01.07.2022 3 / 78

AHP60-50/70 - Installation, Use and Maintenance

CONTENTS

1.

REGULATIONS, RECOMMENDATIONS AND WARNINGS..............................................................5

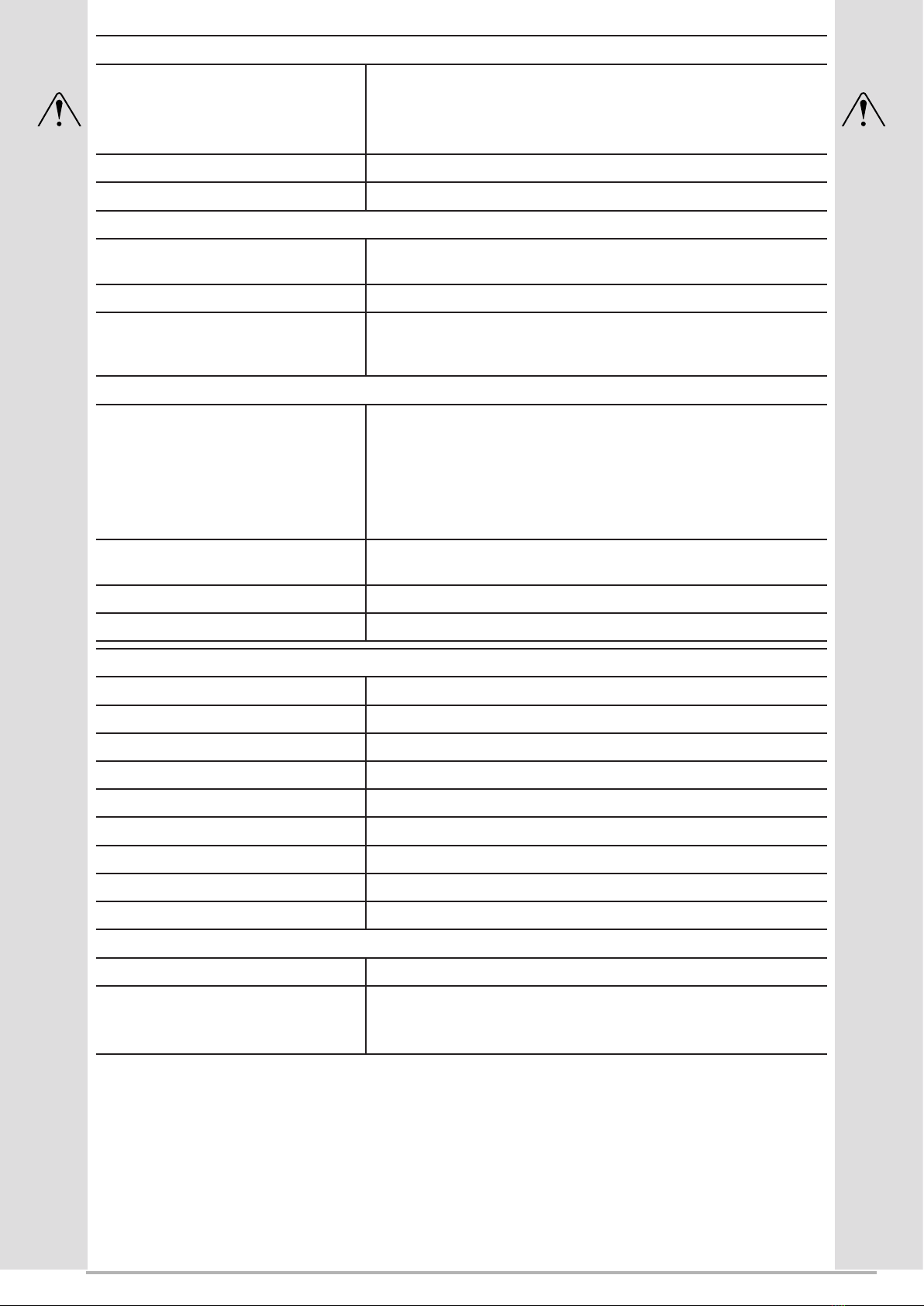

1.1. Applicable regulations and standards ........................................................................................................... 5

1.2. Recommendations and warnings................................................................................................................. 5

2. DESCRIPTION OF THE EQUIPMENT ..............................................................................15

2.1. Designations and scope.............................................................................................................................. 15

2.2. Packaging ................................................................................................................................................... 15

2.3.Denitions ................................................................................................................................................... 15

2.4. Technical data ............................................................................................................................................. 16

2.5. Description .................................................................................................................................................. 20

2.6. Operating principle ...................................................................................................................................... 22

3. INSTALLATION ...................................................................................................................24

3.1. Lifting and handling ..................................................................................................................................... 24

3.2. Installation ................................................................................................................................................... 25

3.3. Installing the outdoor unit ............................................................................................................................ 25

3.4. Installing the control unit ............................................................................................................................. 32

3.5. Position of the centre of gravity and the vibration shock absorbers............................................................ 32

3.6. Hydraulic connections ................................................................................................................................. 33

3.7. Electrical connections ................................................................................................................................. 39

4. PRE-REQUISITES BEFORE COMMISSIONING .............................................................44

4.1.Vericationbeforeswitchingon................................................................................................................... 44

4.2. Switching On ............................................................................................................................................... 45

4.3. Commissioning ........................................................................................................................................... 45

4.4.Primaryloopowrate/cascadebalanceadjustment................................................................................... 45

4.5. Operating

diagram .......................................................................................................................................46

4.6. ECOMOD user interface navigation............................................................................................................ 48

5. CONTROL INTERFACE .....................................................................................................49

5.1. User interface.............................................................................................................................................. 49

5.2. “SET” setpoint menu (For manual operation only) ................................................................50

5.3. Sensor menu [TP] ....................................................................................................................................... 51

5.4. Error menu [Err] .......................................................................................................................................... 51

5.5. Operating hours menu [OHR] ..................................................................................................................... 51

5.6. Parameter menu [Par]................................................................................................................................. 51

6. TROUBLESHOOTING .......................................................................................................52

6.1. Troubleshooting of failures without error code ............................................................................................ 52

6.2. Error codes and diagnostic assistance ....................................................................................................... 52

6.3. Inverter board errors ................................................................................................................................... 59

6.4. Ohmic values of the various sensors .......................................................................................................... 61

7. MAINTENANCE OF THE OUTDOOR UNIT......................................................................62

7.1. Drainage of the outdoor unit on the water side ........................................................................................... 62

7.2. Filling the outdoor unit................................................................................................................................. 62

7.3. Prolonged shutdown ................................................................................................................................... 62

7.4. Periodic checks ........................................................................................................................................... 62