NEW ENERGY NERS-B1.0S-P Owner's manual

COMMERCIAL UNIT

NEW ENERGY

The needing attentions before reading the manual

Please read this manual carefully before doing the installation

This heat pump water heater must be installed by the professional technical

personnel.

Please install the machine and connect the water pipe in accordance with this

manual strictly.

For safety, please make sure to recheck everything is well before power on.

If the machine has any improvement, the content is subject to change without

notice.

1

Please read this manual carefully before installation and operation.

Please keep this manual for future reference.

Applicable models: NERS-B1.0S-P、NERS-B1.5S-P、

Ⅰ.Prologue ············································································································································2

II. Model and Specification············································································································3

Ⅲ Explosive view ···························································································································· ····4

Ⅳ Installation ········································································································································6

Ⅴ Trial running /commissioning ·······························································································9

Ⅵ Display and operation of wired controller ·····································································10

Ⅶ Maintenance·····································································································································19

Ⅷ Wiring diagram ······························································································································20

NERS-B2.0S-P

NERS-B3.0S-P

ATTENTIONS:

1. Please make sure the water systems should be filled with water before the machine start working

2. When the machine is operating, all the valves of the water systems must be in the open position.

3. If without inlet water or stop using for a long time, when re-boot the machine, please according to

the item of attentons.1.

4. A removable filter must be installed at the water inlet and please clean the valve periodically depend

on your locate water quality (every 2 or 3 months).

5. The maximum water temperature is 60C .When you use the water, please adjust the water

temperature to a appropriate temperature (The most comfortable water temperature for shower is

38~42C , if the water temperature above 50C , there will be danger of burns!)

6. The maintenance of the machine must be carried out by the professional personnel.

Ⅰ Prologue

2

Thanks for using heat pump water heater! Please read this manual carefully before installation and

operation! This manual contains the information about installation, commissioning, operation, and

maintenance. The following items should be focused:

1. Before installation, please confirm if your local voltage is match with the voltage showed on the

machine's nameplate and if the carrying capacity of the power supply, wires and sockets are

suitable for this machine's input power.

2. Users are not allowed to change the power cord or socket. Wiring work must be carried out by a

qualified electrician and ensure that the metal part of the machine has a good grounding. Changing

the ground mode is strictly forbidden.

3. After the completion of the construction of all wiring work, please make sure to recheck everything

is well before power on.

4. Installing the machine in the place which the combustible gas may leak is strictly forbidden.

5. Do not put your hands or foreign objects into the air outlet of heat pump unit, otherwise, it will be

dangerous to the people and equipment.

6. In order to obtain a better energy-saving effect, the unit should be installed in a place with well-

ventilated.

7.If the unit power off,please discharge all the water inside.Otherwise,the heat exchanger will be

frozen in winter.

1 Model and parameter sheet:

2 Units Dimensions and drawings

Model

Rated heating capacity

NERS-B1.0S-P

3525

76

860

G3/4"

3/4"G

0.55~0.71

≤51

56

Unit

W

L/h

W

3

m/h

dB

kg

5100

109

1240

G3/4"

G3/4"

0.72~0.94

≤51

60

10300

225

2550

G3/4"

G3/4"

1.81~2.35

≤54

100

3

Input water pipe diameter

Output water pipe diameter

Rated circulation water flow

Noise

Weight

II Model and Specification

C

A

B

R410a

Type

Qty

Brand

Rotary

1

Mitsubishi

Note: Test condition: according to GB/T 21362-2008. Detailed data take nameplate as the final.Products

shall be subject to any changes without additional notices. Part of the products are: Summer low-speed,

winter high-speed, high pressure fan stops, speed adjustment according to the ambient temperature.

Rated output water qty

Rated input power

Power supply

Refrigerant

Compressor

Model

NERS-B1.0S-P

-B1.5S-P

-

220V- ~50Hz

7200

145

1720

G3/4"

G3/4"

1.03~1.34

≤54

65

-

772

323 496

A

BC

894

402 538

1064

401 622

998

392 549

NERS-B1.5S-P NERS-B2.0S-P NERS-B3.0S-P

B2.0S-P

B3.0S-P

240V

NERS

NERS

NERS

Ⅲ Explosive view

NERS-B1.0S-P

NERS-B1.5S-P

4

Fan blade

3

Water pipe panel

Name

Back panel

Evaporator

Shell in tube heat exchanger

Wilo water pump

Inlet pipe module

22

18

20

21

19

17

16

Code

Side grille

Top cover panel

Stand column

Median panel

25

26

24

23

Front panel of air flow

Fan protective net screening

Name

Electric box cover

Maintain panel

Motor

7

5

6

4

2

1

Code

Four-way valve module

Foundation assembly

Compressor

High pressure gauge

Filter module

15

11

13

14

12

9

10

8Water pump fixed screw

PG19 connection

Wire installation panel

Back grille

Motor bracket

7654321 8

15

14

13

10 11

16

17

20

19

21

25

24

23

26

22

18

129

NERS-B3.0S-P

5

NERS-B2.0S-P

Fan blade

3

Water pipe panel

Name

Back panel

Evaporator

Shell in tube heat exchanger

Wilo water pump

Inlet pipe module

22

18

20

21

19

17

16

Code

Side grille

Top cover panel

Stand column

Median panel

25

26

24

23

Front panel of air flow

Fan protective net screening

Name

Electric box cover

Maintain panel

Motor

7

5

6

4

2

1

Code

Four-way valve module

Foundation assembly

Compressor

High pressure gauge

Filter module

15

11

13

14

12

9

10

8Water pump fixed screw

PG19 connection

Wire installation panel

Back grille

Motor bracket

7654321 8

15

14

13

10 11

16

17

20

19

21

25

24

23

26

22

18

129

1. Installation position

1.1 The place should have enough space for installation & maintenance.

1.2 None block to the air inlet and outlet and none strong wind or hurricane could reach.

1.3 The place should well-ventilate, solid, there should be no extra running noise or vibration noise

after loading the unit.

1.4 The place which has enough space for air outlet, which doesn't have combustible gas leakage.

1.5 The place should convenient for wiring and plumbing work.

1.6 Typhoon protection &lightning protection must be done when loading a unit on the roof.

1.7 Snow shed must be needed in winter.

1.8 There should be drainage around the machine to deliver the condensate water.

Unit install position please see below:

Ⅳ Installation

6

Please choose the water tank as below requirements:

This unit can match with pressurized water tank.

2. Installation of the tank

(1) If there is not pressure relief device inside the water tank, make sure to install the press

ure relief device, the parameter value is 0.7MPa.

(2) Water can flow from the drainpipe of the pressure relief device and the drainpipe should

keep communicate with the air.

(3)Pressure discharge device should be cleaned periodical in order to remove the calcium

carbonate deposition and prove that the device is not plugged.

(4)The pipes which connect heat pump unit and water tank should be airtight, water pressure

of the whole system at least should be 0.6MPa.

Note :1) The pipeline should test pressure separately, can not test pressure together

with the unit and water tank.2) The work pressure of the water system is : 0.2~0.6Mpa.

3.1 Do not let the dust and other sundries fall into the pipe system when install the water pipes.

3.2 Install the water pipes after fixing the units.

3.3 A removable filter (40~60 mesh) must be installed at the water inlet and please clean it periodically

depend on your locate water quality.

3.4 Install the drain valve at the bottom of the water pipe for cleaning. Ensure the water flow smooth,

can not up and down alternately, easy to discharge the air and water inside pipes.

3.5 Install the live valve at the water inlet and outlet of the outdoor unit in order to maintenance. When

connect the pipes, rotating the connection pipes by using tongs which fixed in the water pipe joints

of the outdoor unit, can not let the water pipe joints on the unit directly bear the torque of rotation.

3.6 The water tank requires good heat preservation, the distance between circulation inlet and outlet

should be as far as possible in order to make the water circulation equality.

3.7 In winter, the unit can not be power off. If not used for a long time, make sure to discharge the water

inside the unit and water pipes to prevent the heat exchanger or water pipes are cracking.

7

Circulation outlet

Circulation inlet

Hot water outlet

Cold water inlet

Shower

WIRED CONTROLLER

Single circulation heat pump water heater with pressurized water tank install diagram:

Pressurized water tank

:Stop valve

:Water pump

:Filter

:Solenoid valve

: Expansion tank

:Unidirectional

pressure relief valve

:Tap

:Air switch

:Hydraulic switch

3. Pipeline installation

Water pump

Water supply

Optional,water pump is already build-in

4.Electric installation

Electric wiring installation requirements:

1.Electric wiring should according to the local wiring rules.

2.Please use special power supply which the voltage accord with rated voltage.

3.The power supply must have earth wire and the earth resistance should less than 10Ω.

4.Must be construction by professional and technical personnel according to the wiring diagram.

5.Set up the leakage protection device according to the technical standard of electrical equipment.

6. The electric wire diameter as below:

Note:

1.The unit without power cord and plug, users should select the power line according to above

specifications table

2.Power cord should be connected with the corresponding terminals of the units.

3. List of wiring wire diameter and length can tell the situation which voltage drop in 2%

4.When the wire length exceeds the value in the table, please increase the wire diameter.

5. Selecting circulating pump wiring should according to the actual pump power then follow the

provisions of the national regulation.

6. Unit is connected to the line must be equipped with an all-pole disconnection device with

at least 3 mm2 contact distance。

1.5

1.5 1.5

L(mm2)

220V-240V/50Hz

1.5

1.5 1.5

2.5

2.5 2.5

4.0 4.0

2.5

N(mm2)PE(mm2)

8

Model

NERS-B1.0S-P

-B1.5S-P

-

-

B2.0S-P

B3.0S-P

NERS

NERS

NERS

Ⅴ Trial running /commissioning

1、Trial running must after all the installation is completed

2、Please confirm the following matters before the trial operation, put “√”in the boxes after

confirmation

● Unit is installed correctly ● Power supply meets unit's rated need

● Piping, wiring correct ● Unit air inlet/outlet well-ventilated

● Drain off water well ● Leakage protective device act effectively

● Pipe insulation is perfect ●Grounding wire connected correctly

3、After check and ensure correct, then start unit. If the control panel display nothing, that

power supply phase sequence must be reversed, in order to protect the compressor the

unit doesn't switch on. Please replacing the phase sequence and switch on again .Control

panel would display time, setting temperature and current temperature

4、Open unit's water inlet and outlet water valve when depth of Water tank's water is 30cm

higher than unit's inlet port to empty the pipe system, and then press ON/OFF button

switch on the unit, unit's trial running would check the following:

Operation panel 's function keys are normal or not;

4.1 The indicator is normal or not;

4.2 The whole circulating hot water system whether there is water leakage;

4.3 The condensed water discharge is normal or not;

4.4 Unit's gas system pressure is normal or not (according to the water temperature detect

high, low pressure);

4.5 whether there is abnormal sound and vibration in unit running state;

4.6 The wind, sound and condensed water from unit whether effect to neighborhood;

4.7 whether there is leakage of refrigerant。

Note: There is a delay protection in unit, ex: an immediate start or restart, unit would switch on

3 minutes delay in order to protect compressor

9

Ⅵ Display and operation of wired controller

1.Disply and instruction

2.Operation

10

Electric heater

Children lock function

Time off function

Time on function

Outlet water temperature

Setting state sunction

Serial number

Inlet water temperature

Temperature display

Reserve function

Power on / off function

Up function

Down function

Set function

Automatic mode

Cooling mode

Hot water mode

Clock function

Under main interface, press this button to turn on / off; under parameter / parameter setting

/ clock setting / time setting interface, press this button to return to the main interface.

2.1 Turn on / off

Power on state Power off state

1 2 3 4

5

6 11

10

8

12

13 14 1 5 16 17 18

OUT: Outlet water

temperature

IN: Inlet water

temperature

Press or on/off or no operation within 8S,

the data autosave and exit timer setting state.

Timer on has been set

11

Press for 5S, enter timer on setting Then press , minute blinking, press

“▲”or“▼”to set (00~59)

Hour blinking, presss “▲”or“▼”

to set(00~24)

Under main interface, press for 5s,enter time setting state, press “▲”or“▼” to set timer on, then press enter timer

off state, press “▲”or“▼” to set timer off. When finished setting, press to exit.

Note: It is noneffective when timer on and timer off both are 00:00

2.2 Timer setting

Timer off has been set

Then press , minute blinking, press

“▲”or“▼” to set (00~59)

Hour blinking, presss “▲”or“▼”

to set(00~24)

Press enter timer off setting state

Under main interface, press enter hour setting, then press ▲ or ▼ to set, when finish hour setting, press enter

minute setting, press ▲ or ▼ to set, when finish minute setting, press or no operation for 8S to exit.

12

2.3Clock setting

2.4 Lock and unlock

Under main interface, press “▲” or “▼”together for 3S, the buzzer rings “Didi”twice,

the button locked; Under main interface, press “▲” or “▼”together for 3S, the buzzer rings “Didi”twice, the button unlocked.

Press enter clock setting, hour

blinking, press ▲ or ▼ to set(00~24) Press again, minute blinking, press

▲ or ▼ to set(00~59) Press or or no operation within 8S,

data autosave and exit clock setting

press“ ▲ ”or“ ▼”together for 3S

to lock, displays press“ ▲ ”or“ ▼ ”together for 3S

to unlock, does not display

13

Under power off state, press “SET”

to set the temperature

Under power off state, press “SET” enter parameter setting interface. Parameter 0 represent pipe electric heating

setting temperature, parameter 01 represent heating setting temperature, press “▲”and“▼”to adjust the setting

temperature. Parameter 2 and 15 is system parameter, press “▲”and“▼”together for 10S, when hear of “B”, release

the button, then press “▲”or“▼”to adjust the parameter. When finished setting, press “SET” to save and switch to

other parameter. Under this interface, if no operation within 8S, save the current setting then exit parameter setting

state and return to main interface.

2.5 Water temperature and parameter setting / state parameter query

Temperature adjustment area blinkling,

press “▲”and“▼” to set (10~60℃)

Water temperature setting (parameter 0~1)

System parameter setting(parameter2~C)

Under power off state, press “SET”

to set the system parameter

Parameter setting area blinking,

press “▲”and“▼” together for 10S,

when hear of “B”, release the button,

then press “▲”or“▼”to adjust the

parameter.

State parameter query(parameter F~13)

Press “SET” enter temperature

query state, display parameter

F: Water temperature

Press “SET” and display

parameter F: Coil temperature

Press “SET" and display

parameter E: Compressor

outlet temperature

14

Press “SET”and display

parameter 11: Ambient

temperature

Press “SET”and display parameter 13:

Real time paces of EE valve

PP1~PP8 is sensor error EE1~EE8 is system error

2.6 Error code display

Input water temperature

sensor error

System high pressure

error

Press “SET”and display

parameter 10:Compressor

inlet temperature

Press “SET” then display parameter 12

: Output water temperature

15

2.7 System parameter setting sheet

0-28

10-90

1-2

Compressor outlet temperature

Compressor inlet temperature

-9~99℃

-9~99℃

-9~99℃

-9~99℃

10-50

2

2 Items marked with“*”are only available for models equipped with electronic expansion valve.

*

Coil temperature

*

*

*

System coil temperature point to start defrosting

System coil temperature point to stop defrosting

Real time paces of EE valve

5℃

55℃

40min

-5

15℃

6min

30℃

1-12min

0-1

0-1

0-1

-F-F

15-45

0-1

-9~99℃

-9~F9℃

autmatic

1

0

2

35

Water temperature

Ambient temperature

Output water temperature

Reserve

Water temp. differece setting for heat pump restart-up

Reserve

Reserve

16

Overheat discharge

gas temp.

Water flow failuve

Outlet water temp.

sensor failure

1.Tank sensor not connected

to PCB

2.Temp. sensor short circuit or

open circuit.

1.Check if fast connection of tank

sensor is done.

2. Check if temp. sensor in good

conditions,or replace related sensor.

Defrosting

2.8 Error code sheet

17

3. Wired controller installation

3.1 Accessory parts

Name

No Qty

1

2

3

4

Plastic box86x86mm

Wired controller box

Screw 4x25mm

Wired controller cover

1

1

1

1

3.2 Installation diagram

Maintenance:

1 The motor has been lubricate and sealed in advance before left the factory, therefore lubricate is not needed during maintenance。

2 Using a stiff nylon brush to clean the evaporator wings. Before scrub, clean it with vacuum cleaner. If there is compressed air, you

can use high pressure air to clean the condenser or evaporator.

3 Periodic inspecting if the air inlet or outlet is stopped up。

4 Pay close attention to the outlet, inlet/ suction pressure of the system. If there is any abnormity, find out the reason and clearing the

fault.. If you can not determine the reason, get in touch with the technician.

5 Control and protect the equipment, do not adjust the factory setting freely。

6 Periodic inspecting the electrical connections and regularly monitored the operating voltage, operating current and phase balance.

Timely to check the reliability of the electrical components, replace the expired and unreliable parts timely.

7 Air source heat pump water heater uses patent heat exchanger and the outlet water temperature is high. After long time operation,

the heat transfer surface of the water side heat exchanger will be deposited calcium oxide or any other minerals.

If these minerals fouling too much on the heat transfer surface, it will effect heat transfer performance which could lead to power

consumption increase, compressor outlet pressure too high or inlet pressure too low.

So regular contaminant separation is necessary (Please use formic acid, citric acid, acetic acid and other organic acid to clean, any

cleaning agents contains chloral acid or fluoride is strictly forbidden).

System maintenance:

Whether need to refill the refrigerant depend on the value of inlet/suction pressure. The air tight test should be done in case of leakage

or replacements of the components of the gas/refrigerant circulate system. In accordance with the following two situations when refill

the refrigerant:

:1 The refrigerant leak completely

If this happens, you must use 30Kgf/cm2r high pressure nitrogen or refrigerant to do leak detection. Before repair welding, the gas

in the system must be drained. Before refill the refrigerant, the system must be thoroughly dried and vacuum.

a、Connecting the vacuuming pipe to the refrigerant injection needle valve of low pressure side. Using vacuum pump to vacuumize the

system for more than 15 minutes. Then confirm if the vacuum gauge shows at -1.0×105Pa(-76cmHg).

b、After achieving the required vacuum effect, filling the refrigerant to the system with refrigerant bottle. On the nameplate and main

technical parameters we have marked the suitable refrigerant. Make sure to fill the refrigerant at the low pressure side of the system

c、The refilling refrigerant quantity subject to the ambient temperature. If you do not meet the required filling quantity and can not filling

longer, you can turn on the machine, then starting filling continuously from low pressure side, in the meantime must prevent damage

from liquid refrigerant

2 Refill the refrigerant

Connecting the refrigerant filling bottle at the refrigerant injection needle valve of low pressure side and also connecting the pressure

gauge at the low pressure side at the meantime. Then turn on the machine, filling the refrigerant into the system slowly and inspect

the low pressure gauge.

Warning: When doing leakage hunting and air tight test, only high pressure nitrogen and refrigerant is allowed to use, filling oxygen,

acetylene or other flammable or toxic gases is strictly forbidden.

18

Ⅶ Maintenance

Fault phenomenon Fault reason Inspection plan Failt clearance

The machine doesn't work, fail to turn

on the machine though there is display

on operation panel, keyboard out of

work

1,Operation panel circuit were not connected well.

2,Operation panel was damaged

3,Interruption

4, Low voltage

1,Check the circuit connection

2,Substitution method

3,Check the source of interruption, check if the

circuit was longthened by non-shield cable

4, Check the circuit voltage

5, Substitution method

1,Connect the circuit well

2,Change an operation panel

3,Avoid interruption, change the circuit with shield

cable.。

4,Improve the circuit or add a voltage stabilizer

5,Change a CPU board

No display on operation panel and

the machine is out of work

1, The power transformer was damaged

2,The circuit on operation board was

1,Measure with a multimeter

2,Check the circuit

3,Substitution method

4,Substitution method

5,Check the source of interruption, check if

the circuit was longthened by non-shield cable

1,Chagne a power transformer

2,Iron welding

3,Change a operation panel

4, Change a CUP board

5, Avoid interruption, change the circuit with

shield cable.

Fans don't work, no power input

for fans

1,Power cut

2,Circuit breaker

3,CPU damaged (no output)

4, The power transformer was

1, Measure the circuit voltage

2, Measure the circuit

3, Measure the output voltage

4, Measure the winding, measure the output voltage

1, Wait for power supply

2, Connect the circuit

3, Change a CPU

4, Change a transformer

Fans don't work,capacitor was

damaged

1 Capacity going down

2 Open circuit

1, Check the capacity of the capacitor

2, Measure with a multimeter

3, Measure with a multimeter

1, Change a capacitor

2, Change a capacitor

3, Change a capacitor

Fans don't' work, motor is damaged

1, Motor winding breaker

2, Motor winding short circuit

3, Motor winding grounding

Measure the winding Change a motor

Compressor doesn't work, no power

for compressor terminal (No voltage

output for CPU)

1, The machine is not turned on

2, Set temperature is lower than water temperature

3, CPU is damaged

4, Power transformer was damaged'

5, Power cut

1, Check the operation panel

2, Check the set temperature

3, substitution method

4, substitution method

5, Measure the circuit voltage

1, Turn on the machine

2, Reset

3, Change a CPU

4, Change a power transformer

5, Wait for power supply

Compressor doesn’t work,

outlay thermal relay broken

1,Capacitor is damaged

2,Out lay protector of overloading extraposition

is damaged.

1, Check the capacity of capacitor

2, Measuring the value of protector resistance

1, Change a capacitor

2, Change a overloading protecto

Compressor doesn’t work,

built-in thermal relay broken

1,Short of cryogen

2,Low voltage

3,Blockage piston of compressor

4,Compressor is Short of oil with big noise and

high temperatur

1, Measure the voltage, current, water temperature

parameter

2, Measure the voltage

3, Measure the pressure, current, water temperature

parameter

4, Hear the noise, measure the compressor

temperature

1, Fill in cryogen

2, Improve the circuit or add a voltage stabilizer

3, Make shunt capacitance, fill in refrigeration oil

4, Fill in refrigeration oil

No defrost or bad defrost effect

1, Fault of defrost temperature Sensor

2, Loose of defrost temperature Sensor

3, No defrost on defrost temperature Sensor position

4, Defrost inspection time is too long

5, Defrosting setting is not approperate

6, Four-way valve doesn't work or damaged four-way

valve coil

8, four-way valve Gas leakage

9, CPU is damaged

1, Check if the connection of defrost temperature

sensor is correct

2, Check if the connection of defrost temperature

sensor is correct

3, Visual inspection

4, Check the defrosting inspection time

5, Defrosting Temperature point was set too high

6, Check the winding

7, Knock the four-way valve

8, Feel the temperature of the four-way valve,

measure parameters like current and voltage etc

9, Force the defrosting work and check if there is

power output on CPU

1, Change a sensor

2, Change a sensor

3, Adjust the assembling position

4, Reset the time

5, Adjust the temperature value

6, Change a coil

7, Change a four-way valve

8, Change a four-way valve

9, Change a CPU

19

This manual suits for next models

3

Table of contents

Other NEW ENERGY Heat Pump manuals

Popular Heat Pump manuals by other brands

Fisher

Fisher FHOF-WHS-100CE3 Service manual

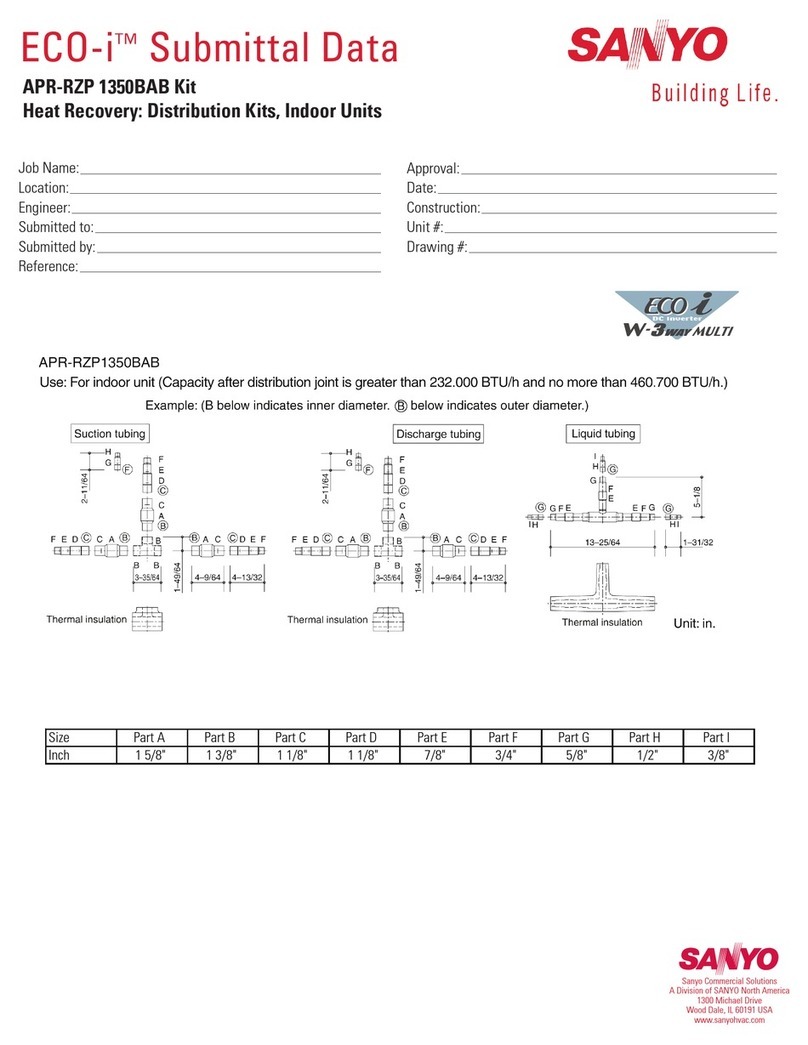

Sanyo

Sanyo ECO-i APR-RZP 1350BAB Kit datasheet

Panasonic

Panasonic WH-SDC07C3E5 Service manual

AIC

AIC DYNAMIS MAX 450 Installation and maintenance manual

Toshiba

Toshiba HWS-P804HR-E1 installation manual

Ideal Heating

Ideal Heating ECOMOD AHP60 50 kW Installation and servicing