Neumann History

1110

Refinements in

Phonographi Te hnology

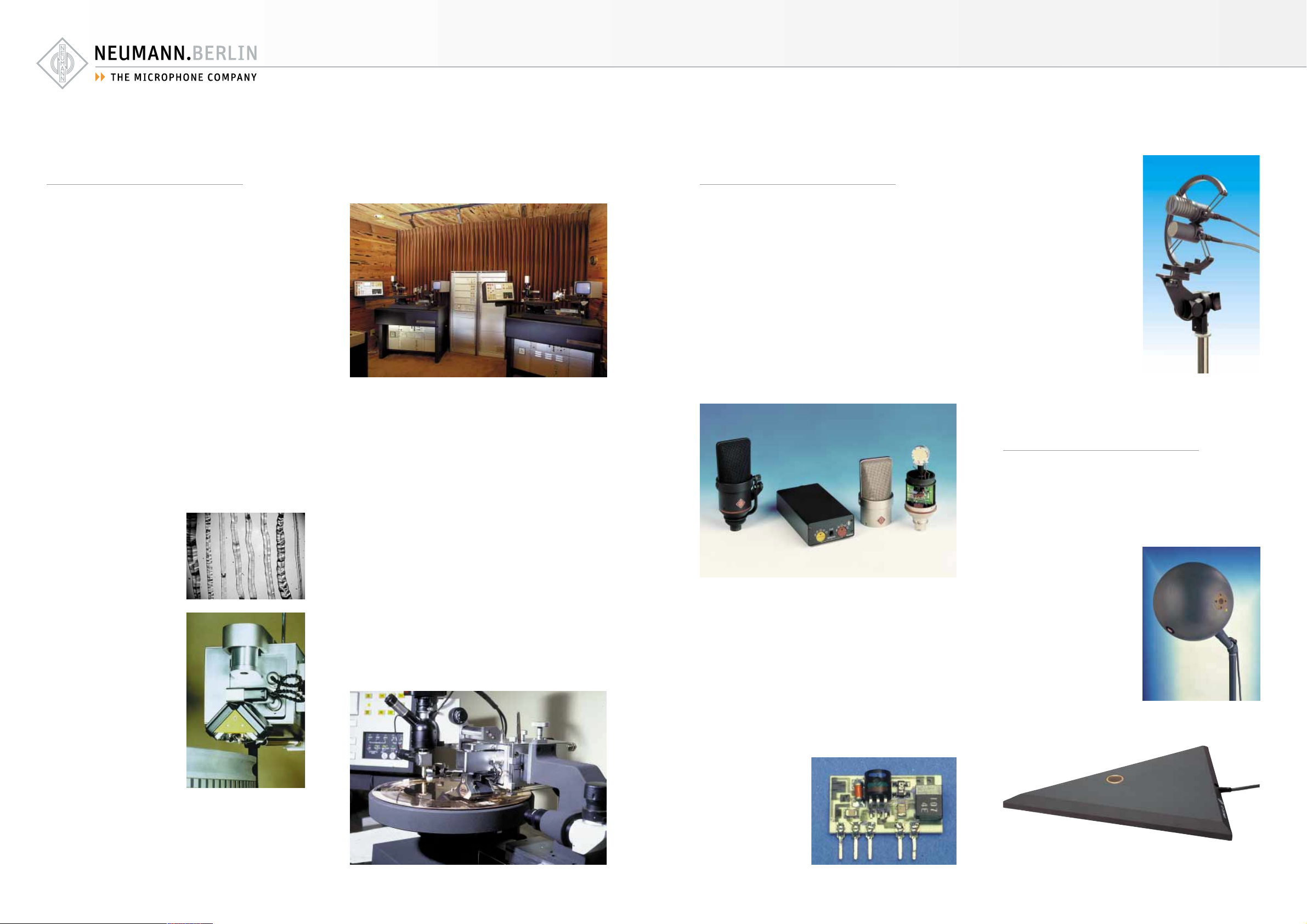

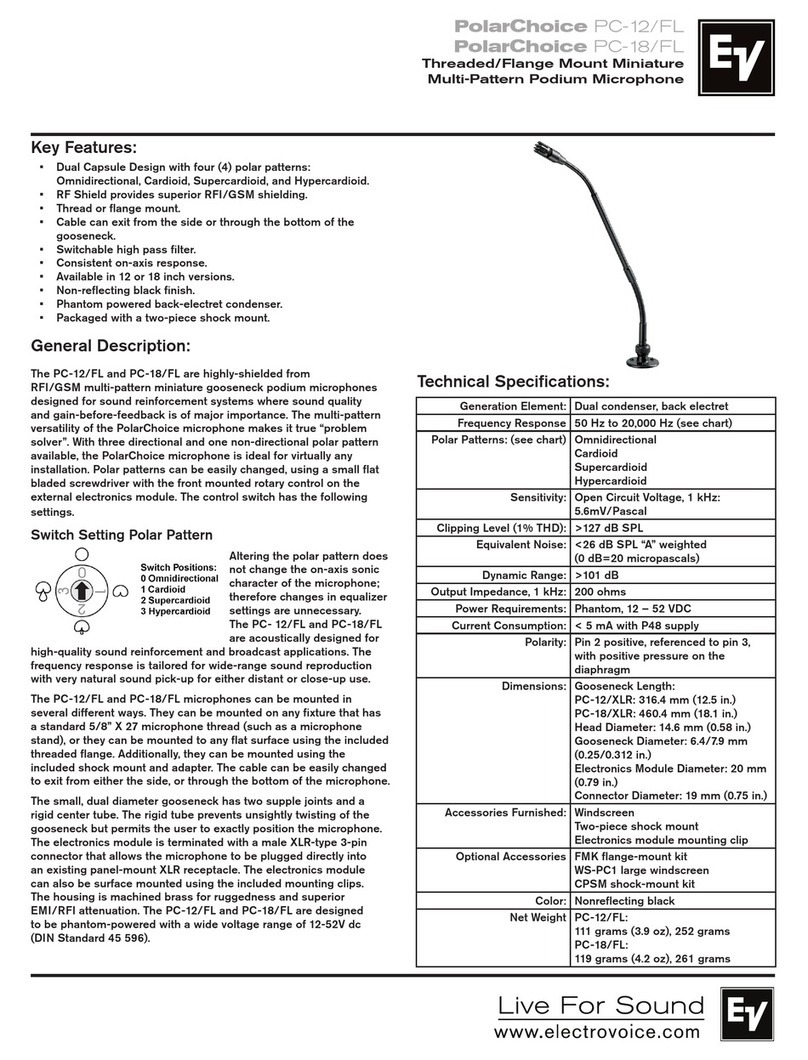

Up until around 1953, Neumann built dis -cut-

ting lathes for phonograph records with a con-

stant groove pitch. Between 1953 and 1955,

Neumann developed a method of varying the

groove pitch depending on the recorded am-

plitude. To this end, an additional playbac

head was mounted on the tape dec . This ad-

ditional playbac head determined the groove

amplitude to be recorded approximately one

half-rotation of the turntable in advance and

fed this value to the cutting lathe as a control

signal via a corresponding drive amplifier. Of

course, this also required a separately varia-

ble pitch drive. For the first time, this made

it possible to extend the playing time of an

LP phonograph record to approx. thirty min-

utes.

So far the records had been monophonic dis s

made using lateral recording. In 1956, Neu-

mann debuted its first stereo dis -cutting

lathe, the ZS 90/45, which supported both lat-

eral and vertical recording. The lathe was set

up to cut the two stereo channels into the two

flan s of the groove at a 45° angle. Over the

years, other dis cutting lathes

were developed, the quality of

which improved continually.

These were all electrodynami-

cal feedbac cutterheads. This

model series continued with

the SX 45, SX 68, SX 74 and

finally the SX 84.

Many companies made a name

for themselves with their prod-

ucts on the dis cutting mar-

et. These included, for exam-

ple, Ortofon, Westrex, Scully,

Fairchild, Dauphine, and others.

By the end of the fifties, Neu-

mann was the only company

left that could deliver com-

plete tape-to-dis transfer

equipment. Neumann saw this

position as a serious obliga-

tion to continue refining pho-

nographic technology. This

was reflected in the refine-

ment of the dis cutting lathes

and improvement of the cut-

ting procedure.

One interesting phenomenon in this connec-

tion is the tracing distortion that results from

the difference in geometric shape between the

tool used to cut the grooves and the playbac

stylus. The cutting stylus is shaped li e a

spade, while the playbac stylus is spherical.

During playbac , this results in tracing distor-

tion, which mainly contains the 2nd harmon-

ic. In 1968, Neumann built the Tracing Simu-

lator that solved this problem.

In the early seventies, Neumann successfully

developed, in conjunction with TELDEC, a me-

chanically recorded video record that was played

bac via a pressure pic up. The experience

gained in this connection led to another signif-

icant improvement in the process of cutting pho-

nograph records. In the beginning, phonograph

records were cut in bee’s wax and for years

thereafter in a phonographic foil coated with

nitro-cellulose lacquer. Neumann introduced the

DMM technology, in which the phonographic foil

was replaced by copper foil, resulting in DD

DD

Direct

MM

MM

Metal MM

MM

Mastering, DMMDMM

DMMDMM

DMM. This resulted in substan-

tially improved pulse fidelity of the recorded

signal, which represented another significant

improvement in the sound quality of phono-

graphic records.

One Step Ahead Again:

The TLM Te hnology

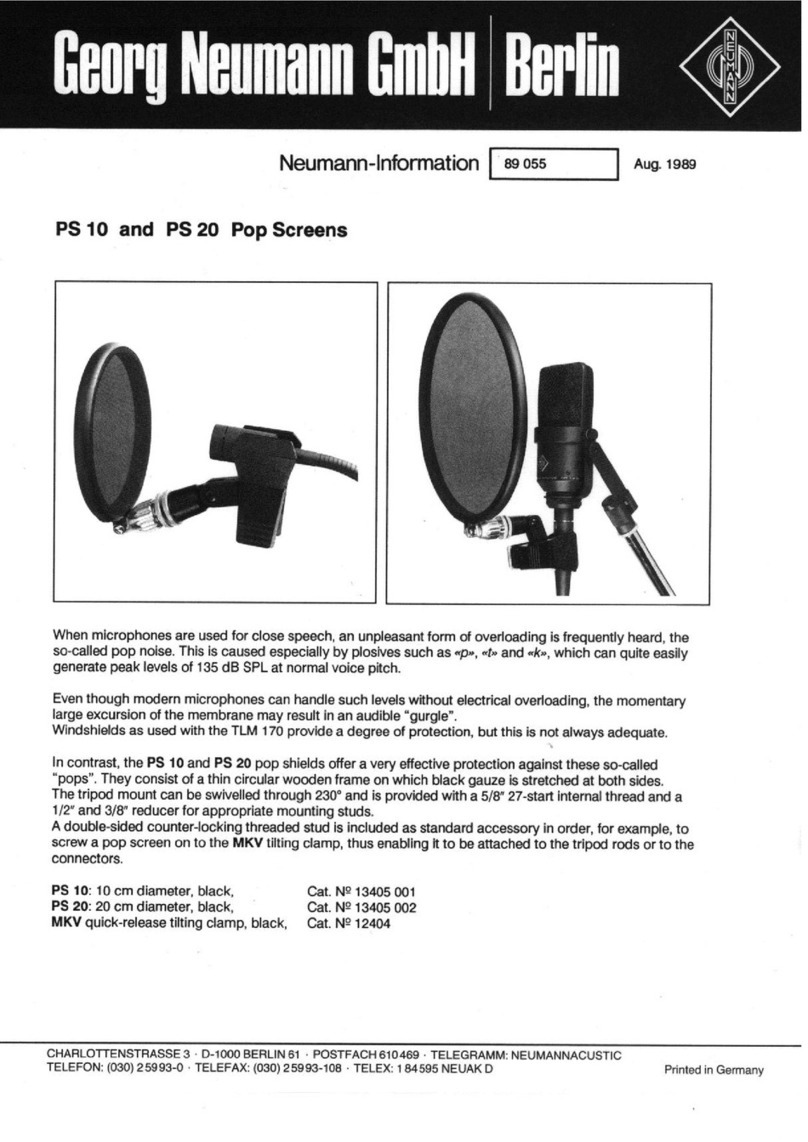

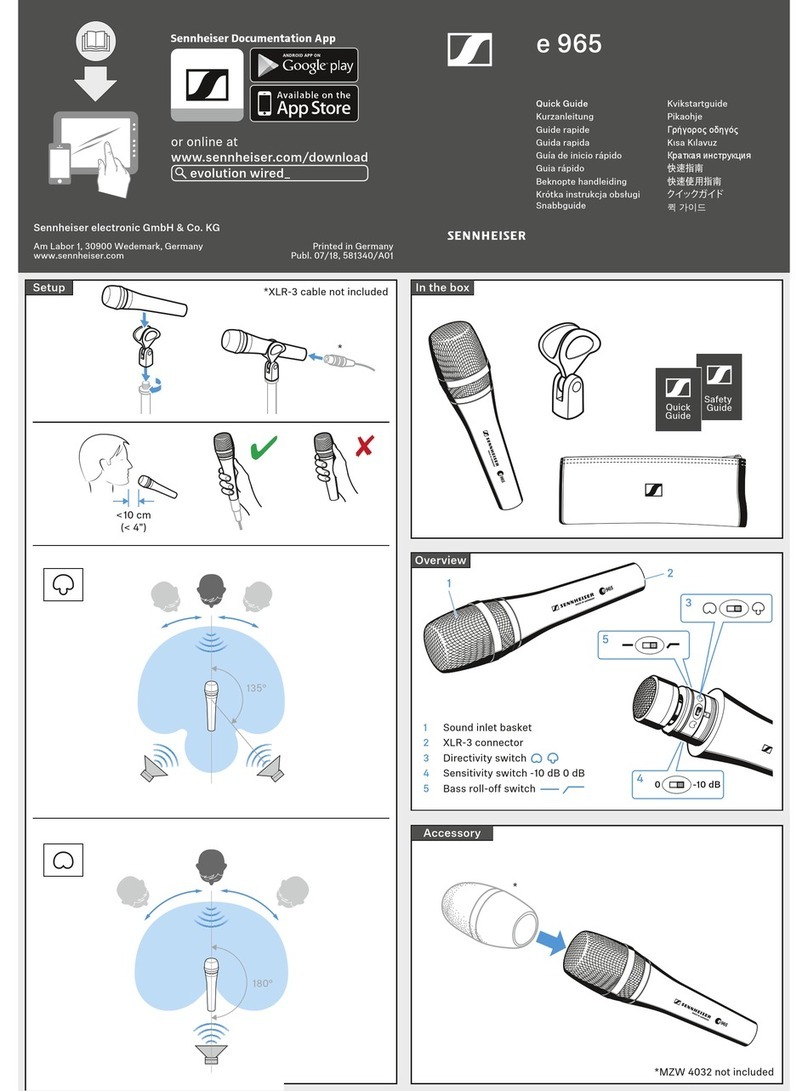

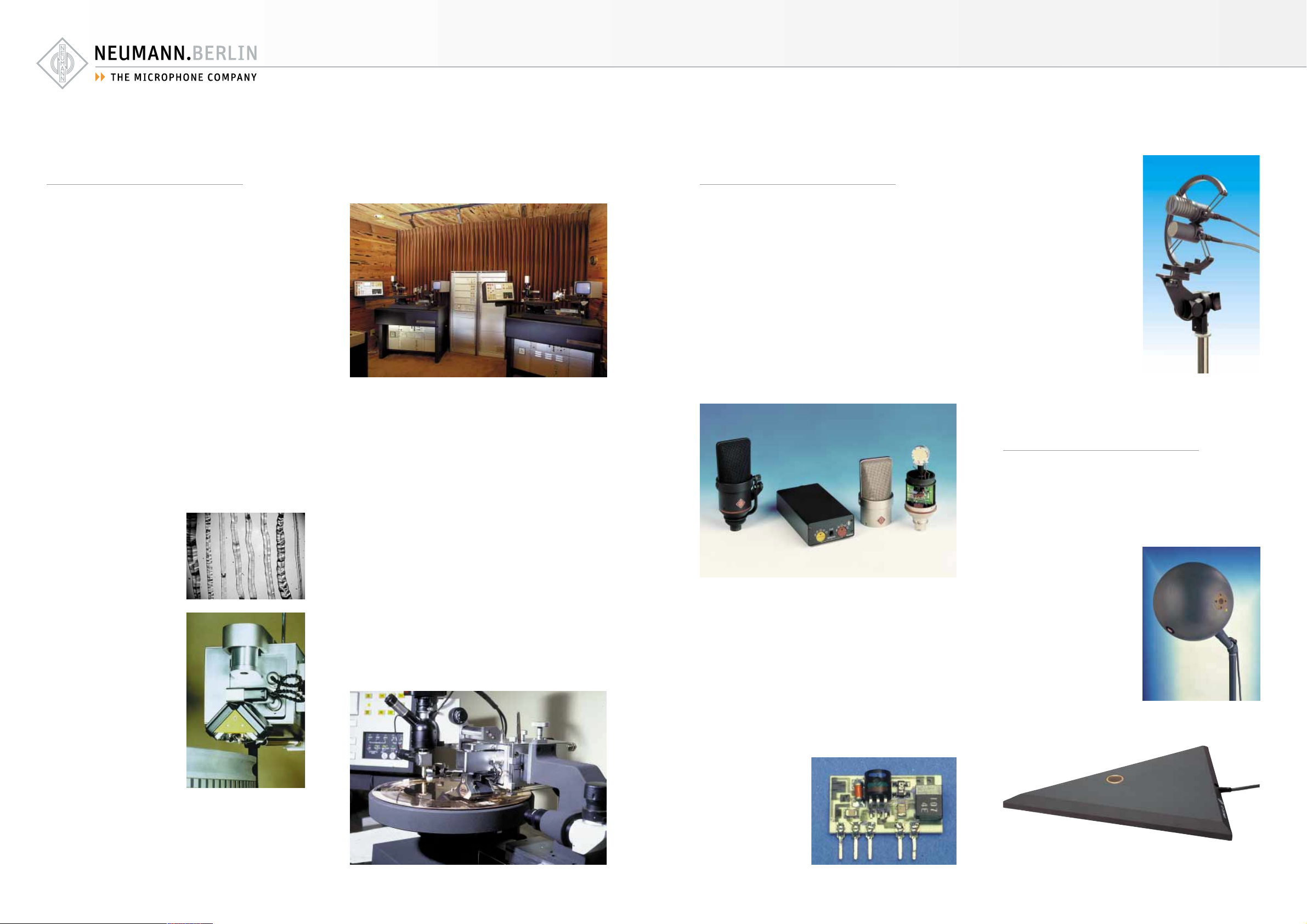

At the 1983 AES-Convention in Amsterdam,

Neumann unveiled a brand new series of mi-

crophones with refined circuitry: the TT

TT

Transfor-

merLL

LL

Less MM

MM

Microphones of the “fet 100” series.

The first representative of this series was the

switchable TLM 170 with five directional pat-

terns from which to choose. It used the same

dual-diaphragm capsule as its somewhat older,

transformer-equipped brother, the U 89.

Each microphone represented a considerable

improvement in the common dynamic range of

studio microphones at its respective time of in-

troduction. Their electronics evidenced lower

residual noise and, simultaneously, higher mod-

ulation levels than predecessor models. Further-

more, they were also a novelty in the mar et

because they were the first to provide wide-an-

gle cardioid and hypercardioid directional pat-

terns in addition to the omnidirectional, cardi-

oid, and figure-eight patterns common at the

time.

The “especially open, free sound” of the TLM

technology, which made it possible to transmit

fine structures “as if a curtain had been pulled

aside”, encouraged Neumann to quic ly equip

other microphones with this system.

In order to be able to fit

the complex circuitry

into miniature micro-

phones, however, it first

too an additional de-

velopment step: hybrid

technology. This tech-

nology even made it

possible to incorporate

all electronics right in the cap-

sule housing, thus giving rise

to the “active capsules” of the

KM 100 series.

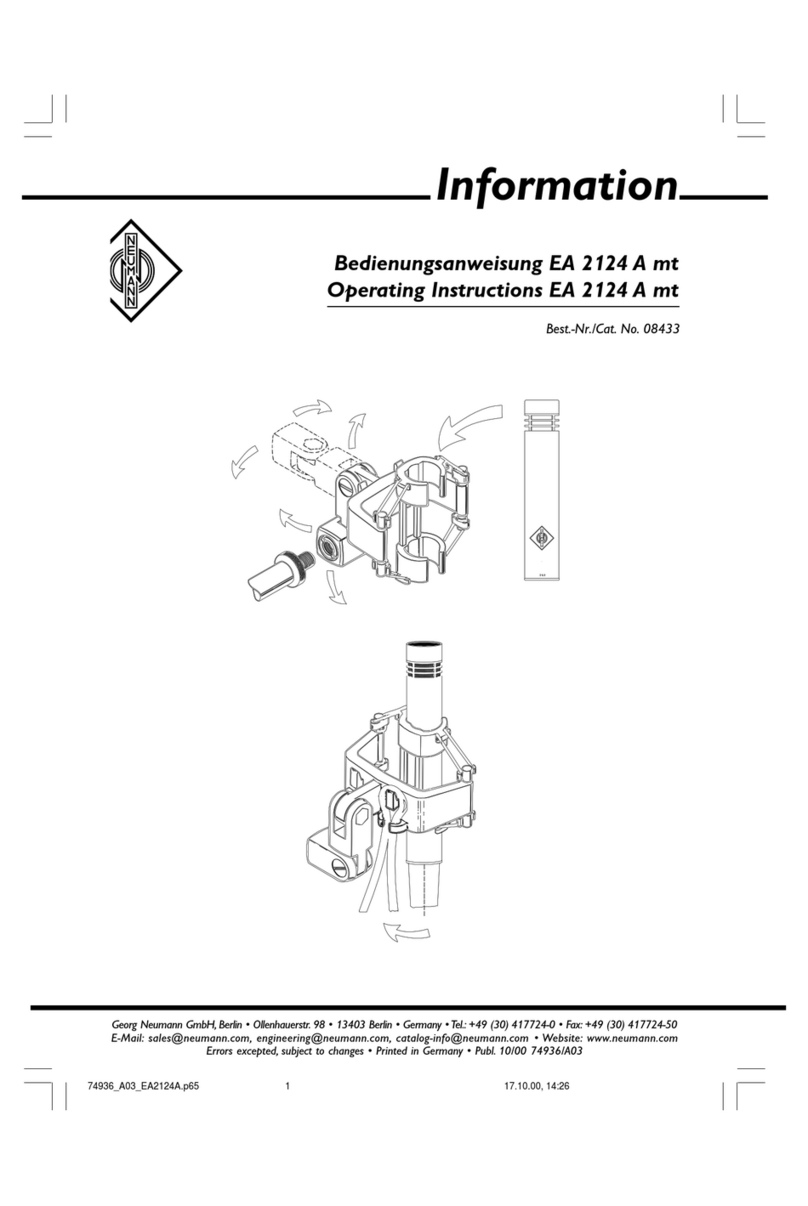

So Neumann’s miniature micro-

phones not only too another

clear step toward improved

technical data, but now the

capsules could be used with the

help of accessories such as

goosenec s, stand mounts, var-

ious cables, and tilting devic-

es without electro-acoustic

loss.

This miniature microphone

family now comprises seven

different capsules with all cus-

tomary directional patterns.

These also include stereo mounts for XY, ORTF

and MS recording techniques.

The Spe ialists

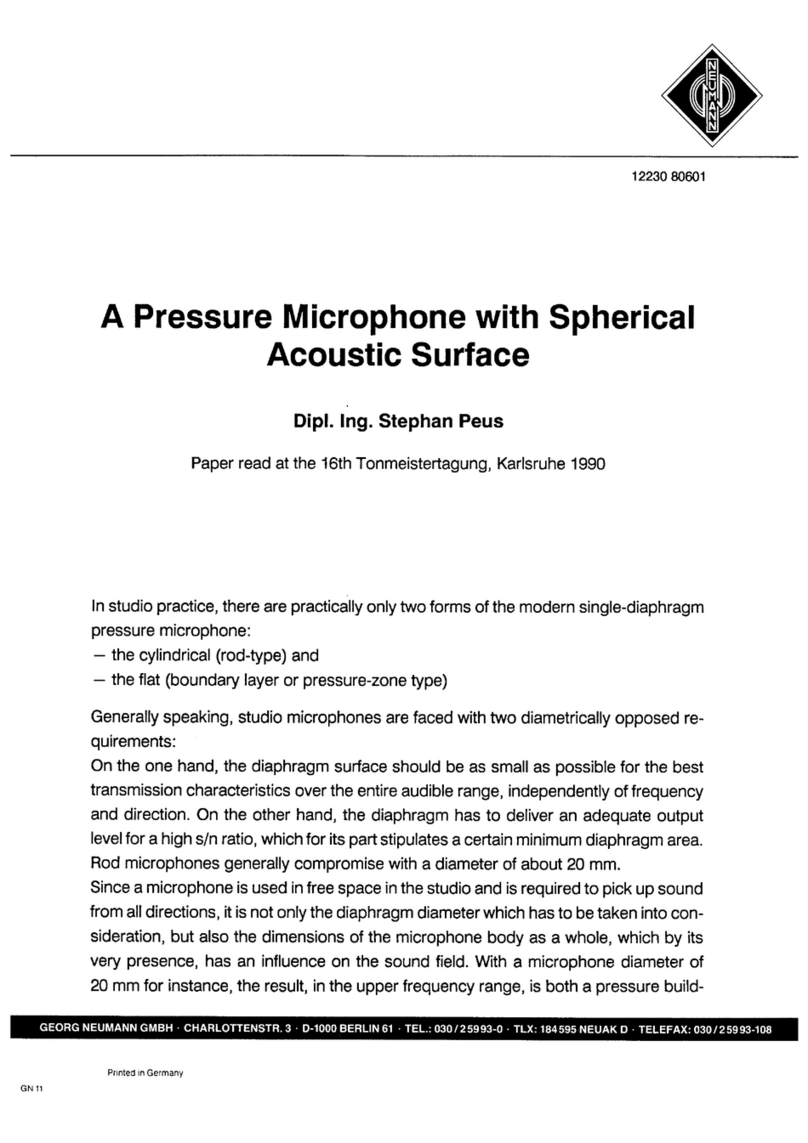

Besides the aforementioned dummy head, in

1992 the KFM 100 Spherical Surface Micro-

phone was introduced for an additional stereo

recording method.

This microphone had two small, high-quality

condenser capsules arrayed on

the diameter of a head-sized

wooden sphere. In the

GFM 132 Boundary Layer Mi-

crophone, these capsules had

been optimised for sound re-

ceived at oblique angles. Thus

the KFM 100 was a micro-

phone for especially natural

stereo recordings with tremen-

dous acoustic depth, ma ing it

ideal for mi ing highly com-

plex acoustic fields, such as

those found in churches and

large halls.