Neways Electric MMT01 User manual

Mid-

mounted motor user manual

1

mounted motor user manual

mounted motor user manual

2

Catalogue

1. About the user manual………………………………………………………… 1

2. Motor parameters……………………………………………………………… 2

3. Drive Unit Structure and Dimensions ………………………………………… 4

4. Vehicle schematic diagram………………………………………………… 5

5. List of installation tools…………………………………………………………6

6. Install the meter………………………………………………………………… 7

7. Install auxiliary switch……………………………………………………………8

8. Install speed sensor………………………………………………………………9

9. Install the drive unit………………………………………………………………11

10. System wiring……………………………………………………………………13

11. Install the front chainring………………………………………………………15

12. Install the full-inclusive chain guard……………………………………………15

13. Install half-wrapped chain guard………………………………………………17

14. Install the crank…………………………………………………………………18

15. Change lubricating oil operation…………………………………………………18

16. Overview of instrument functions………………………………………………20

17. Overview of instrument settings……………………………………………… 22

18. The error code of the instrument corresponds to the fault definition…………24

19. Bill of materials………………………………………………………………… 24

1

About User’s Manual

When installing this product, be sure to follow the instructions given in the user's

manual.

Dear users, in order to better assemble the MMT01 mid-mounted motor, please read

the MMTO1 mid-mounted motor operation manual carefully before assembling. We

will tell you every aspect of motor installation in the most concise language to

facilitate your normal use. At the same time, it helps you to solve the confusion and

obstacles that may arise.

2

Motor Parameters

Voltage (DCV) 36V 48V

Rated Power (W) 250W 350W 350W 500W

Rated Voltage

(%)

≧80%

Wheel Size (inch) 20-28

Rated Rotating

Speed

(KM/H)

350W 500W

30±1 35±1

Maximum

Efficiency (Nm)

350W 500W

≧110 ≧130

Chain Wheel 38T(Optional) 42T(Optional) 44T (optional)

Optional Chain

Cover

Half-wrapped chain cover/Full chain cover

Lubricating

Oil

GL-4 75W/90Vehicle gear oil

Weight(KG) 4.6KG

Built-in Sensor Speed assist, torque assist and wheel speed measurement

Noisy (dB) <50

Working

Environment

-30°C-45°C

Dust-proof/ IP66

3

water-proof

grade

Other functions DC6V/100mAFront and rear light modules, programming

function, variable speed sensor module

Drive Unit Structure and Dimensions

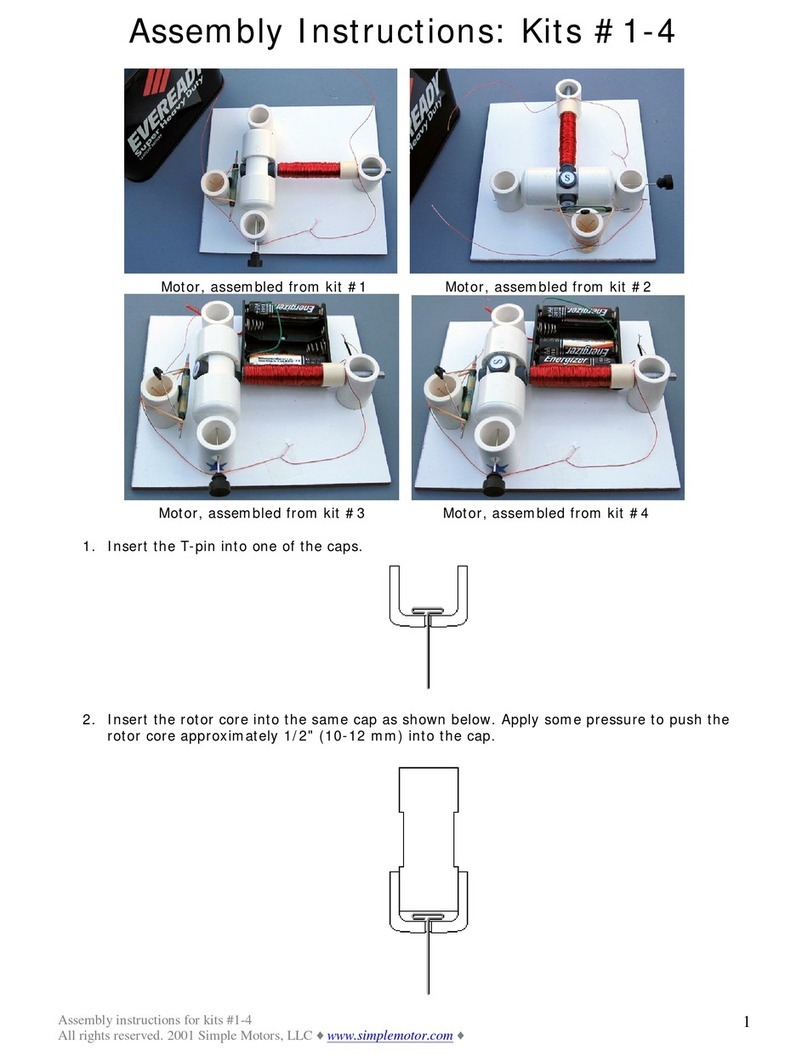

Vehicle schematic diagram

4

Vehicle schematic diagram

5

A. Drive unit B. Front chain wheel

C.External RPM detecting sensor

D. Display E. Auxiliary keypad

6

List of installation tools

Component utilized location tool

Instrument Fixing screwM4

Allen wrench

Drive

components

Install crankset fixing Bicycle bottom bracket

Chain cover fixing screw

Phillips screwdriver

Connecting the frame and

the drive assembly fixing

Allen wrench

Crank mounting screwM8

Allen wrench

Speed sensor

Magnet installation

Slotted screwdriver

Screw to fix the sensorM5

Allen wrench

Install the meter

According to the diameter

of the tube, the choice is

whether you need a rubber

clamp ring and model

(Applicable to handle

specifications: φ22.2, φ

23.4, φ25.4, Φ31.5),

after the bracket and the

instrument are installed,

the rubber clamp ring is

inserted into the bracket as

shown in the figure position

of the wrist so that the

bracket aligns the notch of

the wrist with the notch of

the rubber clamp ring.

Turn the auxiliary switch on

the wrist and put it on the

handlebar for proper

operation. Adjust the angle

of the auxiliary switch to

make the switch easier to

see and operate when

riding. (Suitable for

handlebars with an outer

diameter of Φ22.2mm.

Use an Allen wrench to fix

and tighten the handlebar

fixing screws in the

direction shown in the

figure.

Locking torque: 1N.m

7

A Rubber clamp ring

model (225,254)

Outer diameter

22.2Choose the

rubber clamp ring

model of the tube:

Left clamp ring

Right clamp

Outer diameter

25.4Choose the

rubber clamp ring

model of the tube:

Left clamp ring

Right clamp

B:

Bracket wrist

C:

Hexagon socket

head screw

A Rubber clamp ring

model (225,254)

Outer diameter

φ

22.2Choose the

rubber clamp ring

model of the tube:

Left clamp ring

-225

Right clamp

-225

Outer diameter

φ

25.4Choose the

rubber clamp ring

model of the tube:

Left clamp ring

-254

Right clamp

-254.

Bracket wrist

Hexagon socket

head screw

M4*6

Turn the auxiliary switch on

the wrist and put it on the

handlebar for proper

operation. Adjust the angle

of the auxiliary switch to

make the switch easier to

see and operate when

riding. (Suitable for

handlebars with an outer

diameter of Φ22.2mm.

Use an Allen wrench to fix

and tighten the handlebar

fixing screws in the

direction shown in the

figure.

Locking torque: 1N.m

Install auxiliary switch

Turn the auxiliary switch on

the wrist and put it on the

handlebar for proper

operation. Adjust the angle of

the auxiliary switch to make

the switch easier to see and

operate when riding.

( Suitable for outer diameter

Φ 22.2mm The handle)

8

tool

Install auxiliary switch

Turn the auxiliary switch on

the wrist and put it on the

handlebar for proper

operation. Adjust the angle of

the auxiliary switch to make

the switch easier to see and

( Suitable for outer diameter

D Switch wrist

EHandlebar

diameter

D Switch wrist

EHandlebar

diameter

φ22.2

Use an Allen wrench to fix and

tighten the handlebar fixing

screws in the direction shown

in the figure.

Locking torque:1N.m

Connect the instrument

connector and the client

connector according to the

markings.

Install speed sensor

Before installing the

speed sensor, please

check to make sure

that the gap between

the speed sensor and

the magnet assembly

is 5 To 25mm Inside.

9

Use an Allen wrench to fix and

tighten the handlebar fixing

screws in the direction shown

F: Hexagon

socket head

screwM4*10

tool

Connect the instrument

connector and the client

connector according to the

Connectors in

accordance with

customer

requirements

Install speed sensor

A.

speed sensor

B.

Magnet

assembly

C.

Spokes

D.

Rear fork

F: Hexagon

socket head

screwM4*10

tool

Connectors in

accordance with

customer

requirements

speed sensor

Magnet

assembly

Spokes

Rear fork

10

If the gap is within the

specified range, fix

the speed sensor with

the speed sensor

fixing bolt.

If the gap will exceed

25mm, please use a

spacer between the

sensor and the rear

fork boss to adjust.

Locking torque:1.5-2

N.m

A. Dust cover

B. Sensor fixing

screw M5*12

C. speed sensor

tool

Arrange the speed sensor

and magnet as shown in

the picture, and snap the

magnet onto the spokes.

A. speed sensor

B. Magnet bolt

C. Spokes

Arrange the speed

sensor and magnet as

shown in the figure so

that their centers are

aligned with the center

of the sensor's sensing

area.

Tightening torque

1.5Nm

D. Magnet nut

tool

11

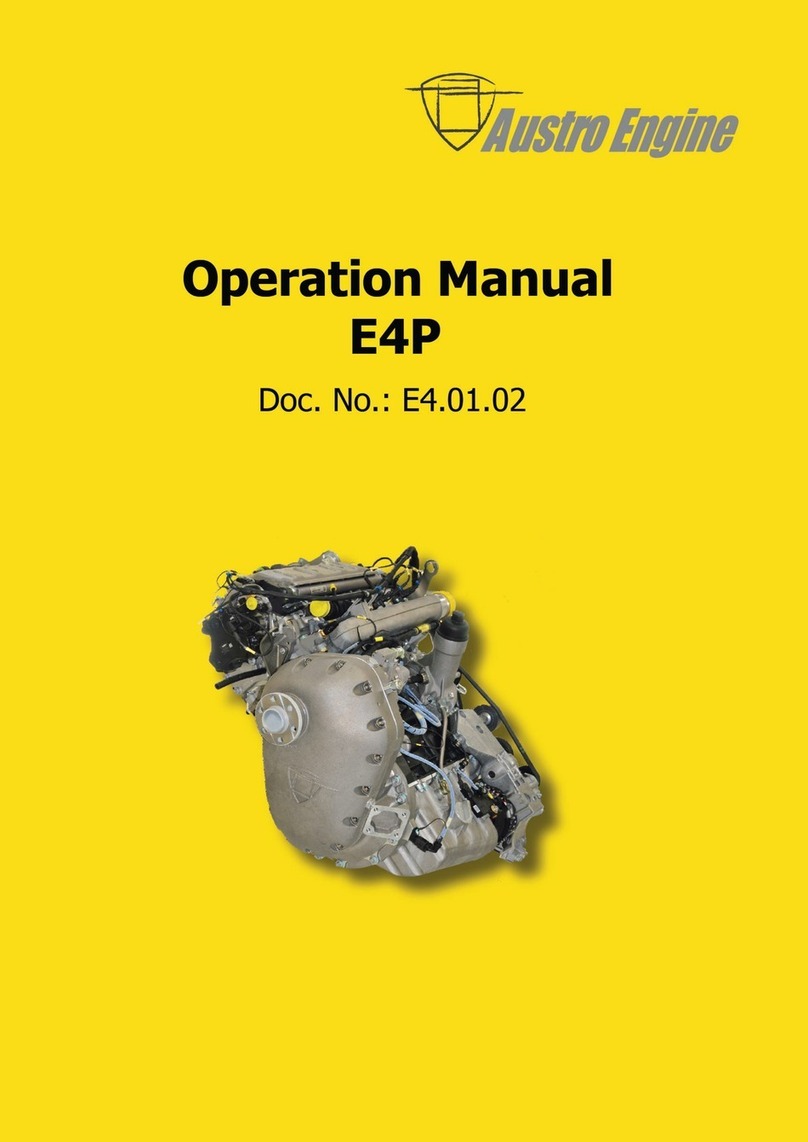

Install the drive unit

Before installing the

drive unit, it needs to

be wired in advance

according to different

models and wiring

structures.

A. Power cable

B. Rear light cable

C. Speed sensor

cable

D. Headlight cable

E. Assembly cable

Align the three

mounting holes in the

drive unit with the

mounting holes in the

frame.

Note: Pay attention

to the corresponding

position of the cable

when aligning the

holes, and note that

the cable cannot be

squeezed by the drive

unit.

A. Mounting hole

B. Drive unit

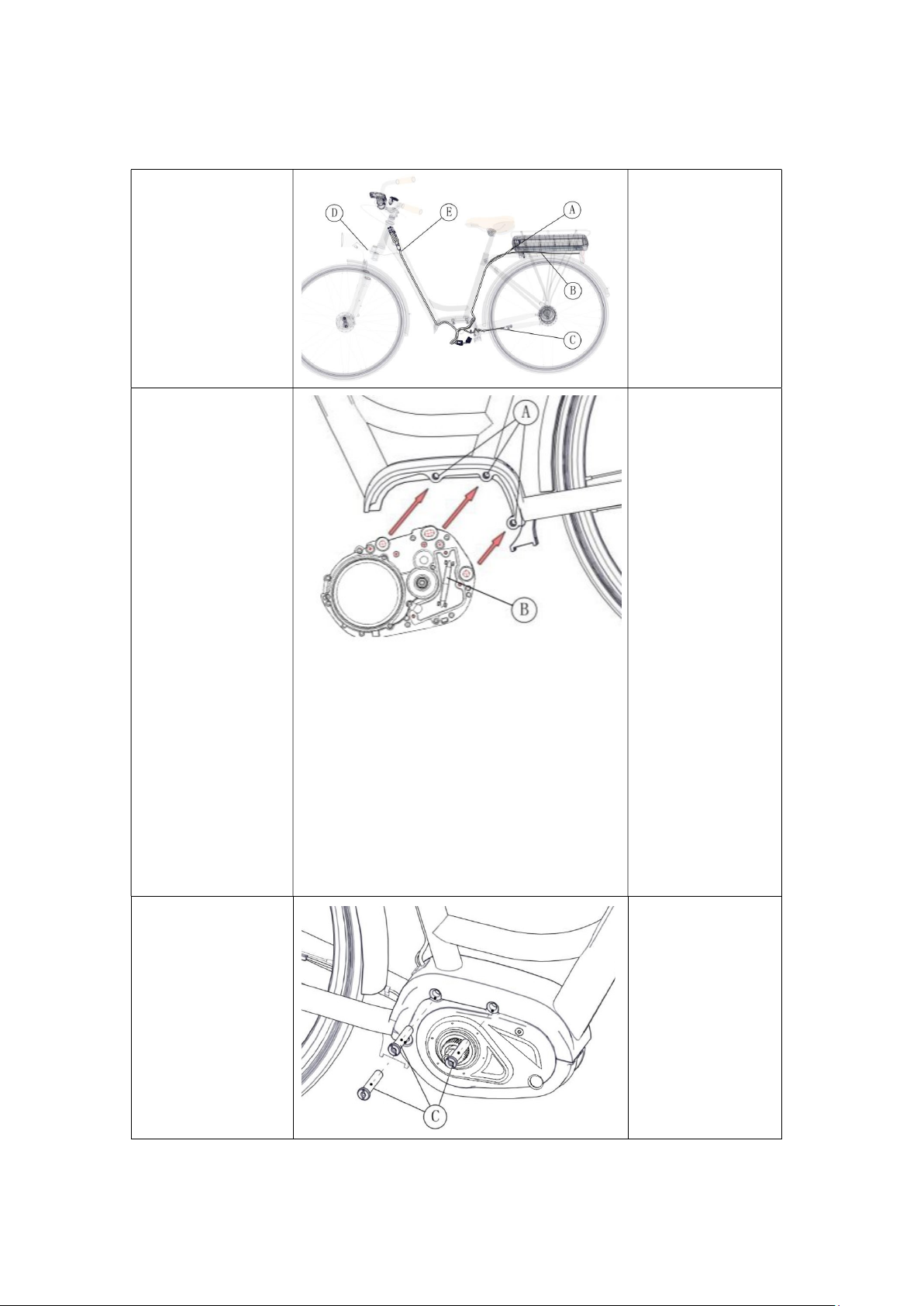

Will M6 Insert the

special nut into the

frame and drive unit

hole from the right

C. M6Long nut

12

Make M6A special

boltinsert into the

frame from the left

side and fixed with

a nut and

tightened to the

specified

The torque.

Locking torque:

18- 20 N.m

D. M6Bolt

tool

Connect the cable

connectors of the

drive unit to the

connectors of other

components

respectively, and fix

the cables at the

designated positions

with cable ties.

E. Tie

Install the housing of

the drive assembly to

the drive unit.

Locking force

1.5Nm

F. M4*8Screw

tool

Use screws to

lock the bottom

of the housing

and the bottom

of the drive unit

body, as shown

in the figure.

If you consider

arrange the brake

cable or shift cable

at the bottom of the

unit body, lock

the C pressure line

plate together.

Locking force1.5Nm

System wiring

power cable

Connect the positive and

negative connectors of the

power cord to the positive and

negative connectors of the

power supply on the

controller end of the drive unit

(2Core)

Speed sensor line

13

A.Motor housing

screw hole

B.Screw hole for

motor right cover

C.Crimping board

D.M4*8Screw

tool

Connect the positive and

negative connectors of the

power cord to the positive and

negative connectors of the

power supply on the

controller end of the drive unit

a.

Power cord positive and

negative

terminals

Connector

A.Driver unit power cord

female end connector

A.Motor housing

screw hole

B.Screw hole for

motor right cover

C.Crimping board

D.M4*8Screw

Power cord positive and

terminals

A.Driver unit power cord

female end connector

Connect the connector of the

speed sensor unit to the

controller speed sensor

connector of the drive unit

(3Core)

Assembly line

Connect the assembly line

connector to the connector at

the end of the drive unit

(10Core)

Front light wire

Connect

the connector of the

front light wire to the front

light wire connector (2Core)

Rear light wire

Connect the connector of the

rear light cord to the rear light

cord connector of the

drive

unit (2Core)

Variable speed sensor line

Connect the connector of the

variable speed sensor to the

connector of the variable

speed sensor port of the drive

unit (3core)

14

Connect the connector of the

speed sensor unit to the

controller speed sensor

connector of the drive unit

b.

Drive unit speed sensor

male connector

B.Speed

sensor female

connector

Connect the assembly line

connector to the connector at

the end of the drive unit

c

.Drive component end

assembly line female end

connector

C.Assembly line male end

connector

the connector of the

front light wire to the front

d.Drive unit female

connector

D.Headlight cable male end

connector

Connect the connector of the

rear light cord to the rear light

drive

e.Drive unit male connector

E

.Rear light wire female end

connector

Connect the connector of the

variable speed sensor to the

connector of the variable

speed sensor port of the drive

f.Drive

unit female connector

F.Variable speed sensor male

connector

Drive unit speed sensor

male connector

sensor female

.Drive component end

assembly line female end

C.Assembly line male end

d.Drive unit female

D.Headlight cable male end

e.Drive unit male connector

.Rear light wire female end

unit female connector

F.Variable speed sensor male

15

Install the front chain ring

Insert the front gear piece into

the spline shaft in the drive

assembly along the spline

direction, and use a tool

(bicycle bottom shaft spline

sleeve) to lock the locking bolt

counterclockwise.

Locking force

30—35N.m

A. Front sprocket

B. Locking bolt (M24*1)

Install the full-inclusive chain guard

This kind of full-wrapped

chain cover needs to be

used with the chain

cover pressure plate and

screws as shown in the

figure to be fixed with

the drive assembly.

16

Open this kind of

all-inclusive chain

cover according to the

product manual and

adjust it to the proper

position so that the

inner side of the chain

cover is close to the

convex surface of the

outer side of the drive

unit. Then use screws

to press the pressure

plate against the inner

wall of the chain cover

and lock the screws.

Locking force:2N.m

A.Full chain

cover

B.Full-inclu

sive chain

cover

tablet

C.M4Phillip

s screw

tool

Install the sprocket

according to the

installation method of

the sprocket.

After installing the gears,

follow the chain cover

product instructions to

assemble the chain

cover completely.

Install half-

wrapped chain guard

Adjust the attachment angle

of the half-

pack chain cover,

and lock the half-

pack chain

cover removal and

attachment with the locking

part of the drive unit with

screws.

Locking force:2N.m

Install the sprocket in

place

according to the installation

method of the sprocket.

Fasten the half-

pack chain

cover with the half-

pack chain

cover bracket with screws.

Locking force 2 N.m

17

wrapped chain guard

Adjust the attachment angle

pack chain cover,

pack chain

cover removal and

attachment with the locking

part of the drive unit with

place

according to the installation

pack chain

pack chain

A. Half-wrappe

d chain cover

mounting

bracket

B. M4Phillips

screw

tool

D.M4Phillips

screw

E.Half-wrapped

chain cover

tool

Install the crank

Mount

the right crank on

the right bottom bracket,

And use one M8 hexagon

socket screws to lock, install

the left crank in the same

way.

Locking force 35-40N.m

Change gear oil operation

Drain oil

Place the right side of

the drive unit up and

horizontally, and

open the oil filling

hole bolt and the oil

drain hole bolt

respectively.

18

the right crank on

the right bottom bracket,

And use one M8 hexagon

socket screws to lock, install

the left crank in the same

Change gear oil operation

A.Right crank

B.Crank

mounting

screwM8

tool

A. Filling hole

B. Oil drain hole

C. Grease hole

bolt

D. Oil drain bolt

tool

Table of contents

Popular Engine manuals by other brands

Parker

Parker ETH Series Mounting instructions

MTU

MTU 12V2000M84 operating instructions

Nice

Nice Era Star P Series Instructions and warnings for installation and use

MTU

MTU 20 V 4000 M93 operating instructions

King gates

King gates Modus Installation and use instructions and warnings

Siemens

Siemens M20 Terminal Technical description