NET GigE PRO Quick start guide

Operational Manual

Gigabit Ethernet CMOS cameras

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

2 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

Table of Contents

TABLE OF CONTENTS ............................................................................................................................................. 2

LIST OF FIGURES .................................................................................................................................................... 4

LIST OF TABLES ...................................................................................................................................................... 5

GENERAL INFORMATION ....................................................................................................................................... 6

SCOPE OF THE MANUAL................................................................................................................................................... 6

RELATED DOCUMENTS .................................................................................................................................................... 6

OVERVIEW ............................................................................................................................................................ 6

SCOPE OF DELIVERY .............................................................................................................................................. 7

CONTENT ..................................................................................................................................................................... 7

OPTIONS...................................................................................................................................................................... 7

OPTIONALLY AVAILABLE HARDWARE ACCESSORIES ................................................................................................................. 7

OPTIONALLY AVAILABLE SOFTWARE ACCESSORIES.................................................................................................................. 8

OPTIONALLY AVAILABLE NET IMAGE PROCESSING LIBRARY FUNCTIONS ..................................................................................... 8

OPTIONALLY AVAILABLE FOR “OPEN CAMERA”CUSTOMERS.................................................................................................... 8

STANDARD CONFORMITY ...................................................................................................................................... 9

LEGAL NOTICE............................................................................................................................................................... 9

ROHS ......................................................................................................................................................................... 9

FCC ............................................................................................................................................................................ 9

CE .............................................................................................................................................................................. 9

SAFETY PRECAUTIONS..........................................................................................................................................10

GENERAL HANDING...................................................................................................................................................... 11

USAGE NOTES.......................................................................................................................................................13

SYSTEM REQUIREMENTS ......................................................................................................................................16

SYNVIEW –SOFTWARE DEVELOPMENT KIT (SDK).............................................................................................................. 16

SPECIFICATIONS....................................................................................................................................................17

OUTLINE DIMENSIONS.................................................................................................................................................. 17

CAMERA MOUNT ........................................................................................................................................................ 18

LENS MOUNT ............................................................................................................................................................. 18

INTERFACES ................................................................................................................................................................ 19

I/O SPECIFICATION....................................................................................................................................................... 21

IMAGE SENSORS .......................................................................................................................................................... 24

STANDARD CAMERA FUNCTIONS .........................................................................................................................33

OVERVIEW ................................................................................................................................................................. 33

3 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

DEVICE CONTROL......................................................................................................................................................... 34

IMAGE FORMAT CONTROL ............................................................................................................................................. 35

ACQUISITION CONTROL................................................................................................................................................. 38

TRIGGERCONTROL ....................................................................................................................................................... 39

EXPOSURECONTROL ..................................................................................................................................................... 42

DIGITAL I/O CONTROL .................................................................................................................................................. 44

TIMERCONTROL .......................................................................................................................................................... 45

GAIN......................................................................................................................................................................... 46

BLACKLEVEL ............................................................................................................................................................... 47

GAMMA .................................................................................................................................................................... 48

LUTCONTROL ............................................................................................................................................................. 49

TRANSPORTLAYERCONTROL ........................................................................................................................................... 50

USERSETCONTROL ....................................................................................................................................................... 53

COLOR TRANSFORMATION CONTROL ............................................................................................................................... 55

EXTENDED CAMERA FUNCTIONS..........................................................................................................................57

OVERVIEW ................................................................................................................................................................. 57

GEOMETRY CORRECTION CONTROL ................................................................................................................................. 58

FLAT FIELD CORRECTION CONTROL.................................................................................................................................. 59

CANNY CONTROL......................................................................................................................................................... 59

THE "OPEN CAMERA" CONCEPT ...........................................................................................................................60

OVERVIEW ................................................................................................................................................................. 60

NET IMAGE PROCESSING LIBRARY FUNCTIONS .................................................................................................................. 60

PROCESSING CAPABILITIES ............................................................................................................................................. 61

FRAME BUFFER OPTIONS .............................................................................................................................................. 62

FPGA DATA FLOW....................................................................................................................................................... 63

IMAGE PROCESSING TYPES............................................................................................................................................. 64

TECHNICAL SUPPORT ...........................................................................................................................................67

IMPRINT...............................................................................................................................................................68

4 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

List of Figures

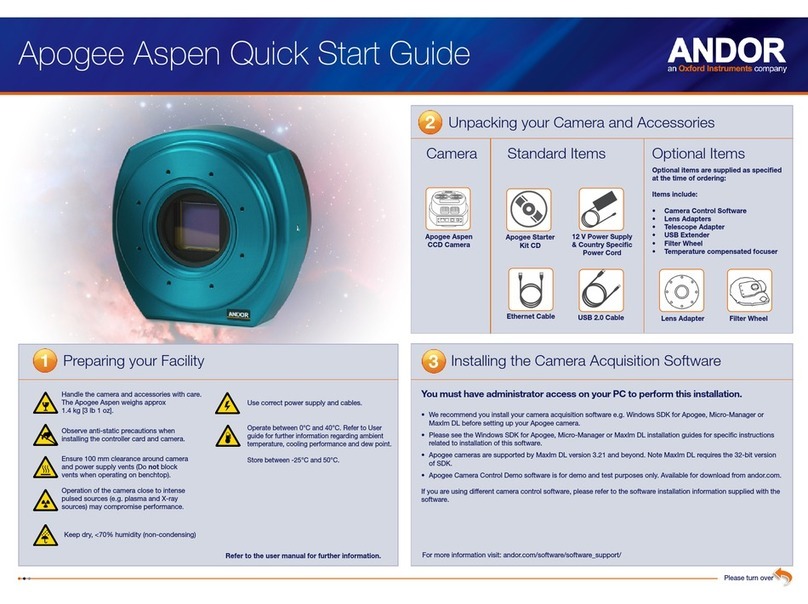

FIGURE 1: C-MOUNT LENS......................................................................................................................................... 14

FIGURE 2: GIGEPRO CAMERA DIMENSION ................................................................................................................... 17

FIGURE 3: CAMERA REAR VIEW WITH AUX PIN ORDER ..................................................................................................... 20

FIGURE 4: DIGITAL DATA INPUT ................................................................................................................................... 21

FIGURE 5: INTERNAL TRIGGER DELAY WITH DEBOUNCE FILTER ............................................................................................ 22

FIGURE 6: DIGITAL DATA OUTPUT ................................................................................................................................ 23

FIGURE 7: DIGITAL OUTPUT TIMING DIAGRAM............................................................................................................... 23

FIGURE 8: IR CUT FILTER CHARACTERISTICS FOR COLOR CAMERAS ....................................................................................... 26

FIGURE 9: AR FILTER CHARACTERISTICS FOR BW/IR CAMERAS........................................................................................... 26

FIGURE 10: EV76C661 NIR ........................................................................................................................................ 27

FIGURE 11: EV76C570 COLOR +BW ........................................................................................................................... 27

FIGURE 12: EV76C560 BW ........................................................................................................................................ 28

FIGURE 13: EV76C560 COLOR .................................................................................................................................... 28

FIGURE 14: MT9V032 BW......................................................................................................................................... 29

FIGURE 15: MT9V032 COLOR ..................................................................................................................................... 29

FIGURE 16: MT9T001 COLOR ..................................................................................................................................... 30

FIGURE 17: MT9P031 BW......................................................................................................................................... 30

FIGURE 18: MT9P001 COLOR ..................................................................................................................................... 31

FIGURE 19: MT9J003 BW.......................................................................................................................................... 31

FIGURE 20: MT9J003 COLOR ...................................................................................................................................... 32

FIGURE 21: TESTPATTERN=1: COLOR BAR ....................................................................................................................... 37

FIGURE 22: TESTPATTERN=2: RAMP +COLOR .................................................................................................................. 37

FIGURE 23: TESTPATTERN=3: NOISE RAMP ..................................................................................................................... 37

FIGURE 24: TESTPATTERN=4: DYNAMIC NOISE RAMP........................................................................................................ 37

FIGURE 25: MACBETH STANDARD COLOR CHECKER ............................................................................................................ 56

FIGURE 26: GEOMETRY CALIBRATION TARGET................................................................................................................... 58

FIGURE 27: PARTITIONING OF IMAGE PROCESSING TASKS BETWEEN CAMERA AND HOST ............................................................ 60

FIGURE 28: IMAGE PROCESSING CAPABILITY OF GIGEPRO INTERNAL FPGA ........................................................................... 61

FIGURE 29: OPEN CAMERA DATA FLOW .......................................................................................................................... 63

FIGURE 30: STANDARD IMAGE PROCESSING..................................................................................................................... 64

FIGURE 31: IMAGE PROCESSING WITH CONTROL LOOP ....................................................................................................... 65

FIGURE 32: CYCLE BUDGET .......................................................................................................................................... 65

5 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

List of Tables

TABLE 1: GIGEPRO IMAGE SENSORS ................................................................................................................................ 6

TABLE 2: OVERVIEW .................................................................................................................................................... 19

TABLE 3: GIGABIT ETHERNET INTERFACE CONNECTOR RJ-45 JACK ........................................................................................ 20

TABLE 4: AUXILIARY I/O CONNECTOR PIN ASSIGNMENT ...................................................................................................... 21

TABLE 5: DIGITAL INPUT CHARACTERISTICS....................................................................................................................... 22

TABLE 6: DIGITAL OUTPUT CHARACTERISTICS.................................................................................................................... 23

TABLE 7: IMAGE SENSORS WVGA AND SXGA .................................................................................................................. 24

TABLE 8: IMAGE SENSORS UXGA AND QXGA .................................................................................................................. 24

TABLE 9: IMAGE SENSORS QSXGA AND WQUXGA .......................................................................................................... 25

TABLE 10: STANDARD CAMERA FUNCTION CONTROL ........................................................................................................ 33

TABLE 11: SUPPORTED PIXEL FORMATS.......................................................................................................................... 36

TABLE 12: THE REGISTER LIST APPLIED BY “USERSETLOAD”/“USERSETSAVE”....................................................................... 53

TABLE 13: ADVANCED IMAGE PROCESSING CAPABILITIES ON STANDARD CAMERA.................................................................... 57

TABLE 14: EXTENDED CAMERA FUNCTION CONTROL......................................................................................................... 58

TABLE 15: FPGA RESOURCES (XILINX) AVAILABLE TO CUSTOMER IMAGE PROCESSING*.......................................................... 61

TABLE 16: FRAME BUFFER OPTIONS ............................................................................................................................. 62

6 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

General information

Scope of the manual

This manual introduces the GigEPRO camera family and covers all common aspects of work with these

cameras. Technical specifications and other model-specific data are listed in section Specifications p.17 .

Related documents

-SynView Quick Start Guide —SynView SDK package overview, installation instructions and quick

start guide.

-GigEPRO NET IP Library data sheets —additional NET image processing library modules for use

with GigEPRO cameras.

-SynView Programmers Guide —SynView API reference guide with programming examples

Overview

The NET GigEPRO camera series is designed for advanced digital image processing applications requiring

real-time image processing functionality of the camera with compliancy to GigE Vision and GenICam

standards. With GigEPRO cameras customers have access to already available NET image processing

functions or can apply own image processing functions or even decide for a combination of all in order

to achieve efficiency improvements in image processing.

Table 1: GigEPRO Image Sensors

Model

b/w - NIR - color

Sensor

Image Sensor

Resolution (H*V)

[pixel]

Sensor size

Shutter

Frame rate

[fps]

GP1041C

CMOS

MT9V032

752 x 480 / WVGA

1/3"

global

86

GP1041M

CMOS

GP4136C

CMOS

EV76C560

1280 x 1024 / SXGA

1/1.8"

global;

rolling; global

reset

60

GP4136M

CMOS

GP4136IR

CMOS

EV76C661

1280 x 1024 / SXGA

1/1.8"

GP4206C

CMOS

EV76C570

1600 x 1200 / UXGA

1/1.8"

global;

rolling; global

reset

50

GP4206M

CMOS

GP1305C

CMOS

MT9T001

2048 x 1536 / QXGA

1/2"

rolling with

global reset

12

GP1503C

CMOS

MT9P001

2592 x 1944 / QSGA

1/2.5"

15

GP1503M

CMOS

MT9P031

2592 x 1944 / QSGA

1/2.5"

15

GP11004C

CMOS

MT9J003

3664 x 2748 / WQUXGA

1/2.3"

7.5

GP11004M

CMOS

7 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

Scope of Delivery

Content

-GigEPRO is offered as follows:

Image Sensor: see Table 1: GigEPRO Image Sensors

FPGA type: XILINX LX45

DDR3 memory size: 1Gbit

-CD-ROM including full SynView installer including:

SynView Software Development Kit (SDK) with viewer software (sv.explorer)

SynView Filter Driver and Kernel Driver

SynView Quick Start Guide

SynView Programmers Guide

GigEPRO Operational Manual (this document)

Options

-GigEPRO can be further customized with the following configuration options:

FPGA type: XILINX LX75, LX100

DDR3 memory size: 2Gbit, 4Gbit

Optionally available hardware accessories

The GigEPRO camera product does not include any accessories. Other equipment must be provided

separately. System components necessary for using this camera series are listed below:

GigEPRO camera mounting plate

The mounting plate can be attached to the bottom of the camera and allows the camera to be

mounted on a tripod with a 1/4” screw. The GigEPRO camera mounting plate comes with four 6mm

M3 screws.

CA-Base-Plate-GigEPRO: Order number 05005800xx (*1)

Auxiliary connection cable

This cable allows you to connect digital IO and auxiliary power to the camera. The cable is 5m long

with a header on one side fitting into the GigEPRO auxiliary I/O connector.

CA-iCube-TRIGGER-5m: standard version Order number 06087600xx (*1)

ZY-iCube-TRIGGER-TC-5m:trailer chain version Order number 06091100xx (*1)

8 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

LAN Cable

This cable is used to connect the camera to host equipment. Ethernet packets (stream and control)

are transmitted via this cable. Please use a LAN cable that supports 1000BASE-T (Cat 5e or over). This

product is able to connect a LAN cable that is equipped with screw lock mechanism.

CA-G18-S10-05: trailer chain version Order number 06077400xx (*1)

CA-G18-S10-10:trailer chain version Order number 06077401xx (*1)

Network Interface Card (NIC) (*2)

This is the interface card to connect to the camera. Usually this card is installed to a PCIe expansion

slot of host PC etc. Please use 1000BASE-T NIC, supporting Jumbo Frame is recommended.

PoE Switching HUB / PoE Power Injector etc. (*2)

Use this equipment when you supply power to the camera from PoE. Please use 1000BASE-T

equipment, supporting Jumbo Frame is recommended.

*1: Optional part. Contact your NET sales contact for details of option units.

*2: Commercial items.

C-mount lenses and Illumination

Contact your NET sales contact for details.

Optionally available software accessories

-GigEPRO calibration tool

Optionally available NET Image Processing library functions

Please ask your NET sales contact for further details

-Geometry correction (GC) and calibration application

-Flat field correction (FFC) and calibration application

-1D and 2D Filter algorithms (Gauss, Laplace, Sobel) and Canny Edge Detection

-Temporal Noise Reduction (TNR)

-Gain offset correction

Optionally available for “Open Camera” customers

-GigEPRO development and debug cable and programming dongle

9 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

-CD-ROM including:

GigEPRO XILINX ISE Project including programming templates

Open Camera Flow Description

Standard Conformity

Legal Notice

The cameras implement the GigE Vision 1.2 standard and were properly registered as GigE Vision

compliant devices with AIA.

The cameras (and supporting libraries) fully implement the GenICam standard, including SFNC (Standard

Features Naming Convention) and GenTL.

RoHS

The product fulfills the requirements of the EU directive RoHS 2011/65/EU in the currently valid version

from 8.June 2011 regarding the restrictive use of certain hazardous materials in electric applications

within the allowable limits.

FCC

This equipment has been tested and found to comply with the limits for a class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communication.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

CE

This apparatus has been certified to meet or exceed the standards for CE compliance per Council

Directives. Pertinent testing documentation is available for verification. This product following the

provision of directive 2004/108/EC.

10 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

Safety Precautions

Before using this product read these safety precautions carefully. Important information is shown in this

Operational Manual to protect users from injuries and property damages and to enable them to use the

product safely and correctly.

Please be sure to thoroughly understand the meanings of the following signs and symbols before reading

the main text that follows, and observe the instructions given herein.

[Definition of Safety Signs]

Notes

*1:“Serious injury” refers to cases of loss of eyesight, wounds, burns (high or low temperature), electric

shock, broken bones, poisoning, etc., which leave after-effects or which requires hospitalization or a long

period of outpatient treatment of cure.

*2:"Light to moderate injuries" refers to injuries, burns, electric shock etc. that do not require

hospitalization or long-term treatment.

*3:"Property damage" refers to cases of extensive damage involving damage to buildings, equipment,

farm animals, pet animals and other belongings.

[Explanation of Safety Symbols]

Safety Signs

Description

WARNING

Indicates a potentially hazardous situation that may result in death or

serious injury (*1) in the event of improper handling.

CAUTION

Indicates a potentially hazardous situation that may result in light to

moderate injuries (*2) or only in property damage (*3) in the event of

improper handling.

Safety Symbols

Description

PROHIBITED

This sign indicates PROHIBITION (Do not).

The content of prohibition is shown by a picture or words beside the symbol.

MANDATORY

This sign indicates MANDATORY ACTION (You are required to do).

The content of action is shown by a picture or words beside the symbol.

11 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

General Handing

WARNING

Stop operation immediately when any abnormality or defect occurs.

If abnormal conditions are present, such as smoke, a burning smell, ingress of water

or foreign matter, or if the equipment is dropped or malfunctions, fire or electric

shock may result. Be always sure to disconnect the power cable from the wall

socket at once and contact your dealer.

Unplug

Do not use the equipment in locations subject to water splashes. Otherwise, fire

or electric shock may result.

Do not

wet

Do not disassemble, repair, or modify the equipment. Otherwise, fire or electric

shock may result. For internal repair, inspection or cleaning, contact your sales

representative.

Never pull

apart

Do not place anything on the equipment.

If metallic objects, liquid, or other foreign matter enters the equipment, fire or

electric shock may result.

Avoid

Do not install the equipment in an unstable or inclined location or locations

subject to vibration or impact. Otherwise, the equipment may topple over and

cause personal injury.

Avoid

During an electrical storm, do not touch the power cable and the connection

cable. Otherwise, an electric shock may result.

Do not touch

Instruction

Use the specified voltage. Use of an unspecified voltage may result in fire or electric

shock.

Do not handle roughly, damaged, fabricated, bent forcefully, pulled, twisted,

bundled, placed under heavy objects or heated the power cable and the

connection cable. Otherwise, fire or electric shock may result.

Avoid

12 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

CAUTION

Observe the following when installing the equipment:

Do not cover the equipment with a cloth, etc.

Do not place the equipment in a narrow location where heat is likely to accumulate.

Otherwise, heat will accumulate inside the equipment, possibly resulting in a fire.

Instruction

Do not place the equipment in locations subject to high moisture, oil fumes,

steam, or dust. Otherwise, fire or electric shock may result.

Avoid

Do not install the equipment in locations exposed to direct sunlight or humidity.

Otherwise, the internal temperature of the equipment will rise, which may cause a

fire.

Avoid

Use only specified the power cable and the connection cables. Otherwise, fire or

electric shock may result.

Instruction

Do not give strong impact against the equipment. It may cause the trouble.

Avoid

When performing connection, turn off power. When connecting the power cable

and the connection cable, turn off the equipment power. Otherwise, fire or electric

shock may result.

Instruction

Do not expose the camera head to any intensive light (such as direct sunlight).

Otherwise, its inner image pickup device might get damaged.

Avoid

Avoid short-circuiting signal output. Otherwise, a malfunction may occur.

Avoid

Avoid giving a strong shock against the camera body. It might cause a breakdown

or damage. If your camera is used in a system where its camera connector is

subjected to strong repetitive shocks, its camera connector is possible to break

down. If you intend to use your camera in such a situation, if possible, bundle and

fix a camera cable in the place near the camera, and do not transmit a shock to the

camera connector.

Avoid

13 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

Usage Notes

Read the documentation

Read the camera documentation before using the camera.

Camera power

Incorrect input power can damage the camera. Follow guidelines in section Power Supply

p.19. Do not reverse power polarity. Do not connect or disconnect other cables when the camera power

is on.

Opening the camera

Do not open the camera. Do not let liquid, dust, flammable or metallic material to get inside the camera.

Environmental storage conditions

Temperature: -20°C ~ 60°C

Humidity: 90% or less (no condensation)

Environmental operating conditions

Always use the camera in conditions meeting the specification in this chapter. Do not use the product in

locations where the ambient temperature or humidity exceeds the specifications. In a thermal

challenging environment the customer needs to ensure sufficient heat dissipation with a thermal

connection to the bottom of the camera housing and sufficient airflow.

Non adequate thermal connection may increase heat induced noise or degrade image quality in other

ways and internal components may be adversely affected up to camera outages due to overheating.

Temperature

Range

Measurement

Environmental

0°C ~ 45°C

close to the camera case

Camera housing

≤ 50°C

at camera case

Camera internal

≤ 65°C

read internal temperature sensor

Humidity

Relative

Environmental

20 %–90 %

non-condensing

Maintenance

Turn off power to the equipment and wipe it with a dry cloth. If it becomes severely contaminated,

gently wipe the affected areas with a soft cloth dampened with diluted neutral detergent. Never use

14 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

alcohol, benzene, thinner, or other chemicals because such chemicals may damage or discolor the paint

and indications.

Cleaning the sensor window

Avoid cleaning the sensor window if possible. Keep lens cap closed as long as no lens is attached, avoid

touching the sensor. If necessary, clean the sensor window using compressed air. If further cleaning is

required, use lint-free, ESD-safe cloth wiper. Avoid cloth that could generate static charge or that could

scratch the window. The camera should be cleaned in an ESD-safe area. The person performing cleaning

should be earthed.

Connectors

Take care when handling the camera so that no damage can be done to the connectors. Prevent foreign

objects in the connectors.

Handle carefully

Always transport the camera in its original packaging. Do not drop the equipment or allow it to be

subject to strong impact or vibration, as such action may cause malfunctions. Do not damage the

connection cable, since this may cause wire breakage. If the camera is not in use, attach the lens cap to

the camera to protect the image pickup surface. If the equipment is not to be used for a long duration,

turn off power to the camera for safety.

Check compatibility of lens

Depending on lens and lighting an image can be reflected as a ghost into the imaging area. This is not a

fault of the camera. Depending on the lens the performance of the camera might not be brought out

fully due to deterioration in resolution and brightness in the peripheral area, aberration and other side

effects. Be sure to check lens and lightning you plan to use for compatibility with your camera. When

installing a lens in the camera make sure that it is not tilted. Use a mounting screw free from defects and

dirt. Otherwise the lens might not be removable from the camera.

Install lenses with a protrusion from bottom of the screw equal or less than 10 mm. If a lens does not

fulfill this condition it might damage the camera when trying to be installed.

10mm or less

C-mount lens Bottom of

the screw

Figure 1: C-Mount Lens

15 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

Dropping Frames

Depending on your PC or Gigabit Ethernet interface board configurations, images may not be captured

properly (e.g. dropping frames). In this case, change to frame rate setting lower.

Occurrence of moiré

If you shoot thin stripe patterns, moiré patterns (interference fringes) may appear. This is not a

malfunction.

Electromagnetic fields

Keep the camera away from strong electromagnetic fields. Avoid static charging and handle the camera

in ESD protected area. If an intense magnetic or electromagnetic field is generated near the camera or

connection cable, noise may be generated on the screen. If this occurs, move the camera or the cable.

Following information is only for EU-member states:

The use of the symbol indicates that this product may not be treated as household waste.

By ensuring this product is disposed correctly, you help to prevent potential negative

consequences for the environment and human health, which could otherwise be caused by

inappropriate waste handling of this product. For more detailed information about the take-

back and recycling of this product, please contact your supplier where you purchased the

product.

16 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

System Requirements

SynView –Software Development Kit (SDK)

compliancy

GigE Vision, GenTL and GenICam (with XML files)

supported image processing

libraries

Halcon, Imaging Library, VisionPro, LabView Vision, Matlab (and all GenTL

consumer)

supported operating systems

Windows XP (32 bit), Windows 7 (32/64 bit), Linux (32/64 bit)

17 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

Specifications

Outline Dimensions

Figure 2: GigEPRO Camera Dimension

CAD files on request

18 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

Camera Mount

4 mounting screw holes are available on the camera's bottom side to mount the camera on the GigEPRO

camera mounting plate, two close to the front side and two close to the back side of the camera as

outlined in Figure 2: GigEPRO Camera Dimension. The holes are M3 and screw length of 3mm is allowed.

Lens Mount

C-Mount

All GigEPRO models are equipped in the factory with a C-mount adapter (1–inch thread diameter, 32

threads per inch, 17.526 mm flange back) which is adjusted to precisely fulfill the C-mount flange back

distance. Modifications to this adjustment are strongly discouraged since the factory precision is lost.

CS-Mount

The GigEPRO camera supports CS-Mount with 12.5 mm flange back after removing the C-Mount adapter

from the camera head. To remove the C-Mount adapter the two 1mm hex-socket screws on the top and

bottom side of the camera's head can be released. After the two screws in the mounting points are

loosened the C-mount adapter can be released. The CS-Mount lens can then be installed directly into the

cameras head. When finished with adjusting fasten the flange back position of the lens with the two

screws again to fix your adjustments.

19 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

Interfaces

Table 2: Overview

standard Ethernet

connector

RJ45 with screw locking, GigE Vision Camera Interface Standard for Machine Vision

Version 1.2, 1 Gbit/s IEEE802.3ab conformity

conformity LAN cable

twisted pair (category 5e or better)

LAN cable length

up to 100m (for unshielded twist pair (UTP) cable)

auxiliary cable

connector

8 pin connector, 9-24 V Auxiliary Power

digital input/output

external trigger input (Line0) = opto coupled (open collector)

external strobe output (Line1) = opto coupled (open collector)

external strobe output (Line2) = opto coupled (open collector)

Power Supply

The camera supports two ways of supplying power:

-Supply from LAN cable (PoE)

-Supply from auxiliary camera cable

If both PoE and Auxiliary power are connected, power is taken from Auxiliary Power.

Power consumption varies among individual models from 2.5W up to 4W.

Auxiliary DC Power Input

The camera accepts 9–24 V DC power input on its auxiliary I/O connector.

Power over Ethernet (PoE)

The GigEPRO cameras are “PoE” compatible cameras according to the Power over Ethernet standard

version IEEE 802.3af. They should be used with PoE switches (“endspans”) or power injectors

(“midspans”) complying with the IEEE 802.3af specification.

Both PoE modes (A and B) are supported by the camera.

GigEPRO cameras are classified in the power level class 0.

When connecting multiple PoE cameras to a single PoE switch verify how much total power the switch

can provide and how it handles cases when the limit is exceeded.

Note:

Please control the power supply of the camera to be off when plugging in or pulling out the I/O

connector. Always use a LAN cable with a lock screw and secure the camera cable as close as possible to

the camera body in order to avoid physical damage to the camera connector and electronics.

20 / 68

Please note that all data and illustrations are subject to error, change and omissions without notice. GigEPRO

Operational Manual - Rev. 1.02-1409

Connector Pin Assignment

Figure 3: Camera rear view with AUX pin order

Ethernet Connector

The camera uses the Gigabit Ethernet interface and is fully compatible with the 1000BASE-T standard

(also known as IEEE 802.3ab) —Gigabit Ethernet over copper.

The camera does not support Fast Ethernet networks (100BASE-TX).

Table 3: Gigabit Ethernet Interface Connector RJ-45 Jack

Pin No.

I/O

Signal

Function

1

I/O

BI_DA+ / VDC+

Bidirectional Data A (+) / Power (+)

2

I/O

BI_DA- / VDC+

Bidirectional Data A (-) / Power (+)

3

I/O

BI_DB+ / VDC-

Bidirectional Data B (+) / Power (-)

4

I/O

BI_DC+ / VDC+

Bidirectional Data C (+) / Power (+)

5

I/O

BI_DC- / VDC+

Bidirectional Data C (-) / Power (+)

6

I/O

BI_DB- / VDC-

Bidirectional Data B (-) / Power (-)

7

I/O

BI_DD+ / VDC-

Bidirectional Data D (+) / Power (-)

8

I/O

BI_DD- / VDC-

Bidirectional Data D (-) / Power (-)

Table of contents

Other NET Security Camera manuals

Popular Security Camera manuals by other brands

Earth Networks

Earth Networks AXIS Q6155-E System installation, operation and maintenance manual

Swann

Swann Maxi Day/Night Cam Security Camera S243-4NU Specification sheet

Dahua

Dahua K6 user manual

Bosch

Bosch FlexiDomeXF VDC-485V04-20 Brochure & specs

Night Owl

Night Owl CAM-MZ420-425M Specifications

Lorex

Lorex Vantage SG650 quick start guide