Newgrind Rhino RS150 User manual

Rhino Resurfacing Machine

Operator’s Manual

RS150 1.5HP

RM250 3HP

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

GENERAL SAFETY RULES

WARNING! Read and understand all

instructions. Failure to follow all instruc-

tions listed below, may result in electric

shock, re and/or serious personal injury.

SAVE THESE INSTRUCTIONS.

Work Area

1. Keep your work area clean and well lit.

Cluttered oors and dark areas invite

accidents.

2. Do not operate equipment in

explosive atmospheres, such as in the

presence of ammable liquids, gases or

dust. Grinding can create sparks which

may ignite the dust or fumes.

3. Keep bystanders, children, and

visitors away while operating equip-

ment. Distractions can cause you to lose

control.

Electrical Safety

4. Do not abuse the cord. Never use the

cord to pull the equipment or pull the

plug from an outlet. Keep cord away

from heat, oil, sharp edges or moving

parts. Replace damaged cords immedi-

ately. Damaged cords increase the risk

of electric shock.

5. When operating equipment outside,

use an outdoor extension cord marked

"W-A" or "W". These cords are rated for

outdoor use and reduce the risk of

electric shock.

6. Avoid accidental starting. Be sure stop

button is depressed before plugging in.

Starting equipment with your nger on

the start buttons or plugging in equip-

ment that have the buttons depressed

invites accidents.

Personal Safety

7. Stay alert, watch what you are doing

and use common sense when operating

equipment. Do not use equipment while

tired or under the inuence of drugs,

alcohol, or medication. A moment of

inattention while operating equipment

may result in serious personal injury.

8. Do not overreach. Keep proper

footing and balance at all times. Proper

footing and balance enables better

control of the equipment in unexpected

situations.

9. Use safety equipment. Always wear

eye protection. Dust mask, non-skid

safety shoes, hard hat, or hearing

protection must be used for appropriate

conditions. Ordinary eye or sunglasses

are NOT eye protection.

10. DO NOT Turn on equipment while

the machine is tilted back. Any tooling

fastened to the machine can eject and

become a lethal projectile.

Equipment Use and Care

11. The equipment is designed to

remove excess surface material. To

prevent damage to the equipment

and/or serious personal injury, beware

of protruding objects or other debris on

or embedded in the surface being

nished.

12. Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing equip-

SPECIFICATIONS

Model RM150 1.5HP RM150 3HP

Input Power

120V 50/60Hz

380

-

460V

+/

-

15%50/60Hz

Amps

12A

14

-

16A

Plug Type

15A 125V

3P4W 30A 480V 3~

(NEMA L16-30P)

Disc Diameter

5" / 127mm

Disc Speed (RPM)

133-665 200-900

Machine Width

14" / 355mm

Weight

150lbs / 69kg 150lbs / 69kg

ment. Such preventive safety measures

reduce the risk of starting the equip-

ment accidentally.

13. Maintain equipment with care. Keep

tools and accessories in good condition.

Properly maintained tools with sharp

cutting edges are less likely to fail and

are easier to control.

14. Check for binding of moving parts,

breakage of parts, and any other condi-

tion that may aect the equipment's

operation. If damaged, have equipment

serviced before using. Many accidents

are caused by poorly maintained equip-

ment.

15. Use only tools and accessories that

are recommended by the manufacturer

for your equipment. Tools and accesso-

ries that may be suitable for style of

equipment, may become hazardous

when used on another style of equip-

ment.

SERVICE

16. DO NOT modify the machine. Modi-

cations will void warranty and could

result in unsafe operation of equipment.

17. Equipment service should be

performed only by qualied repair

personnel. Service or maintenance

performed by unqualied personnel

could result in a risk of injury.

18. When servicing equipment, use only

identical replacement parts. Use of

unauthorized parts may create a risk of

electric shock or injury.

USE PROPER EXTENSION CORD. Make

sure your extension cord is in good

condition. When using an extension cord,

be sure to use one heavy enough to carry

the current your product will draw. An

undersized cord will cause a drop in line

voltage resulting in loss of power and

overheating. For model HDX465 use

10gauge cord or larger. For model

HDX465HV use 12 gauge cord or larger. If

in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier

the cord.

SPECIFIC SAFETY RULES

DO NOT let comfort or familiarity with

product (gained from repeated use)

replace strict adherence to equipment

safety rules. If you use this equipment

unsafely or incorrectly, you can suer

serious personal injury.

1. Tools and accessories must be rated

for at least the speed stated on the

equipment serial plate. Tools and other

accessories running over rated speed

can y apart and cause injury.

2. Always use safety glasses or goggles.

Ordinary eye or sun glasses are NOT

safety glasses.

3. Make sure cord is clear of wheels and

cutting discs. Do not wrap cord around

your arm or wrist. If control of equip-

ment is lost, cord may become wrapped

around you and cause personal injury.

4. Adequate ventilation of your work

area is very important when using

equipment. Use a dust mask or appro-

priate respirator.

5. Due to the dusty nature during use of

this equipment, be sure to clean equip-

ment often to remove dust accumula-

tions. Carefully blow the dust out of the

motor, VFD and dust covered areas

frequently.

6. Always install the dust skirt before

operation.

7. Check the tools and accessories

carefully for cracks or damage before

operation. Replace cracked or damaged

tools or and accessories immediately.

8. Hold the equipment rmly with both

hands during operation.

9. Do not leave the equipment running

unattended.

10. Do not touch the tools immediately

after operation; they may be extremely

hot and could burn your skin.

WARNING: Misuse or failure to follow

the safety rules stated in this instruction

manual may cause serious personal

injury. SAVE THESE INSTRUCTIONS.

Machine Operation:

The Variable Frequency Drive (VFD) is

designed to allow the user to operate the

equipment on either single phase or

three phase power for the 3HP model.

The equipment is able to operate on

either 50 Hz or 60 Hz frequencies. The

VFD will automatically adjust for phase

or frequency input which will raise or

lower head speed on the machine.

LED DISPLAY – Shows PAD speed when

machine is running and says stop when

plugged in but not running.

Starting the equipment:

Apply downward pressure on the handle

to alleviate some pressure o of the tools

and press the green or blue start button.

Once the equipment gets started, gently

release the downward pressure and start

grinding.

The equipment is designed to rotate the

tooling in either the forward direction

(green button) or reverse direction (blue

button) depending on operating needs.

Use the equipment in the forward rotation

mode (green button) unless reverse

rotation is needed. This will ensure consis-

tent tool wear and tool prole. The use of

the equipment in the reverse rotation is

only needed when surface being nished

is uneven and causes the equipment to

pull in an undesired direction or when the

tooling is glazed and needs to be

re-dressed.

Use the knob, located on the right side of

the handle control box, to adjust speed of

equipment.Before starting the equipment,

ensure that the speed is set to the

lowest speed available as displayed on

the VFD screen. Doing so will prevent

unexpected high speed start up which

could cause some tools to eject or

cause undesirable marks to the surface

being finished.

DO NOT LIFT THE EQUIPMENT OFF THE

GROUND WHILE STARTING! Doing so can

cause the tools to release from the equip-

ment and cause damage to the surface

being nished and harm to the user!

Stopping the equipment:

To stop the equipment, turn speed control

knob to the slowest setting and push the

red stop button on the face of the handle

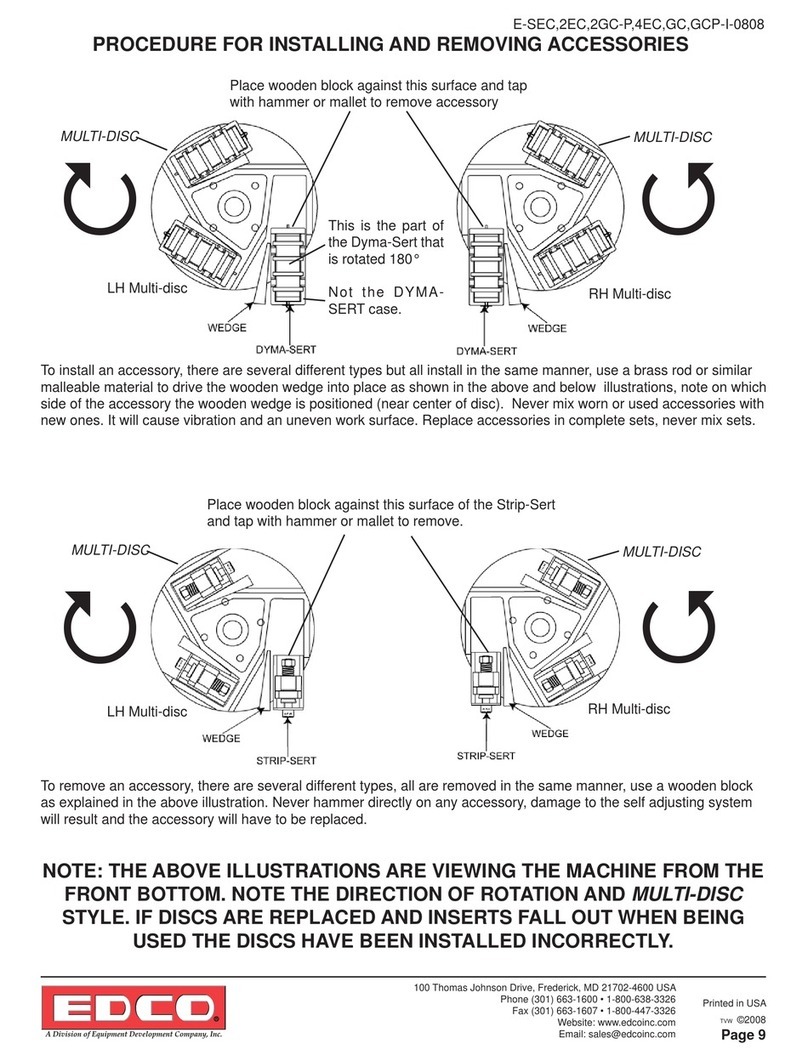

Changing tools and accessories:

Always turn o and disconnect power

from the machine when performing any

operations to the bottom of the machine!

When removing and inserting tool

plates or adapter plates, be sure to

inspect rubber grommets for signs for

wear and replace any damaged

grommets.

Using grommets that are damaged

or missing can cause unexpected

equipment operation and increase the

chance of tool plate / adapter plate

ejection or violent vibration leading to

loss of control of equipment!

Handle adjustment:

To adjust the handle, pull the hand

latch or step on foot latch on the

handle and move handle up or down

to the desired position. Avoid

stepping on or tangling handle

control cable when adjusting the handle

position. Make sure that the latch clicks

in place

when the desired position is achieved.

Failure to check for positive engagement

could result in damage to the equipment

or injury to the user as the handle could

release unexpectedly when the machine

is being operated or tilted back!

VFD features:

The machine is outtted with a VFD

(Variable Frequency Drive) enabling the

user to select the desired operating speed.

The VFD also possesses many features

such as:

- Under voltage protection - Over current

protection

- 60Hz and 50Hz capability (international)

- Wide voltage range

(200-230V +/- 15% for 230V model)

(380-460V +/- 15% for 460V model)

- Soft start

- Speed display - Load display

- Current limiting

Maintenance:

General:

- Disconnect power before performing

any maintenance, cleaning, or repair to

your equipment!

- When the equipment is not in use,

make sure that the adapter plate assem-

blies have something attached to them

to protect the Velcro. Resting the

machine directly on unprotected Velcro

will crush the fastening material causing

the Velcro to become unusable.

Daily:

- Wipe down the equipment after every

job.

- Gently remove dirt and debris from the

Velcro hook material using a wire brush.

This will ensure maximum adhesion.

- Check that the handle bolts are tight.

- Vacuum or wipe underside of machine.

- Inspect plug ends for signs of carbon

deposits or arcing.

- Check all fasteners and tighten if

necessary.

Weekly:

- Inspect handle wires for damage.

- Blow o VFD heat sink with

compressed air. - Blow out VFD cooling

n fan(s) with low

pressure compressed air (30psi or less).

- Cleaning the fan(s) prevents fan failure

and

potential VFD overheating. Do not

over-speed

the fan(s) with compressed air!

- Blow o motor fan with compressed

air.

- Remove tool plate holders and wipe

down

bearing shields with a damp cloth. Do

not use any sharp object or abrasive pad

to clean the bearing shields. This can

compromise the bearing seal! Re-install

tool plate drivers using blue medium

strength thread locking compound.

- Using a soft scrub pad, remove any

excess dirt build up from the bottom

plate and back side of pad drivers.

- Inspect tool plate driver grommets for

signs of wear. Replace grommets that

show signs of extensive wear.

Monthly:

- Check all strain reliefs and make sure

they are tight so as to avoid cords being

pulled out of the VFD or handle.

- Remove tool plate drivers and inspect

threads to make sure that there are no

signs of cross threading or stripping.

- Clean and lubricate wheels.

- Clean and lubricate latch mecha-

nisms.

The VFD is protected from voltage

fluctua-tions within the specified

voltage range. Check voltage before

plugging in equip-ment to insure safe

operation.

If a machine is plugged into a power

source that is above the machine’s

maximum voltage capability (ex. 230V

model plugged into a 460V power

source) this will damage and/or destroy

the internals of the VFD and void

warranty!

LIMITED EQUIPMENT WARRANTY OF SALE

New Grind Inc. warrants that each

new unit manufactured for New Grind Inc.

to be free from defects in material

and workmanship in normal use and

service for a period of (2) one year from

date of shipment to the original retail

or equip-ment rental center owner.

Accessories or equipment furnished and

installed on the product by New Grind

Inc. but manufac-tured by others,

including, but not limited to engines,

motors, electrical components,

transmissions etc., shall carry the

accesso-ry manufacturers own

warranty. New Grind Inc. will, at its

option, repair or replace, at the New

Grind Inc. factory or at a point designated

by New Grind Inc. any part which shall

appear to the satisfaction of New Grind

Inc. inspection to have been defective in

material or workmanship. New Grind Inc.

reserves the right to modify, alter and

improve any part or parts without

incurring any obligation to replace

any part or parts previously sold

without such modified, altered

or improved part or parts. This

warranty is in lieu of and excludes all

other warranties, expressed, implied,

statutory, or otherwise created under

applicable law including, but not

limited to the warranty of

merchantability and the warranty

of fitness for a particular purpose in no

event shall seller or the manufacturer

of the product be liable for special,

incidental, or

For VFD error codes please see attached document

consequential damages, including loss of

prots, whether or not caused by or result-

ing from the negligence of seller and/or

the manufacturer of the product unless

specically provided herein. In addition,

this warranty shall not apply to any

products or portions there of which have

been subjected to abuse, misuse, improp-

er installation, maintenance, or operation,

electrical failure or abnormal conditions

and to products which have been

tampered with, altered, modied,

repaired, reworked by anyone not

approved by seller or used in any manner

inconsistent with the provisions of the

above or any instructions or specications

provided with or for the product

FORCE MAJEURE

Seller’s obligation hereunder are subject

to, and Seller shall not be held responsible

for, any delay or failure to make delivery of

all or any part of the product due to labor

diculties, res, casualties, accidents, acts

of the elements, acts of God, transporta-

tion diculties, delays by a common

carrier, inability to obtain product, materi-

als or components or qualied labor

sucient to timely perform part of or all of

the obligations contained in these terms

and conditions, governmental regulations

or actions, strikes, damage to or destruc-

tion in whole or part of manufacturing

plant, riots, terrorist attacks or incidents,

civil commotions, warlike conditions,

ood , tidal waves, typhoon, hurricane,

earthquake, lightning, explosion or any

other causes, contingencies or circum-

stances within CANADA not subject to the

Seller’s control which prevent or hinder

the manufacture or delivery of the

products or make the fulllment of these

terms and conditions impracticable. In the

event of the occurrence of any of the

foregoing, at the option of Seller, Seller

shall be excused from the performance

under these Terms and Conditions, or the

performance of the Seller shall be

correspondingly extended. This document

sets forth the terms and conditions pursu-

ant to which the purchaser (“Purchaser”)

will purchase and New Grind Inc. (“Seller”)

will sell the products, accessories, attach-

ments (collectively the products “) ordered

by the Purchaser. These terms and condi-

tions shall govern and apply to the sale of

Seller’s products to Purchaser, regardless

of any terms and conditions appearing on

any purchase order or other forms submit-

ted by Purchaser to Seller, or the inconsis-

tency of any terms therein and herein.

LIABILITY LIMITATIONS

The remedies of the user set forth under

provisions of warranty outlined above are

the exclusive and total liability of New

Grind Inc. with the respect to their sale or

the equipment and service furnished

hereunder, in connection with the perfor-

mance or

breach thereof, or from the sale, delivery,

installation, repair or technical direction

covered by or furnished under the sale,

whether based on contract, warranty,

negligence, indemnity, strict liability, or

otherwise shall not exceed the purchase

price of the unit of equipment upon which

such liability is based.

New Grind Inc. will not in any event be

liable to the user, any successors in

interest or any beneciary or assignee

relating to this sale for any consequential,

incidental, indirect, special or punitive

damages arising out of this sale or any

breach thereof, or any defects on, or

failure of, or malfunction of the equipment

under this sale based upon loss of use, lost

prots or revenue, interest, lost goodwill,

work stoppage, impairment of other

goods, loss by reason of shutdown or non-

operation, increased expenses of opera-

tion of the equipment, cost of purchase or

replacement power of claims of users or

customers of the user for service interrup-

tion whether or not such loss or damage is

based on contract, warranty, negligence,

indemnity, strict liability, or otherwise.

New Grind Inc. reserves the right to

modify, alter and improve any part or parts

without incurring any obligation to

replace any part or parts previously sold

without such modied, altered or

improved part or parts.

No person is authorized to give any other

warranty or to assume any additional

obligation on New Grind Inc.'s behalf

unless made in writing and signed by an

ocer of New Grind Inc.

TERMS & CONDITIONS

1. PRICE

All prices set forth on any purchase

order or other document are F.O.B.

Sellers facility or distribution point, as

may be determined by Seller

(F.O.B.Point). All prices are exclusive of

any and all taxes, including, but not

limited to, excise, sales, use, property or

transportation taxes related to the sale

or use of the products, now or hereafter

imposed, together with all penalties and

expenses.

Purchaser shall be responsible for

collecting and/or paying any and all

such taxes, whether or not they are

stated in any invoice for the Products.

Unless otherwise specied herein, all

prices are exclusive of inland transporta-

tion, freight, insurance and other costs

and expenses relating to the shipment

of the Products from the F.O.B. point to

Purchaser’s facility. Any prepayment by

Seller of freight insurance and other

costs shall be for the account of

Purchaser and shall be repaid to Seller.

2. PAYMENT TERMS

Payment terms are as follows:

New Grind Inc. Machines - Payment prior

to delivery.

*All past due accounts are subject to a

late payment fee of 1.5% per month or a

maximum allowed by law if dierent,

along with the expenses incidental to

collection including reasonable

attorney’s fees and costs.

*Seller reserves the right to hold

shipments against past due accounts.

*Seller reserves the right to alter

payment terms.

3. FREIGHT TERMS

All shipments will be made F.O.B.

shipping point as designated in these

Terms and Conditions, and title shall

pass at the F.O.B. point. Delivery to the

initial common carrier shall constitute

delivery to the Purchaser. Any claims for

loss or damage during shipment are to

be led with carrier by the Purchaser.

Seller will not assume responsibility for

the performance of the carrier.

Backorders will be shipped in the most

practical fashion with charges consis-

tent with our freight policy established

with the original order. UPS, FED EX,

MAIL or shipments by other couriers are

subject to the same terms and condi-

tions as outlined in paragraph #3

”Freight Terms”.

4. DELIVERY, DAMAGES, SHORTAGES

Seller shall use reasonable eorts to

attempt to cause the Products to be

delivered as provided for in these Terms

& Conditions. Delivery to the initial

common carrier shall constitute the

delivery to the Purchaser. Sellers

responsibility, in so far as transportation

risks are concerned ceases upon the

delivery of the Products in good condi-

tion to such carrier at the F.O.B. point

and all the Products shall be shipped at

the Purchaser’s risk. Seller shall not be

responsible or liable for any loss of

income and/or prots, or incidental,

special, consequential damages result-

ing from Seller’s delayed performance in

shipment and delivery.

5. RETURN OF DEFECTIVE PRODUCTS

Defective or failed material shall be held

at the Purchaser’s premises until autho-

rization has been granted by Seller to

return or dispose of Products. Products

that are to be returned for nal inspec-

tion must be returned Freight Prepaid in

the most economical way. Credit will be

issued for material found to be defective

upon Seller’s inspection based on prices

at time of purchase.

6. PRODUCTS ORDERED IN ERROR

Products may be returned, provided

that claim is made and Seller is notied

within 7 days of receipt of Products, and

the Products are in original buyer’s

possession not more than 30 days prior

to return, subject to Seller’s approval. If

Products are accepted for return, they

must be Freight Prepaid and buyer will

be charged a minimum of 15% restock-

ing charge, plus a charge back for

outbound freight charges if the original

order was shipped prepaid. Returns are

not accepted for any Products that are

specically manufactured to meet the

buyer’s requirement of either specica-

tions or quantity.

AGREEMENTS

These Terms and Conditions constitute the

entire agreement between Seller and

Purchaser as it relates to terms and condi-

tions of sale, and supersedes any and all

prior oral or written agreements,

correspondence, quotations or under-

standings heretofore in force between the

parties relating to the subject matter

hereof. There are no agreements between

Seller and Purchaser with respect to the

Product herein except those specically

set forth in and made part of these terms

and conditions. Any additional terms,

conditions and/or prices are rejected by

Seller. These terms and conditions may be

modied, cancelled or rescinded only by a

written agreement of both parties execut-

ed by their duly authorized agents.

New Grind Inc.

103B- 81 Golden Dr

Coquitlam BC

V3K 6R2

Telephone:

1-888-467-0242

carissa@newgrind.com

www.newgrind.com

www.newgrind.com

SV01C

Operating Instructions

SMVector - Frequency Inverter

37

SV01C

Troubleshooting and Diagnostics

5.3 Fault Messages

The messages below show how they will appear on the display when the drive trips. When looking at the Fault History (P500), the

.will not appear in the fault message.

Fault Cause Remedy (1)

High Temperature fault Drive is too hot inside • Reduce drive load

• Improve cooling

LAssertion Level fault • Assertion Level switch is changed

during operation

• P120 is changed during operation

• P100 or P121...P123 are set to a

value other than 0 and P120 does

not match the Assertion Level

Switch.

• Make sure the Assertion Level switch

and P120 are both set for the type

of input devices being used, prior to

setting P100 or P121...P123.

See 3.2.3 and P120.

Personality fault Drive Hardware • Cycle Power

• Power down and install EPM with valid

data

• Reset the drive back to defaults (P199

= 3, 4) and then re-program

• If problem persists, contact factory

technical support

Control fault An EPM has been installed that is either

blank or corrupted

f F Incompatible EPM fault An EPM has been installed that contains

data from an incompatible parameter

version

.d Dynamic Braking fault Dynamic braking resistors are overheating • Increase active decel time

(P105, P126, P127).

• Check mains voltage and P107

External fault • P121…P123 = 21 and that digital input

has been opened.

• P121…P123 = 22 and that digital input

has been closed.

• Correct the external fault condition

• Make sure digital input is set properly

for NC or NO circuit

EPM fault EPM missing or defective Power down and replace EPM

Internal faults Contact factory technical support

.Invalid message received • A network message was received while

in Remote Keypad mode

• A remote keypad message was

received while in Network mode

Only the remote keypad or the network

can be connected at one time; see P100

LLoss of 4-20 mA signal fault 4-20 mA signal (at TB-25) is below 2 mA

(P163 = 1)

Check signal/signal wire

OEM Defaults data fault Drive is powered up with

P199 =1 and OEM settings in the EPM are

not valid.

Install an EPM containing valid OEM

Defaults data or change P199 to 0.

High DC Bus Voltage fault Mains voltage is too high Check mains voltage and P107

Decel time is too short, or too much regen

from motor

Increase active decel time

(P105, P126, P127) or install Dynamic

Braking option

(1) The drive can only be restarted if the error message has been reset

38 SV01C

Troubleshooting and Diagnostics

Fault Cause Remedy (1)

Digital Input

Configuration fault (P121...

P123)

More than one digital input set for the

same function

Each setting can only be used once (except

settings 0 and 3)

Only one digital input configured for MOP

function (Up, Down)

One input must be set to MOP Up, another

must be set to MOP Down

PID mode is entered with setpoint

reference and feedback source set to the

same analog signal

Change PID setpoint reference (P121…

P123) or feedback source (P201).

One of the digital inputs (P121…P123) is

set to 10 and another is set to 11…14.

Reconfigure digital inputs

One of the digital inputs (P121…P123)

is set to 11 or 12 and another is set to

13 or 14.

PID enabled in Vector Torque mode (P200

= 1 or 2 and P300 = 5) PID cannot be used in Vector Torque mode

Remote keypad fault Remote keypad disconnected Check remote keypad connections

LLow DC Bus Voltage fault Mains voltage too low Check mains voltage

1No Motor ID fault An attempt was made to start the drive

in Vector or Enhanced V/Hz mode prior to

performing the Motor Auto-calibration

See P300…P399 for Drive Mode setup

and calibration.

Module communication fault Communication failure between drive and

Network Module.

Check module connections

Network Faults Refer to the module documentation. for

Causes and Remedies.

Output fault:

Transistor fault

Output short circuit Check motor/motor cable

Acceleration time too short Increase P104, P125

Severe motor overload, due to:

• Mechanical problem

•Drive/motor too small for application

• Check machine / system

• Verify drive/motor are proper size for

application

Boost values too high Decrease P168, P169

Excessive capacitive charging current of

the motor cable

• Use shorter motor cables with lower

charging current

• Use low capacitance motor cables

• Install reactor between motor and drive.

Failed output transistor Contact factory technical support

Output fault: Ground fault Grounded motor phase Check motor and motor cable

Excessive capacitive charging current of

the motor cable

Use shorter motor cables with lower

charging current

Motor Overload fault Excessive motor load for too long • Verify proper setting of P108

• Verify drive and motor are proper size

for application

(1) The drive can only be restarted if the error message has been reset

39

SV01C

Troubleshooting and Diagnostics

Fault Cause Remedy (1)

Flying Restart fault Controller was unable to synchronize with

the motor during restart attempt; (P110

= 5 or 6)

Check motor / load

Single-Phase fault A mains phase has been lost Check mains voltage

Start fault Start command was present when power

was applied (P110 = 0 or 2).

• Must wait at least 2 seconds after

power-up to apply Start command

• Consider alternate starting method (see

P110).

(1) The drive can only be restarted if the error message has been reset

AC Technology Corporation • 630 Douglas Street • Uxbridge, MA 01569 • USA

+1 (508) 278-9100

SV01C

This manual suits for next models

1

Table of contents

Other Newgrind Floor Machine manuals