NEW BRUNSWICK SCIENTIFIC innOva 4200 User manual

Incubator Shaker

MANUAL No. M1233-0053

Revision L

June 7, 2005

NEW BRUNSWICK SCIENTIFIC CO., INC.

BOX 4005 •44 TALMADGE ROAD •EDISON, NJ 08818-4005

Telephone: 1-732-287-1200 •1-800-631-5417

Fax: 732-287-4222 •Telex: 4753012 NBSCO

4200

2

New Brunswick Scientific User’s Guide

3

Innova 4200 •M1233-0053 User’s Guide

INTERNATIONAL OFFICES:

BELGIUM

New Brunswick Scientific NV-SA

Stationsstraat 180/4

3110 Rotselaar

België/Belgique

Tel: 32 (0)16 56 28 31

Fax: 32 (0)16 57 27 53

GERMANY

New Brunswick Scientific GmbH

In Der Au 14

D-72622 Nürtingen

Deutschland

Tel: 49 (0)7022 932490

Fax: 49 (0)7022 32486

CHINA

New Brunswick Scientific Co., Inc.

Room 1501, Xiangjiang Building, No. 18

Lane 1265, Zhongshan Road (W)

Shanghai 200051, P.R. China

Tel: 86 21 3223 0203

Fax: 86 21 6278 7182

THE NETHERLANDS

New Brunswick Scientific BV

Kerkenbos 1101, 6546 BC Nijmegen

P.O Box 6826, 6503 GH Nijmegen

Nederland

Tel: 31 (0)24 3717 600

Fax: 31 (0)24 3717 640

FRANCE

New Brunswick Scientific SARL

3, rue des Deux-Boules

75001 Paris

France

Tel: 33 (0)1 4026 2246

Fax: 33 (0)1 4026 5423

UNITED KINGDOM

New Brunswick Scientific (UK) Ltd.

17 Alban Park

St. Albans, Herts. AL4 0JJ

United Kingdom

Tel: 44 (0)1727 853855 or 0800 581331

Fax: 44 (0)1727 835666

Web: www.nbsuk.co.uk

4

New Brunswick Scientific User’s Guide

CAUTION!

This equipment must be operated as described in this manual.

If operational guidelines are not followed, equipment damage and

personal injury can occur.

Please read the entire User’s Guide before attempting to use this unit.

5

Innova 4200 •M1233-0053 User’s Guide

Copyright Notice

New Brunswick Scientific Company, Inc.

Box 4005 44 Talmadge Road

Edison, New Jersey 08818-4005

©Copyright 2005 New Brunswick Scientific Co., Inc.

All Rights Reserved.

Reproduction, adaptation, or translation without prior written permission from

New Brunswick Scientific is prohibited.

Disclaimer Notice

New Brunswick Scientific Co., Inc. reserves the right to change

information in this document without notice. Updates to information in this

document reflect our commitment to continuing product development and

improvement.

Manual Conventions

Bold Text in bold face type emphasizes key words or

phrases.

#NOTE:

CAUTION!

WARNING!

Caution messages appear before procedures

which, if caution is not observed, could result

in damage to the equipment.

Notes contain essential information that

deserves special attention.

Warning messages alert you to specific

procedures or practices which, if not followed

correctly, could result in serious personal

injury.

6

New Brunswick Scientific User’s Guide

Innova Shakers are warranted by New Brunswick Scientific Co., Inc.

for two years or 10,000 hours of actual shaker use, whichever comes later.

This warranty covers parts and labor for the entire machine, with the exception

of glassware and its contents. This warranty covers faulty components and

assembly, and our obligation under this warranty is limited to repairing or replacing

the shaker or part thereof which shall, within two years after date of shipment or

10,000 hours of operating time, prove to be defective after examination. This

warranty does not cover any loss of time, materials, biological or biochemical by-

products caused by any work interruption resulting from shaker failure, nor does it

extend to any Innova Shaker which has been subjected to misuse, neglect, accident

or improper installation or application. In addition, the warranty does not apply to

any Innova Shaker that has been repaired or altered outside the NBS factory without

prior authorization from New Brunswick Scientific. For a period of two years (or

more) after the shipment date, the Innova warranty will be in effect as long as

the shaker has not been in operation for a total of 10,000 hours. After the

10,000 hours of operating time have elapsed, the Innova warranty may

still be in effect, as long as the two-year minimum warranty period

has not been reached. Operating time is based on actual usage

of the shaker, as determined by the shaker’s internal

electronic clock. Any tampering or alteration of

the clock will void the 10,000-hour

warranty.

W A R R A N T Y

7

Innova 4200 •M1233-0053 User’s Guide

TABLE OF CONTENTS

1OVERVIEW.....................................................................................................................................................9

2SPECIFICATIONS........................................................................................................................................10

3INSPECTION & VERIFICATION .............................................................................................................12

3.1 INSPECTION OF BOXES.............................................................................................................................12

3.2 PACKING LIST VERIFICATION..................................................................................................................12

4PREPARING THE LOCATION..................................................................................................................13

4.1 PHYSICAL LOCATION...............................................................................................................................13

4.2 ENVIRONMENT ........................................................................................................................................13

4.3 UNPACKING OF EQUIPMENT ....................................................................................................................13

4.4 INSPECTION OF EQUIPMENT.....................................................................................................................13

5INNOVA 4200 FEATURES..........................................................................................................................14

5.1 KEYPAD FEATURES .................................................................................................................................14

5.2 LOCKING CABINET ..................................................................................................................................15

6GETTING STARTED...................................................................................................................................18

6.1 VOLTAGE CONFIGURATION.....................................................................................................................18

1. Verify that the Shaker is disconnected from the power source...............................................................18

6.2 SETTING FREQUENCY..............................................................................................................................19

6.3 STANDARD PLATFORM INSTALLATION....................................................................................................20

6.4 QUICK CHANGE ACCESSORY PLATFORM INSTALLATION.........................................................................20

6.5 INSTALLATION OF CLAMPS .....................................................................................................................21

6.5.1 Clamp Hardware Application Charts................................................................................................22

6.6 MAKING ELECTRICAL CONNECTIONS......................................................................................................22

7INNOVA 4200 OPERATION.......................................................................................................................24

7.1 CONTINUOUS RUN OPERATION ...............................................................................................................24

7.2 TEMPERATURE ........................................................................................................................................25

7.3 TEMPERATURE OFFSET CALIBRATION.....................................................................................................26

7.4 TIMED RUN OPERATION..........................................................................................................................27

7.5 ALARM FUNCTIONS.................................................................................................................................27

7.6 TOTAL RUNNING TIME ............................................................................................................................28

7.7 USING THE INNOVA 4200 AS A QUIESCENT INCUBATOR..........................................................................28

7.8 REDUCING DEHYDRATION.......................................................................................................................29

7.9 AIR DEFLECTOR INSTALLATION ..............................................................................................................30

7.10 GASSING CULTURES IN THE INNOVA 4200...............................................................................................31

7.11 ACCESSORY RECORDER CONNECTOR......................................................................................................31

7.12 USING ANCILLARY EQUIPMENT WITH THE INNOVA 4200........................................................................32

7.12.1 Electrical Moisure-Proof Plug......................................................................................................33

8PREVENTIVE MAINTENANCE................................................................................................................35

8.1 DISABLING THE MAINT LIGHT...............................................................................................................35

8.2 CLEANING PROCEDURES .........................................................................................................................35

9SERVICE PROCEDURES ...........................................................................................................................37

9.1 MOTOR BELT REPLACEMENT ..................................................................................................................37

9.2 FULL MOTOR ASSEMBLY REPLACEMENT................................................................................................38

8

New Brunswick Scientific User’s Guide

9.3 PARTIAL MOTOR ASSEMBLY REPLACEMENT...........................................................................................40

9.4 REMOVING THE RECIRCULATING FAN.....................................................................................................41

9.5 BEARING HOUSING REPLACEMENT .........................................................................................................41

9.6 LIGHT REPLACEMENT..............................................................................................................................43

9.7 TEMPERATURE SENSOR ADJUSTMENT.....................................................................................................45

9.8 CONTROL BOARD REPLACEMENT............................................................................................................46

9.8.1 ESD Precautions................................................................................................................................46

9.8.2 Replacing the Temperature Control Board.......................................................................................46

9.8.3 Replacing the Main Control Board ...................................................................................................48

10 TROUBLESHOOTING ................................................................................................................................50

10.1 TROUBLESHOOTING GUIDE .....................................................................................................................50

10.2 FUSE REPLACEMENT ...............................................................................................................................50

11 REPLACEMENT PARTS & ACCESSORY INFORMATION................................................................52

11.1 REPLACEMENT PARTS DESCRIPTIONS & PART NUMBERS .......................................................................52

11.2 ACCESSORY DESCRIPTIONS & PART NUMBERS.......................................................................................52

11.2.1 Quick Change Platform Kit ..........................................................................................................52

11.2.2 Accessory Platforms......................................................................................................................53

11.2.3 Accessory Clamps.........................................................................................................................53

11.2.4 Accessory Test Tube Racks...........................................................................................................54

11.2.5 Optional Accessory Kits................................................................................................................54

11.3 CLAMP HARDWARE KITS ........................................................................................................................54

12 DRAWINGS...................................................................................................................................................56

12.1 SCHEMATICS ...........................................................................................................................................56

12.2 INDEX OF DRAWINGS...............................................................................................................................71

13 INDEX.............................................................................................................................................................72

9

Innova 4200 •M1233-0053 User’s Guide

1

1

O

OV

VE

ER

RV

VI

IE

EW

W

New Brunswick Scientific’s Innova 4200 Incubator Biological Shaker is a very versatile shaker

for the biological research laboratory. The Innova 4200 provides a temperature-controlled

environment that can be equipped with various accessories to adapt it for the culture of

microorganisms, cell culture and hybridization.

Automatic features include an interlock door that shuts off the shaker when the door is open,

chamber temperature shutoff, and overload/unbalanced sensor that automatically limits the speed

of the shaker when an unbalanced or overloaded condition is detected. Audible and visual alarms

alert the user when the temperature or speed is out of range.

Microprocessor controller with feedback controls the temperature and speed of the shaker.

Temperature and speed setpoints are entered and changed using the membrane switch keypad.

Setpoints and the actual values are displayed on the 3/8” (9.5 mm) bright LED display. The

shaker operates continuously, or in a timed mode via a programmable timer for shaking periods

of 0.1 hr–99.9 hrs. An audible and visual alarm indicates the end of a timed cycle. The triple

eccentric drive is counterbalanced and provides horizontal plane rotary motion in ¾″(19 mm)

circular motion. A 1″(25.4 mm) model is also available.

The Innova 4200 has a (0–5 Volt) analog chart recorder outputs for speed or temperature.

The 4200 is stackable (up to two units), and accommodates routine laboratory accessories like

Rollers, Magnetic Stirrers, Rockers, and Shakers. A wide variety of platforms and accessories

are available for the Innova 4200.

10

New Brunswick Scientific User’s Guide

2

2

S

SP

PE

EC

CI

IF

FI

IC

CA

AT

TI

IO

ON

NS

S

Innova 4200 Incubator Shaker

construction

Heavy gauge stainless steel

door

26 3/8″H x 22″W (670 mm x 559 mm)

Cabinet double paned

glass window 19¼″H x 11 3/8″W (489 mm x 289 mm)

fluorescent light

13 watt–provides illumination inside chamber

shelves

2 Stainless Steel 20″W x 20″L (508 mm x 508 mm)–adjustable–

(½″(12.7 mm) centers)

internal AC

receptacle 200W AC–waterproof w/ mating connector–can be used w/

magnetic stirrer, spinner flask, rocker, roller & shakers

platform 18″W x 18″L (457 mm x 457 mm)

Dimensions overall†24.4″W x 28.7″L x 36.4″H (620 mm x 729 mm x 925 mm)

chamber

20½″W x 20½″L x 24.8″H (520 mm x 520 mm x 630 mm)

Electrical 1200 Watts–120/100/200/240V–50/60Hz

Indicator 3 digit LED

Recorder Output Two 0-5 Volt–tracks temperature & speed w/ optional recorder

alarm

Audible & visible indicates when speed deviates ±5 rpm–audible

alarm can be deactivated

control

±1 rpm–acceleration control minimizes splashing caused by

sudden starts and stops

display

1 rpm increments

drive

Triple-eccentric counterbalanced drive w/ 9 sealed for life, ball

bearings

Shaking motion ¾″(19 mm) circular–standard

1″(25.4) optional

motor

1/15 HP, 3-phase solid-state, brushless ball bearing DC motor

range

25–400 rpm, 25-300 rpm for stacked unit

timer

Programmable shaking continuous →99.9 hours–setable in 0.1

hr. increments–alarm sounds at end of shaking period

automatic

restart Setpoints & operating status retained by non-volatile memory–

auto restart after power is restored

door interlock

Shaker shuts off when door is open

Safety unbalanced/

overload sensor Limits speed automatically when unbalanced or overload

condition is detected

chamber

temperature Heater shuts off if temperature exceeds operating range

†51.2 (130 cm) front to back w/ door open

11

Innova 4200 •M1233-0053 User’s Guide

Innova 4200 Incubator Shaker

Options stacking kit Provides stacking for up to (2) Innova 4200 shakers

alarms Audible & Visual–when temperature deviates > 1.0°C–audible

alarm can be deactivated

ambient

15–35°C/Humidity–up to 90% non-condensing

Temperature control ±0.1°C

heaters

Resistance w/ high temperature safety cutoff

range 5°C above ambient to 75°C (50 Hz units) or 80°C (60 Hz

units)

uniformity

±.3°C NOM.

Weight net 275 lb. (125 kg.)

gross 335 lb. (152 kg.)

CAUTION!

Do not set the temperature above:

• 75°C for 50 Hz units

• 80°C for 60 Hz units.

12

New Brunswick Scientific User’s Guide

3

3

I

IN

NS

SP

PE

EC

CT

TI

IO

ON

N

&

&

V

VE

ER

RI

IF

FI

IC

CA

AT

TI

IO

ON

N

3.1 Inspection of Boxes

After you have received your order from New Brunswick Scientific, inspect the boxes

carefully for any damage that may have occurred during shipping. Report any damage to

the carrier and to your local NBS Sales Order Department or local NBS distributor.

3.2 Packing List Verification

Verify on your NBS packing list that you have received the correct materials.

13

Innova 4200 •M1233-0053 User’s Guide

4

4

P

PR

RE

EP

PA

AR

RI

IN

NG

G

T

TH

HE

E

L

LO

OC

CA

AT

TI

IO

ON

N

4.1 Physical Location

The surface where you place the Innova 4200 should be smooth, level, and sturdy, and

must be able to accommodate 300-400 lbs. for single units, or 600 lbs. for stacked units.

The feet can be adjusted for necessary leveling. Loosen the locking nuts on the threaded

studs attached to the feet of the shaker. Retighten when you have achieved the correct

level for your shaker.

4.2 Environment

The Innova 4200 operates properly under the following conditions:

• ambient operating temperature range 15°C–35°C

• relative humidity up to 90% non-condensing

• main voltage fluctuation not to exceed 10 %

• indoor use only

WARNING!

The Innova 4200 is very heavy and may require special equipment to

transport. Never try to lift or move the unit by yourself.

4.3 Unpacking of Equipment

Save all packing materials and User’s Guide.

If any part of your order was damaged during shipping, missing pieces, or fails to

operate properly, please fill out the Customer Service Form 6300 and return by

fax. This form can be found in the envelope that contains the warranty card.

4.4 Inspection of Equipment

Verify against the packing list that you have received everything you ordered. If

anything is missing, contact your NBS sales representative right away.

14

New Brunswick Scientific User’s Guide

5

5

I

IN

NN

NO

OV

VA

A

4

42

20

00

0

F

FE

EA

AT

TU

UR

RE

ES

S

5.1 Keypad Features

• LED DISPLAY 3 digit LED display shows shaker ON/OFF

status, speed, setpoints, hours remaining &

measured temperature

• START/STOP KEY Start/stops the shaking motion–activates or

stops the timer when a timed run is desired

• SELECT KEY Allows users to enter the SET MODE for setpoint

changes

• VKEY Adjust setpoint of a displayed parameter up

• WKEY Adjust setpoint of a displayed parameter down

• STATUS INDICATORS 4 indicator lights–located to the left of the

LED display–displays status for the following:

MAINT Remains lit after 10,000 hours of use–Accumulated

running time is internally monitored and may be

displayed as a guideline. Refer to Section 8.1 on

disabling.

SET Indicates that the shaker is in the SET MODE and

Setpoints are displayed and can be altered

TIME Indicates that the timer is in operation

(programmable to run for pre-set time from 0.1 hour

to 99.9 hours without stopping an ongoing run).

The timer can be disengaged or reset

MUTE Indicates the status of the audible alarm. When

MUTE indicator is illuminated, the audible alarm

device is disabled

15

Innova 4200 •M1233-0053 User’s Guide

• FUNCTION INDICATORS 4 indicator lights–located to the right of the

LED display–displays the following parameters:

RPM Revolutions per minute

HOURS Time remaining in cycle

°CTemperature of chamber

*Not used at this time

Figure 1: Keypad Detail

5.2 Locking Cabinet

The Innova 4200 is equipped with a locking cabinet door to keep the contents of the

chamber secure. A set of two keys are shipped with the unit. The lock is located on the

door handle.

FUNCTION

INDICATORS

STATUS

INDICATORS

START/STOP

KEY

SELECT KEY

LED DISPLAY

16

New Brunswick Scientific User’s Guide

Figure 2: Innova 4200 Front Panel

Figure 3: Innova 4200 Side Panel

DOOR

HANDLE

CABINET

DOOR

KEYPAD

LOWER

FRONT PANEL

Switch Panel

Detail

PORT FOR

OPTIONAL

GASSING

MANIFOLD

CABINET

LOCK

17

Innova 4200 •M1233-0053 User’s Guide

Figure 4: Innova 4200 Rear Panel

ELECTRICAL

SPECIFICATION

PLATE

IEC-320

Power Connector

Frequency

Selector

Recorder

Connector

18

New Brunswick Scientific User’s Guide

6

6

G

GE

ET

TT

TI

IN

NG

G

S

ST

TA

AR

RT

TE

ED

D

WARNING!

Always verify the voltage of the Innova 4200 before plugging it in.

6.1 Voltage Configuration

The Innova 4200 is set to the appropriate line voltage prior to shipment. The VOLTAGE

SELECTOR is on the back panel of the shaker (See Figure 4). It is a universal power-

entry device that can adapt to worldwide power requirements.

Check the voltage selector as a precaution, to be sure it is set to the correct voltage before

you plug in the unit.

If you need to reset the voltage for the Innova 4200, have a qualified electrical or service

engineer perform the following procedure.

CAUTION!

The following procedure must be performed only by a qualified Electrical

or Service Engineer.

1. Verify that the shaker is disconnected from the power source.

2. Use a flat head screwdriver to push the FUSE DRAWER LOCK TAB down and pull out

the FUSE DRAWER (see Figure 5 below).

3. Remove the

VOLTAGE SELECTOR INSERT and rotate the selector until the desired

voltage is found.

19

Innova 4200 •M1233-0053 User’s Guide

Figure 5: Voltage Selector

4. Place the VOLTAGE SELECTOR INSERT back into the FUSE DRAWER. Verify that the

correct voltage is displayed through the VOLTAGE WINDOW.

5. Slide the FUSE DRAWER back into the FUSE HOUSING and verify that it locks into

place.

6. Use the following table to set the correct voltage for your unit:

Voltage Configuration Table

¾” Stroke Innova Model # Voltage of Unit

M1233–0005 100V 50/60 HZ

M1233–0004 120V 50/60 HZ

M1233–0006 220V 50/60 HZ

M1233–0007 240V 50/60 HZ

1” Stroke Innova Model # Voltage of Unit

M1233–0015 100V 50/60 HZ

M1233–0014 120V 50/60 HZ

M1233–0016 220V 50/60 HZ

M1233–0017 240V 50/60 HZ

6.2 Setting Frequency

The Innova 4200 is set to the appropriate frequency prior to shipment. The FREQUENCY

SWITCH is on the back panel of the shaker (See Figure 4). If you need to reset to the

frequency prior to operation, perform the following steps:

CAUTION!

If the Innova 4200 is being operated in Europe, CE Labeling requires that

the following procedure be performed only by a qualified Electrical or

Service Engineer.

20

New Brunswick Scientific User’s Guide

1. Verify that the shaker is disconnected from the power source.

2. Slide the small red switch up for 50 Hz (see Figure 6 below).

3. Slide the small red switch down for 60 Hz.

Figure 6: Frequency Selector Switch

6.3 Standard Platform Installation

#NOTE:

There are two small plastic straps that hold the bearing housing in place

for shipping. Be sure to remove the straps from the unit.

Before you operate the shaker, a platform must be attached. Platforms are purchased

separately. To attach a platform perform the following steps:

1. Open the door of the shaker.

2. Remove the four HEX SCREWS from the subplatform of the bearing housing with the

HEX KEY (supplied).

3. Place the platform on the upper bearing housing and align the holes in the platform

over the holes in the upper bearing housing.

4. Place the

HEX SCREWS in the four holes. Tighten with the HEX KEY. This secures

the platform to the shaker.

6.4 Quick Change Accessory Platform Installation

1. Open the door of the shaker.

2. Place the QUICK CHANGE PLATFORM on the shaker.

3. Place the four platform HEX SCREWS in the four holes on the platform and tighten

with the HEX WRENCH (provided).

4. Slide the

FLASK PLATFORM in between the side guides on the inside of the QUICK

CHANGE PLATFORM.

Table of contents

Other NEW BRUNSWICK SCIENTIFIC Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

Sumake

Sumake SS-1203A Original instructions

GFL

GFL 3012 operating instructions

Eden

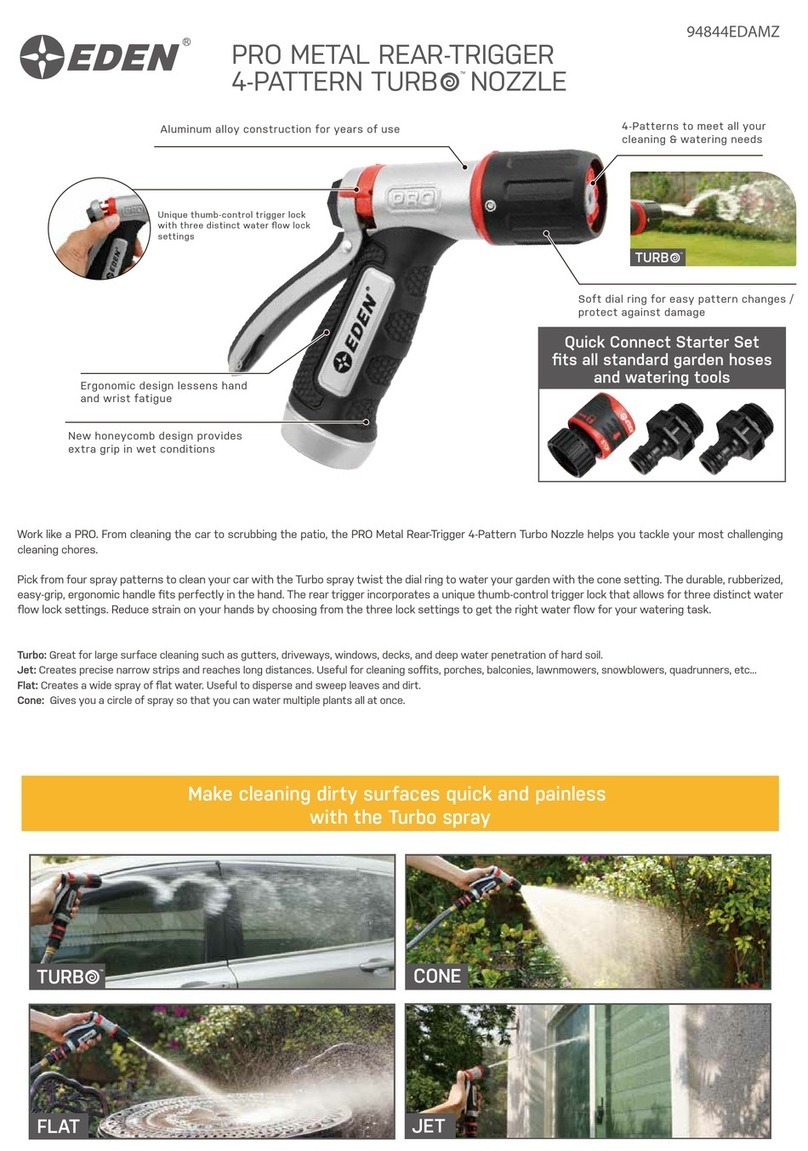

Eden 94844EDAMZ quick start guide

Goizper Group

Goizper Group iK VECTOR CONTROL Operator's manual

Excalibur

Excalibur Larius Operating and operating and maintenance instructions

DeVilbiss

DeVilbiss NEPTUNE Series Operation manual

P.Lindberg

P.Lindberg 9062244 Original user manual

Norac

Norac UC4.5 installation manual

TurfEx

TurfEx US1000-1 Owner's manual and installation instructions

Amazone

Amazone FT 1001 operating manual

Central Pneumatic Professional

Central Pneumatic Professional 43430 Assembly and operating instructions

Fimco

Fimco LG-29-P owner's manual