E-SEC,2EC,2GC-P,4EC,GC,GCP-I-0808

Printed in USA

©2008 TVW

Page 10

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com

INSTRUCTIONS FOR CHANGING ACCESSORIES

1. Disconnect the machine from the power source before

performing any work on the equipment. To disconnect the

power source remove the spark plug lead on gasoline

and propane models or unplug the electrical models at

the grinder.

2. Tip Grinder back on the handle until handle remains on

contact with the slab. NOTE: FOR GASOLINE MODELS,

TAKECARETHATGASOLINEOROILDOESNOTSPILL

FROM THE ENGINE, Turn gasoline cutoff valve off.

Brace securely or have someone hold the handle against

the slab. The grinding discs will be visible and accessable

for inspection and installation of accessory items.

3. Installing Multi-disc assemblies (for use with scarifiers,

silabide pads, wire brushes and Dyma-Serts). The multi-

discs are designed as lefthand (LH) or righthand (RH)

depending on the direction of rotation: the LH is on the left

side(clockwise) andRH ison theright side(counter clock-

wise) as viewed from the bottom side of the machine. The

single disc grinders use the RH disc. NOTE: Multi-Discs

come standard with the EDCO grinders in this manual.

The multi-disc assemblies use a 3/8” dia. x 2” long roll pin

to attach them to the shaft(s) under the grinder (refer to

page 11).

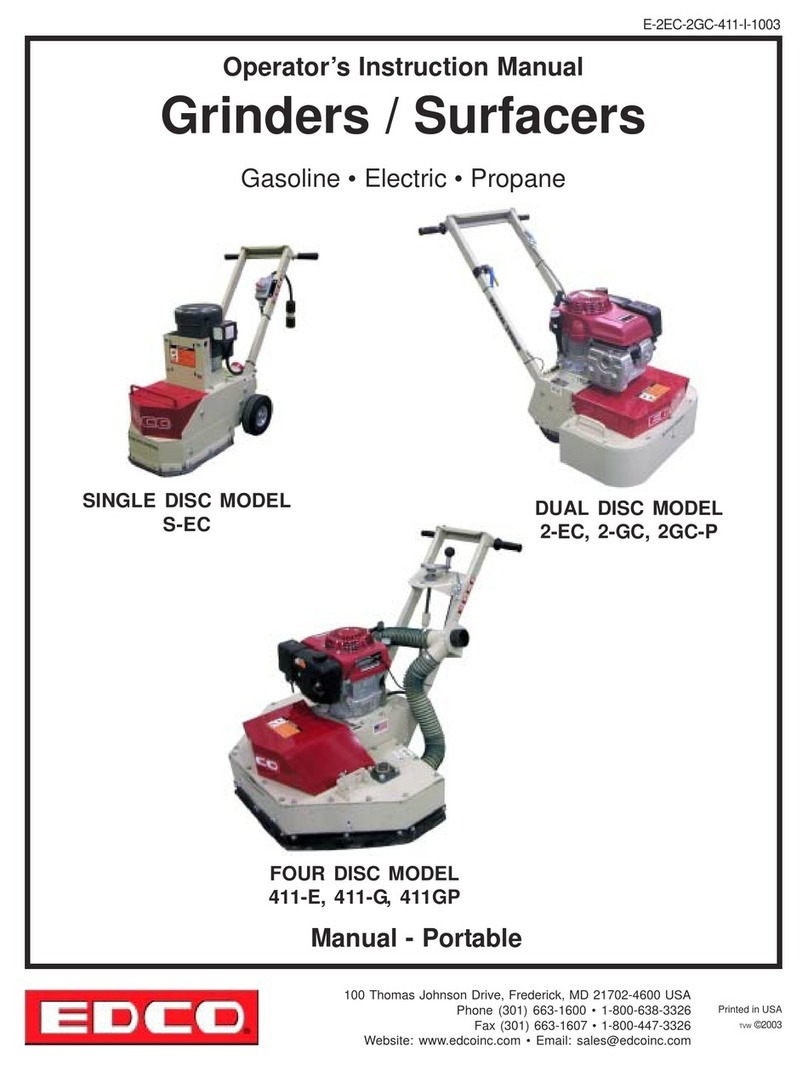

4. When installing the surfacer disc assemblies instead

of the Multi-disc assemblies (refer to figure 7). The discs

are triangular and must be allowed to pass each other

without colliding.

5. Installing grinding stones. Grinding stones are used on

the multi-disc assembly. A total of 3 stones are used with

each multi-disc and are held in place with a hardwood

wedge. The wedges are placed on the inside of the stone

(refer to page 10). Use a second wedge and hammer or

mallet to drive the wedge securely into place.

6. Installing wire brushes. The steel wire brushes are

used on the multi-disc assembly (3 per multi-disc). They

are held in place with a hardwood wedge driven in on the

inside of the brush toward the center of the disc, refer to

the previous page.All accessories are held in place in the

same manner.

7. Installing Scarifiers. The scarifier assemblies consist

of disposable scarifiers and a reusable scarifier case. The

case is held into the multi-disc assembly with a hardwood

wedgedrivenin on the insideof the casetoward the center

of the disc, refer to the previous page. All inserts are held

in place in the same manner.

The scarifiers can be added or removed from the case

withoutdisturbingthe case. Oneend of thescarifieris short

andhasa tab.The tab issimplyinserted under thelip of the

case and the other end is pressed into the spring loaded

slot and seated firmly. Refer to diagram on page 11.

To remove the scarifier from the case, simply pry the

rounded end of the frame out of the spring loaded slot.

Installing Dyma-Serts: TheDyma-Sert assemblyconsists

ofadisposableDyma-Sertcutter,a shock absorbing rubber

block, and a reusable Dyma-Sert case. Three Dyma-Sert

assemblies are used on each multi-disc. The case is held

on the multi-disc assembly by using a hardwood wedges

driven in on the inside of the case. Refer to diagram on

page 11.

The Dyma-Serts can be added or removed from the reus-

able case. One end of the Dyma-Sert has a lip. The lip is

simply inserted under the lip of the case and the other end

is pressed into the spring loaded slot at the other end and

seated firmly. Refer to page 11.

Figure 7

Allignment of Surfacer Disc

Assemblies on 4EC/GC Models