Spraying,

Low Pressure Spraying , Priming/Cleaning, or Rolling. Align the Pressure

Control Knob with indicator on the Sprayer Housing to set the function.

High Pressure Spray

Low Pressure Spray Rolling

Prime/Clean

Returns not accepted & warranty void if sprayer is

not properly cleaned immediately after every use.

Returns not accepted & warranty void if sprayer is

not properly cleaned immediately after every use.

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL |8 | 9

Clean Sprayer immediately to prevent permanent damage. Clean Sprayer immediately to prevent permanent damage.

9

9

9

9

9

9

9

TO RELIEVE SPRAYER PRESSURE

SETUP NOTE: Remove or cover objects that you want to protect from overspray (paint mist).

1. Attach Paint Hose to Paint Hose

Outlet and tighten with wrench.

1. Turn Power Switch off and unplug unit

from outlet

2. Switch Prime/Spray switch to Prime mode. Note: Always set to Prime mode

between uses.

3. Point gun into paint pail and activate

Sprayer Trigger to relieve pressure.

4. Turn Trigger Knob to Locking poistion.

2. Attach Paint Hose to Paint Gun

and tighten with two wrenches. 3. Turn Pressure Control Knob to

Low Pressure Spray setting.

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL8 |

9

BEFORE STARTING

1) CHECK all fittings and connections in the pump system,

hose, and gun to ensure that they are tight.

CHECK to ensure that there is a spray tip in the gun,

and that the tip is the correct size for the coating you

are to spray. (There are various tips available, for each

type of coating or configuration.)

2) MAKE SURE the power source is securely grounded and

match the motor rating of your sprayer.

3) New spray: Oil is used by the factory for testing and

protection. It is necessary to flush unit before spraying.

Clean the pump with warm soapy water. Make sure

the hydraulic oil in the pump is clean and sufficient in

volume then begin the following procedure

1. Remove spray tip from gun

2. Put the input hose and pressure relief tube into the

bucket with some water,

3. Turn on the motor and push the pressure valve

upright. In a few seconds, water will begin to flow

up through the tube and flow out from outlet valve,

tighten the outlet valve deasil, then tighten the

pressure valve deasil.

4. When the pressure reaches up to around 207bar,

check if there is any leakage on the outlet hose, if it’s

leaking, Please check. Don’t stop or deflect leaks with

your hand, body, glove or rag.

5. If it doesn’t leak, open the spray gun and test spray.

Clean the oil in pump. Change the soapy water and

use clean water when the spray is clean.

6. Turn off power, Continue to spray until there is no

more water.

7. Unlock trigger lock. Put the pressure valve upright, till

no soapy water in pump.

Whenever instructed to relieve pressure, Stop spraying,

Check or service equipment or install or clean spray tip.

1. Engage trigger safety lock on gun. Turn Off power

and turn sprayer pressure control to lowest pressure

setting.

2. Hold gun against side of flushing pail. Trigger gun

into pail to relieve pressure.

3. Turn off pump and release fluid pressure by turning

the pressure relief prime valve located on the side of

the pump down.

OPERATING INSTRUCTIONS

PRESSURE RELEASE PROCEDURE

9

Returns not accepted & warranty void if sprayer is

not properly cleaned immediately after every use.

Returns not accepted & warranty void if sprayer is

not properly cleaned immediately after every use.

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL |10 | 11

Clean Sprayer immediately to prevent permanent damage. Clean Sprayer immediately to prevent permanent damage.

12

12

12

12

12

12

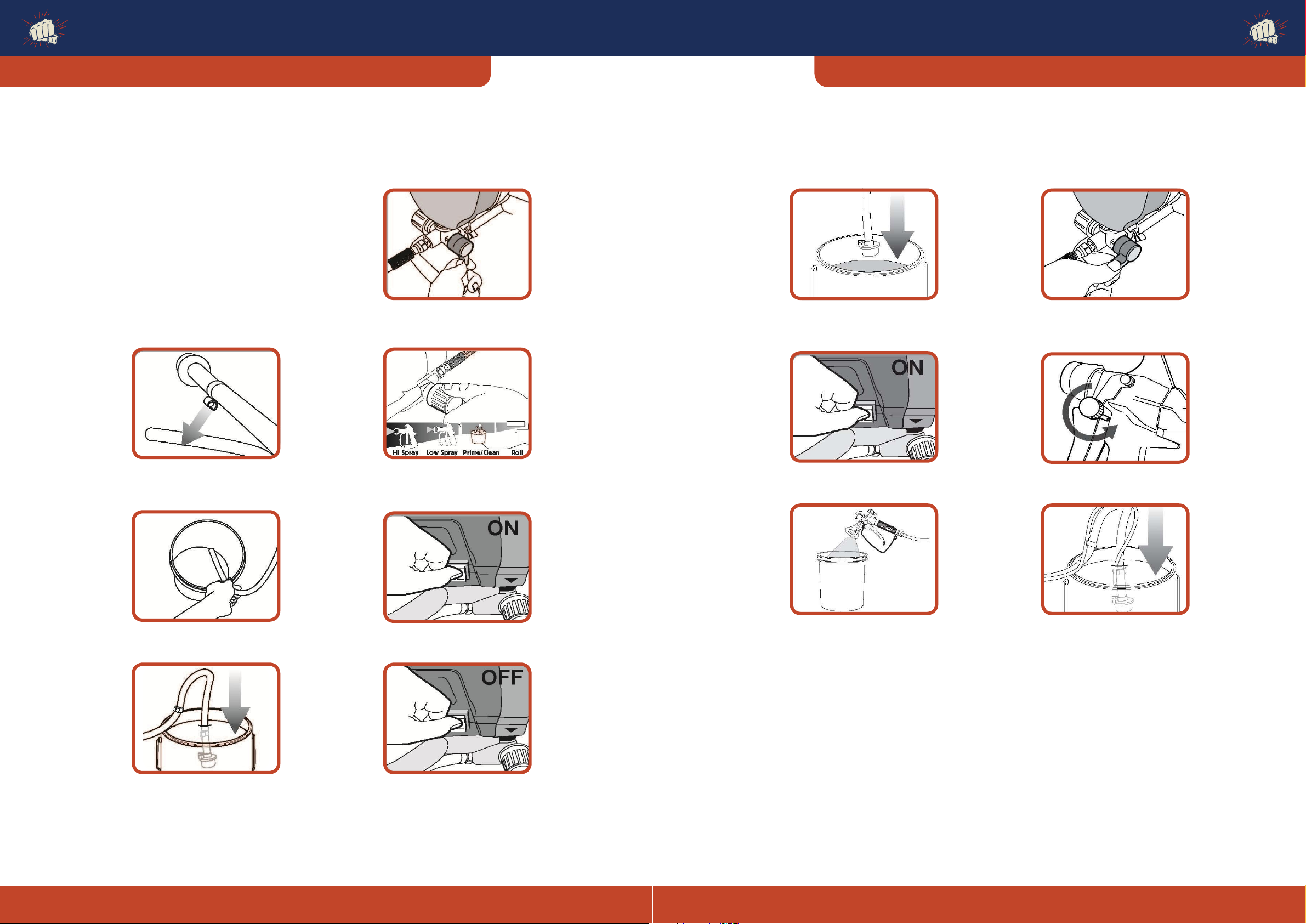

PRIMING SPRAY GUN

PRIMING AND STARTUP STEPS

This procedure is used for first time operation and also to flush

storage fluids out of the Sprayer.

Priming Water-Based vs. Oil-Based Paints

Oil-based Paint:

Flush with mineral spirits followed by warm clean water.

WARNING! TO PREVENT FIRE:

When using mineral spirits, ground gun by holding it against a

metal container while flushing.

Water-based (Latex) Paint:

Flush with warm clean water.

3. Submerge Suction Tube in

water or flushing solvent. 7. Sprayer will start pumping and water

or flushing solvent as well as air

bubbles will be purged from system.

Let fluids discharge from Priming Tube

into waste bucket for 30 to 60 seconds

then switch Power to Off.

11

11

10. Paint should work itself from

Suction Tube to Sprayer to Priming

Tube until paint discharges from

Return Tube. Point gun into waste

bucket and pull trigger.

13. Remove the Priming Tube from the

waste bucket and clip to Suction Tube

and submerge in paint pail.

14. If the motor stops, the pump and

tubes are primed. If it does not stop,

repeat priming steps.

15. Start Painting.

2. Place Priming Tube in waste bucket. 6. Plug in Sprayer and turn on power.

11

11

9. Switch Power to On. 12. Stop spraying and activate trigger lock.

11

1. Separate smaller Priming Tube

from Suction Tube. 5. Adjust Pressure Control Knob to

Prime/Clean setting.

11

8. Remove Suction Tube from water

or flushing solvent and submerge

in paint pail.

11. Turn Spray/Prime Switch to Spray

mode and continue to spray into

waste bucket.

4. Turn Prime/Spray switch to

Prime mode.

11

Returns not accepted & warranty void if sprayer is

not properly cleaned immediately after every use.

Returns not accepted & warranty void if sprayer is

not properly cleaned immediately after every use.

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL |12 | 13

Clean Sprayer immediately to prevent permanent damage. Clean Sprayer immediately to prevent permanent damage.

13

13

13

13

13

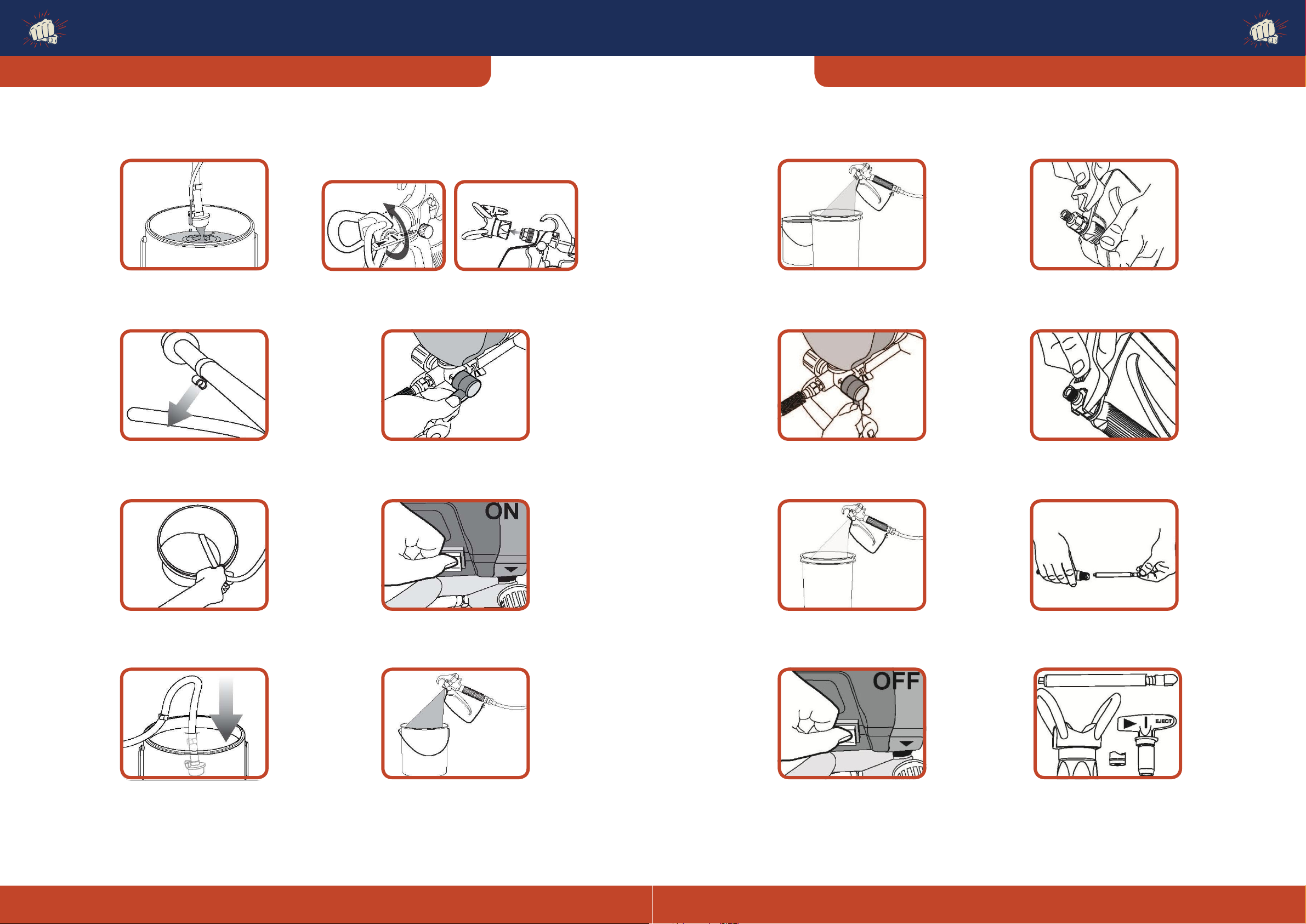

PAINTING CLEARING SPRAY TIPPAINTING TECHNIQUES

Before painting, ensure the Sprayer has been primed (see Priming

and Startup steps) and verify that Nozzle Tip is aligned properly.

Note: Remove or cover objects that you want to protect

from overspray and paint mist.

Occasionally, the Spray Gun Tip will become clogged with paint.

Follow these instructions to clear Spray Gun Tip.

Before painting, ensure the Sprayer has been primed (see Priming

and Startup steps) and verify that Nozzle Tip is aligned properly.

Keep the gun approximately 30cm from the surface.

1. Once primed, adjust nozzle to

Spray setting. 1. Switch power off and set Trigger Lock.1. Keep gun straight and move

arm across at a steady rate

while staying 30cm from the

surface .

2. Do not fan the gun or paint will

be uneven.

3. Overlap strokes by half, always

aim stroke at bottom edge of

last stroke.

Overlap

Strokes

2. Start spraying at the lowest

setting on the Pressure Control

Knob and increase pressure as

needed by turning clockwise to

create a good spray pattern.

14

14

2. Adjust nozzle to clean setting.

14

5. Unlock Trigger.

14

6. Spray into waste bucket until

clog clears.

14

7. Release Trigger and engage

Trigger Lock.

14

8. Adjust nozzle to Spray mode.

14

3. Turn Spray/Prime Switch to Spray mode.

14

4. Turn power on.

14

Returns not accepted & warranty void if sprayer is

not properly cleaned immediately after every use.

Returns not accepted & warranty void if sprayer is

not properly cleaned immediately after every use.

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL |14 | 15

Clean Sprayer immediately to prevent permanent damage. Clean Sprayer immediately to prevent permanent damage.

15

16

16

16

16

16

16

16

16

15

15

15

15

15

15

15

15

CLEANING

1. Relieve pressure and drain

paint from tube. 9. Change to waste bucket as

paint thins. 13. Remove trigger guard from

housing.

2. Separate tubes. 10. Turn to Prime mode. 14. Unscrew nut.6. Turn to Spray mode.

3. Place Priming Tube in empty

waste bucket. 11. Continue to flush until clear. 15. Remove filter.

4. Submerge Suction Tube in

water or flushing fluid. 12. Release trigger, turn power off

and relieve pressure. 16. Clean all parts in warm, soapy

water or flushing fluid with a

bristled brush.

5. Unthread spray tip and remove.

7. Switch power to on.

8. Spray paint into paint pail.

Returns not accepted & warranty void if sprayer is

not properly cleaned immediately after every use.

Returns not accepted & warranty void if sprayer is

not properly cleaned immediately after every use.

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL |16 | 17

Clean Sprayer immediately to prevent permanent damage.

17

17

17

17

17

17

17

17

17

18

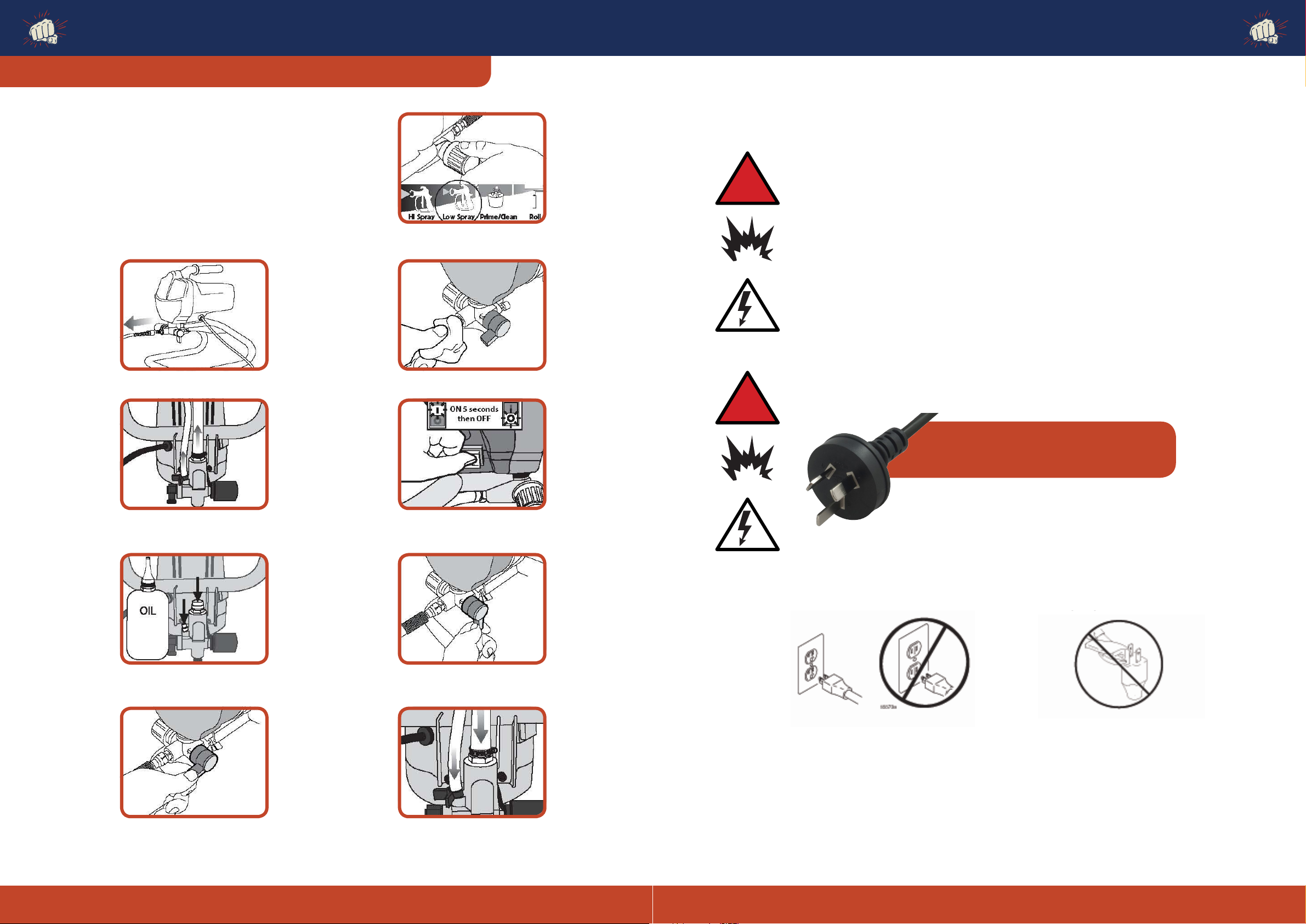

Grounding and Electric Requirements

Grounding Instructions

This product must be grounded. In the event of an eletrical short circuit, grounding reduces the risk of electric

shock by providing an escape wire for the electric current. This product is equipped with a cord having a grounding

wire with an appropriate grounding plug . The plug must be plugged into an outlet that is properly installed and

grounded in accordance with all local codes and orinances.

Improper installation of the grounding plug can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not connect the green grounding wire to either flat blade

terminal. The wire with insulation having a green outer surface with or without yellow stripes is the grounding wire

and must be connected to the grounding pin. Check with a qualified electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt as to whether the product is properly grounded. Do

not modify the plug provided. If the plug will not fit the outlet, have the proper outlet installed by a qualified electrican.

The sprayer cord includes a grounding wire with an appropriate grounding contact.

Never use an outlet that is not grounded or an adapter.

Do not use the sprayer if the electrical cord has a damaged ground contact. Only use an extension cord with

an undamaged ground contact.

Warning!

The Plug According to the state!

The sprayer requires for type 470:

220-240Vac, 50Hz,11A, 1 phase,

circuit with a grounding receptacle.

18

Grounding and Electric Requirements

Grounding Instructions

This product must be grounded. In the event of an eletrical short circuit, grounding reduces the risk of electric

shock by providing an escape wire for the electric current. This product is equipped with a cord having a grounding

wire with an appropriate grounding plug . The plug must be plugged into an outlet that is properly installed and

grounded in accordance with all local codes and orinances.

Improper installation of the grounding plug can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not connect the green grounding wire to either flat blade

terminal. The wire with insulation having a green outer surface with or without yellow stripes is the grounding wire

and must be connected to the grounding pin. Check with a qualified electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt as to whether the product is properly grounded. Do

not modify the plug provided. If the plug will not fit the outlet, have the proper outlet installed by a qualified electrican.

The sprayer cord includes a grounding wire with an appropriate grounding contact.

Never use an outlet that is not grounded or an adapter.

Do not use the sprayer if the electrical cord has a damaged ground contact. Only use an extension cord with

an undamaged ground contact.

Warning!

The Plug According to the state!

The sprayer requires for type 470:

220-240Vac, 50Hz,11A, 1 phase,

circuit with a grounding receptacle.

GROUNDING AND ELECTRICAL REQUIREMENTS

!

!

Grounding Instructions

LONG TERM STORAGE

When cleaning for long term storage (more than 48 hours).

It is very important that the Paint Sprayer is not stored with any water

or water-based material left in the Pump, Hose, Tubes, or Spray Gun.

This will corrode the product.

IMPORTANT: Clean the Sprayer before storage. See

“Cleaning”on pages 14-15.

1. Remove paint hose if not already removed.

2. Turn the unit over and loosen the Clamps

from both Tubes, then disconnect Tubes

from the Pump Body.

3. Add one ounce of light household oil or a

pump storage product into each inlet.

4. Turn Prime/Spray switch to Spray.

6. Hold a rag over the paint hose outlet.

5. Turn Pressure Control Knob to Low/Spray.

7. Switch Power to ON for five seconds, then

turn the power OFF.

8. Turn Prime/Spray switch to Prime, this will

keep storage fluids in sprayer.

9. Replace the Tubes and secure with the Clamps.

10. Wipe the sprayer with a clean cloth. Store in a clean dry location out of reach of children.

Returns not accepted & warranty void if sprayer is

not properly cleaned immediately after every use.

This product must be grounded. In the event of

an electrical short circuit, grounding reduces the

risk of electric shock by providing an escape wire

for the electric current. This product is equipped

with a cord having a grounding wire with an

appropriate grounding plug . The plug must be

plugged into an outlet that is properly installed

and grounded in accordance with all local codes

and ordinances.

Improper installation of the grounding plug can

result in a risk of electric shock.

If repair or replacement of the cord or plug is

necessary, do not connect the green grounding

wire to either flat blade terminal. The wire with

insulation having a green outer surface with

or without yellow stripes is the grounding wire

and must be connected to the grounding pin.

Check with a qualified electrician or serviceman

if the grounding instructions are not completely

understood, or if you are in doubt as to whether

the product is properly grounded. Do not modify

the plug provided. If the plug will not fit the

outlet, have the proper outlet installed by a

qualified electrician.

The sprayer cord includes a grounding wire with an appropriate grounding contact.

The sprayer requires for type 470:

220-240Vac, 50Hz,11A, 1 phase, circuit

with a grounding receptacle.

Never use an outlet that is not grounded

or an adapter. Do not use the sprayer if the electrical cord has a

damaged ground contact. Only use an extension

cord with an undamaged ground contact.

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL |18 | 19

19

Smaller gauge or longer extension cords may reduce sprayer performance.

Spray gun: ground through connection to a properly grounded fluid hose and pump.

Fluid supply container: follow local code.

Solvent and Oil-based fluids: follow local code. Use only conductive metal pails placed on a grounded surface

such as concrete. Do not place the pail on a nonconductive surface such as paper or cardboard, which interrupts

grounding continuity.

Grounding the metal pail: Connect a ground wire to the pail by clamping one end to pail and other end to ground such as

a water pipe.

To maintain grounding continuity when flushing or relieving pressure: hold metal part of the spray gun firmly to the

side of a grounded metal pail, then trigger the gun.

Electrical bonding

A hose, hose assembly, and spray gun assembly shall be constructed to provide electrical bonding to dissipate static

electricity from the tip of the Spray gun through the spray gun assembly and the couplings at the ends of the hose to the

pump assembly. The spray gun assembly shall also provide an external means to dissipate static electricity during the

cleaning process when spraying into a metal container.

Construction

Black hose is constructed of an extruded, seamless themoplastic inner tube, chemically bonded to multi-layers of high

tensile synthetic resistant polyurethane cover. A static drain element of flexible, electrically conductive material is located

between the braid layers.

FEATURES

·Polyurethane cover permits greater flexibility and tighter bends

·Resistant to flex fatigue

·Dissipates static charge

·Will not swell or degrade in contact with most paint chemicals, oils and most other solvents

·Light weight- approximately half that of comparable rubber or wire hose

·O.D smaller than comparable rubber hose without reducing the I.D., pressure rating, or fluid-carrying capacity

·Highly abrasion resistant

·Extrmely durable

Daily Maintain

Equipment lifetime is rely on daily maintain. The following respects should be obeyed:

1. Read the Manual carefully before first using.

2. Check the electrical requirement before each working.

3. Thorough cleaning equipment and the accessories after using.

4. Coil the tube after cleaning, in case of any damage.

5. Add some lubricant if long time not use.

19

Smaller gauge or longer extension cords may reduce sprayer performance.

Spray gun: ground through connection to a properly grounded fluid hose and pump.

Fluid supply container: follow local code.

Solvent and Oil-based fluids: follow local code. Use only conductive metal pails placed on a grounded surface

such as concrete. Do not place the pail on a nonconductive surface such as paper or cardboard, which interrupts

grounding continuity.

Grounding the metal pail: Connect a ground wire to the pail by clamping one end to pail and other end to ground such as

a water pipe.

To maintain grounding continuity when flushing or relieving pressure: hold metal part of the spray gun firmly to the

side of a grounded metal pail, then trigger the gun.

Electrical bonding

A hose, hose assembly, and spray gun assembly shall be constructed to provide electrical bonding to dissipate static

electricity from the tip of the Spray gun through the spray gun assembly and the couplings at the ends of the hose to the

pump assembly. The spray gun assembly shall also provide an external means to dissipate static electricity during the

cleaning process when spraying into a metal container.

Construction

Black hose is constructed of an extruded, seamless themoplastic inner tube, chemically bonded to multi-layers of high

tensile synthetic resistant polyurethane cover. A static drain element of flexible, electrically conductive material is located

between the braid layers.

FEATURES

·Polyurethane cover permits greater flexibility and tighter bends

·Resistant to flex fatigue

·Dissipates static charge

·Will not swell or degrade in contact with most paint chemicals, oils and most other solvents

·Light weight- approximately half that of comparable rubber or wire hose

·O.D smaller than comparable rubber hose without reducing the I.D., pressure rating, or fluid-carrying capacity

·Highly abrasion resistant

·Extrmely durable

Daily Maintain

Equipment lifetime is rely on daily maintain. The following respects should be obeyed:

1. Read the Manual carefully before first using.

2. Check the electrical requirement before each working.

3. Thorough cleaning equipment and the accessories after using.

4. Coil the tube after cleaning, in case of any damage.

5. Add some lubricant if long time not use.

Smaller gauge or longer extension cords may

reduce sprayer performance.

Spray gun: ground through connection to a

properly grounded fluid hose and pump.

Fluid supply container: follow local code.

Solvent and Oil-based fluids: follow local

code. Use only conductive metal pails placed

on a grounded surface such as concrete.

Do not place the pail on a nonconductive

surface such as paper or cardboard, which

interrupts grounding continuity.

Grounding the metal pail: Connect a ground

wire to the pail by clamping one end to pail

and other end to ground such as a water

pipe.

To maintain grounding continuity when

flushing or relieving pressure: hold metal

part of the spray gun firmly to the side of a

grounded metal pail, then trigger the gun. • Keep all screws, nuts, washers, gaskets, and electrical

fittings removed during repair procedures. These parts

usually are not provided with replacement kits.

• Test repairs after problems are corrected.

• If sprayer does not operate properly, review

repair procedure to verify you did it correctly. See

Troubleshooting, page 8.

• Overspray may build up in the air passages. Remove any

overspray and residue from air passages and openings

in the enclosures whenever you service sprayer.

• Do not operate the sprayer without the motor shroud in

place. Replace if damaged. Motor shroud directs cooling

air around motor to prevent overheating and insulates

the control board from accidental electric shock.

• Do not run sprayer dry for more than 30 seconds. Doing

so could damage pump packings.

• Protect the internal drive parts of this sprayer from

water. Openings in the cover allow for air cooling of the

mechanical parts and electronics inside. If water gets

in these openings, the sprayer could malfunction or be

permanently damaged.

• Prevent pump corrosion and damage from freezing.

Never leave water or water-base paint in sprayer when

its not in use in cold weather. Freezing fluids can

seriously damage sprayer. Store sprayer with Pump

Armor to protect sprayer during storage.

Flammable materials spilled on hot, bare, motor

could cause a fire or explosion. To reduce risk of

burns, fire or explosion, do not operate sprayer

with cover removed.

To reduce risk of serious injury, including electric shock:

• Do not touch moving or electric parts with fingers or

tools while testing repair.

• Unplug sprayer when power is not required for testing.

• Install all covers, gaskets, screws and washers before

you operate sprayer.

The equipment lifetime relies on regular maintenance. The following respects should be obeyed:

1. Read the Manual carefully before first using.

2. Check the electrical safety before each operation.

3. Thoroughly clean the equipment and accessories in accordance with the cleaning instructions after each use.

4. Coil the tube after cleaning, in case of any damage.

5. Add lubricant according to the instructions if the machine will not be in use for more than 48 hours.

A hose, hose assembly, and spray gun

assembly shall be constructed to provide

electrical bonding to dissipate static

electricity from the tip of the spray gun

through the spray gun assembly and the

couplings at the ends of the hose to the

pump assembly. The spray gun assembly

shall also provide an external means

to dissipate static electricity during the

cleaning process when spraying into a metal

container.

Construction

The spray hose is constructed from extruded,

seamless thermoplastic inner tube,

chemically bonded to multi-layers of high

tensile synthetic resistant polyurethane

cover. A static drain element of flexible,

electrically conductive material is located

between the braid layers.

Features

• Polyurethane cover permits greater

flexibility and tighter bends

• Resistant to flex fatigue

• Dissipates static charge

• Will not swell or degrade in contact with

most paint chemicals, oils and most other

solvents

• Light weight- approximately half that of

comparable rubber or wire hose

• O.D smaller than comparable rubber hose

without reducing the I.D., pressure rating, or

fluid-carrying capacity

• Highly abrasion resistant

• Extremely durable

ELECTRICAL BONDING

CAUTION

DAILY MAINTENANCE

GENERAL REPAIR INFORMATION

!

!

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL |20 | 21

28

Micro Computer Controlled

Board

Sealing ring replace:

1. Removed the rear cover with 5”allen wrench.

2. Loosen two screws on pump frame with 5”allen wrench, the pump to be removed from the pump frame.

3. Loosen four screws which connector the pump and pump cover with 4”allen wrench.

4. Open the pump cover, take out the connecting rod component and the gear.

5. Screw out the connector with special sleeve.

6. Carefully check the piston rod and seal and o-ring and other parts for wear and scratches, if any, should be replaced immediately,

(head the ball into the connector seat, can remove piston, sealing ring, etc.)

7. With special sleeve screw the connector to pump body and tighten in place.

8. Put the connector assembly and gear into pump hosing.

9. Locking pump cover and pump housing with screw, then pump loaded on the frame, and cover the rear cover.

10. Assembled the Suction tube and Priming tube component.

11. According to operating Instructions steps to activate and check the equipment without dripping.

Note:

1. All components apply a little oil before assembled.

2. Even if a sealing ring is damaged, must be replaced the whole repair parts.

230V Airless Sprayer Electrical Installation Drawing

Electricity (230V)

Heat Pressure Control

Protection Switch

Electrical

Switch

Motor

a. Joint stopper b. O-ring 22.5*1.8 c. Stopper sleeve

d. Position washer e. Copper washer f. Felt

g. Connector seat h. Copper guide bushing i. Connector

28

Micro Computer Controlled

Board

Sealing ring replace:

1. Removed the rear cover with 5”allen wrench.

2. Loosen two screws on pump frame with 5”allen wrench, the pump to be removed from the pump frame.

3. Loosen four screws which connector the pump and pump cover with 4”allen wrench.

4. Open the pump cover, take out the connecting rod component and the gear.

5. Screw out the connector with special sleeve.

6. Carefully check the piston rod and seal and o-ring and other parts for wear and scratches, if any, should be replaced immediately,

(head the ball into the connector seat, can remove piston, sealing ring, etc.)

7. With special sleeve screw the connector to pump body and tighten in place.

8. Put the connector assembly and gear into pump hosing.

9. Locking pump cover and pump housing with screw, then pump loaded on the frame, and cover the rear cover.

10. Assembled the Suction tube and Priming tube component.

11. According to operating Instructions steps to activate and check the equipment without dripping.

Note:

1. All components apply a little oil before assembled.

2. Even if a sealing ring is damaged, must be replaced the whole repair parts.

230V Airless Sprayer Electrical Installation Drawing

Electricity (230V)

Heat Pressure Control

Protection Switch

Electrical

Switch

Motor

a. Joint stopper b. O-ring 22.5*1.8 c. Stopper sleeve

d. Position washer e. Copper washer f. Felt

g. Connector seat h. Copper guide bushing i. Connector

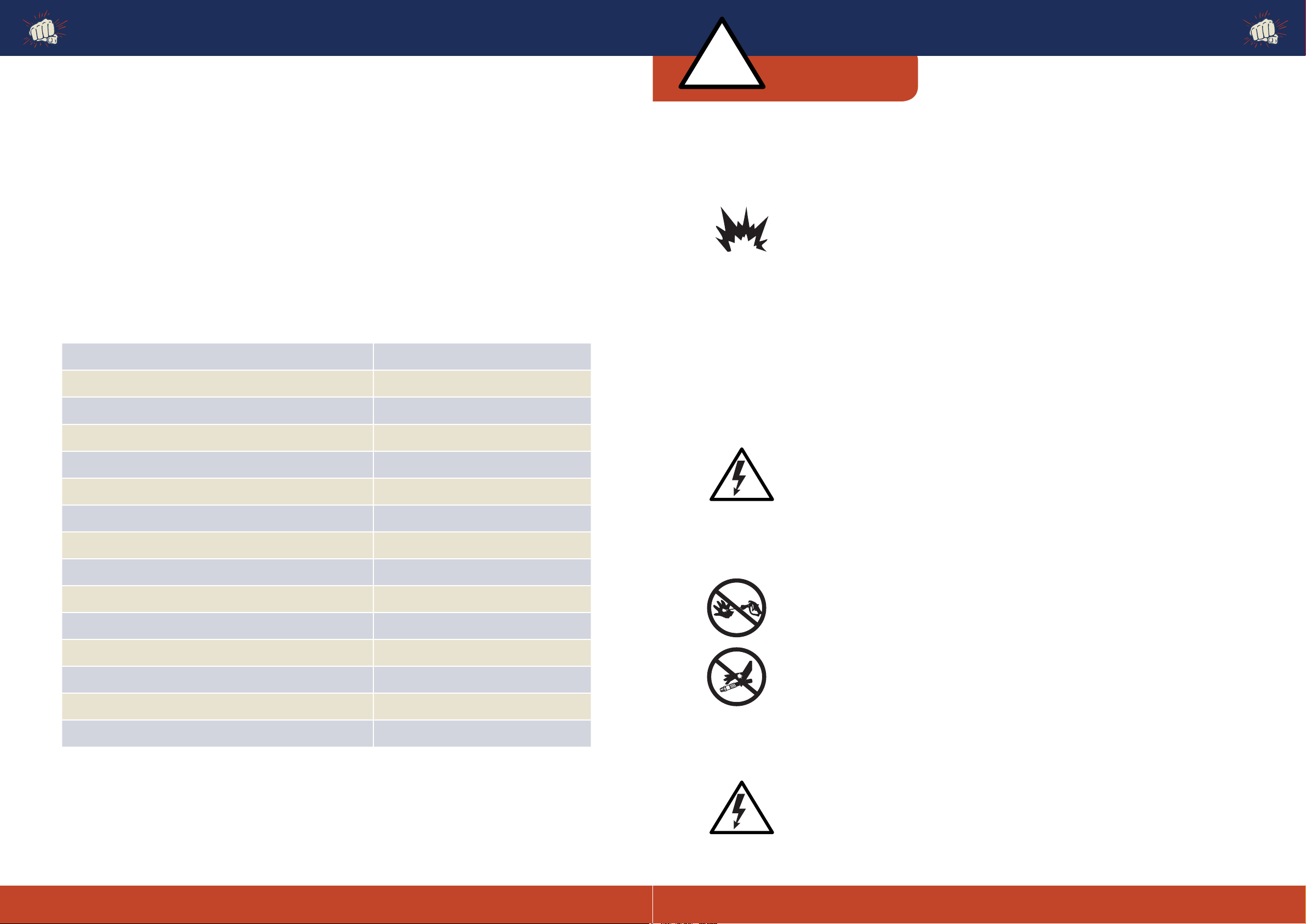

Problem What To Check

(If check is OK, go to next check) What To Do

(When check is not OK, refer to this column)

Motor Won’t Operate

Basic Fluid

Pressure 1. Pressure control knob setting. Motor will not run

if set at minimum (fully counter-clockwise). 1. Slowly increase pressure setting to see if motor

starts.

2. Spray tip or fluid filter may be clogged. 2. Relieve pressure, then clear clog or clean gun

filter.

3. Machines does not pump. 3. Depress reset button beneath the pump to loosen

the ball.

Basic Mechanical 1. Pump frozen or hardened paint.

1. Thaw sprayer if water or water-based paint has

frozen in sprayer. Place sprayer in warm area to

thaw. Do not start sprayer until thawed completely.

If paint hardened (dried) in sprayer, replace pump

packings.

2. Displacement pump connecting rod pin.

Pin must be completely pushed into connecting rod

and retaining spring must be firmly in groove or

pump pin.

2. Push pin into place and secure with spring

retainer.

3. Motor. Remove drive housing assembly. 3. Replace motor if fan won’t turn.

Low Output 1. Worn spray tip. 1.Relieve pressure, replace tip.

2. Verify pump does not continue to stroke when

gun trigger is released. 2. Service pump.

3. Prime valve leaking. 3. Relieve pressure, then repair prime valve.

4. Suction tube connections. 4. Tighten any loose connections. Check o-ring on

suction tube.

5. Electric supply with volt meter.

Meter must read 220-240 Vac or 110V(According to

models). Low voltages reduce sprayer performance.

5. Reset building circuit breaker; replace building

fuse. Repair electrical outlet or try another outlet.

6. Extension cord size and length. 6. Replace with a correct, grounded extension cord.

7. Leads from motor to circuit board for damaged or

loose wire connectors. Inspect wiring insulation and

terminals for signs of overheating.

7. Be sure male terminal pins are centered and

firmly connected to female terminals. Replace

any loose terminals or damaged wiring. Securely

reconnect terminals.

8. Worn motor brushes which must be

greater than 1/4 in. (6 mm). 8. Replace brushes.

9. Motor brushes binding in brush holders. 9. Clean brush holders. Remove carbon dust by

using compressed air to blow out brush dust.

10. Low stall pressure. Turn pressure control knob

fully clockwise. 10. Replace pressure control assembly.

11. Motor armature for shorts by using an armature

tester (growler) or perform spin test. 11. Replace motor.

TROUBLESHOOTING SEALING RING REPLACEMENT

230V AIRLESS SPRAYER ELECTRICAL INSTALLATION DRAWING

1. Common Problems of Equipment 1. Removed the rear cover with 5” Allen wrench.

2. Loosen two screws on pump frame with 5” Allen wrench,

the pump to be removed from the pump frame.

3. Loosen four screws which connector the pump and

pump cover with 4” Allen wrench.

4. Open the pump cover, take out the connecting rod

component and the gear.

5. Screw out the connector with special sleeve.

6. Carefully check the piston rod and seal and o-ring and

other parts for wear and scratches, if any, should be

replaced immediately, (head the ball into the connector

seat, can remove piston, sealing ring, etc.)

7. With special sleeve screw the connector to pump body

and tighten in place.

8. Put the connector assembly and gear into pump hosing.

9. Locking pump cover and pump housing with screw, then

pump loaded on the frame, and cover the rear cover.

10. Assembled the Suction tube and Priming tube

component.

11. According to operating Instructions steps to activate

and check the equipment without dripping.

NOTE:

1. Apply a little oil to all components before assembly. 2. Even if a sealing ring is damaged you must replace all

worn parts.

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL |22 | 23

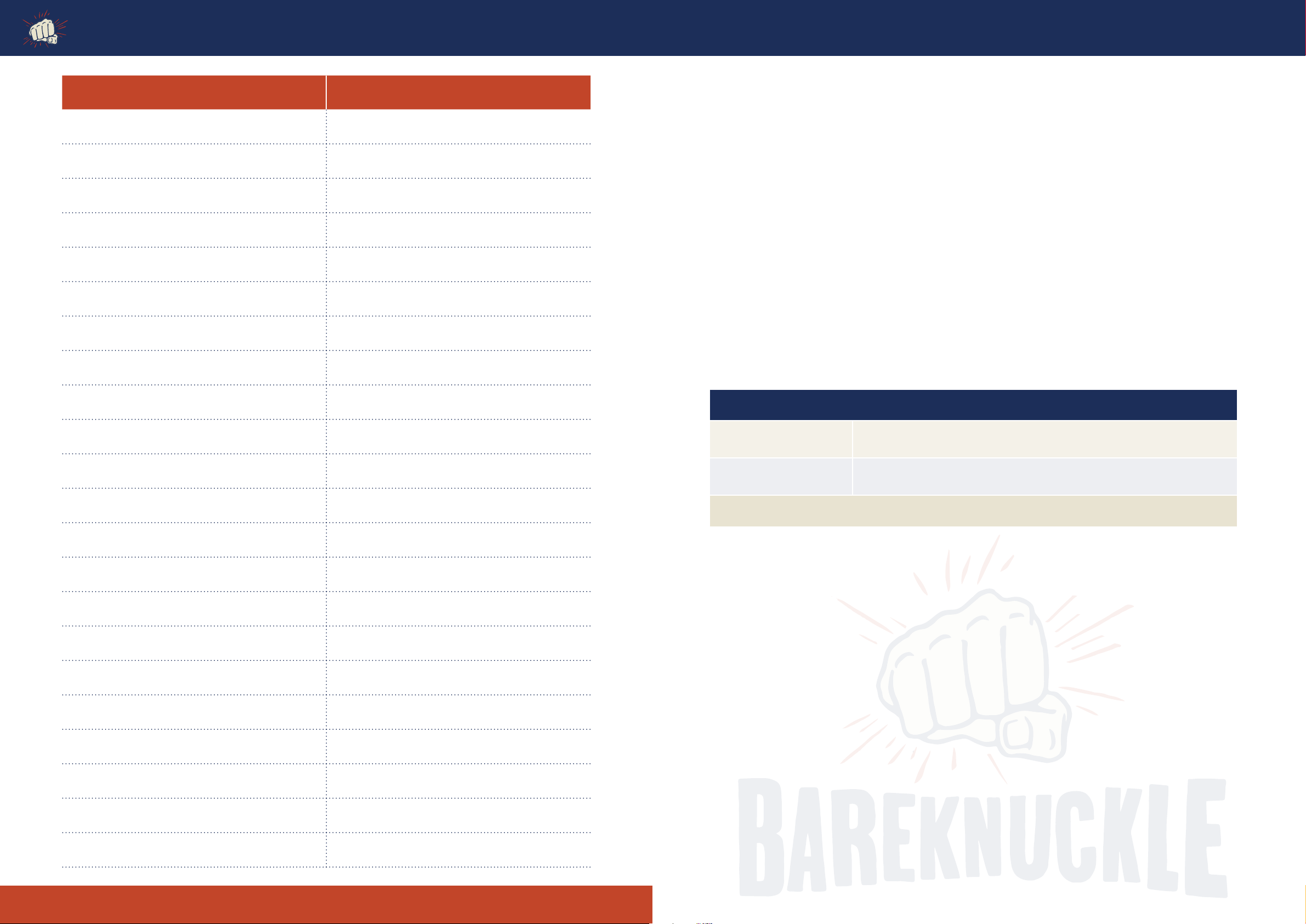

No. Description Qty. No. Description Qty. No. Description Qty.

1 Hex Bolt M6*20 2 45 Paint Input adaptor 1 89 Hex bolt M4*10 2

2 Pump cover 1 46 Pressure relief plug 1 90 Hex bolt M6*25 2

3 Output Gear bushing 2 47 Power switch 1 91 PCB supporter 1

4 Rolling bearing 1 48 Hex bolt M5* 14 3 92 Bolt M4*10 1

5 Output pole 1 49 Housing 1 93 Wire connector 1

6 Gear 1 50 Power plug 1 94 Nylon Cable tie 1

7 Gear bushing 2 51 Locking ring 1 95 Safety cover 1

8 Gear washer 1 52 Exhaust tube 1 96 PCB Assembly 1

9 Output gear 1 53 Wire Fastening seat 1 97 Tapping screw 2

10 Screw 1 54 Screw 3.5*10 3 98 Power cord fixer 1

11 Paint outlet 1 55 Bolt M4*10 1 99 Bolt M4*20 2

12 O-ring 10*8 1 56 Motor assembly 1 100 Shield 1

13 Output spring 1 57 Pin 3*12 2 101 O-ring 2.4*1.8 1

14 Mandrel 1 58 Hex bolt M5*14 4 102 Stopper 1

15 Steel ball 6.4 1 59 Spring washer 5 4 103 Copper gasket 1

16 Seal seat 1 60 Joint stopper 2 104 Touch control spring 1

17 Output washer 1 61 O-ring 1 105 Touch control pole 1

18 Pump 1 62 O-ring 22.5*1.8 1 106 O-ring 10*1.5 1

19 Plastic washer 1 63 Stopper sleeve 1 107 Touch control seat 1

20 Screw seat insert 1 64 Position washer 1 108 Touch control stem 1

21 Pressure relief valve seat 1 65 Copper washer 1 109 Flat washer 4 1

22 O-ring 5*1.8 1 66 Felt 1 110 Spring washer 4 1

23 Ring 1 67 Connector seat 1 111 Pole stopper 1

24 Pressure relief valve pole 1 68 Copper guide bushing 1 112 Pump frame assembly 1

25 Spring 1 69 Connector 1 130 Bush 1

26 Spring seat 1 70 Pin 5*12 2 131 Filter 1

27 Pin 3*8 1 71 Lock sleeve 1 132 Rubber stopper 1

28 Switch seat 1 72 White seal 1 133 Airless paint sprayer 1

29 Switch knob 1 73 Sealing washer 1 134 Paint hose 7.6m 1

30 Pin 2.5*25 1 74 Pressure control pin 1 135 Socket 22mm 1

31 Filtrate seat assembly 1 75 O-ring 8.8*1.9 1 136 Manual 1

32 Inlet pipe lock ring 1 76 O-ring 27*2.4 1 137 Wrench 1

33 Suction tube 1 77 Hex bolt M3*10 2 138 Hex wrench 4mm 1

34 Priming tube 1 78 Pressure seal cover 1 139 Hex wrench 5mm 1

35 Clip 1 79 Micro switch 1 140 Bush 1

36 Large clamp 1 80 Micro switch cover 1

37 Small clamp 1 81 Pressure control switch 1

38 Nylon cable tie 1 82 Switch cover 1

39 Inlet spring holder 1 83 Pressure adjusting spring 1

40 Input spring 1 84 Spring pusher 1

41 Steel ball 12.7 1 85 Pressure knob 1

42 Input seal 1 86 Pressure control bolt 1

43 Input washer 1 87 Up handle 1

44 O-ring 17*1.8 1 88 Below handle 1

PARTS LIST

26

Explode view for RP8623NL

BAREKNUCKLE WELTERWEIGHT

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL24 |

PAINT PROJECT PAINT COLOUR

The Bareknuckle Welterweight Airless Spray Machine comes

with a 12 month limited warranty. This warranty is against

any manufacturing defect in material or workmanship

under normal use as defined in the Bareknuckle

Welterweight Airless Sprayer Operating Instructions and

Safety Manual. This warranty does not cover replacement

of items as a result of normal operating wear and tear,

malfunction, damage or wear caused by misusing this

machine or maintenance not carried out as per this

manual, or any abuse or negligence, misuse, accident,

substitution of non genuine parts.

This product is designed and intended for DIY / household

use only. This warranty will be void if the product is used

for commercial use or income producing purposes.

In the event of a warranty claim, the product shall be

returned to the place of purchase with the original proof of

purchase:

For a warranty claim, we reserve the right to:

• repair or replace the goods (or part thereof)

• resupply a refurbished machine

• repair any item that is deemed necessary

If the resultant inspection of the product does not show a

defect in the material or workmanship, repair to the item

will be made at a reasonable cost to you. This cost may

include the costs of parts, labor and transportation.

The warranty becomes void if the correct operating,

cleaning and storage instructions have not been followed

by the user as defined by these Bareknuckle Welterweight

Operating Instructions and Safety manual.

A 12 month limited warranty ( from the original date or

purchase) is provided with this machine. Please retain

proof of purchase for any warranty claims and return to the

place of purchase.

In no event will HDI Trading Pty Ltd be liable for any

indirect, incidental or consequential damages resulting

from the sale or use of this product.

WARRANTY INFORMATION - IMPORTANT

Bareknuckle Welterweight Airless Paint Sprayer

Original Date of Purchase:

Place Purchased:

Please retain a copy of the receipt as proof of purchase.

Bareknuckle Welterweight - Airless Paint Sprayer OPERATING INSTRUCTIONS & SAFETY MANUAL26 |

BareknuckleOperatingInstructions

andSafetyManual

Forportablesprayapplication

ofpaintsandcoatings

HDI Trading Pty Ltd 2A/274 Macquarie Rd, Warners Bay NSW 2282 Australia

Product Code 174694 Made in China

WELTERWEIGHT

AIRLESSPAINT

SPRAYER

Table of contents

Popular Paint Sprayer manuals by other brands

Central Pneumatic

Central Pneumatic PAINT SPRAY GUN 30224 Assembly and operating instructions

Black Ridge

Black Ridge T100 instruction manual

AQUAJOE

AQUAJOE AJ-WW30-TND quick guide

Central Pneumatic

Central Pneumatic 93205 Assembly and operating instructions

EUROPRO

EUROPRO AC-50-G user manual

EUROPRO

EUROPRO Compact-Pro 120 user manual