NEURON THC User manual

NEURON

C N C E L E C T R O N I C S

INDUSTRIAL

TORCH HEIGHT

CONTROL

NEURON CNC ELECTRONICS

08.01.2020

USER MANUAL

USER MANUAL

System Description

When operating a CNC Plasma table, it is important to maintain a fixed cutting height of the

torch throughout the cutting process in order to achieve good cut quality. While the plasma torch

tip-to-plate distance can be automatically set at the start of a cut by the Initial Height Sensing

(IHS) switch, it is difficult to maintain this exact height throughout the cut. Remember that a

typical plasma cutting torch tip-to-plate distance is only 1.5 mm and that normal sheet metal and

plate stock are not perfectly flat. In addition, the heat generated during the cutting process can

cause warpage in the material which makes it even more difficult to maintain this stand-off

height. If the torch gets too close to the material during cutting it can cause premature wear to

the cutting nozzle and also result in more backside dross. Even worse, the torch can crash into

the material if the plate is warped enough over a longer cut which consumes some of the 1.5 mm

starting cut height. Conversely, if the torch pulls too far away from the material it can negatively

impact the cut quality and also cause the torch to lose the arc during cutting.

The THC module functions based on the principle that the amount of voltage in the plasma arc

between the torch and the material is directly proportional to the length of the plasma arc. In other

words, if the torch is closer to the plate the arc voltage will be less than if the torch is further away

from the plate assuming all other cutting parameters are equal.

The Neuron.THC torch height control system is the most technologically advanced arc

voltage control system in the plasma cutting industry. It is designed to offer arc voltage control

capabilities to any plasma cutting system. The Neuron.THC quickly and accurately sets the arc

transfer height of the torch using an “Ohmic” or/and “Float Head” plate sensing technique. The

Neuron.THC system uses advanced DSP (digital signal processing) software servo control loops to

control speed, position and arc voltage with unparalleled precision. The system is fully

programmable via 10/100 Base-T Ethernet communications.

The Neuron.THC can attain speeds in excess of 200 inches per minute in the arc voltage control

mode and speeds in excess of 500 inches per minute in the position control mode.

Safety

Installation, as well as repairs, made to the Neuron.THC System should only be performed by

qualified personnel. The Neuron.THC system use D.C. for operation. In addition, it will be necessary

to make connections to the D.C. output of the plasma power supply. These voltages can be in

excess of 300 volts. Fatal shock hazard does exist. Exercise extreme caution while working in these

areas. Please refer to the plasma power supply manufacturer’s operating manual for additional

information.

Various other safety hazards exist while operating a plasma arc cutting system. Please see the

plasma power supply manufacturer’s operating manual for information on eye, skin, and hearing

protection, as well as other information required to safely operate the equipment.

System Components

The Neuron.THC System consists of the following components:

•Control module

•Plasma interface module

•Operator’s control module

•UCCNC Plugin and Screen set for plasma cutting applications

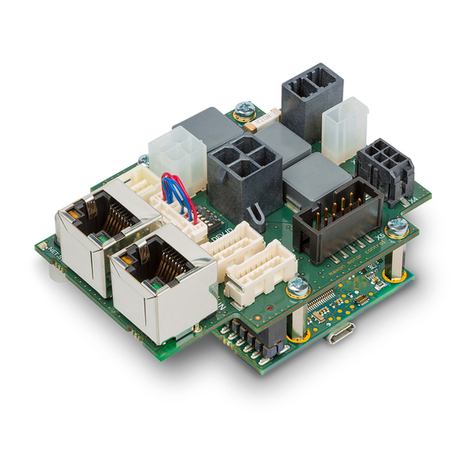

Control module

The control module houses a microcontroller, and I/O interface. This unit provides arc voltage

control, and interfaces with the torch driver through the Pulse/Direction interface, the CNC UCCNC

machine through the Ethernet interface, and the plasma system through standard discrete I/O

interfaces.

USER MANUAL

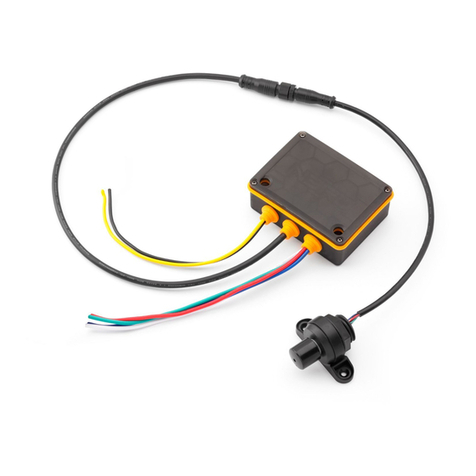

Plasma system interface module

It provides precise, scaled feedback of the plasma arc voltage to the control module. It also

provides a convenient control signal interface to the Neuron.THC.

Operator Control Module

The Operator Control Module includes screw terminals for connection “Cutting Run/Stop” switch,

“Torch Up”, “Torch Down” buttons and an installed rotary/push knob selector for THC setup and

control.

Specifications

Input power

12V DC, 0.8A

Operating temperature

-10º C to 40º C

Operating humidity

95% relative humidity

Pulse/Dir interace

Open collector, protected +5V 100mA

Ethernet communication

Shielded RJ-45 Cat-5e, Up to 100 m (4-wire Cat-

5e), I/O transmission speed 10/100 Mbps auto-

negotiation

Parallel digital input

NO/NC dry contact

Lifter limit switches

Home switch, IHS switch and Ohmic sensor

Maximum Z axis speed

15000 mm/min

Voltage divider ratio

10:1(internal), 20:1 (Hypertherm cutter)

Arc voltage range

25-250V

Warranty

1 year

Control module has a size 145x90x45 mm with DIN mounting standard and can be easily

embedded inside the CNC box.

USER MANUAL

Plasma interface board (Divider)

Operator panel board

USER MANUAL

Features

The Neuron.THC comes standard with the following features:

•Works with ALL plasma cutters

•Connect via 10/100 Base-T Ethernet interface to UCCNC CNC and controls Z axis directly

(Internal motion controller, Software DSP (digital signal processing) control loop, 500 uSec

cycle)

•Unlimited number of cut profiles for different metal thicknesses. Quickly switch between

profiles and the ability to quick edit them

•Set point resolution - 0.25V

•Set point range - 25 - 250V (set just by clicking the mouse button and wheel on the

Target Arc Voltage textbox on Control Panel or turning the encoder knob on the operator

panel)

•Maximum control accuracy - +/- 0.25V

•Height control accuracy +/-0.125 mm (.005") using a properly configured Z-axis.

•Voltage feedback (divider) - 1:20 (for Hypertherm), 1:10 (internal) of Arc Voltage

•100 kHz maximum step frequency (50% Duty cycle)

•Automatic or manual control of the cutting sequence

•Sample voltage mode - THC measures the voltage at the end of the AVC Delay and uses it

as a set point for the remainder of the cut.

•Programmable THC OFF (Hold signal) control to help prevent torch crashing when end of

cut, circle of small radius - enable/disable, mm.

•Programmable arc voltage limiter to help prevent torch crashing when crossing a kerf -

enable/disable, level, voltage

•Programmable arc voltage control loop proportional gain (system response)

•Skip IHS mode - If the next starting point is within this distance of the end of the previous

cut, the THC skips the IHS.

•Improved Jog - the lifter initially jogs 0.25 mm. After 0.5 second, it begins continuous

motion at the IHS Speed. After 1.5 seconds, the lifter increases the speed to the

programmed Manual Speed

Jog just by clicking the mouse button and wheel on the Position textbox or by pressing the

up / down button on Operator Panel

•Automatic Collision Avoidance. This safety feature allows the control to automatically

adjust the torch height during a cut to help prevent torch crashes.

•Retract height selectable between full or programmed partial raise height

•Programmable automatic positioner speed

•Programmable manual positioner speed

•Programmable maximum Z axis stroke (Soft Limit function)

•Programmable arc transfer height

•Programmable pierce height

•Programmable pierce time

•Programmable cutting height

•Programmable AVC (automatic voltage control) delay time

•Programmable torch retract height

•Programmable Jump height above the workpiece that the torch is raised to clear the top

dross puddle that can form during the pierce.

•Programmable IHS (initial height sensing) touch speed

•Programmable crossover height (high-to-low speed transition point)

•Buffered Step & Direction for direct interface to Motor Drive

•All inputs (include arc voltage) are isolated and Simple wiring (RJ45 connectors)

•Built-in pierce and cut time counter to control consumables

•Integrated diagnostic system informs the operator of the errors that occurred

•Ability to tune arc voltage converter

•Plotting the arc voltage and save to file for diagnostics

•Easy Software update using the utility Neuron Flasher

USER MANUAL

System Requirements

Power Requirements

The Neuron.THC system has a terminal block power plug. 12V DC 0.8A required.

Do not use 12V power from CNC PC! Use separated power supply.

The performance of the Neuron.THC is tightly coupled to the lifter and motor characteristics. The

Neuron.THC was designed as a conventional plasma height control and the lifter does not include

any position feedback.

The lifter screw pitch affects the lifter linear speed and the control loop gain when operating with

arc voltage. The lifter friction and maximum torch weight affect the point at which the lifter will

require a brake to maintain position. For these reasons, the motor and lifter characteristics are

critical and must be tightly controlled.

The following is a partial list of lifter and motor characteristics that are compatible with this

controller.

• Lifter Ball screw/Rack pitch = 4 –20 mm/rev

• Lifter with UP limit (homing sensor)

• Lifter capable of 200 in/min.

• Lifter should have low backlash and little mechanical play

WARNING:

The performance of the Neuron.THC is tightly coupled to the lifter and motor

characteristics. To ensure proper operation, a customer designed lifter should be fully

tested with this controller under all anticipated operating conditions.

What Is Plasma

Plasma is a fourth state of matter, an ionized gas which has been heated to an extremely high

temperature and ionized so that it becomes electrically conductive. The plasma arc cutting and

gouging processes use this plasma to transfer an electrical arc to the workpiece. The metal to be

cut or removed is melted by the heat of the arc and then blown away. While the goal of plasma

arc cutting is the separation of the material, plasma arc gouging is used to remove metals to a

controlled depth and width.

Plasma torches are similar in design to the automotive spark plug. They consist of negative

and positive sections separated by a center insulator. Inside the torch, the pilot arc starts in the

gap between the negatively charged electrode and the positively charged tip. Once the pilot arc

has ionized the plasma gas, the superheated column of gas flows through the small orifice in the

torch tip, which is focused on the metal to be cut.

In a Plasma Cutting Torch a cool gas enters Zone B, where a pilot arc between the electrode

and the torch tip heats and ionizes the gas. The main cutting arc then transfers to the workpiece

through the column of plasma gas in Zone C. By forcing the plasma gas and electric arc through a

small orifice, the torch delivers a high concentration of heat to a small area. The stiff, constricted

plasma arc is shown in Zone C. Direct current (DC) straight polarity is used for plasma cutting, as

shown in the illustration. Zone A channels a secondary gas that cools the torch. This gas also

assists the high velocity plasma gas in blowing the molten metal out of the cut allowing for a fast,

slag - free cut.

USER MANUAL

Arc Initialization

There are two main methods for arc initialization.

High Frequency Start

This start type is widely employed, and has been around the longest. Although it is older

technology, it works well, and starts quickly. But, because of the high frequency high voltage

power that is required generated to ionize the air, it has some drawbacks. It often interferes

with surrounding electronic circuitry, and can even damage components. Also, a special circuit

is needed to create a Pilot arc. Inexpensive models will not have a pilot arc, and require

touching the consumable to the work to start. Employing a HF circuit also can increase

maintenance issues, as there are usually adjustable points that must be cleaned and

readjusted from time to time.

Blowback Start

This start type uses air pressure supplied to the cutter to force a small piston or cartridge

inside the torch head back to create a small start between the inside surface of the

consumable, ionizing the air, and creating a small plasma flame. This also creates a “pilot arc”

that provides a plasma flame that stays on, whether in contact with the metal or not. This is a

very good start type that is now used by several manufacturers. Its advantage is that it

requires somewhat less circuitry, is a fairly reliable and generates far less electrical noise

For entry level air plasma CNC systems, the blowback style is much preferred to minimize

electrical interference with electronics and standard PCs but the High frequency start still rules

supreme in larger machines from 200 amps and up. These require industrial level PC’s and

electronics and even commercial manufacturers have had issues with faults because they have

failed to account for electrical noise in their designs.

CNC Plasma

Plasma operations on CNC machines is quite unique in comparison to milling or turning and is

a bit of an orphan process. Uneven heating of the material from the plasma arc will cause the

sheet to bend and buckle. Most sheets of metal do not come out of the mill or press in a very

even or flat state. Thick sheets (30mm plus) can be out of plane as much as 50mm to 100mm.

Most other CNC gcode operations will start from a known reference or a piece of stock that has a

known size and shape and the gcode is written to rough the excess off and then finally cut the

finished part. With plasma the unknown state of the sheet makes it impossible to generate gcode

that will cater for these variances in the material.

A plasma Arc is oval in shape and the cutting height needs to be controlled to minimize

beveled edges. If the torch is too high or too low then the edges can become excessively beveled.

It is also critical that the torch is held perpendicular to the surface.

USER MANUAL

Torch to work distance can impact granularity

Negative cut angle: torch too low, increase torch to work distance.

Positive cut angle: torch too high, decrease torch to work distance.

Note: A slight variation in cut angles may be normal, as long as it is within tolerance.

The ability to precisely control the cutting height in such a hostile and ever-changing environment

is a very difficult challenge. Fortunately, there is a very linear relationship between Torch height

(Arc length) and arc voltage as this graph shows.

This graph was prepared from a sample of about 16,000 readings at varying cut height and the

regression analysis shows 7.53 volts per mm with 99.4% confidence. In this particular instance

this sample was taken from an Everlast 50 amp machine.

Torch voltage then becomes an ideal process control variable to use to adjust the cut height.

Let’s just assume for simplicity that voltage changes by 10 volts per mm. This can be restated to

be 1 volt per 0.1mm (0.04”). Major plasma machine manufacturers (e.g. Hypertherm, Thermal

Dynamics and ESAB), produce cut charts that specify the recommended cut height and estimated

arc voltage at this height as well as some additional data. So, if the arc voltage is 1 volt higher

than the manufacturers specification, the controller simply needs to lower the torch by 0.1 mm

(0.04”) to move back to the desired cut height. Neuron torch height control unit is used to

manage this process.

Arc OK Signal

Plasma machines that have a CNC interface contain a set of dry contacts (e.g. a relay) that

close when a valid arc is established and each side of these contacts are bought out onto pins on

the CNC interface. A plasma table builder should connect one side of these pins to field power and

the other to an input pin. This then allows the Neuron controller to know when a valid arc is

established and also when an arc is lost unexpectedly.

USER MANUAL

Initial Height Sensing

Because the cutting height is such a critical system parameter and the material surface is

inherently uneven, a Z axis mechanism needs a method to sense the material surface. There are

two methods this can be achieved. A “float” switch and an electrical or “ohmic” sensing circuit

that is closed when the torch shield contacts the material.

Float Switches

The torch is mounted on a sliding stage that can move up when the torch tip contacts the

material surface and trigger a switch or sensor. Also, Neuron controller use the switch hysteresis

obtained in the setup procedure.

Regardless what probing method is implemented, it is strongly recommended that float switch

is implemented so that there is a fallback or secondary signal to avoid damage to the torch from

a crash.

Ohmic Sensing

Ohmic sensing relies on contact between the torch and the material acting as a switch to

activate an electrical signal that is sensed by the Neuron controller. Provided the material is

clean, this can be a much more accurate method of sensing the material as a float switch which

can cause deflection of the material surface. This ohmic sensing circuit is operating in an

extremely hostile environment so a Neuron Ohmic contact sensor is implement to ensure safety

of both the CNC electronics and the operator. In plasma cutting, the earth clamp attached to the

material is positive and the torch is negative. It is recommended that The ohmic circuit uses a

totally separate isolated power supply that activates an opto-isolated relay to enable the probing

signal to be transmitted to the Neuron controller.

Corner Lock / Velocity Anti-Dive

The CNC trajectory planner is responsible for translating velocity and acceleration commands into

motion that obeys the laws of physics. For example, motion will slow when negotiating a corner.

Whilst this is not a problem with milling machines or routers, this poses a particular problem for

plasma cutting as the arc voltage increases as motion slows. This will cause the THC to drive the

torch down. Modern CNC systems like Mach3, Mach4, UCCNC, LinuxCNC support the real-time

macros that allow to enable or disable automatic voltage control from program g-code. Neuron

controllers has a separated Hi-Speed “THCOFF” input for this.

Head Safety Lock /Kerf Detect

If the plasma torch passes over a void while cutting, arc voltage rapidly rises and the THC

responds by violent downward motion which can smash the torch into the material possibly

damaging it. This is a situation that is difficult to detect and handle. To a certain extent it can be

mitigated by good nesting techniques but can still occur on thicker material when a slug falls

away. This is the one problem that has yet to be solved within the Neuron controller.

One suggested technique is to monitor the rate of change in torch volts over time (dv/dt)

because this parameter is orders of magnitude higher when crossing a void than what occurs due

to normal warpage of the material. The following graph shows a low-resolution plot of dv/dt (in

blue) while crossing a void. The red curve is a moving average of torch volts.

So, it should be possible to compare the moving average with the dv/dt and halt THC operation

once the dv/dt exceeds the normal range expected due to warpage.

USER MANUAL

Hole and Small Shape Cutting

It is recommended that you slow down cutting when cutting holes and small shapes.

The generally accepted method to get good holes from 37mm dia. and down to material

thickness with minimal taper using an air plasma is:

1. Use recommended cutting current for consumables.

2. Use fixed (no THC) recommended cutting height for consumables.

3. Cut at 60% to 70% of recommended feed rate for consumables and material.

4. Start lead in at or near center of hole.

5. Use perpendicular lead in.

6. No lead out, either a slight over burn or early torch off depending on what works best

for you.

You will need to experiment to get exact hole size because the kerf with this method will be

wider than your usual straight cut.

This slow down and real-time macro for THCOFF can be achieved by manipulating the feed rate

directly in your post processor or by using special rules (for Sheetcam or Plasmicon CAM

software).

Connection diagram

Input signal interface schematic

USER MANUAL

INSTALLATION

1. Mount the Neuron.THC into the CNC box.

2. Connect Home and Initial Height Sensing (Float Head and/or Ohmic Sensor) switches to

screw terminals on the Control Module.

3. Connect the Neuron.THC Control Module to the RJ45 (Cat5e) Ethernet connector on the PC

or Ethernet switch (0.5 m minimal cable length).

4. Connect the plasma system interface PCB to the RJ45 (CAT5) connector on the Control

Module.

5. Connect the Torch Lifter motor driver to Pulse/Direction RJ45 connector (using adapter) on

the Control Module.

6. Connect the power supply (DC 12 volt / 0.8A) to screw terminals on the Control Module.

NOTE: All interconnection RJ45 cat5e cable has the PIN TO PIN connection.

Recommended grounding and shielding practices

Introduction

This part is describing the grounding and shielding necessary to protect a plasma cutting system

installation against radio frequency interference (RFI) and electromagnetic interference (EMI)

noise. It addresses the three grounding systems described below.

Note: These procedures and practices are not known to succeed in every

case to eliminate RFI/EMI noise issues. The practices listed here have been

used on many installations with excellent results, and we recommend that

these practices be a routine part of the installation process. The actual

methods used to implement these practices may vary from system to

system, but should remain as consistent as possible.

Types of grounding

1. The safety, protective earth (PE), or service ground. This is the grounding system that

applies to the incoming line voltage. It prevents a shock hazard to any personnel from any

of the equipment, or the work table. It includes the service ground coming into the plasma

system and other systems such as the CNC controller and the motor drivers, as well as the

supplemental ground rod connected to the work table. In the plasma circuits, the ground

is carried from the plasma system chassis to the chassis of each separate console through

the interconnecting cables.

2. The DC power or cutting current ground. This is the grounding system that completes the

path of the cutting current from the torch back to the plasma system. It requires that the

positive lead from the plasma system be firmly connected to the work table ground bus

with a properly sized cable. It also requires that the slats, on which the workpiece rests,

make good contact with the table and the workpiece.

3. RFI and EMI grounding and shielding. This is the grounding system that limits the amount

of electrical “noise” emitted by the plasma and motor drive systems. It also limits the

amount of noise that is received by the CNC and other control and measurement circuits.

This grounding/shielding process is the main target of this document.

Steps to take

1. All motor and drive related leads need full shielding and twisted pair connectors. The

shields should all be connected back to a star ground point at the driven ground rod.

2. Torch leads need to be shielded (outer cover with braided metal shield) that should be

grounded only at the high frequency generator end.....back to the star ground point. The

USER MANUAL

rest of the leads must be isolated from any machine metallic parts.... preferably inside a

plastic nonconductive power track.

3. Chassis of plasma power supply (with high frequency generator should be mounted away

(as far as practically possible) from the PC, and should be grounded directly to the star

ground point.

4. PC should be as far away from the plasma power supply, should get its AC sourced

through an uninterruptible power supply with surge protection. PC chassis should be

grounded directly to the star ground point.

5. If a remote wired pendant is used, it should have a shielded cable, also grounded to the

star ground point.

6. The gantry of the cutting machine should be grounded to the star ground point.

7. The torch carriage and z axis slide should be grounded to the star ground.

8. The computer monitor should be connected to the computer with a shielded cable. The

mouse also needs to be shielded.

Note: each ground wire to the star ground needs to be separate....no "daisy chaining" as

this can create ground loops.

The work ground from the plasma should be bolted directly to the star ground (no welding clamp)

The cutting slat bed should be connected directly to the star ground as well.

The star ground point should be right on the ground rod, or within about 6 feet, any extra cable

length should be shortened, no cables on the machine should have any coiled extra length.

This is the minimum that should be done on any CNC installation with high frequency plasma....

this often, but not always, eliminates electrical noise interference problems!

Voltage Divider Installation - General

!!!! WARNING!!!!

TURN OFF ALL POWER BEFORE WORKING ON

EQUIPMENT

The voltage divider provides a feedback signal which is derived from the actual cutting arc

voltage of the plasma power supply. The Neuron.THC control uses this feedback signal to control

the cutting height of the torch. The voltage divider used in the Neuron.THC a 10:1 signal. This

simply means that a cutting voltage of 100 volts results in a signal of 10 volts provided to the

control. The power supply positive and power supply negative connections on the voltage divider

should be connected to the proper output points of the plasma power supply.

USER MANUAL

Powermax plasma unit. Internal divider 20:1

USER MANUAL

Powermax plasma unit. Raw Arc Voltage.

Note: connection points for raw arc voltage can be different (depend from the model of the

cutter)

USER MANUAL

Other plasma unit. Raw Arc Voltage.

USER MANUAL

Setup Main module.

Motor driver differential interface schematic

Optocoupler input is the best available option in terms of resistance to interference and

convenience of connection. For each signal, twisted pair of cables is needed.

If motor driver has optocoupler inputs then there is no need to connect GND of the devices too.

Signs on the drive may differ so you should first read the documentation carefully. It can be e.g.

PUL+/PUL- and SIGN+/SIGN-, however it is not a rule. Servo drives often have two different

types of STEP/DIR inputs.

There is connection variant with shared (common) GND wire. This variant (most Gecko micro step

drivers) is a little bit worse because of lower interference resistance and it is a bit more difficult to

connect.

USER MANUAL

In this case, we do not use twisted cable and that is why the connection is more exposed to

the influence of interferences.

It is important to do not connect STEP- and DIR- pins with GND of the device because it

will cause short circuit and output stages damage.

THC kit has a special adapter PCB for connecting Neuron differential Pulse/Dir output to the

motor driver.

Set JP1, JP2 jumpers to 1-2 pins for differential connection:

USER MANUAL

Set JP1, JP2 jumpers to 2-3 pins for shared ground connection:

Table of contents

Popular Controllers manuals by other brands

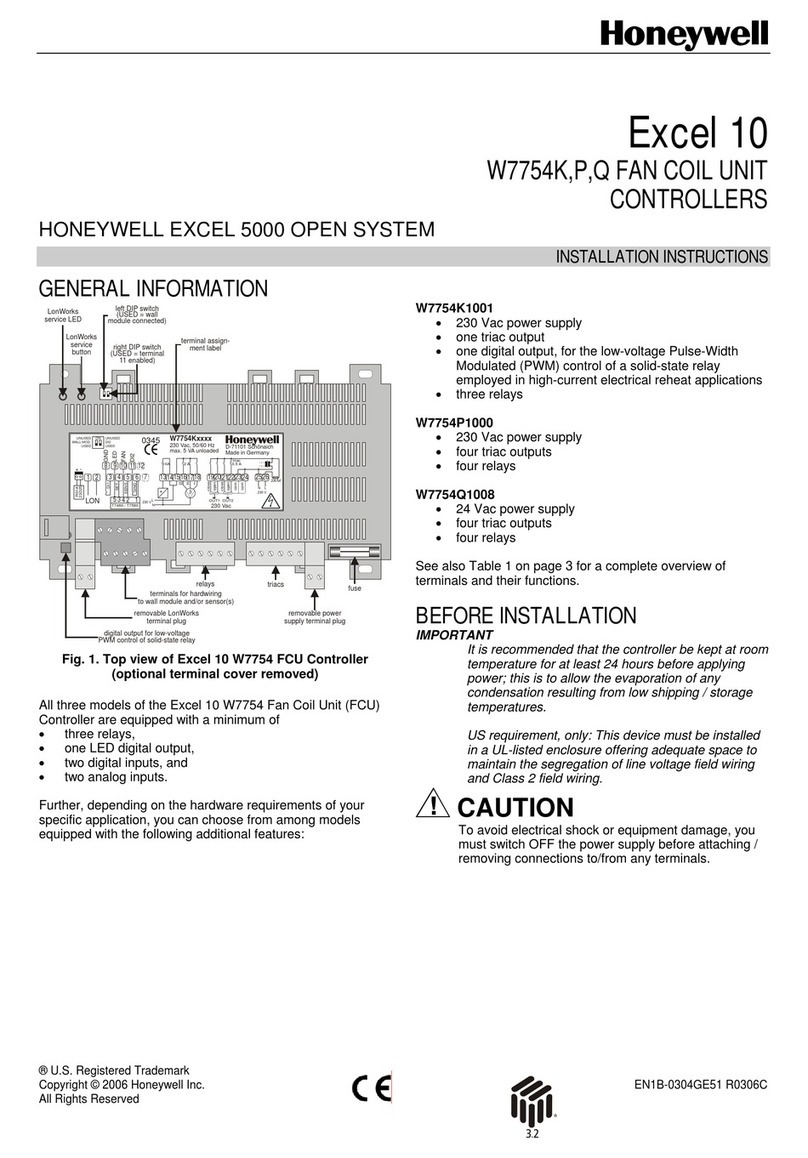

Honeywell

Honeywell Excel 10 installation instructions

VIEWEG

VIEWEG VC 1000 Series operating instructions

Distech Controls

Distech Controls EC-BOS-8 installation guide

GCE druva

GCE druva PTLH0FT Instructions for use

Rockwell Automation

Rockwell Automation PowerFlex 700S user manual

CARLO GAVAZZI

CARLO GAVAZZI RSBS Series manual