New Home 1712S User manual

AAASewing.com

New Home

1712S & 1718S

Instruction Manual

NH1712S/1718S

New Home Instruction Manual

www.aaasewing.com

NH1712S & 1718S Owners Manual/ User Guide

AAASewing.com

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the

followings:

Read all instructions before using this appliance.

DANGER— To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug this sewing machine from the

electric outlet immediately after using and before cleaning.

2. Always unplug before replacing a sewing machine bulb. Replace bulb with same type rated 15 Watts.

WARNING—To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or near

children.

2. Use this appliance only for its intended use as described in this owner’s manual.

Use only attachments recommended by the manufacturer as contained in this owner’s manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water.

Return this sewing machine to the nearest authorized dealers or service center for examination, repair, electrical

or mechanical adjustment.

4. Never operate the appliance with any air opening blocked. Keep ventilation openings of this sewing machine and

foot controller free from accumulation of lint, dust and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

8. To disconnect, turn all controls to the off (“O”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch this sewing machine off (“O”) when making any adjustment in the needle area, such as threading the

needle, changing the needle, threading the bobbin or changing the presser foot, and the like.

15. Always unplug this sewing machine from the electrical outlet when removing covers, lubricating, or when making

any other adjustments mentioned in this owner’s manual.

SAVE THESE INSTRUCTIONS

New Home Instruction Manual

www.aaasewing.com

NH1712S & 1718S Owners Manual/ User Guide

AAASewing.com

SECTION 1. ESSENTIAL PARTS ..................2

Name of Parts ........................................................2

SECTION 2. GETTING READYTO SEW.......3

Extension Table......................................................3

Accessories Storage Box .......................................3

Standard Accessories ............................................4

Connecting the Machine to the Power Supply .......5

Presser Foot Lifter..................................................6

To Attach and Remove the Presser Foot ...............6

Changing Needle ...................................................7

To check the needle ...............................................7

Selecting needle and fabric....................................7

Setting Spool Pins..................................................8

Removing or Inserting the Bobbin Case ................8

Winding the Bobbin ................................................9

Threading Bobbin Case .........................................9

Threading the Machine ........................................10

Needle Threader .................................................. 11

Drawing Up Bobbin Thread.................................. 11

Balancing Needle Thread Tension .......................12

Adjusting Bobbin Thread Tension ........................12

Pattern Selector Dial ............................................13

Stitch Length Control............................................13

Stitch Width Control .............................................13

Reverse Stitch Button ..........................................14

Dropping the Feed Dog........................................14

SECTION 3. BASIC SEWING ......................15

Straight Stitch Sewing ..........................................15

To Change Sewing Direction................................15

Using the Seam Guides on the Needle Plate.......16

Turning Square Corners.......................................16

Variable Needle Position ......................................16

Zigzag Stitching....................................................17

SECTION 4. UTILITY STITCHING ............... 17

Overcasting .......................................................... 17

Tricot Stitch .......................................................... 18

Knit Stitch ............................................................. 18

Straight Stretch Stitch .......................................... 19

Sewing on Buttons ............................................... 20

Buttonhole ....................................................... 21-22

Corded Buttonhole ............................................... 23

Zipper Application................................................. 24

Blind Stitch Hemming........................................... 25

SECTION 5. DECORATIVE STITCHING ..... 26

Shell Tuck............................................................. 26

Stretch Stitch Patterns ......................................... 26

Smocking ............................................................. 27

Box Stitching (NH1718S exclusive)...................... 27

Applique ............................................................... 28

Decorative Satin Stitch Pattern

(NH1718S exclusive)............................................ 28

SECTION 6. CARE OFYOUR MACHINE.... 29

Dismantling and Assembling................................ 29

Hook Race Unit .................................................... 29

Cleaning the Feed Dog ........................................ 29

Sewing Light......................................................... 30

Troubleshooting ................................................... 31

TABLE OF CONTENTS

New Home Instruction Manual

www.aaasewing.com

NH1712S & 1718S Owners Manual/ User Guide

AAASewing.com

2

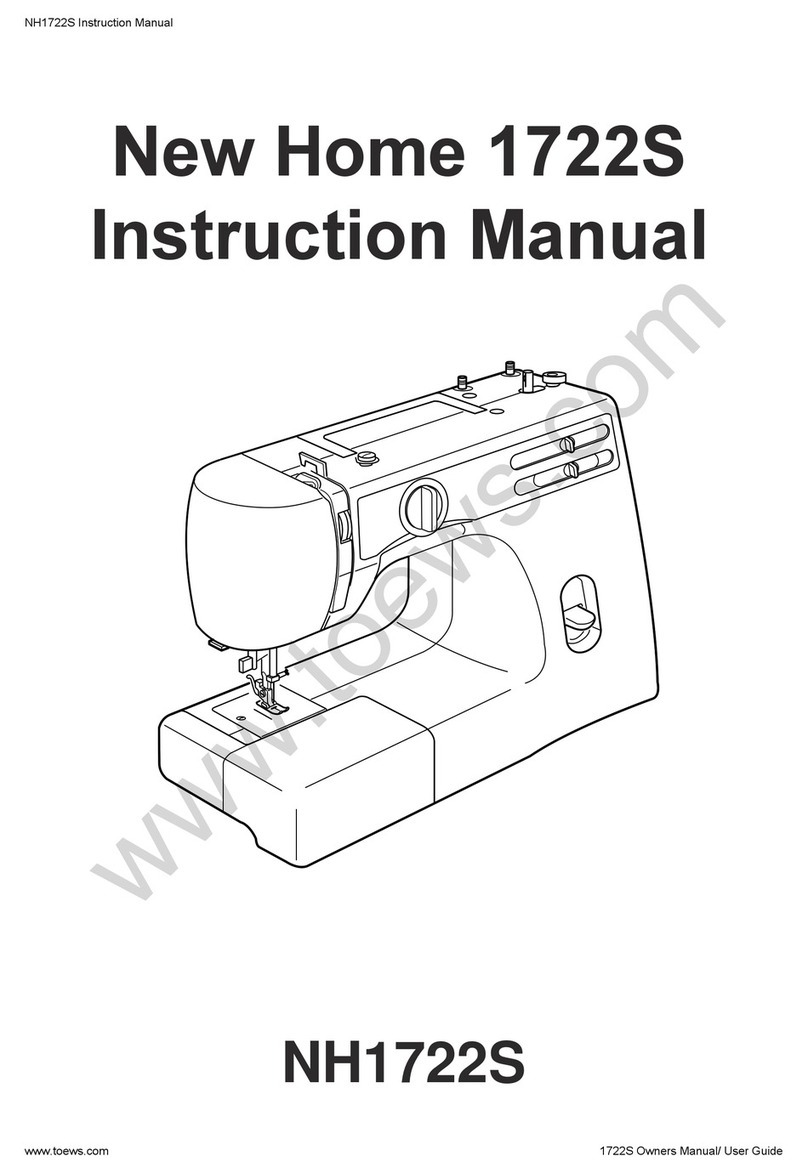

qReverse stitch button

wPattern selector dial

eStitch width control

rStitch length control

tBobbin winder stopper

yBobbin winder spindle

uSpool pins

iBobbin winder thread guide

oThread guide

!0 Thread take-up lever

!1 Thread tension dial

!2 Face plate

!3 Thread cutter

!4 Needle threader (Model NH1718S exclusive)

!5 Needle plate

!6 Presser foot holder

!7 Needle clamp

!8 Needle

!9 Presser foot

@0 Extension table

@1 Carrying handle

@2 Handwheel

@3 Power switch

@4 Machine socket

@5 Free arm

@6 Buttonhole lever

@7 Presser foot lifter

SECTION 1. ESSENTIAL PARTS

Name of Parts

1

2

3

4

5

6

78

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

New Home Instruction Manual

www.aaasewing.com

NH1712S & 1718S Owners Manual/ User Guide

AAASewing.com

3

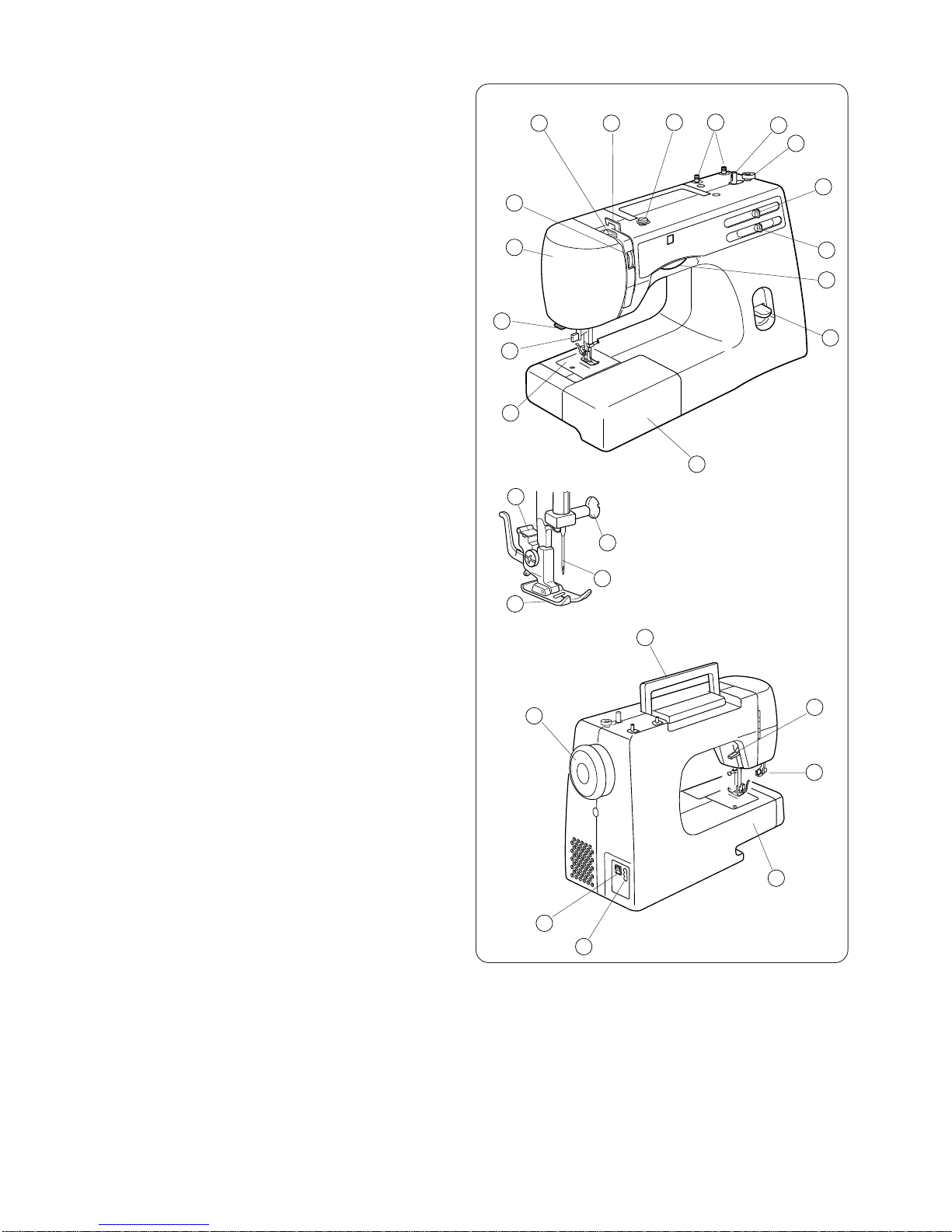

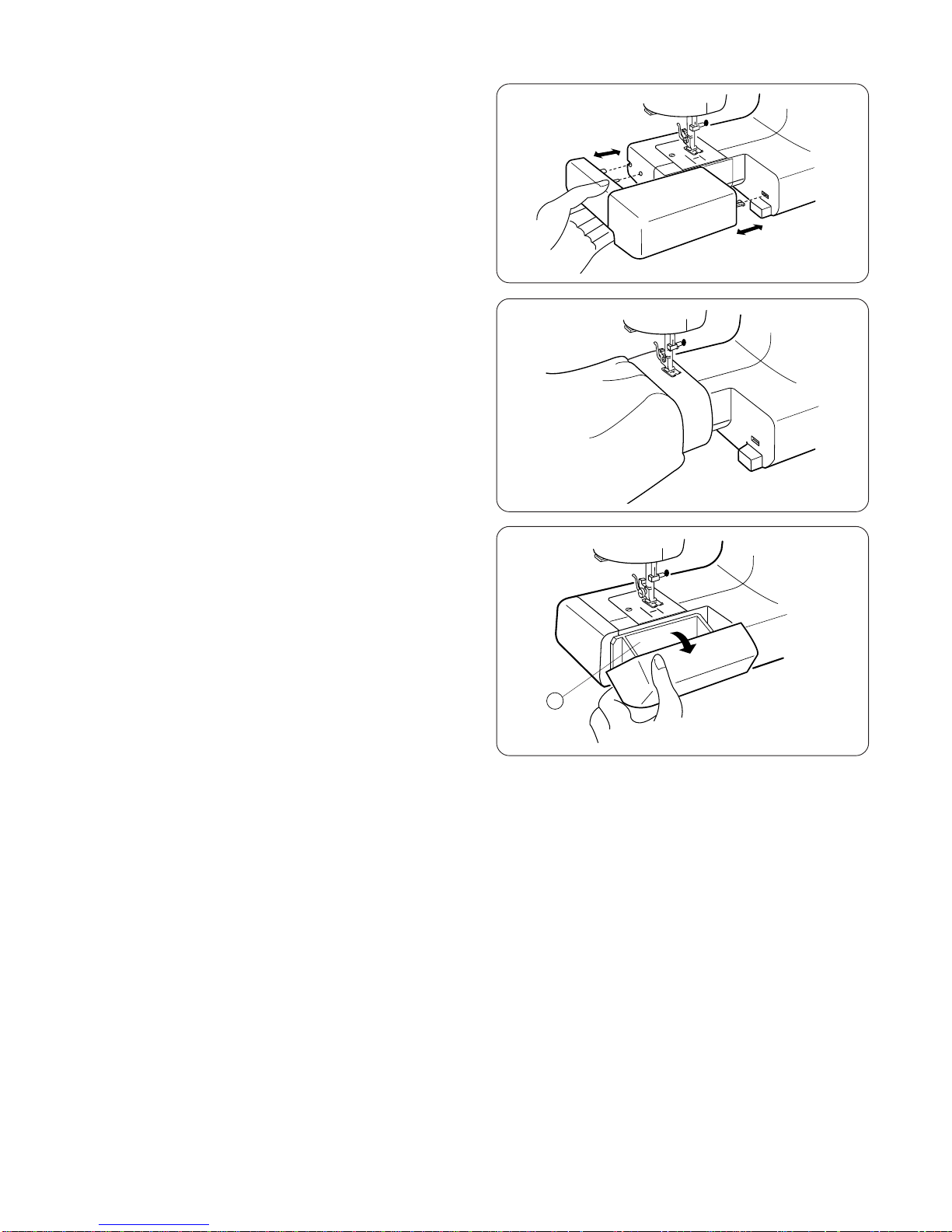

Extension Table

The extension table provides added sewing surface

and can be easily removed for free arm sewing.

Detaching the table:

Pull the table away from the machine.

Attaching the table:

Push the extension table until it snaps into the

machine.

•Advantages and uses of free arm

—Avoid fabric bunching around the needle when bartacking

to reinforce pockets, plackets and waistlines.

— For stitching sleeves, waistbands, pant legs or any

circular garment area

—For darning socks or mending knees, elbows or areas of

wear in children's clothes

SECTION 2. GETTING READY TO SEW

Accessories Storage Box

Sewing accessories are conveniently located in the extension

table.

qAccessories storage box

1

New Home Instruction Manual

www.aaasewing.com

NH1712S & 1718S Owners Manual/ User Guide

This manual suits for next models

1

Table of contents

Other New Home Sewing Machine manuals