Newgrind RHINO RLP800 User manual

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

resurfacing machine operator's Manual

equipment usages

• Concrete leveling, grinding and polishing

• Glue, thinset and mastic removal

• Terrazzo grinding and polishing

• Stone grinding and polishing

!

Rhino RLP800 user Manual

2

Table of Contents

EQUIPMENT USES................................................................................................

RLP800 DIAGRAM ..............................................................................................

RLP800 BOTTOM DIAGRAM ...............................................................................

MACHINE SPECIFICATIONS .................................................................................

Tooling ...........................................................................................................

Average Production Rates............................................................................

GENERAL SAFETY INSTRUCTIONS ......................................................................

Work Area Safety ..........................................................................................

Electrical Safety ...........................................................................................

Personal Safety .............................................................................................

Equipment Use and Care .............................................................................

Service ..........................................................................................................

Specific Safety Rules ..................................................................................

MACHINE OPERATION ........................................................................................

Starting the Equipment ................................................................................

Stopping the equipment ..............................................................................

Changing Tools and Accessories ................................................................

Handle Adjustment ......................................................................................

Double Grommet System ............................................................................

MAINTENANCE ....................................................................................................

General Maintenance ...................................................................................

Weekly Maintenance ....................................................................................

Monthly Maintenance ...................................................................................

Yearly Maintenance ......................................................................................

TROUBLE SHOOTING DATA ANALYZER (EDA) .....................................................

CONNECTS TO OIL PRESSURE SWITCH DIAGRAM ...............................................

CONNECTS DIRECT TO GAS VALVE DIAGRAM ......................................................

LIMITED EQUIPMENT WARRANTY OF SALE ........................................................

FORCE MAJEURE .................................................................................................

LIABILITY LIMITATIONS ......................................................................................

TERMS & CONDITIONS ........................................................................................

AGREEMENTS .....................................................................................................

1

3

4

5

5

5

6

6

6

7

7

7

8

8

8

9

9

10

10

10

10

10

11

11

11

12

13

14

15

15

16

17

3

Rhino RlP800 diagram

ENGINE START BUTTON POWER ON LIGHT CLUTCH ON LIGHT

VARIABLE THROTTLE

SPEED ADJUSTMENT

MULTI ARTICULATING HANDLE

UPPER RATCHET

BATTERY ON/OFF SWITCH

DUAL PROPANE CYLINDERS

BATTERY QUICK DISCONNECT

MULTI-ARTICULATING

HANDLE FOOT LEVER

LOWER RATCHET

UHMW FLOATING

DUST SKIRT

UHMW FIXED

DUST SKIRT

DUAL VACUUM MANIFOLD PORT

HEAVY DUTY WHEELS

QUICK BELT CHANGE BOLTS

3/4” WRENCH X 6

2 UNDER PLUS 2 ON EACH SIDE

BIASED WEIGHT-KIT POSTS

26 HP MOTOR

CATALYTIC MUFFLER

WITH O2SENSOR

EASY ACCESS AIR FILTER

HAND GRIPS

VACUUM CONNECTOR PORT

TACHOMETER

CLUTCH ON/OFF SWITCH

Rhino RLP800 bottom diagram

QUICK-CHANGE DRIVE BELT

HYTREL COUPLER SPIDER GEAR

4

SINGLE OR DOUBLE GROMMET

TOOL PLATE

MOUNTING SYSTEM

COUNTER-CLOCKWISE

SPINNING RHINO TOOL

PLATES (RED)

CLOCKWISE

SPINNING RHINO TOOL

PLATES (BLACK)

DUAL VACUUM PORTS

SECONDRY DRIVE

SPROCKETS X 5

RHINO STYLE TOOLING

ATTACHES USING 8MM SCREW

- PUCKS AND TRAPEZOIDS

ATTACH USING 6MM OR

8 MM SCREWS

MAIN DRIVE SPROCKET

ADJUSTABLE

IDLER SPROCKETS X 2

(1 ON EACH SIDE)

5

Rhino RLP800 machine specifications

POWER Propane - 2 x 3.2 Gallon Cylinders

HP 26

MACHINE WEIGHT 800 lbs

BIASED WEIGHT KIT MAX WEIGHT 180 lbs

COMBINED WEIGHT 980 lbs

DISC SPEED 200-900 rpm

VARIABLE SPEED CONTROL YES

NUMBER OF GRINDING HEADS 6

COUNTER-ROTATING HEADS YES

DISK SIZE 7 inches

GRINDING FOOTPRINT 20 inches

QUICK CHANGE TOOLING PLATES YES

QUICK BELT CHANGING SYSTEM YES

WET OR DRY GRINDING YES

UHMW FLOATING DUST SKIRT YES

MULTI-ARTICULATING HANDLE YES

CAN BE USED AS AN EDGER YES – grinds to within 1/8 of the edge

DUAL VACUUM MANIFOLDS YES

Tooling

RHINO STYLE TOOLING YES

STANDARD TRAPEZOID YES

Average Production Rates

(on Medium Hard Concrete)

EXTREMELY HEAVY REMOVAL 700-1200 sq./ft. per hour

HEAVY REMOVAL 800-1400 sq./ft. per hour

LIGHT REMOVAL 1200-1600 sq./ft. per hour

GRINDING AND PROFILING 900-1300 sq./ft. per hour

POLISHING 1400-2000 sq./ft. per hour

6

Rhino RlP800 MACHINE specifications continued

WARNING! Read and understand all instructions.

Failure to follow all instructions listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS.

Work Area

1. Keep your work area clean and well lit. Cluttered floors and dark areas invite accidents.

2. Do not operate equipment in explosive atmospheres, such as in the presence of flammable liquids, gases or dust.

Grinding can create sparks which may ignite the dust or fumes.

3. Keep bystanders, children, pets and visitors away while operating equipment. Distractions can cause you to lose control.

4. Use appropriate dust control vacuum system when Dry Grinding, Polishing or Sanding

PROPANE Safety

1. Always turn propane tank valve off when not in use.

2. When finished using always turn propane off to stop engine. This clears the fuel line hose & regulator which prevents

any nuisance odor of propane.

3. When filling tanks never go past full.

NOTE:

It is good practice to only fill tanks ¾ full as this allows room for gas expansion with higher temperatures.

This also prevents liquid propane from entering the regulator which causes rough running and can clog the

regulator with residue.

4. Keep tanks in the upright position when full until the level has dropped to ½ full before lowering position of bottom

handle section. This prevents the straw from sucking liquid.

!

MODEL SPECIFICATIONS

Battery (APP16L) 12V 16Ah

Engine Briggs and Stratton 810CC LPG Vapor Only

Tank (PS5306TC) 3.2 Gallon

Disc Diameter 7" / 178mm

Disc Speed (RPM 200 - 900

Machine Width 20" / 508mm

Weight 800lbs / 363kg

GENERAL SAFETY instructions

7

Rhino RlP800 safety instructions continued

Personal Safety

1. Stay alert, watch what you are doing and use common sense when operating equipment. Do not use equipment

while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating

equipment may result in serious personal injury.

2. Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enables better

control of the equipment in unexpected situations.

3. Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions. Ordinary eye or sunglasses are NOT eye protection.

4. DO NOT turn on equipment while the machine is tilted back. Any tooling fastened to the machine can

come off and cause damage or injury.

Equipment Use and Care

5. The equipment is designed to remove excess surface material. To prevent damage to the equipment

and/or serious personal injury, beware of protruding objects or other debris on or embedded in the surface

being finished.

6. Maintain equipment with care. Keep tools and accessories in good condition. Properly maintained tools

with sharp cutting edges are less likely to fail and are easier to control.

7. Check for binding of moving parts, breakage of parts, and any other condition that may affect the

equipment's operation. If damaged, have equipment serviced before using. Many accidents are caused

by poorly maintained equipment.

8. Use only tools and accessories that are recommended by the manufacturer for your equipment.

Tools and accessories that may be suitable for one style of equipment, may become hazardous when used

on another style of equipment.

NOTE:

Running machine under severe load with excess tool point pressure can cause v-belt slippage which

results in clutch failure.

Severe load examples are rubberized/elastomeric coatings, very soft substrate with incorrect tooling,

very rough uneven floors with large aggregate exposure, excessive lippage, large holes or divots etc.

SOLUTION:

Install tools with higher grit and/or larger surface area as well as harder bond (eg. change from soft or

medium bond to hard bond) style of tool can go to larger buttons and/or more segments or change to

trapezoid bars.

Next step will be to counterbalance machine by hanging weights on the handle to reduce head pressure.

Operator can also reduce RPM to slow down cutting/grinding.

PCDs will need to have carbide riders to reduce point pressure and depth of cut. On very soft concrete

it may be necessary to apply densifier (possibly multiple times and/or acrylic admixture or epoxy to

increase hardness before grinding).

SERVICE

9. DO NOT modify the machine. Modifications will void warranty and could result in unsafe operation of equipment.

10. Equipment service should be performed only by qualified repair personnel. Service or maintenance

performed by unqualified personnel could result in a risk of injury.

11. When servicing equipment, use only identical replacement parts. Use of unauthorized parts may void warranty.

Rhino RlP800 safety instructions continued

SPECIFIC SAFETY RULES

DO NOT let comfort or familiarity with product (gained from repeated use) replace strict adherence to equipment

safety rules. If you use this equipment unsafely or incorrectly, you can cause serious personal injury.

1. Tools and accessories must be rated for at least the speed stated on the equipment serial plate.

Tools and other accessories running over rated speed can fly apart and cause injury.

2. Adequate ventilation of your work area is very important when using equipment. Use a dust mask or

appropriate respirator.

3. Due to the dusty nature, during use of this equipment, be sure to clean equipment often to remove dust

accumulations. Carefully blow the dust out of the engine and check the air filter under the shroud cap.

If necessary, replace the air filter.

4. Always check if the floating dust skirt is in good condition and touching the floor before operation.

5. Check the tools and accessories carefully for damage before operation. Replace damaged tools and or

accessories immediately.

6. Hold the equipment firmly with both hands during operation.

7. Do not leave the equipment running unattended.

8. Do not touch the tools immediately after stopping operation; they may be extremely hot and could burn your skin.

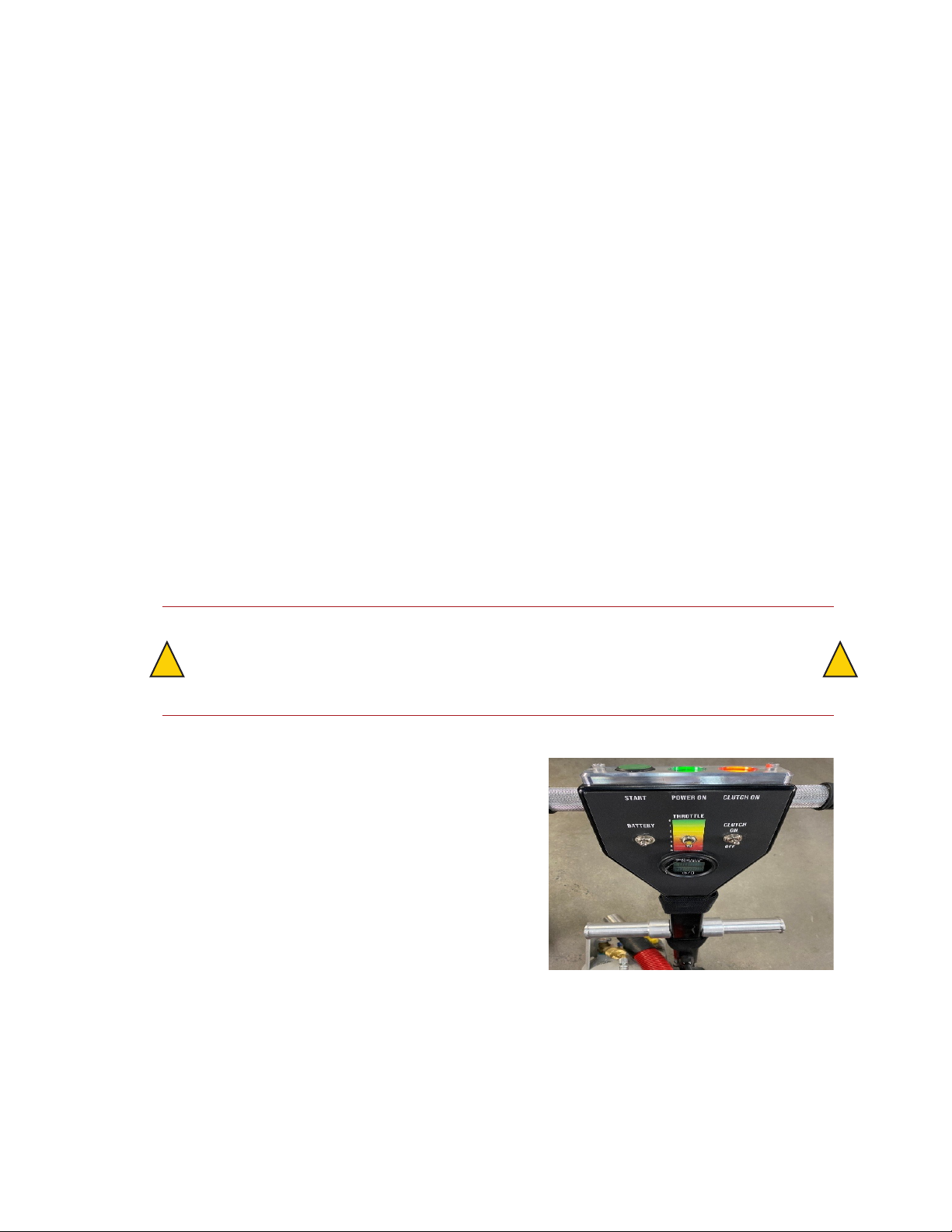

Machine Operation:

The engine runs with propane vapor only designed to allow

the user to operate the equipment with lower and higher

RPM (3600 MAX). Never run at full Throttle!

LCD DISPLAY – Shows RPM of the engine and running hours.

Starting the equipment:

Once a day if the machine is in use Check the oil level and check for any leaks, either oil or propane.

1. Turn on propane

• Make sure tanks are not overfilled

• Don’t tilt more than 15 degrees so as to not suck up liquid.

• As tank level goes down you can increase to 45 degrees.

2. Turn on battery switch.

8

! !

WARNING:

Misuse or failure to follow the safety rules stated in this instruction manual may cause

serious personal injury.

SAVE THESE INSTRUCTIONS.

Rhino RlP800 machine operation continued

9

3. Make sure clutch switch is off (if its on the orange light will come on) Also make sure that you have

the correct tooling on the tool plates and that the drive pins are properly seated into the grommets.

A spray of WD40 on the grommets helps the pins to go in particularly on new grommets.

NOTE:

Never engage clutch more than three times in one minute.

This will overheat the magnetic field and damage the clutch.

4. Depress green start button until engine starts.

• Let engine run for 5 minutes or so to warm up.

5. Increase engine RPM by holding throttle switch down to increase to 2000-2200 RPM.

6. Engage Clutch and start grinding.

7. To stop grinding - decrease RPM and then disengage clutch by turning off toggle switch

(the orange light will turn off)

8. Turn off battery switch to stop engine.

9. If machine is not being used for more than 15 minutes or longer then turn off propane at the tank.

NOTE: The equipment is designed to rotate the tooling in one direction ONLY.

RED plates spin counterclockwise while the BLACK plates spin clockwise.

The orientation of tooling is important for directional tooling, such as PCD’s.

Heads speed is controlled by throttling the engine. RPM of the engine will be shown on the tachometer.

NOTE: Do not run the machine with the propane tank over filled. Do not run the machine tilted back or with

the propane tank leaning more 15° vertically. Do not store the machine leaning back, not following

the manufacture recommendations could cause damage to the equipment or injuries.

Never exceed the maximum speed of the tooling being used! Doing so could cause tooling to eject

from the tool plate holder or cause irreparable damage to the surface being finished.

DO NOT TILT OR LIFT THE EQUIPMENT OFF THE GROUND WHILE STARTING OR RUNNING!

Doing so can cause the tools to release from the equipment and cause damage to the surface being finished

and harm to the user!

Stopping the equipment:

To stop the equipment. We advise that closing the propane tank valve and bleeding the line is the proper way

for stopping the machine, although in emergency stop or a fast tool change over it is possible to stop the

engine by using the battery kill switch. In both cases the clutch MUST be disengaged first.

Changing tools and accessories:

Always turn off the engine and wait for a full stop when performing any operations to the bottom of the machine!

To change tool segments on the tooling plate, use a 13mm wrench or socket and/or a battery powered impact

driver. Remove 8mm bolt and lock washer, inspect threads if still in good condition they may be used to mount

new segments. Always start screws by hand first to avoid cross threading. Be cautious to not over-tighten.

When removing and inserting tool plates or adapter plates, be sure to inspect rubber grommets for signs

of wear and replace any damaged grommets.

Using grommets that are damaged or missing can cause unexpected equipment operation and increase

the chance of tool plate / adapter plate ejection or violent vibration leading to loss of control of equipment

and, damage to the tool plates and drive heads.

Rhino RlP800 machine operation continued

10

RLP800 Maintenance:

General:

- Kill the battery switch and close the propane while performing any maintenance, cleaning, or repairs to your equipment!

- When the equipment is not in use, make sure that the adapter plate assemblies have something attached to

them to protect the Velcro. Resting the machine directly on unprotected Velcro will crush the fastening material

causing the Velcro to become unusable.

Weekly:

- Wipe down the equipment after every job.

- Gently remove dirt and debris from the Velcro hook material using a wire brush. This will ensure maximum adhesion.

- Check that the handle bolts are tight.

- Vacuum or wipe underside of machine.

- Inspect exposed electric connection ends for signs of carbon deposits or arcing. Tighten loose screws

- Check for any Oil or Propane leak.

- Check the air filter.

- Check all fasteners and tighten if necessary.

Handle adjustment:

To adjust the handle, pull either hand latch or depress foot latch on the handle and move handle up or down

to the desired position. Make sure that latch teeth engage completely when the desired position is achieved.

NOTE: Failure to check for positive engagement could result in damage to the equipment or injury to the

user as the handle could release unexpectedly when the machine is being operated or tilted back!

RLP800 DOUBLE GROMMET SYSTEM

There are 4 positions controlling tool plate articulation.

NOTE: Drive heads always have 6 grommets in every position.

Check grommets for wear and replace any torn or damaged grommets.

RIGID – This setup has 6 grommets on the drive heads and no grommets on the tool plate drive pins. Rigid position

is used for heavy PCD removal of thick coatings such as glue, mastic, thinset, epoxy flake/chip, elastomeric/rub-

berized parkade coatings etc. Rigid is also used for grinding a floor flat. When grinding/polishing concrete do not

use Rigid position if you are doing cream, salt and pepper or minimum aggregate exposure.

FLEX – This setup requires 6 additional grommets on each tool plate. These grommets are pushed onto each drive

pin with the thick side facing up. Flex is used for general grinding and polishing and normal removal of thinset,

coatings, glue and mastic.

SEMI FLEX – This setup requires 6 grommets placed on every tool plate drive pin. The grommets are placed with the

thin side up. This position is good for general grinding and polishing on wavy floors as well as very light removal of

thinset, glue, mastic and coatings. Also good for salt and pepper and minimum aggregate exposure.

FULL FLEX – This setup requires 3 grommets on each tool plate except they are pushed on with the thick side

facing up. This allows for maximum articulation to follow the floor as much as possible. This is used for cream

polish, salt and pepper and minimum aggregate exposure on wavy floors. Do not use this position on soft or rain

damaged concrete or for PCD or coarse diamond removal. Doing so will cause premature damage to grommets,

drive heads and tool plate drive pins.

Rhino RlP800 maINTENANCE continued

11

Monthly:

- Inspect handle wires for damage.

- Clean or replace air filter.

- Blow off engine fan with compressed air (30psi or less).

- Remove tool plate holders and wipe down seal plates with a damp cloth. Do not use any sharp object or

abrasive pad to clean the seal plates.

- Using a soft scrub pad, remove any excess dirt build up from the bottom plate and back side of pad drivers.

- Inspect tool plate driver grommets for signs of wear. Replace grommets that show signs of extensive wear.

Yearly - or after 100 hours of use:

- Change the oil and the oil filter.

SAE 5W30 (it takes 2.1L with a new filter) Check for possible overflow.

Oil Filter - P# B&S 695396.

- Change the Air Filter - P# B&S 798897

- Clean and lubricate wheels.

- Clean and lubricate handle latch mechanism.

Oil draining valve Oil cap and dip stick Oil filter

Rhino RlP800 TROUBLE SHOOTING DATA ANALYZER (EDA)

Installation:

Always start by disconnecting the 12 volt power supply battery before attempting installation/repair

of an engine equipped with the EDA system. Voltage spikes can occur, resulting in circuit damage.

CONNECTING EDA TO YOUR ENGINE:

- Red wire connects to the positive power source.

- Black wire connects to the ground on your engine.

NOTE: The ground wire should be kept as short as possible 12” supplied max.

- Blue wire connects to the oxygen sensor.

- Green wire has three optional connections:

No connection EDA functions as a warning light only.

Connects to an oil pressure switch (see diagram for oil switch hook up - page 12).

Connects direct to gas valve (see diagram without oil switch hook up - page 13).

Rhino RlP800 TROUBLE SHOOTING DATA ANALYZER (EDA) continued

12

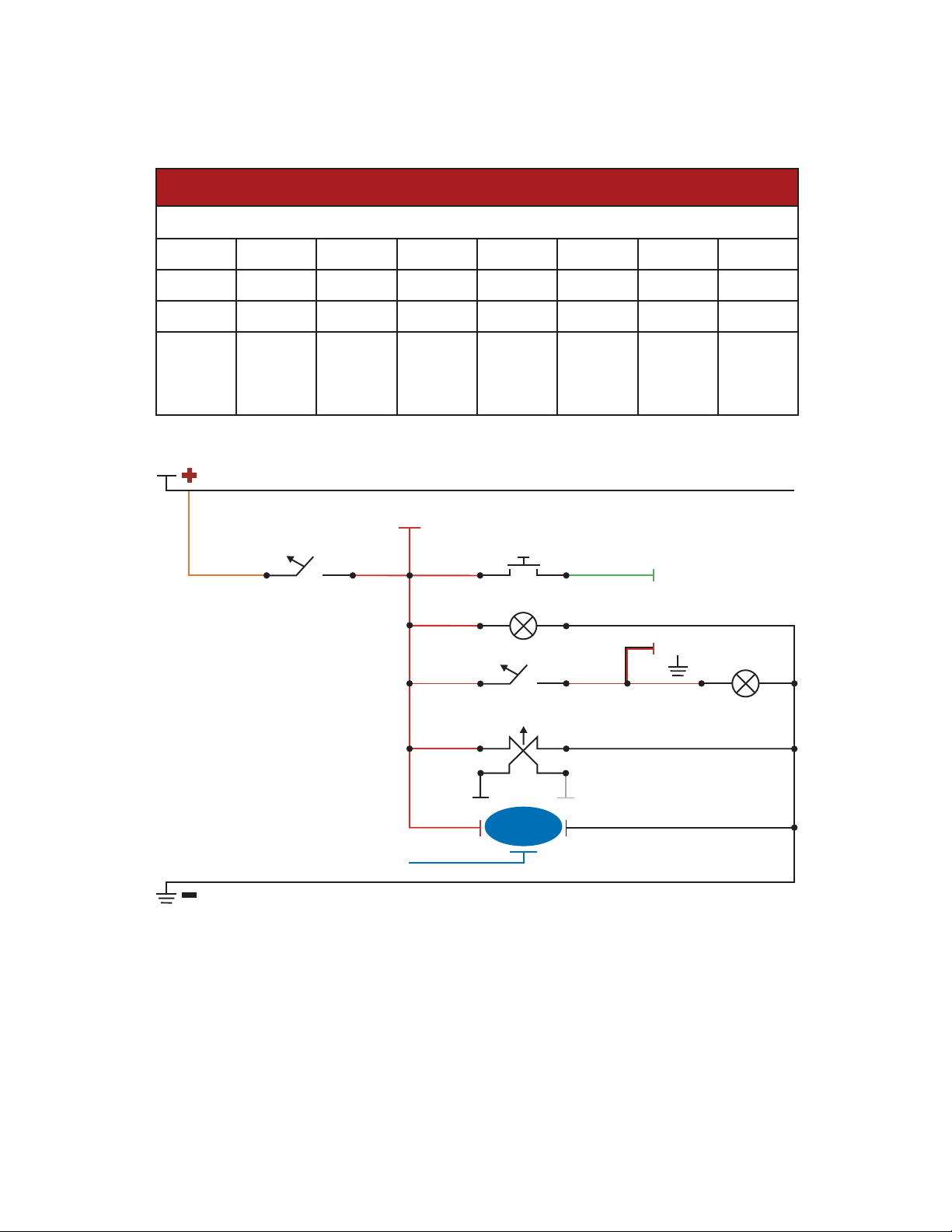

BLOCK CONNECTOR RLP800

TOP HANDLE WIRE

Orange + Black - Red + White/Black White Blue Red/Black + Green +

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

Battery +

Starter

Solenoid +

Battery -

Clutch -

EmissionAN+

Lock Out

Solenoid +

Actuator - Actuator + Tachometer S Clutch + Yellow +

Engine

Starter

OPERATION:

- The start up hold period begins when the ignition switch is activated. During this 7-8 second period the red

light glows while the system is calibrating itself.

- With all systems checked and passed the red light turns green indicating the engine is ready to start.

- After the engine has started, it takes approximately 90 seconds for the engine to reach operating temperature.

At this point if the light continues to glow green the engine adjustments and components are functioning properly.

If the engine is not adjusted properly or if there is a component failure the green light will turn to flashing red for

60 seconds. After 60 seconds flashing red, it will turn to solid red. If EDA is wired directly to the gas valve or oil

switch the engine will shut down when solid red is displayed.

RPM sensor

battery on/off start engine N.O.

EDA/EMS

battery on indicator

clutch on/off red w/black

to negative

actuator actuator

actuator toggle switch

engine starter +

clutch +

clutch on

indicator

tachometer

Rhino RlP800 TROUBLE SHOOTING DATA ANALYZER (EDA) continued

13

ground

black red

ground

battery (12V)

green

gas valve

key switch

blue

module

connector

O sensor

Hook-up with no oil

pressure switch

- If EDA is wired as a warning light the continuous glowing red light while running indicates something is wrong

with the engine. Note: EDA samples the fuel to air ratio every second, using five second sampling average to

determine all components are functioning properly.

- EDA green light/red light feature allows the operator/installer to use EDA as a tuner to determine optimum

fuel to air ratio for the engine it is installed on.

ENGINE CONDITIONS THAT WILL CAUSE A RED ALERT/ PRE-ALERT:

- Clogged or restricted air filter

- Regulator not adjusted correctly

- Vapor regulator exposed to liquid ingestion, freeze up requires regulator re-adjustment

- Overfilled cylinder or the wrong cylinder for a vapor application

- Damaged regulator from liquid ingestion, no longer adjustable, stretched diaphragms

- Damaged/worn/improperly adjusted spark plugs

- Low ignition voltage or no ignition on one or more cylinders

- Low compression on one or more cylinders

Rhino RlP800 WARRANTY

14

LIMITED EQUIPMENT WARRANTY OF SALE

NewGrind Inc. warrants that each new unit manufactured by NewGrind Inc. to be free from defects in

material and workmanship in normal use and service for a period of three years from date of shipment to

the original retail or equipment rental center owner. Accessories or equipment furnished and installed on

the product by NewGrind Inc. but manufactured by others, including, but not limited to engines, motors,

electrical components, transmissions etc., shall carry the accessory manufacturers own warranty.

NOTE:

Belts, Bearings and Clutches are not covered under warranty. Regulators that are damaged from

running Liquid Propane, are also not covered under warranty.

NewGrind Inc. will, at its option, repair or replace, at the NewGrind Inc. factory or at a point designated by

NewGrind Inc. any part which shall appear to the satisfaction of NewGrind Inc. inspection to have been

defective in material or workmanship. NewGrind Inc. reserves the right to modify, alter and improve any

part or parts without incurring any obligation to replace any part or parts previously sold without such

modified, altered or improved part or parts. This warranty is in lieu of and excludes all other warranties,

expressed, implied, statutory, or otherwise created under applicable law including, but not limited to

the warranty of merchantability and the warranty of fitness for a particular purpose in no event shall

seller or the manufacturer of the product be liable for special, incidental, or consequential damages,

including loss of profits, whether or not caused by or resulting from the negligence of seller and/or the

manufacturer of the product unless specifically provided herein. In addition, this warranty shall not apply

to any products or portions there of which have been subjected to abuse, misuse, improper installation,

maintenance, or operation, electrical failure or abnormal conditions and to products which have been

tampered with, altered, modified, repaired, reworked by anyone not approved by seller or used in any

manner inconsistent with the provisions of the above or any instructions or specifications provided with

or for the product.

Rhino RlP800 force majeure

15

FORCE MAJEURE

Seller’s obligation hereunder are subject to, and Seller shall not be held responsible for, any delay or failure to

make delivery of all or any part of the product due to labor difficulties, fires, casualties, accidents, acts of the

elements, acts of God, transportation difficulties, delays by a common carrier, inability to obtain product,

materials or components or qualified labor sufficient to timely perform part of or all of the obligations

contained in these terms and conditions, governmental regulations or actions, strikes, damage to or destruction

in whole or part of manufacturing plant, riots, terrorist attacks or incidents, civil commotions, warlike

conditions, flood , tidal waves, typhoon, hurricane, earthquake, lightning, explosion or any other causes,

contingencies or circumstances within CANADA not subject to the Seller’s control which prevent or hinder

the manufacture or delivery of the products or make the fulfillment of these terms and conditions

impracticable. In the event of the occurrence of any of the foregoing, at the option of Seller, Seller shall be

excused from the performance under these Terms and Conditions, or the performance of the Seller shall

be correspondingly extended. This document sets forth the terms and conditions pursuant to which the

purchaser (“Purchaser”) will purchase and New Grind Inc. (“Seller”) will sell the products, accessories,

attachments (collectively the products “) ordered by the Purchaser. These terms and conditions shall

govern and apply to the sale of Seller’s products to Purchaser, regardless of any terms and conditions

appearing on any purchase order or other forms submitted by Purchaser to Seller, or the inconsistency

of any terms therein and herein.

LIABILITY LIMITATIONS

The remedies of the user set forth under provisions of warranty outlined above are the exclusive and total

liability of NewGrind Inc. with the respect to their sale or the equipment and service furnished hereunder, in

connection with the performance or breach thereof, or from the sale, delivery, installation, repair or technical

direction covered by or furnished under the sale, whether based on contract, warranty, negligence, indemnity,

strict liability, or otherwise shall not exceed the purchase price of the unit of equipment upon which such

liability is based.

NewGrind Inc. will not in any event be liable to the user, any successors in interest or any beneficiary

or assignee relating to this sale for any consequential, incidental, indirect, special or punitive damages arising

out of this sale or any breach thereof, or any defects on, or failure of, or malfunction of the equipment under

this sale based upon loss of use, lost profits or revenue, interest, lost goodwill, work stoppage, impairment

of other goods, loss by reason of shutdown or non-operation, increased expenses of operation of the

equipment, cost of purchase or replacement power of claims of users or customers of the user for service

interruption whether or not such loss or damage is based on contract, warranty, negligence, indemnity, strict

liability, or otherwise.

NewGrind Inc. reserves the right to modify, alter and improve any part or parts without incurring any obliga-

tion to replace any part or parts previously sold without such modified, altered or improved part or parts.

No person is authorized to give any other warranty or to assume any additional obligation on NewGrind Inc.'s

behalf unless made in writing and signed by an officer of NewGrind Inc.

Rhino RlP800 terms & Conditions

16

1. PRICE

All prices set forth on any purchase order or other document are F.O.B. Sellers facility or distribution point, as may

be determined by Seller (F.O.B. Point). All prices are exclusive of any and all taxes, including, but not limited to,

excise, sales, use, property or transportation taxes related to the sale or use of the products, now or hereafter

imposed, together with all penalties and expenses. Purchaser shall be responsible for collecting and/or paying

any and all such taxes, whether or not they are stated in any invoice for the Products. Unless otherwise specified

herein, all prices are exclusive of inland transportation, freight, insurance and other costs and expenses relating

to the shipment of the Products from the F.O.B. point to Purchaser’s facility. Any prepayment by Seller of freight

insurance and other costs shall be for the account of Purchaser and shall be repaid to Seller.

2. PAYMENT TERMS

Payment terms are as follows: NewGrind Inc. Machines - Payment prior to delivery.

*All past due accounts are subject to a late payment fee of 1.5% per month or a maximum allowed by law if

different, along with the expenses incidental to collection including reasonable attorney’s fees and costs.

*Seller reserves the right to hold shipments against past due accounts.

*Seller reserves the right to alter payment terms.

3. FREIGHT TERMS

All shipments will be made F.O.B. shipping point as designated in these Terms and Conditions, and title shall

pass at the F.O.B. point. Delivery to the initial common carrier shall constitute delivery to the Purchaser. Any

claims for loss or damage during shipment are to be filed with carrier by the Purchaser.

Seller will not assume responsibility for the performance of the carrier. Backorders will be shipped in the

most practical fashion with charges consistent with our freight policy established with the original order.

UPS, FED EX, MAIL or shipments by other couriers are subject to the same terms and conditions as outlined

in paragraph #3 ”Freight Terms”.

4. DELIVERY, DAMAGES, SHORTAGES

Seller shall use reasonable efforts to attempt to cause the Products to be delivered as provided for in these

Terms & Conditions. Delivery to the initial common carrier shall constitute the delivery to the Purchaser.

Sellers responsibility, in so far as transportation risks are concerned ceases upon the delivery of the

Products in good condition to such carrier at the F.O.B. point and all the Products shall be shipped at the

Purchaser’s risk. Seller shall not be responsible or liable for any loss of income and/or profits, or incidental,

special, consequential damages resulting from Seller’s delayed performance in shipment and delivery.

5. RETURN OF DEFECTIVE PRODUCTS

Defective or failed material shall be held at the Purchaser’s premises until authorization has been granted by

Seller to return or dispose of Products. Products that are to be returned for final inspection must be returned

Freight Prepaid in the most economical way. Credit will be issued for material found to be defective upon

Seller’s inspection based on prices at time of purchase.

Rhino RlP800 terms & Conditions continued

17

6. PRODUCTS ORDERED IN ERROR

Products may be returned, provided that claim is made, and Seller is notified within 7 days of receipt of

Products, and the Products are in original buyer’s possession not more than 30 days prior to return, subject

to Seller’s approval. If Products are accepted for return, they must be Freight Prepaid and buyer will be

charged a minimum of 15% restocking charge, plus a charge back for outbound freight charges if the original

order was shipped prepaid. Returns are not accepted for any Products that are specifically manufactured

to meet the buyer’s requirement of either specifications or quantity.

NewGrind Inc.

103B- 81 Golden Drive, Coquitlam BC, CANADA V3K 6R2

Telephone: 1-888-467-0242

www.newgrind.com

agreements

These Terms and Conditions constitute the entire agreement between Seller and Purchaser as it relates to

terms and conditions of sale and supersedes any and all prior oral or written agreements, correspondence,

quotations or understandings heretofore in force between the parties relating to the subject matter hereof.

There are no agreements between Seller and Purchaser with respect to the Product herein except those

specifically set forth in and made part of these terms and conditions. Any additional terms, conditions

and/or prices are rejected by Seller. These terms and conditions may be modified, canceled or rescinded

only by a written agreement of both parties executed by their duly authorized agents.

Other manuals for RHINO RLP800

1

Table of contents

Other Newgrind Floor Machine manuals

Popular Floor Machine manuals by other brands

Numatic

Numatic TT-3450S operating instructions

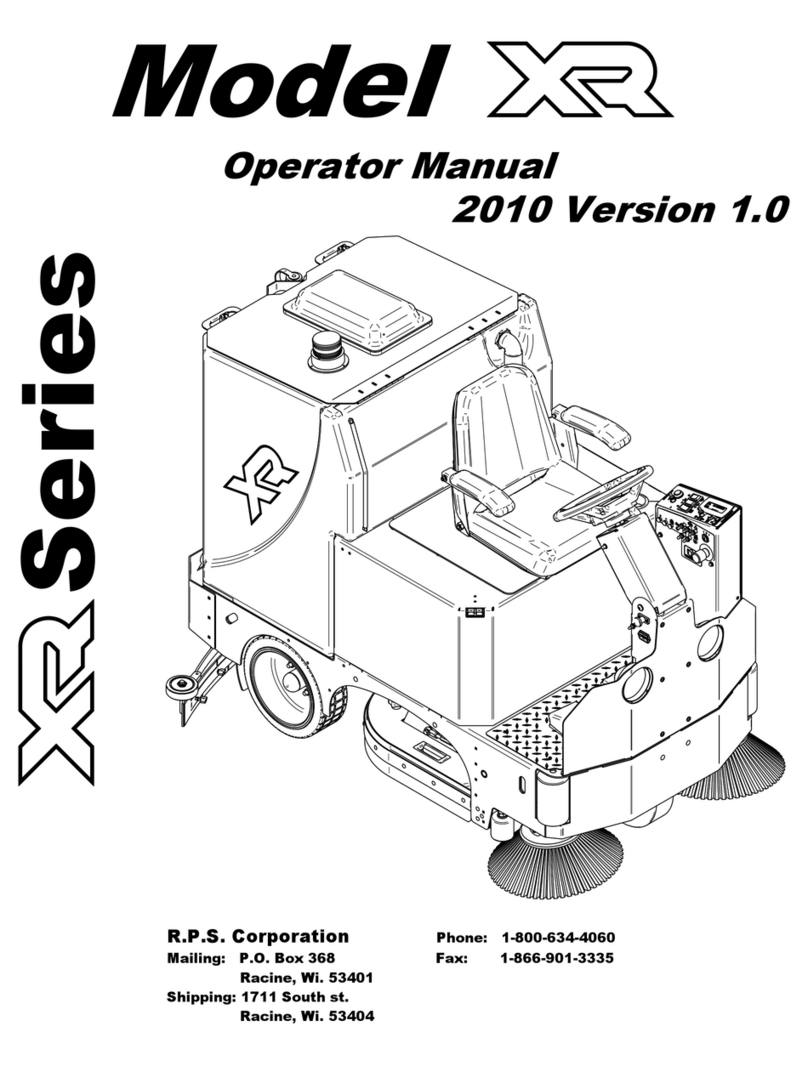

R.P.S. Corporation

R.P.S. Corporation XR 2010 Operator's manual

Nobles

Nobles EZ Rider HP Specifications

Nilfisk-Advance

Nilfisk-Advance Advenger BR 600S Series Instructions for use

KENT

KENT Klenzor 16 MPH Specifications

Viper

Viper SCRUBBER FANG 18C owner's manual