NERONE MID User manual

MID

NERONE

®

Revision 00 - 06/2021

convection ovens

EN

USE AND MAINTENANCE MANUAL

Translation of the original instructions

USE AND MAINTENANCE MANUAL

NERONE MID

3

EN

TABLE OF CONTENTS

TABLE OF CONTENTS ................................. 3

TECHNICAL DATA SHEETS.......................... 5

TECHNICAL DATA SHEETS........................ 11

USE AND MAINTENANCE MANUAL ........... 17

1. GENERAL PRELIMINARY INFORMATION

....................................................18

1.1. Purpose of the document...........................18

1.2. Supply and preservation ............................18

1.3. Symbols used in the manual......................18

1.4. Regulatory framework ...............................19

1.5. Warranty...................................................19

2. SAFETY WARNINGS........................20

2.1. Obligations and prohibitions ......................21

2.1.1. Obligations ................................................... 21

2.1.2. Prohibitions................................................... 21

3. IDENTIFICATION AND DESCRIPTION. 22

3.1. Equipment identification............................22

3.2. Intended use.............................................22

3.3. Description ...............................................23

3.3.1. Types of cooking and ovens ............................ 23

3.4. Main components......................................24

4. RECEIPT AND HANDLING ................25

4.1. Equipment receipt.....................................25

4.1.1. Packaging removal and inspection................... 25

4.1.2. Packaging disposal........................................ 25

4.2. Handling...................................................26

5. INSTALLATION ...............................27

5.1. Installation site .........................................27

5.1.1. Features of installation site............................. 27

5.1.2. Minimum safety distances .............................. 28

5.2. Positioning on support structure ................28

5.3. Fumes exhaust - hood installation..............29

6. CONNECTIONS...............................30

6.1. Electrical connection .................................30

6.1.1. Electrical power supply connection .................. 30

6.1.2. Equipotential clamp connection....................... 30

7. CONTROL PANELS ......................... 31

7.1. “DIGITAL” version control panel..................31

7.1.1. Display ......................................................... 32

7.1.2. Keyboard functionality and user interface......... 32

7.2. “MECHANICAL” version control panel .........33

8. USE ..............................................34

8.1. First use ...................................................34

8.2. Activation .................................................34

8.3. Product loading and cooking......................35

8.3.1. Product loading ............................................. 35

8.3.2. Set a cooking................................................ 35

8.3.3. New recipe creation (ONLY “DIGITAL” VERSION). 37

8.3.4. Cooking with recipe already saved (ONLY “DIGITAL”

VERSION)...................................................... 37

8.3.5. H2O injection adjustment (ONLY “DIGITAL” VER-

SION) ........................................................... 38

8.3.6. Cooking with core probe and ∆°T (ONLY “DIGITAL”

VERSION)...................................................... 38

8.4. Other functions .........................................39

8.5. Switching off ............................................40

9. CLEANING .....................................41

9.1. Cleaning safety warnings...........................41

9.2. Clean the cooking chamber .......................42

9.3. Cleaning the glass.....................................42

9.4. Special Cleaning of the cooking chamber ...43

10. MAINTENANCE ..............................44

10.1. Routine maintenance ................................44

10.1.1. Inspecting after delivery ................................. 44

10.2. Extraordinary maintenance ........................44

10.2.1. Door disassembly for maintenance operations .. 45

10.2.2. Door gasket replacement................................ 46

10.2.3. Internal glass disassembly / replacement ......... 47

10.2.4. Tray supports disassembly.............................. 48

10.2.5. Lamp replacement......................................... 49

11. DIAGNOSTICS................................50

11.1. Probes alarm ............................................50

11.2. Actions on the adjustment in progress........50

11.3. Signals .....................................................50

12. DECOMMISSIONING AND DISPOSAL 51

12.1. Long periods of inactivity...........................51

12.2. Disposal ...................................................51

NERONE MID

EN

4

USE AND MAINTENANCE MANUAL

NERONE MID

5

EN

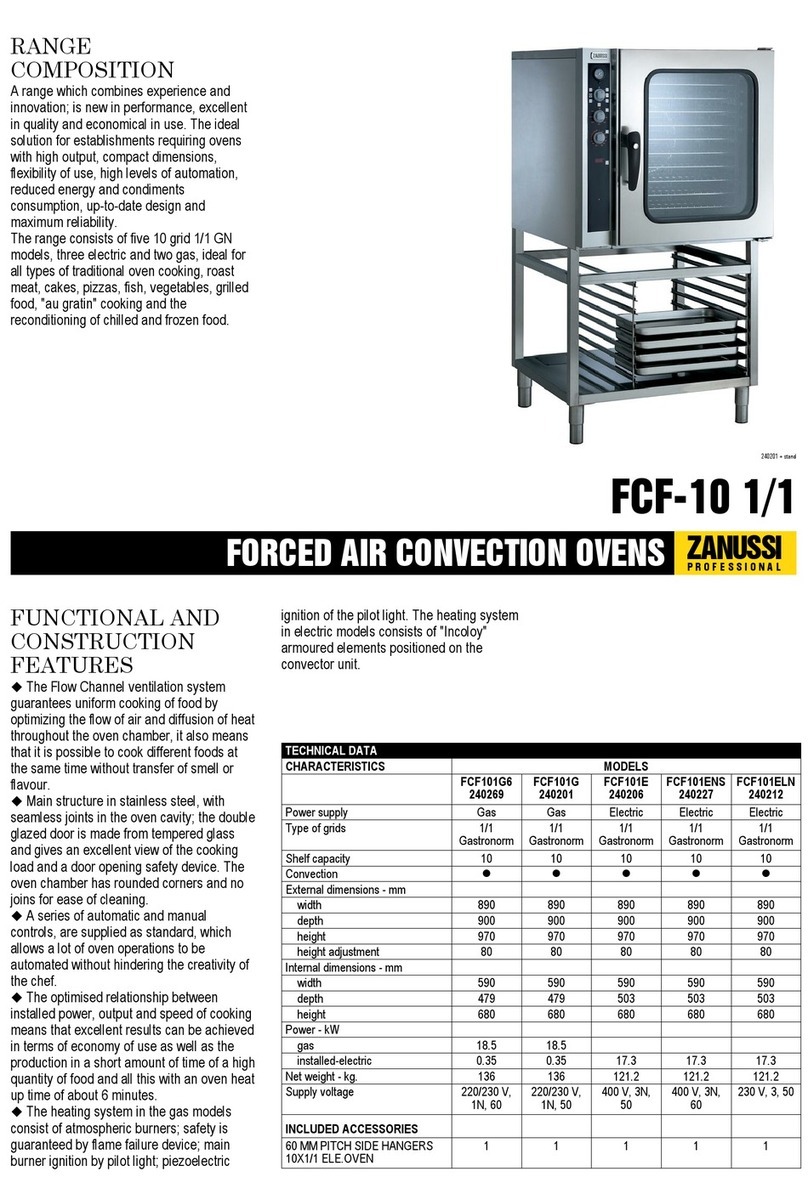

TECHNICAL DATA SHEETS

NERONE MID

EN

6

TECHNICAL FEATURES

Version Electrical - Digital

Trays capacity 4 - 600x400 mm / 4 - GN 1/1

Distance between trays 80 mm

Chamber dimensions L 680 x P 520 x H 360 mm

External dimensions L 840 x P 910 x H 670 mm

Total electrical power 5.45 kW

Voltage 220-240 V / 380-415 V 3/3+N 50/60 Hz

Total power consumption 24.8 A

Packaging dimensions L 880 x P 955 x H 820 mm

Net weight 79 kg

Gross weight with packaging 101 kg

04 trays/grids

Digital convection oven, with or without water injection, capacity 4trays or grids 600x400 mm or GN 1/1

LH SWING DOOR

(standard)

RH SWING DOOR

(optional)

FUNCTIONS

CONVECTION H2O

DIRECTION

INVERSION

RECIPES

CORE PROBE LIGHT

DELTA T°

USE AND MAINTENANCE MANUAL

NERONE MID

7

EN

TECHNICAL FEATURES

Version Electrical - Digital

Trays capacity 5 - 600x400 mm / 5 - GN 1/1

Distance between trays 80 mm

Chamber dimensions L 680 x P 480 x H 440 mm

External dimensions L 840 x P 910 x H 750 mm

Total electrical power 6.45 kW

Voltage 220-240 V / 380-415 V 3/3+N 50/60 Hz

Total power consumption 29.3 A

Packaging dimensions L 880 x P 955 x H 900 mm

Net weight 87 kg

Gross weight with packaging 109 kg

05 trays/grids

Digital convection oven, with or without water injection, capacity 5trays or grids 600x400 mm or GN 1/1

LH SWING DOOR

(standard)

RH SWING DOOR

(optional)

FUNCTIONS

CONVECTION H2O

DIRECTION

INVERSION

RECIPES

CORE PROBE LIGHT

DELTA T°

NERONE MID

EN

8

TECHNICAL FEATURES

Version Electrical - Digital

Trays capacity 6 - 600x400 mm / 6 - GN 1/1

Distance between trays 80 mm

Chamber dimensions L 680 x P 480 x H 520 mm

External dimensions L 840 x P 910 x H 830 mm

Total electrical power 7.65 kW

Voltage 220-240 V / 380-415 V 3/3+N 50/60 Hz

Total power consumption 35 A

Packaging dimensions L 880 x P 955 x H 980 mm

Net weight 91 kg

Gross weight with packaging 114 kg

06 trays/grids

Digital convection oven, with or without water injection, capacity 6trays or grids 600x400 mm or GN 1/1

LH SWING DOOR

(standard)

RH SWING DOOR

(optional)

FUNCTIONS

CONVECTION H2O

DIRECTION

INVERSION

RECIPES

CORE PROBE LIGHT

DELTA T°

USE AND MAINTENANCE MANUAL

NERONE MID

9

EN

TECHNICAL FEATURES

Version Electrical - Digital

Trays capacity 7 - 600x400 mm / 7 - GN 1/1

Distance between trays 80 mm

Chamber dimensions L 680 x P 520 x H 620 mm

External dimensions L 840 x P 910 x H 930 mm

Total electrical power 10.7 kW

Voltage 220-240 V / 380-415 V 3/3+N 50/60 Hz

Total power consumption 49 A

Packaging dimensions L 880 x P 955 x H 1080 mm

Net weight 106 kg

Gross weight with packaging 129 kg

07 trays/grids

Digital convection oven, with or without water injection, capacity 7trays or grids 600x400 mm or GN 1/1

LH SWING DOOR

(standard)

RH SWING DOOR

(optional)

FUNCTIONS

CONVECTION H2O

DIRECTION

INVERSION

RECIPES

CORE PROBE LIGHT

DELTA T°

NERONE MID

EN

10

TECHNICAL FEATURES

Version Electrical - Digital

Trays capacity 10 - 600x400 mm / 10 - GN 1/1

Distance between trays 80 mm

Chamber dimensions L 680 x P 480 x H 840 mm

External dimensions L 840 x P 910 x H 1150 mm

Total electrical power 12.7 kW

Voltage 220-240 V / 380-415 V 3/3+N 50/60 Hz

Total power consumption 58 A

Packaging dimensions L 880 x P 955 x H 1300 mm

Net weight 127 kg

Gross weight with packaging 150 Kg

10 trays/grids

Digital convection oven, with or without water injection, capacity 10 trays or grids 600x400 mm or GN 1/1

LH SWING DOOR

(standard)

RH SWING DOOR

(optional)

FUNCTIONS

CONVECTION H2O

DIRECTION

INVERSION

RECIPES

CORE PROBE LIGHT

DELTA T°

USE AND MAINTENANCE MANUAL

NERONE MID

11

EN

TECHNICAL DATA SHEETS

NERONE MID

EN

12

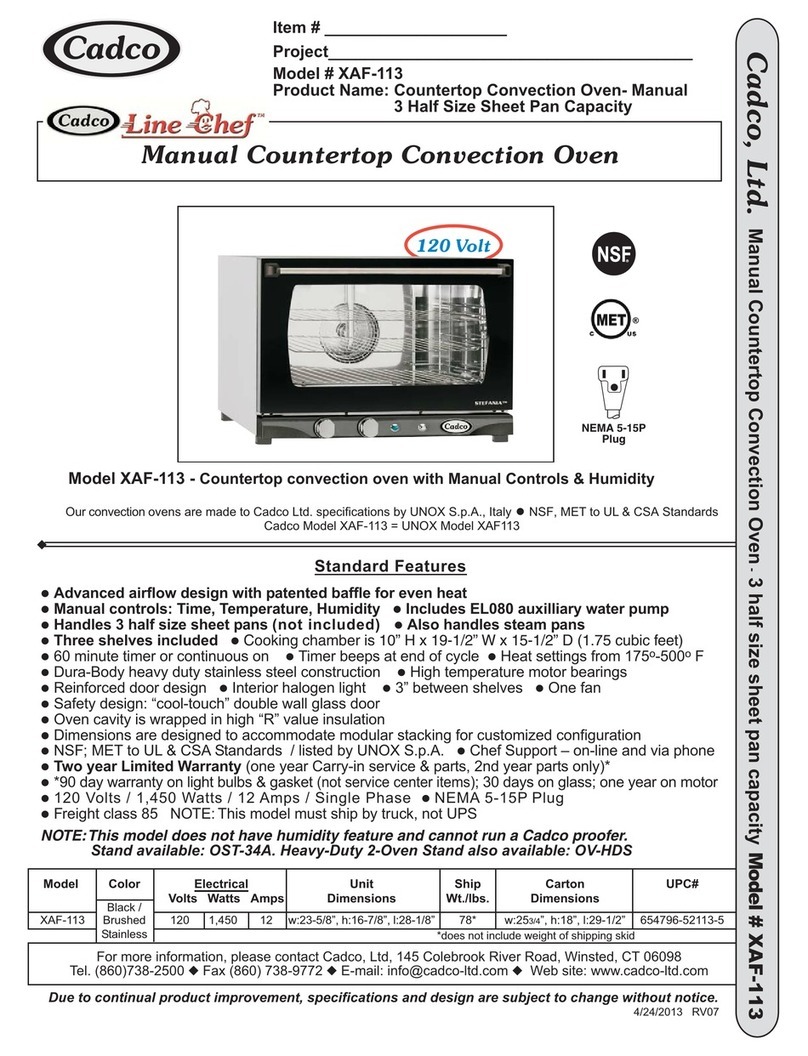

TECHNICAL FEATURES

Version Electrical - Mechanical

Trays capacity 4 - 600x400 mm / 4 - GN 1/1

Distance between trays 80 mm

Chamber dimensions L 680 x P 520 x H 360 mm

External dimensions L 840 x P 910 x H 670 mm

Total electrical power 5.45 kW

Voltage 220-240 V / 380-415 V 3/3+N 50/60 Hz

Total power consumption 24.8 A

Packaging dimensions L 880 x P 955 x H 820 mm

Net weight 79 kg

Gross weight with packaging 101 kg

04 trays/grids

Mechanical convection oven, with or without water injection, capacity 4trays or grids 600x400 mm or GN 1/1

LH SWING DOOR

(standard)

RH SWING DOOR

(optional)

FUNCTIONS

CONVECTION

DIRECTION

INVERSION

H2O

LIGHT

USE AND MAINTENANCE MANUAL

NERONE MID

13

EN

TECHNICAL FEATURES

Version Electrical - Mechanical

Trays capacity 5 - 600x400 mm / 5 - GN 1/1

Distance between trays 80 mm

Chamber dimensions L 680 x P 480 x H 440 mm

External dimensions L 840 x P 910 x H 750 mm

Total electrical power 6.45 kW

Voltage 220-240 V / 380-415 V 3/3+N 50/60 Hz

Total power consumption 29.3 A

Packaging dimensions L 880 x P 955 x H 900 mm

Net weight 87 kg

Gross weight with packaging 109 kg

05 trays/grids

Mechanical convection oven, with or without water injection, capacity 5trays or grids 600x400 mm or GN 1/1

LH SWING DOOR

(standard)

RH SWING DOOR

(optional)

FUNCTIONS

CONVECTION

DIRECTION

INVERSION

H2O

LIGHT

NERONE MID

EN

14

TECHNICAL FEATURES

Version Electrical - Mechanical

Trays capacity 6 - 600x400 mm / 6 - GN 1/1

Distance between trays 80 mm

Chamber dimensions L 680 x P 480 x H 520 mm

External dimensions L 840 x P 910 x H 830 mm

Total electrical power 7.65 kW

Voltage 220-240 V / 380-415 V 3/3+N 50/60 Hz

Total power consumption 35 A

Packaging dimensions L 880 x P 955 x H 980 mm

Net weight 91 kg

Gross weight with packaging 114 kg

06 trays/grids

Mechanical convection oven, with or without water injection, capacity 6trays or grids 600x400 mm or GN 1/1

LH SWING DOOR

(standard)

RH SWING DOOR

(optional)

FUNCTIONS

CONVECTION

DIRECTION

INVERSION

H2O

LIGHT

USE AND MAINTENANCE MANUAL

NERONE MID

15

EN

TECHNICAL FEATURES

Version Electrical - Mechanical

Trays capacity 7 - 600x400 mm / 7 - GN 1/1

Distance between trays 80 mm

Chamber dimensions L 680 x P 520 x H 620 mm

External dimensions L 840 x P 910 x H 930 mm

Total electrical power 10.7 kW

Voltage 220-240 V / 380-415 V 3/3+N 50/60 Hz

Total power consumption 49 A

Packaging dimensions L 880 x P 955 x H 1080 mm

Net weight 106 kg

Gross weight with packaging 129 kg

07 trays/grids

Mechanical convection oven, with or without water injection, capacity 7trays or grids 600x400 mm or GN 1/1

LH SWING DOOR

(standard)

RH SWING DOOR

(optional)

FUNCTIONS

CONVECTION

DIRECTION

INVERSION

H2O

LIGHT

NERONE MID

EN

16

TECHNICAL FEATURES

Version Electrical - Mechanical

Trays capacity 10 - 600x400 mm / 10 - GN 1/1

Distance between trays 80 mm

Chamber dimensions L 680 x P 480 x H 840 mm

External dimensions L 840 x P 910 x H 1150 mm

Total electrical power 12.7 kW

Voltage 220-240 V / 380-415 V 3/3+N 50/60 Hz

Total power consumption 58 A

Packaging dimensions L 880 x P 955 x H 1300 mm

Net weight 127 kg

Gross weight with packaging 150 Kg

10 trays/grids

Mechanical convection oven, with or without water injection, capacity 10 trays or grids 600x400 mm or GN 1/1

LH SWING DOOR

(standard)

RH SWING DOOR

(optional)

FUNCTIONS

CONVECTION

DIRECTION

INVERSION

H2O

LIGHT

USE AND MAINTENANCE MANUAL

NERONE MID

17

EN

USE AND MAINTENANCE

MANUAL

NERONE MID

EN

18

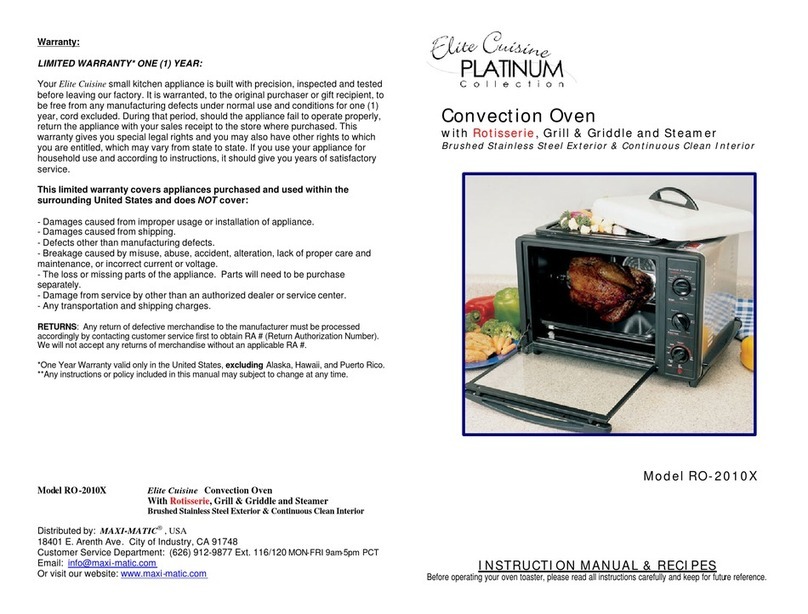

1. GENERAL PRELIMINARY INFORMATION

Thank you for purchasing one of our products.

Carefully read this manual before carrying out installation, maintenance and/or before using the equipment.

This manual is attached to all versions of the equipmentNERONEMID.

The Manufacturer is not liable for breakages, accidents or various problems due to non-compliance with and in any case the

non-application of the provisions contained in this manual.

1.1. PURPOSE OF THE DOCUMENT

This User and Maintenance Manual represents the reference document, drawn up by the manufacturer of the equipment,

aimed at operators and specialised personnel who will come into contact with it during its entire life cycle.

The purpose of the document is to provide information for the correct use of the machine, from installation to disposal,bringing

attention to the dangers that may arise from incorrect use and taking into account the reasonably foreseeable incorrect

behaviour of the operator.

1.2. SUPPLY AND PRESERVATION

The manual is supplied in electronic format.

This manual is an integral part of the equipment.

Keep this manual in a place that is accessible to all users for future consultation. In case of transfer or sale of the equipment,

be sure to provide the new user with this manual, so that they may be properly informed about the installation procedure, the

use and safety requirements.

1.3. SYMBOLS USED IN THE MANUAL

Symbols are used throughout the manual to emphasise information of significant importance.

The ones used are provided below:

SYMBOL TYPE DESCRIPTION

WARNING Symbol used to identify important warnings for the safety of the operator and/

or equipment.

FORBIDDEN

Symbol used to identify operations that must not be performed or behaviours

that must not be adopted as they could cause personal injury or damage to the

machine.

OBLIGATION

Symbol used to identify particularly important information inside the manual.

The information also regards the safety of personnel involved in use of the

equipment.

USE AND MAINTENANCE MANUAL

NERONE MID

19

EN

1.4. REGULATORY FRAMEWORK

The equipment has been designed according to the regulatory framework described in the declarations of conformity

accompanying the product and the identification plate placed on the same, as well as requirements, which can be downloaded

directly from the manufacturer’s website.

1.5. WARRANTY

The warranty terms established by law apply. Should the product be faulty, contact the nearest Authorised Service Centre, or

the reference Dealer.

The following documentation must be forwarded in order to repair the equipment;

▪copy of the invoice with the date of purchase of the product;

▪description of the fault.

NERONE MID

EN

20

2. SAFETY WARNINGS

The Manufacturer cannot be held liable for any damage, suffered by people or things,

caused by non-compliance with the aforementioned requirements or deriving from

tampering with even a single part of the equipment and from the use of non-original spare

parts.

Do not place flammable materials and or heat sources close to the oven (min. safety

distance 0.6 m laterally).

This professional equipment can only be used and cleaned by adults (> 18 years in Europe

or other limits defined by the local regulatory framework) with normal physical and mental

health and adequately trained and informed on the subject of health and safety in the

workplace.

Hot steam may flow out during oven operation. Burns hazard!

During operation, the cooking chamber reaches high temperatures. Do not touch the

internal parts of the oven. Always use the special oven gloves to extract and insert trays.

Danger of burns due to contact!

All operations regarding maintenance and replacement of parts must be carried out by

qualified technical personnel.

The power supply must be disconnected before carrying out maintenance, control, cleaning

operations.

It is strictly forbidden to make changes to the equipment.

Do not start the equipment with wet hands or when there is contact with water.

Replace any broken or faulty components only with original spare parts.

Table of contents

Other NERONE Convection Oven manuals

Popular Convection Oven manuals by other brands

Jenn-Air

Jenn-Air W122 use and care manual

Toastmaster

Toastmaster COV760B Use and care guide

Wolfgang Puck

Wolfgang Puck Bistro BTOBR0010 user manual

Panasonic

Panasonic NN-CF874B Operating instruction and cook book

gourmetmaxx

gourmetmaxx GF-1306 instruction manual

GGM gastro

GGM gastro LUNA Installation and user manual