1User Information.......................................................................................... 6

1.1 Purpose of the document........................................................................................................ 6

1.2 Locations in the operating manual.......................................................................................... 6

1.3 Diagrams................................................................................................................................. 6

2General safety instructions........................................................................ 7

2.1 Obligations and liability............................................................................................................ 7

2.2 Representation of safety symbols........................................................................................... 9

2.3 Organisational measures ...................................................................................................... 10

2.4 Safety and protection equipment .......................................................................................... 10

2.5 Informal safety measures...................................................................................................... 10

2.6 User training.......................................................................................................................... 11

2.7 Safety measures in normal operation ................................................................................... 12

2.8 Danger from residual energy................................................................................................. 12

2.9 Maintenance and repair work, fault elimination..................................................................... 12

2.10 Design changes..................................................................................................................... 12

2.10.1 Spare and wear parts and aids ............................................................................................. 13

2.11 Cleaning and disposal........................................................................................................... 13

2.12 User workstation.................................................................................................................... 13

2.13 Warning symbols and other signs on the machine ............................................................... 14

2.13.1 Positions of warning symbols and other labels..................................................................... 15

2.14 Dangers if the safety information is not observed................................................................. 17

2.15 Safety-conscious working ..................................................................................................... 17

2.16 Safety information for users .................................................................................................. 18

2.16.1 General safety and accident prevention information............................................................. 18

2.16.2 Field sprayer operation.......................................................................................................... 21

2.16.3 Cleaning, maintenance and repairs ...................................................................................... 22

3Loading and unloading............................................................................. 23

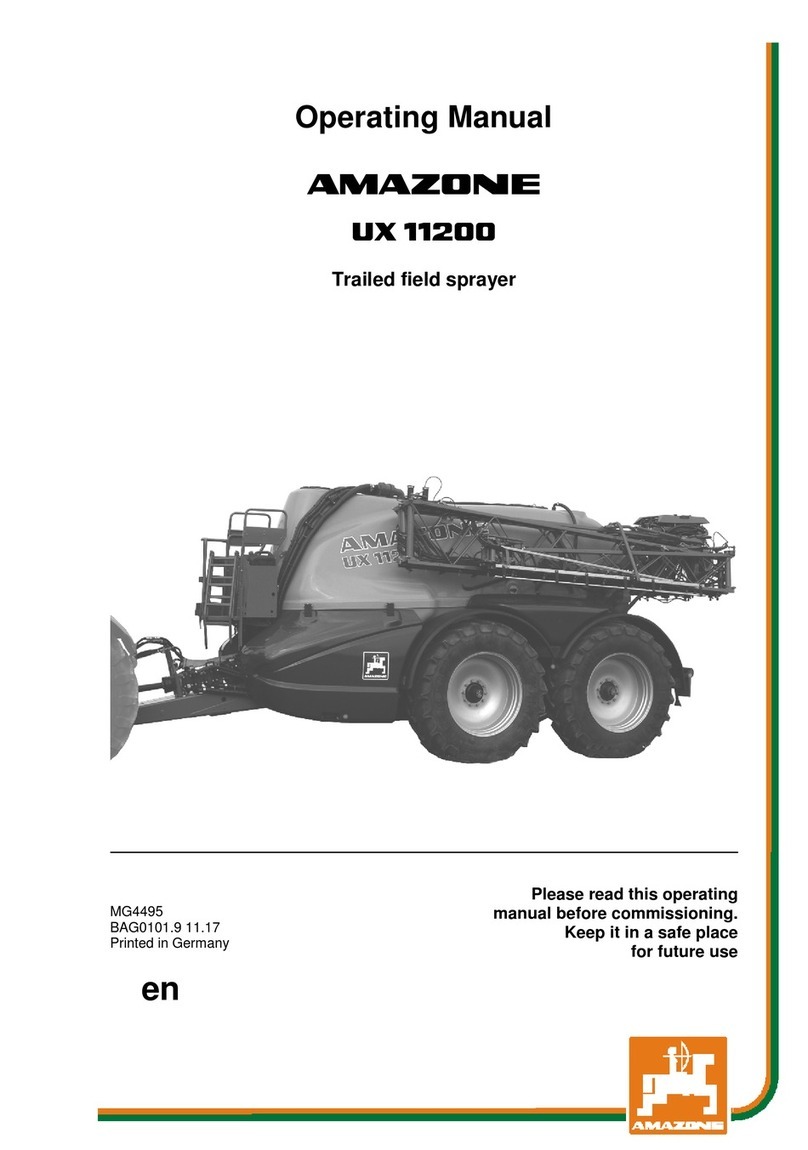

4Product description .................................................................................. 24

4.1 Overview ............................................................................................................................... 24

4.2 Overview of Flow Control...................................................................................................... 25

4.3 Technical data....................................................................................................................... 26

4.3.1 Payload ................................................................................................................................. 26

4.4 Intended use.......................................................................................................................... 27

4.5 Danger areas and danger points........................................................................................... 28

4.6 Rating plate and CE mark..................................................................................................... 29

4.7 Three-point attachment frame............................................................................................... 29

4.8 Transport device (removable) ............................................................................................... 30

4.9 Transportation equipment ..................................................................................................... 31

4.10 Camera system ..................................................................................................................... 31

5UF01 and FT 1001 without Flow Control ........................................... 32

5.1 Filling the front tank via the UF01 field sprayer .................................................................. 32

5.2 Filling the UF01 spray liquid tank via the front tank............................................................ 34

6UF01 and FT1001 with Flow Control (optional)................................. 35

6.1 Flow Control liquid circuit ...................................................................................................... 35

6.2 Additional tank for flushing water.......................................................................................... 36

6.3 Connect field sprayer with Flow Control and front tank ........................................................ 37

6.4 Automatic mode .................................................................................................................... 38

6.5 Manual mode......................................................................................................................... 39

6.6 Front tank submenu .............................................................................................................. 40

6.7 Filling..................................................................................................................................... 41

4 FT BAG0065.6 02.19