NEVADANANO MPS User manual

NNTS Proprietary Information

SM-UM-0005-03

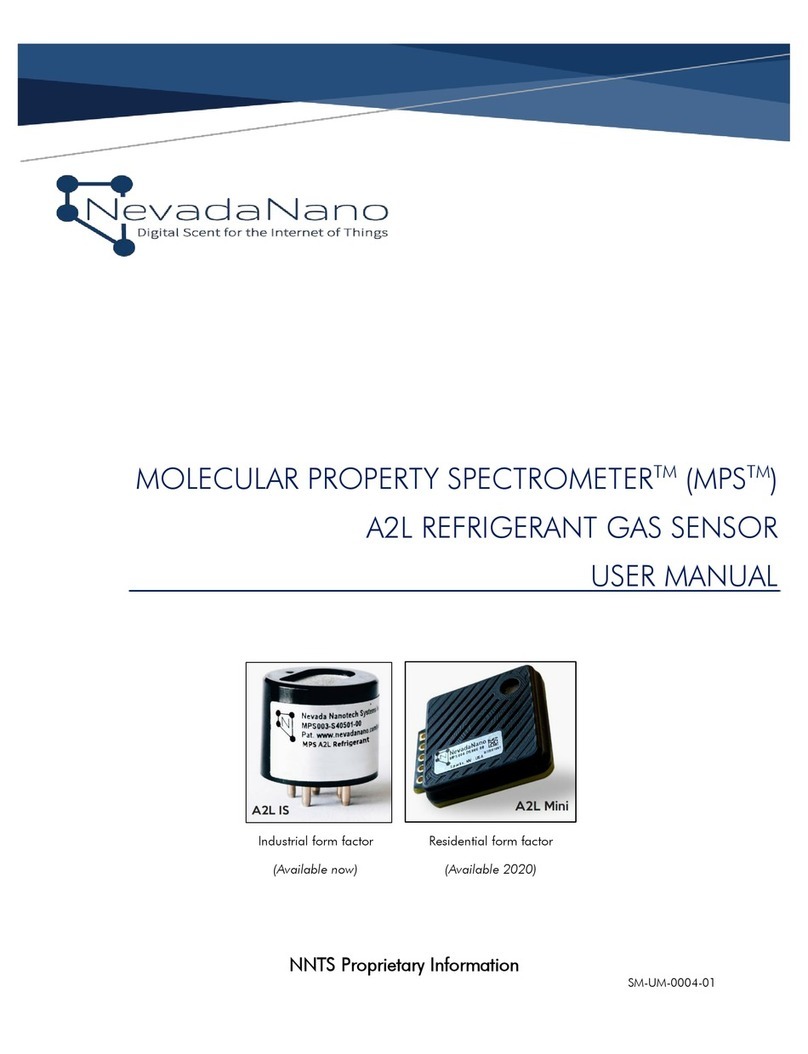

MOLECULAR PROPERTY SPECTROMETERTM (MPSTM)

A2L REFRIGERANT GAS SENSOR

EVALUATION UNIT USER MANUAL

1

SM-UM-0005-03

Notices

SM-UM-0005-03

Copyright © 2020-2021 Nevada Nanotech Systems Inc. All rights reserved.

1395 Greg Street, Suite 102

Sparks, Nevada 89431

All Rights Reserved

This publication is protected by copyright and all rights are reserved. No part of it may be reproduced or transmitted by

any means or in any form, without prior consent in writing from NevadaNano.

The information in this document has been carefully checked and is believed to be accurate. However, changes are

made periodically. These changes are incorporated in the newer publication editions. NevadaNano may improve and/or

change products described in this publication at any time. Due to continuing system improvements, NevadaNano is not

responsible for inaccurate information which may appear in this manual. For the latest product updates, consult the

NevadaNano website at www.nevadanano.com. In no event will NevadaNano be liable for direct, indirect, special

exemplary, incidental, or consequential damages resulting from any defect or omission in this document, even if advised

of the possibility of such damages.

In the interest of continued product development, NevadaNano reserves the right to make improvements in this

document and the products it describes at any time, without notices or obligation.

The Molecule logo is a trademark of Nevada Nanotech Systems Inc. Use of the logos for commercial purposes without

the prior written permission of NevadaNano may constitute trademark infringement and unfair competition in violation

of federal and state laws.

NevadaNano, the Molecule logo, Molecular Property Spectrometer, and MPS are trademarks of Nevada Nanotech

Systems Inc.

Other trademarks and trade names may be used in the document to refer to either the entities claiming the marks and

names or their products. Nevada Nanotech Systems Inc. disclaims any proprietary interest in trademarks and trade

names other than its own.

Please Recycle

Shipping materials are recyclable. Please save them for later use, or dispose of them appropriately.

2

SM-UM-0005-03

Contents

1. System Overview...............................................................................................................................................3

2. System Setup......................................................................................................................................................4

3. Conducting a Test.............................................................................................................................................6

Appendix A: Alternative Communication Configuration .................................................................................. 10

3

SM-UM-0005-03

1. System Overview

The Molecular Property SpectrometerTM (MPSTM) A2L Refrigerant Gas Sensor Evaluation

Unit is a user-friendly sensor system developed for assessing refrigerant gas detection

performance. The evaluation system is shown in Figure 1. The sensor’s pins connect to the

provided evaluation PCB for communication with a PC (USB) or breakout to individual

sensor signals (optional 5-wire harness). The sensor contains the MPS sensing element,

environmental sensor, microprocessor, and supporting electronics. A quarter-turn plastic

gas mask and housing is included to provide a sealed headspace above the sensor for test

gas delivery.

Figure 1 - (a) MPSTM A2L Refrigerant Gas Sensor, PCB with housing, gas-delivery mask, and USB A-

to-micro-B cable. (b) Sensor bottom-side detail.

The complete MPS™ A2L Refrigerant Gas Sensor Evaluation Unit kit consists of:

MPSTM Sensor Interface Software and Drivers

Evaluation PCB + housing

Gas delivery mask with integrated barbs

USB A-to-micro-B cable

1/4” Tygon tubing (McMaster: 6516T17)

Micro USB plug (not shown--optional)

MPSTM A2L Refrigerant Gas Sensor (sold separately)

(b)

(a)

4

SM-UM-0005-03

2. System Setup

The MPSTM A2L Refrigerant Gas Sensor Evaluation Unit receives power and interfaces either with a

PC via USB (default configuration for evaluation) or by using the UART protocol through a 5-wire

harness. The user interacts with the sensor while using the MPSTM Sensor Interface Software. With

this application, the user can:

establish communication with the sensor to start, pause, and end evaluation tests

examine data in real-time

record test notes

save data to .csv file

The MPSTM Sensor Interface, accompanying drivers, and Firmware Upgrade Instructions are

available at: https://www.nevadanano.com/downloads/

The user should first install the FTDI Driver, followed by a system restart, and then install the MPSTM

Sensor Interface Software. The setup procedure follows:

1. It is recommended that the computer used to operate the MPS sensor be powered

on prior to plugging the sensor in, since the MPS receives its power from the

computer. Interruption in power to the sensor will result in a sensor fault.

2. Connect the micro-USB cable to the MPS, then connect the opposite end of the

USB cable to a USB port on the computer. The MPS will automatically receive power

from the computer.

3. If a gas delivery manifold is not required, proceed to Step 4. If a mixture of

refrigerant and air is being used to interrogate the sensor, please note the

following:

a. Using the supplied ¼ -in tubing, connect the test gas system to one of the

integrated barbed connectors on the MPS gas mask.

Test gas should be supplied to the sensor at rates no greater than

300 mL/min.

The use of Nafion 1tubing is recommended to humidify the test gas

stream.

1For more information on Nafion, including its permeability for various gases, refer to:

http://www.permapure.com/products/nafion-tubing/

5

SM-UM-0005-03

The MPS should be initialized in the zero-air mixture used to dilute

the refrigerant when the sensor is powered on.

b. Attach the gas mask to the housing by aligning the arrow on the gas mask

at the 10 o’clock position and inserting the three tabs into the housing. Turn

the mask clockwise until the arrows on the housing and mask align and the

mask “clicks” into place. The barbs will be aligned across the horizontal axis

of the housing.

Figure 2 –Proper gas mask attachment is achieved when the arrow points align and the barbs are

in the horizontal position.

4. Open the MPS Sensor Interface application from the desktop icon:

5. Click the “Find MPS Devices” button and select the MPS A2L Refrigerant Gas Sensor

connected to the computer (Figure 3). The sensor name is found on the sensor

serial number in the form: Bxxxxxxxxx.

6

SM-UM-0005-03

Figure 3 –Selecting the active MPS™ A2L Refrigerant Gas Sensor.

6. The MPS sensor is now ready for testing. Proceed to the A2L Refrigerant Gas Sensor

User Manual (available at: https://www.nevadanano.com/downloads/), and read

thoroughly before continuing.

3. Conducting a Test

When interrogating the sensor with pre-diluted mixtures of refrigerant, always start the flow of

zero-air baseline gas over the MPS and wait ~1 minute for baseline gas to replace ambient air

before proceeding. The Concentration Unit functionality is not available for A2L. It automatically

reports in %LEL units, with %vol/%LEL per ISO 10156. Click Start to begin data acquisition. The unit

will acquire 10 baseline readings (Figure 4, highlighted in green). After this stabilization period, the

sensor is ready for testing.

(a)

7

SM-UM-0005-03

Figure 4 –Acquiring sensor environmental baselines at the beginning of a test.

During a test, the system generates a new data point every 2 seconds. Data can be visualized on

the MPS™ Sensor Interface Software in real time throughout a test. Graphs can be resized and

zoomed in and out while data are being collected. Graphs can be reset to auto-scale by double

clicking on the desired axis.

The MPS™ A2L Refrigerant Gas Sensor must be in an idle state before shutdown. Pause the current

test and wait for the system status dialogue to display “Idle”, then save or clear the data. The USB

cable can now be disconnected.

The user must enter test notes by clicking the “Edit Test Notes” button highlighted in green in

Figure 5 any time prior to saving data.

8

SM-UM-0005-03

Figure 5 –Example test notes dialogue box.

After entering the experimental test notes, click “Save Data”. A dialogue box will appear to prompt

the user to select a directory for saved test data. After saving, the user can now clear the data and

begin another test by clicking ‘x’ on the tab and going to File->New.

Throughout a test, data are continuously updated and stored in a temporary directory. Once a test

is complete, data can be saved to a drive location specified by the user. The folder created in this

step is named using the following format:

Year_Month_Day-Time SensorName_testName

Here is an example:

2019_07_24-173313 B320290041_InitialTest

Avoid using hyphen and special characters ( - , \ , /, %, & ) when saving data.

The data folder will contain:

9

SM-UM-0005-03

1. timelog.txt –This file provides the start, pause, re-start, and end times of a test.

Here is an example:

2019_07_24 - 17_22_10: Started

2019_07_24 - 17_28_00: Stopped

2019_07_24 - 17_33_13: Data saved

2. mpsData.csv –This is a comma-separated-value formatted file that contains all the

data from the test, organized in columns:

Time

[s]

Cycle

T [C]

P [kPa]

RH [%]

Gas ID

Conc [%LEL]

3. testNotes.txt –This file provides a record of the test notes entered in the user

dialogue box before saving.

10

SM-UM-0005-03

Appendix A: Alternative Communication Configuration

An evaluation that requires direct communication to the MPSTM A2L Refrigerant Gas Sensor via

UART is shown in Figure 6. This configuration requires that the optional micro USB plug be inserted

into the unused USB port when actively interfacing with the sensor via the 5-pin header located on

the sensor PCB. The recommended 5-Pin mating connector has a Molex P/N: 0050579205. Please

consult with NevadaNano regarding communication or system integration issues.

Figure 6 –Alternative communication configuration. The micro USB plug (a) is inserted prior to

interfacing with the sensor via the 5-pin header (b)

Given the custom nature of this configuration, the following should be considered:

Reversing the polarity of the input power will result in a damaged sensor

Improper installation of the micro USB plug could result in interference on the

communication line, corrupt or missing data, etc.

The analog output of the sensor is available in all configuration scenarios

Table 1 details the pinout of the 5-pin header located on the MPSTM A2L Refrigerant Gas

Sensor evaluation PCB.

Table 1: 5-pin header pinout

Pin Number

Function

1

GND

2

V+ (3.3V to 5V ±5%)

3

Sensor TX

4

Sensor RX

5

Analog Out

(a)

(b)

SM-UM-0005-03

Nevada Nanotech Systems Inc.

1395 Greg Street, Suite 102

Sparks, Nevada 89431

United States

Tel: +1 775 972 8943

Fax: +1 775 972 8078

info@nevadanano.com

www.nevadanano.com

Other manuals for MPS

1

Table of contents

Other NEVADANANO Accessories manuals