NEVADANANO MPS User manual

NNTS Proprietary Information

MOLECULAR PROPERTY SPECTROMETER (MPS )

FLAMMABLE GAS SENSOR

EVALUATION UNIT USER MANUAL

TM

TM

1

SM-UM-0001-02

Notices

SM-UM-0001-02 (062018)

Copyright © 2018 Nevada Nanotech Systems Inc. All rights reserved.

1395 Greg Street, Suite 102

Sparks, Nevada 89431

All Rights Reserved

This publication is protected by copyright and all rights are reserved. No part of it may be reproduced or transmitted by

any means or in any form, without prior consent in writing from NevadaNano.

The information in this document has been carefully checked and is believed to be accurate. However, changes are made

periodically. These changes are incorporated in the newer publication editions. NevadaNano may improve and/or change

products described in this publication at any time. Due to continuing system improvements, NevadaNano is not

responsible for inaccurate information which may appear in this manual. For the latest product updates, consult the

NevadaNano web site at www.nevadanano.com. In no event will NevadaNano be liable for direct, indirect, special

exemplary, incidental, or consequential damages resulting from any defect or omission in this document, even if advised of

the possibility of such damages.

In the interest of continued product development, NevadaNano reserves the right to make improvements in this document

and make the products it describes at any time, without notices or obligation.

The Molecule logo is a trademark of Nevada Nanotech Systems Inc. Use of the logos for commercial purposes without the

prior written permission of NevadaNano may constitute trademark infringement and unfair competition in violation of

federal and state laws.

NevadaNano, the Molecule logo, Molecular Property Spectrometer, and MPS are trademarks of Nevada Nanotech Systems

Inc.

Other trademarks and trade names may be used in the document to refer to either the entities claiming the marks and

names or their products. Nevada Nanotech Systems Inc. disclaims any proprietary interest in trademarks and trade names

other than its own.

Please Recycle

Shipping materials are recyclable. Please save them for later use, or dispose of them appropriately.

2

SM-UM-0001-02

Table of Contents

System Overview and Setup ....................................................................................................................... 3

1.1 Kit Contents.................................................................................................................................. 3

1.2 Gas Testing Setup ........................................................................................................................4

1.3 System Setup ............................................................................................................................... 5

1.4 System Operation ........................................................................................................................ 7

Data Collection & Analysis......................................................................................................................... 10

1.5 Test Notes ................................................................................................................................... 11

1.6 Saving Data..................................................................................................................................12

General Guidelines ......................................................................................................................................13

Definitions ...................................................................................................................................................13

3

SM-UM-0001-02

System Overview and Setup

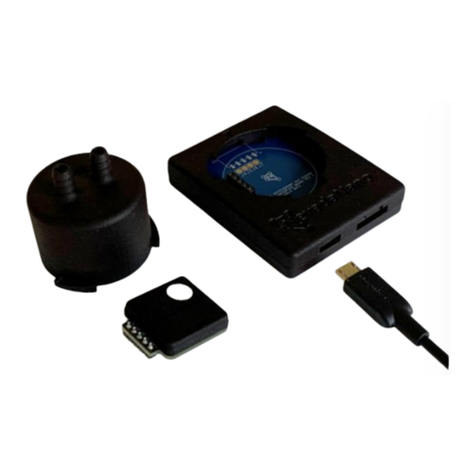

The Molecular Property SpectrometerTM (MPSTM) Flammable Gas Sensor Evaluation Unit is a user-

friendly sensor system developed for assessing flammable gas detection performance. The

evaluation system is shown in Figure 1. The sensor is 32.0 øx 13.8 mm with 1.5-mm connector pins

and connects to a provided PCB for communication with a PC (USB) or breakout to individual sensor

signals (optional 5-wire harness). The sensor contains the MPS MEMS sensing element,

environmental sensor, microprocessor, and supporting electronics inside a flame-proof housing. A

quarter-turn plastic gas mask and housing is included to provide a sealed headspace above the

sensor for test gas delivery.

Figure 1 –(a) MPS s7 Flammable Gas Sensor, housing, and gas delivery mask. (b) Sensor bottom-side detail.

1.1 Kit Contents

The complete MPS™Customer Evaluation Unit kit consists of:

MPSTM S7 flammable gas smart-sensor

MPS Sensor Interface software and drivers

Sensor PCB + housing

Gas delivery mask with integrated barbs

USB A to micro B cable

1/4” Tygon tubing (McMaster: 6516T17)

(b)

(a)

4

SM-UM-0001-02

1.2 Gas Testing Setup

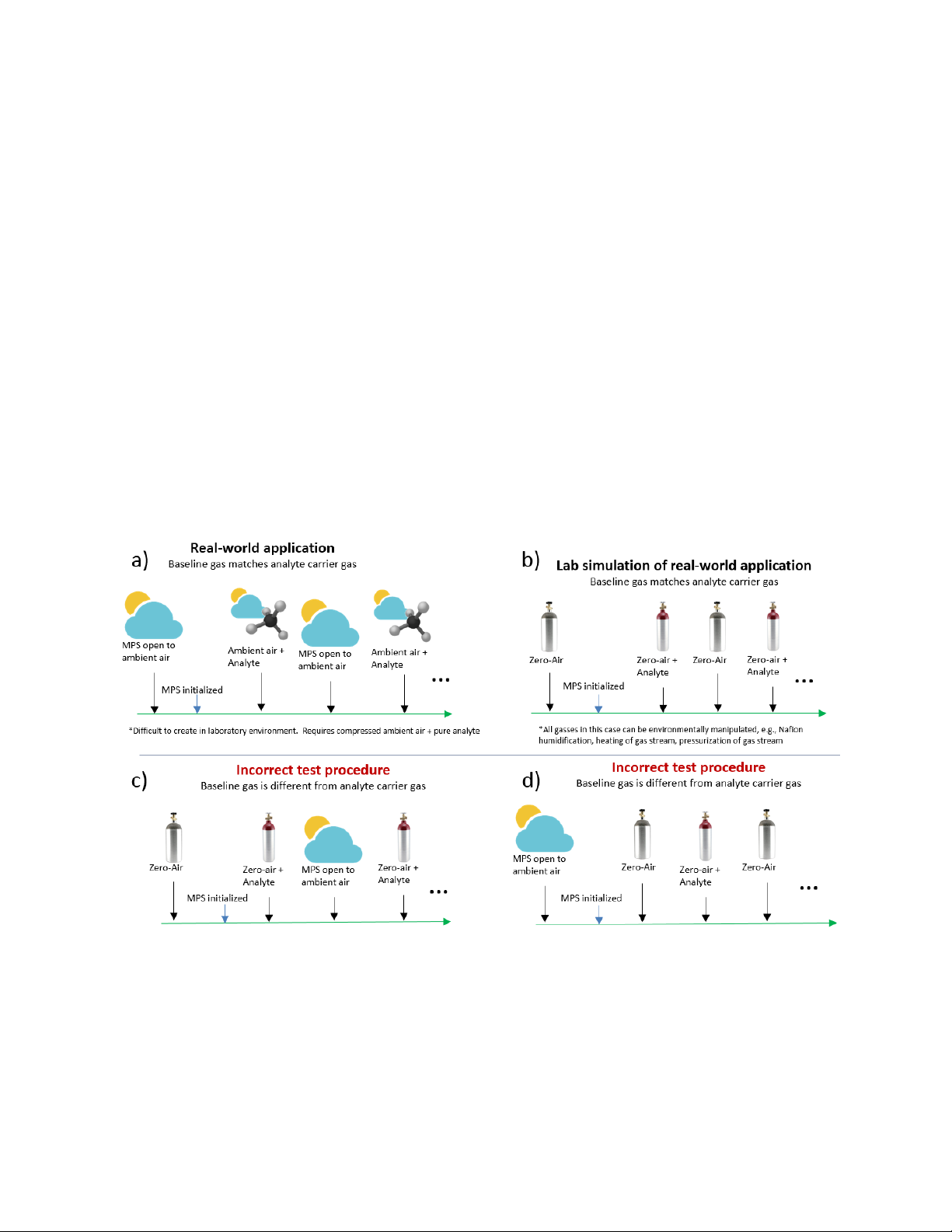

The MPS measures molecular properties to determine the quantity of flammable gas present in a

sample. The system is optimized for "real-world" cases. As such, the effects of humidity,

temperature and pressure are automatically compensated out. However, sudden, wholesale

changes to the molecular properties of the sample--i.e. artificial changes which can only be

generated in a lab test rig--can lead to inaccurate MPS outputs. (This of course excludes changes due

to the presence of flammable gas.) An example of an inadvisable change (shown in Fig. 2c, d) would

be alternating between ambient air (which contains argon, carbon dioxide and other trace gases)

and flammable gas + synthetic "zero air" balance (which contains none of the trace constituent

gasses in ambient air). To simulate the real-world application (Fig. 2a) in artificial laboratory testing,

the same type of “air” must be used for the background and the carrier of the flammable gas for the

duration of the test. An example of a proper protocol is shown in Fig. 2b. Using a variation of the

“incorrect” procedure will invalidate the accuracy of MPS measurements.

The best practice for performance testing in a laboratory is to use a humidified zero-air background,

followed by a switch to a humidified analyte stream with the same zero-air composition as balance

gas, then a switch back to humidified zero-air to clear the test chamber. This mimics real-world MPS

performance, where flammable gas is introduced into relatively invariant ambient air (Fig. 2a).

Figure 2 –Correct testing of MPS in (a) real-world application and (b) laboratory environments. Incorrect test

procedures are shown in (c, d). In both cases, the analyte and carrier gas are dissimilar during the test, causing

inaccurate results.

Other manuals for MPS

1

Table of contents

Other NEVADANANO Accessories manuals