Newport Electronics P6000A User manual

P6000A/P5000

OUTPUT OPTIONS

ISOLATED PARALLEL BCD

DUAL 8 A RELAY

ISOLATED ANALOG OUTPUT

11361ML-01

NOTE: Refer to 10627ML-XX for P6000 Output Options Manual.

© Copyright 1995, NEWPORT ELECTRONICS, INC. ALL RIGHTS RESERVED.

This documentation may not be copied, photocopied, reproduced, translated, or

reduced to any electronic medium or machine-readable form, in whole or in part,

without prior written consent of NEWPORT ELECTRONICS, INC.

i

TABLE OF CONTENTS

ISOLATED PARALLEL BCD OPTION PAGE

1.0 GENERAL INFORMATION ..............................................................................1

2.0 MECHANICAL INSTALLATION.........................................................................1

3.0 ELECTRICAL CONNECTIONS .........................................................................1

3.1 Power ................................................................................................1

3.2 BCD Outputs ...........................................................................................2

3.3 Polarity Output.........................................................................................4

3.4 Decimal Point Binary Address...................................................................4

3.5 Overflow Output........................................................................................4

3.6 Alarm Outputs .........................................................................................5

3.7 DATA READY Output...............................................................................5

3.8 Instrument Select Inputs ...........................................................................5

3.9 HOLD Input .............................................................................................5

4.0 JUMPER SELECTION.....................................................................................6

5.0 CONTROLLER INTERCONNECTIONS..............................................................7

5.1 Interconnections with a Parallel BCD Printer ...............................................7

5.2 Interface with Programmable Controllers.....................................................9

6.0 PARALLEL BCD DRAWINGS........................................................................ 10

ILLUSTRATIONS

Figure 5-1 Connections with a Parallel BCD Printer

Using Right-hand Decimal Point ..................................................7

Figure 5-2 Connections with a Parallel BCD Printer

Using Left-hand Decimal Point.....................................................8

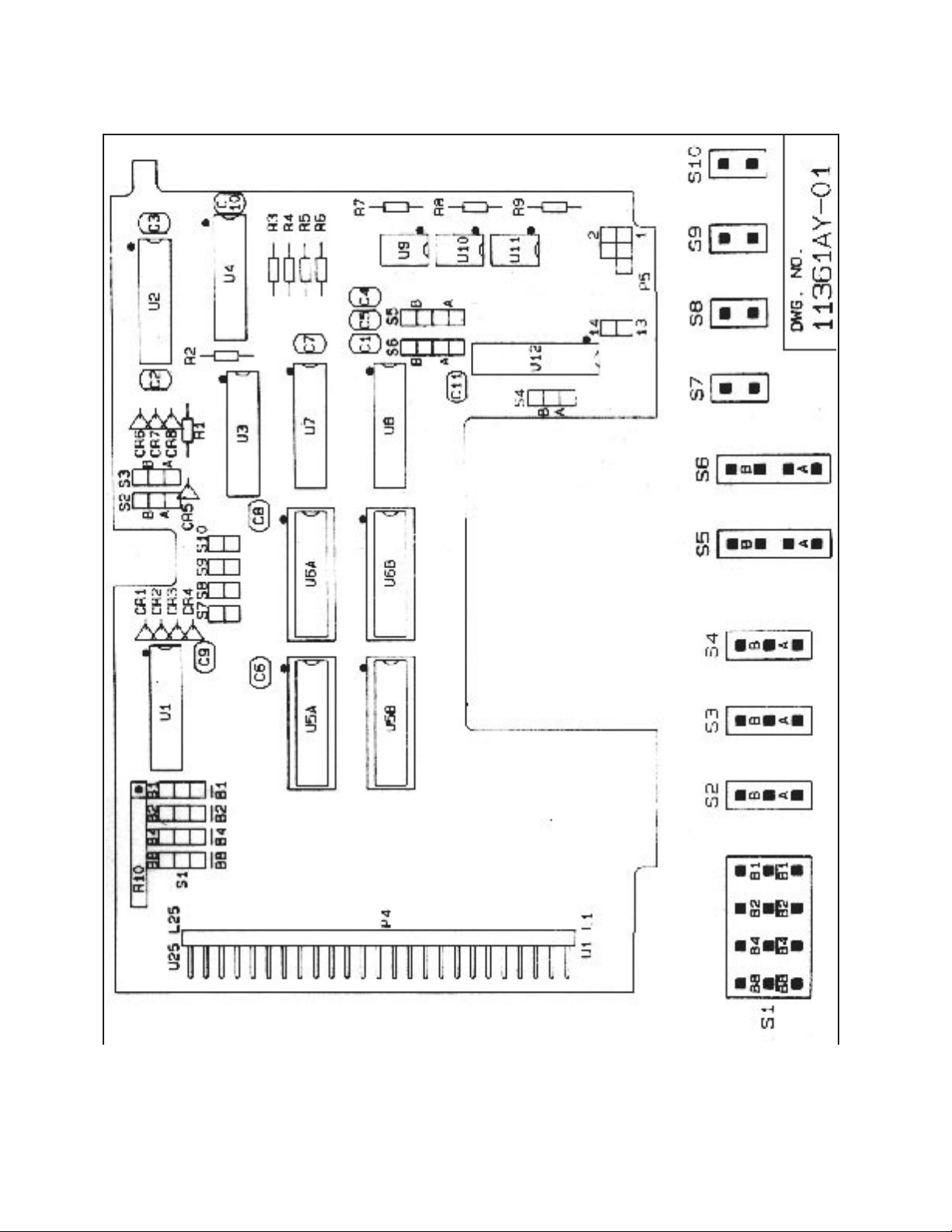

Figure 6-1 Parallel BCD Board Assembly Diagram...................................... 10

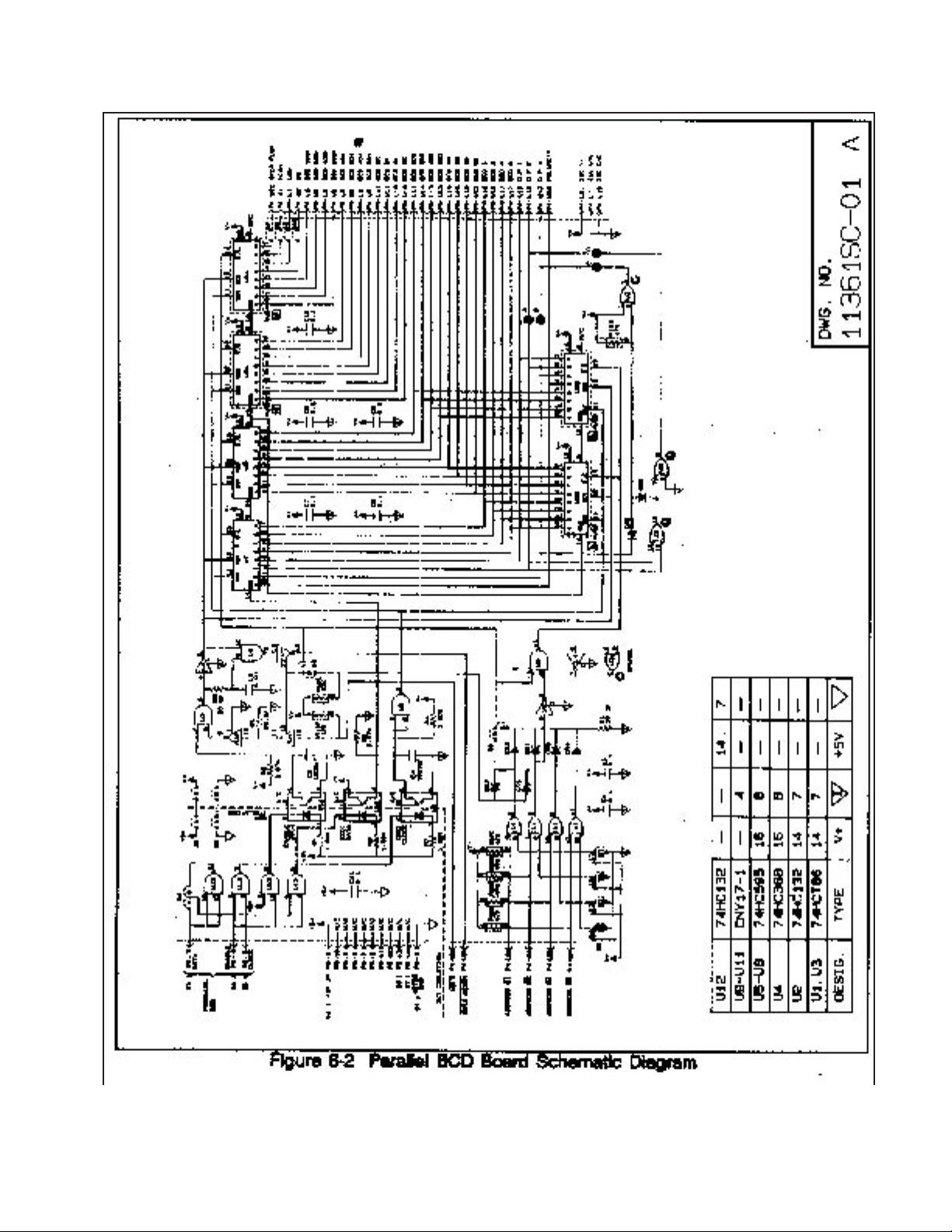

Figure 6-2 Parallel BCD Board Schematic Diagram..................................... 11

Table 3-1 Required Address to Enable Outputs ...........................................3

Table 3-2 Decimal Point Binary Address.....................................................4

CHG ECO NO DATE BY CHK

B 9261 21 JAN 98 ML

ii

DUAL 8 A RELAY OPTION PAGE

1.0 GENERAL INFORMATION .............................................................................. 12

2.0 MECHANICAL INSTALLATION......................................................................... 12

3.0 ELECTRICAL CONNECTIONS AND JUMPER SELECTION ................................ 12

3.1 Relay Outputs.......................................................................................... 12

3.2 S3 of the Relay Board............................................................................... 13

4.0 RELAY BOARD DRAWINGS........................................................................... 14

ILLUSTRATIONS

Figure 3-1 TB4 Connector with Electrical Connections................................... 12

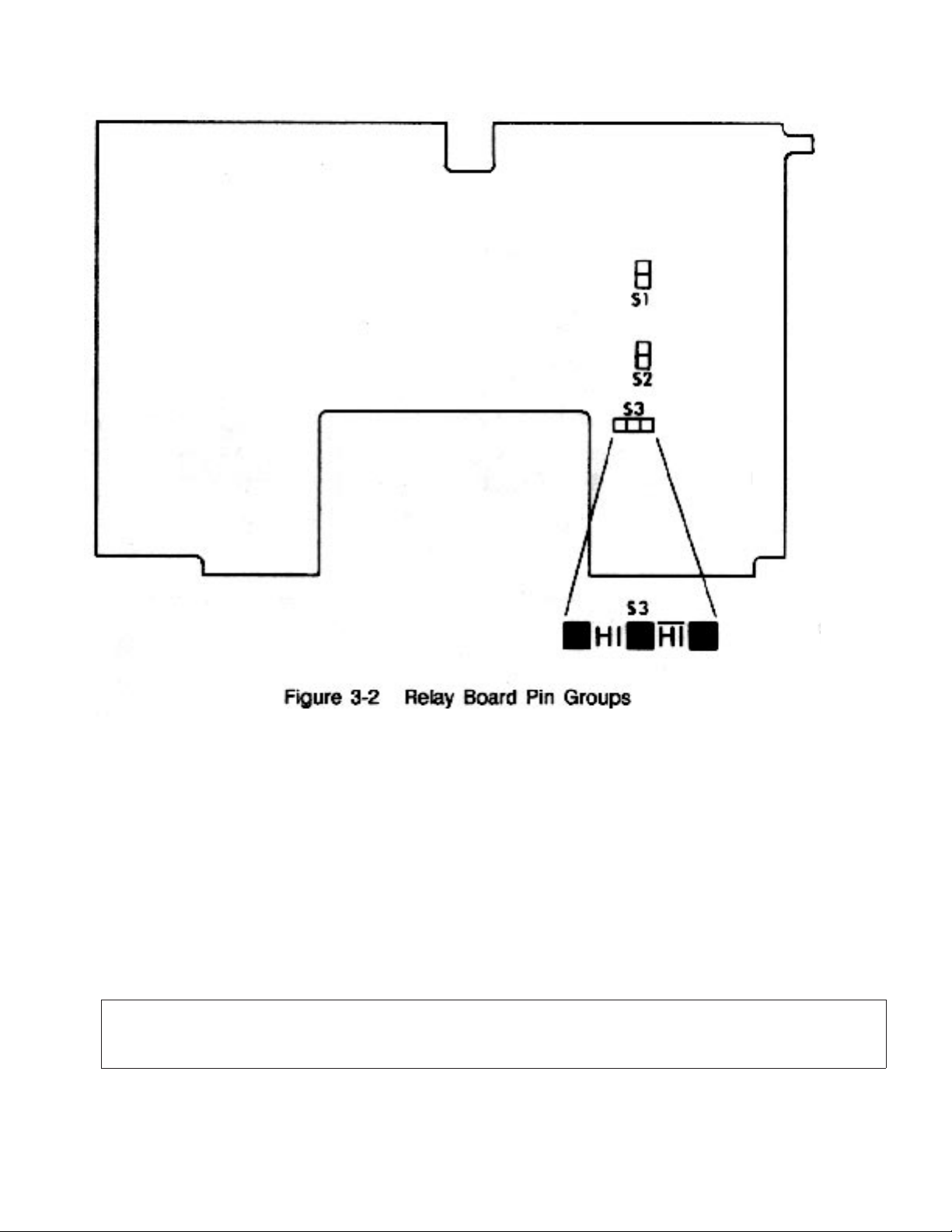

Figure 3-2 Relay Board Pin Groups ............................................................. 13

Figure 4-1 Relay Board Assembly Diagram .................................................. 14

Figure 4-2 Relay Board Schematic Diagram ................................................. 15

iii

ISOLATED ANALOG OUTPUT OPTION PAGE

1.0 GENERAL INFORMATION .............................................................................. 16

2.0 SPECIFICATIONS .......................................................................................... 16

2.1 Power and Signals ................................................................................... 16

2.2 Environment............................................................................................. 16

2.3 Output Control ......................................................................................... 16

3.0 ELECTRICAL CONNECTIONS & ADJUSTMENT LOCATIONS ............................ 17

4.0 CONFIGURATION PROCEDURE ..................................................................... 17

4.1 Output Range Selection............................................................................ 18

4.2 Display Range Selection........................................................................... 18

4.3 Span Range Selection .............................................................................. 18

4.4 Offset Range Selection ............................................................................. 19

5.0 MECHANICAL INSTALLATION......................................................................... 20

6.0 FRONT PANEL SETUP................................................................................... 20

7.0 CALIBRATION................................................................................................ 21

7.1 Voltage Output (V01)................................................................................ 21

7.2 Current Output (I01, I02)............................................................................ 21

7.3 Current Output (I02).................................................................................. 22

7.4 Preamp Zero Adjust (R7)........................................................................... 23

8.0 ISOLATED ANALOG OUTPUT DRAWINGS ...................................................... 24

ILLUSTRATIONS

Figure 3-1 Isolated Analog Output Option Rear View ..................................... 17

Figure 8-1 Isolated Analog Output Assembly Diagram................................... 24

Figure 8-2 Isolated Analog Output Schematic Diagram.................................. 25

Table 4-1 Output Ranges........................................................................... 18

Table 4-2 Display Ranges.......................................................................... 18

Table 4-3 Span Ranges............................................................................. 19

Table 4-4 Offset Ranges............................................................................ 20

iv

1

ISOLATED PARALLEL BCD OPTION

1.0 GENERAL INFORMATION

The optional parallel BCD board works concurrently in two output modes: 6-digit

parallel BCD (24 lines) and addressable 3-digit. In addition to the 6-digit BCD, this

board outputs the alarm condition (High, Low and Go), polarity, overflow, and

decimal point binary address signals. The outputs are three-state and electrically

isolated from the main board. They are active when the appropriate address is

applied on connector P4, pins L24, U24, L23, and U23. The inputs are internally

connected to the main board via the interconnection of P5 with J5.

Outputs are available on P4, a 50-pin dual-row header at the rear of the board. The

P4 mates with a standard, 50-pin mass-terminated connector. The P4 outputs can

be frozen by making the HOLD input (P4-U21) low. Although the BCD outputs are

always valid, the DATA READY signal goes active low for approximately 0.2

millisecond when BCD data is updated.

2.0 MECHANICAL INSTALLATION

The parallel BCD board is positioned as an upper board in the P6000A/P5000.

Refer to the exploded view in the main board manual.

To avoid electrical shock be sure to disconnect the unit from its power supply.

To install:

1. Hold the board upside-down with components facing the main board.

2. Position the P5 pins to mate with the J5 connector on the power supply

board.

3. Push the board downward until it rests on the upper rear panel and the

display board.

3.0 ELECTRICAL CONNECTIONS

NOTE: The software switch SS3 of Configuration 2 must be set (XXX1XX)

to activate the parallel BCD board. For more information, refer to

Section 4.1 of the P6000A/P5000 main board manual.

3.1 POWER

A n is olat ed + 5 V ±10% ext ernal power supply is required and s hould be c onnect ed t o pi n

P4-L21 (+5 V) and pin P4-L19 (ISO GND). If isolation is not required, S5A, S5B, S6A, and

S6B may be installed to power the parallel BCD option by the main board.

2

3.2 BCD OUTPUTS

The board is factory-set as 6-digit parallel BCD. Outputs are enabled when the

binary address on the instrument select lines, pins L24, U24, L23, and U23, match

the board address (set by pin group S1). The output polarity is normally positive

true (reversible by S4) and each output can drive 10 LSTTL loads.

(N/C) ALARM LOW L1 U1 ALARM HIGH (N/C)

(N/C) N/C 2 2 ALARM GO (N/C)

(N/C) N/C 3 3 N/C (N/C)

(N/C) N/C 4 4 N/C (N/C)

(N/C) BCD 400 k 5 5 BCD 800 k (N/C)

(N/C) BCD 100 k 6 6 BCD 200 k (N/C)

(ISO GND) ISO GND 7 7 N/C (N/C)

(N/C) BCD 40 k 8 8 BCD 80 k (N/C)

(N/C) BCD 10 k 9 9 BCD 20 k (N/C)

(N/C) BCD 4 k 10 10 BCD 8 k (N/C)

(N/C) BCD 1 k 11 11 BCD 2 k (N/C)

(ALARM HIGH) D P 2 12 12 D P 4 (ALARM LOW)

(BCD 400 k) BCD 400 13 13 BCD 800 (BCD 800 k)

(BCD 100 k) BCD 100 14 14 BCD 200 (BCD 200 k)

(BCD 40 k) BCD 40 15 15 BCD 80 (BCD 80 k)

(BCD 10 k) BCD 10 16 16 BCD 20 (BCD 20 k)

(BCD 4 k) BCD 4 17 17 BCD 8 (BCD 8 k)

(BCD 1 k) BCD 1 18 18 BCD 2 (BCD 2 k)

(ISO GND) ISO GND 19 19 D P 1 (OVERFLOW)

(DATA READY) DATA READY 20 20 POLARITY (ALARM GO)

*ISO V+, 4 5 TO 5 5 V 21 21 *HOLD (HOLD)

(N/C) N/C 22 2 2 OVERFLOW (N/C)

*BOARD ADDR B4 23 23 *BOARD ADDR B8

*(BCD 1-800 ENABLE) BD ADDR B1 24 24 *BD ADDR B2(BCD 1-800k ENABLE)

(N/C) N/C L25 U25 N/C (N/C)

( ) Output in addressable 3-digit-at-a-time mode

* An input

N/C No internal connection

3

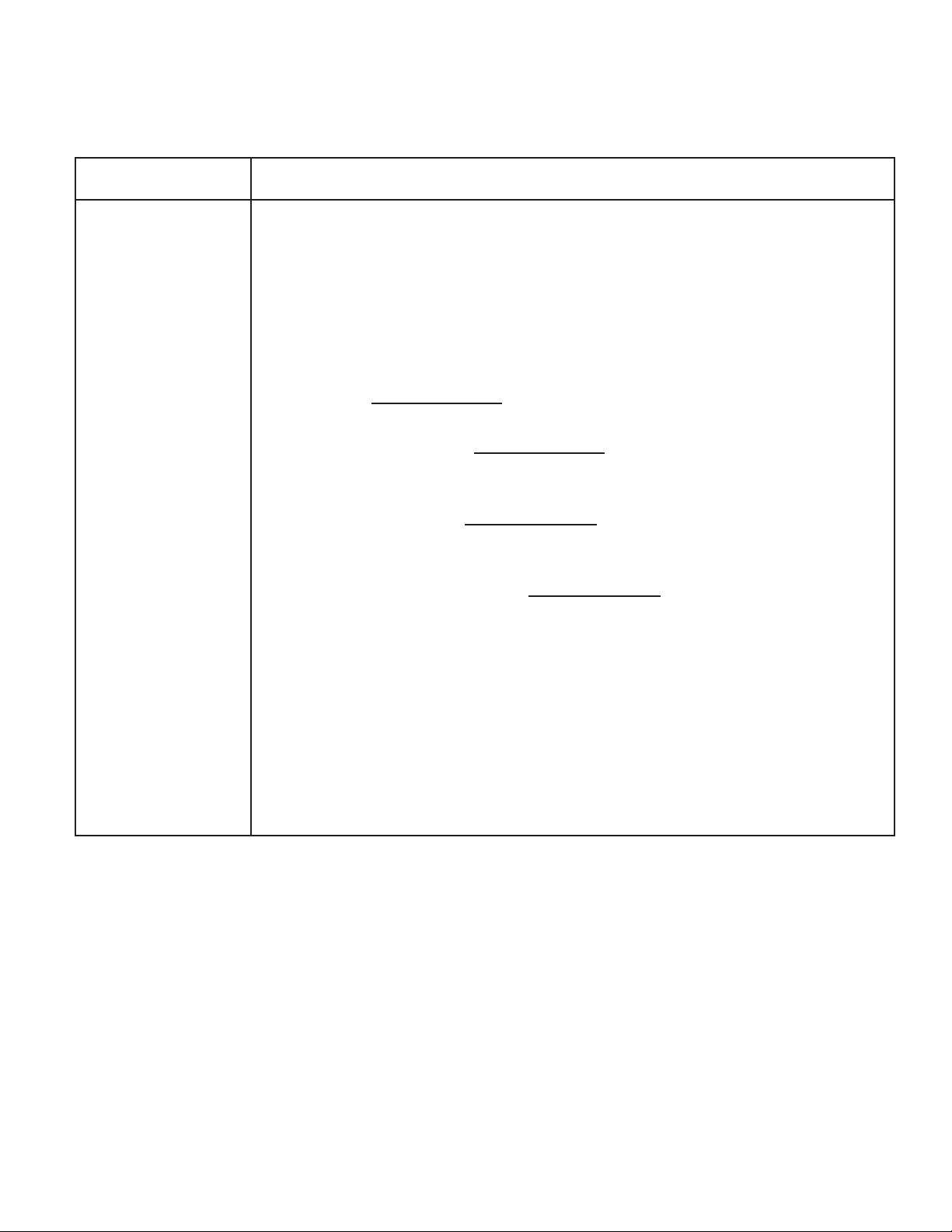

To enable the outputs, install jumpers on the pin groups and apply the proper address

on the instrument select lines as indicated below:

6-Digit

Parallel BCD S1 Positions Connector P4 with

Instrument Select Lines

U23 L23 U24 L24

Install jumpers on B8, B4, B2, B1* 0000

S2-A and S3-A; U5A B8, B4, B2, B1 0001

and U6A on XU5A B8, B4, B2, B1 0010

and XU6A sockets. B8, B4, B2, B1 0011

B8, B4, B2, B1 0100

B8, B4, B2, B1 0101

B8, B4, B2, B1 0110

B8, B4, B2, B1 0111

B8, B4, B2, B1 1000

B8, B4, B2, B1 1001

B8, B4, B2, B1 1010

B8, B4, B2, B1 1011

B8, B4, B2, B1 1100

B8, B4, B2, B1 1101

B8, B4, B2, B1 1110

B8, B4, B2, B1 1111

Addressable 3-Digit

Parallel BCD S1 Positions Connector P4 with

Instrument Select Lines

U23 L23 U24 L24

ENABLES ENABLES

BCD 1 - 800 BCD 1k - 800k

OVRFLW, HI,LO,GO D.P. 1,2,4, POL

Install a jumper on

S2-B and S3-B. X, X, B2, B1 X, X, X, 0 X, X, 0, 1

U5A and U6A on X, X, B2, B1 X, X, X, 1 X, X, 0, 0

XU5B and XU6B X, X, B2, B1 X, X, X, 0 X, X, 1, 1

sockets. X, X, B2, B1 X, X, X, 1 X, X, 1, 0

0 = Open or TTL High level (more than 2.0 V) X = Don't Care

1 = Ground or TTL Low level (less than .8 V) * = Default Setting

Table 3-1 Required Address to Enable Outputs

4

3.3 POLARITY OUTPUT

This three-state output is active when Digits 1, 2 and 3 are enabled. Signal

polarity can be reversed by a push-on jumper at S4. With a jumper on S4-A, a

high level corresponds to a positive display value.

3.4 DECIMAL POINT BINARY ADDRESS (D.P. 1, 2 AND 4)

These three-state outputs are enabled with Digits 1, 2 and 3. Signal polarity can be

reversed by a push-on jumper at S4. With a jumper on S4-A, the outputs represent

positive true binary address of a right-hand decimal point (see Table 3-2).

Decimal Point Position D.P. 4 D.P. 2 D.P. 1

FFFFFF. 001

FFFFF.F 0 1 0

FFFF.FF 0 1 1

FFF.FFF 1 0 0

FF.FFFF 1 0 1

F.FFFFF 1 1 0

Table 3-2 Decimal Point Binary Address

3.5 OVERFLOW OUTPUT

This three-state output is active when Digits 4, 5 and 6 are enabled. S4 reverses

the polarity. When a jumper is installed on S4-A, an overflow condition makes this

output go high. In this case, all of the digits of the parallel BCD board

represent a "9" (BCD 1001). The decimal point address corresponds to the

point selected as Fixed Range decimal point. S7 connects this output to

pin U22 of the P4 connector.

5

3.6 ALARM OUTPUTS (HI, LO, GO)

These three-state outputs are enabled with Digits 4, 5 and 6. S8, S9, and S10

connect HI, LO, and GO to P4-U1, L1 and U2, respectively. The polarity is positive

true (high level corresponds to an alarm condition) when a jumper is installed on

S4-A.

3.7 DATA READY OUTPUT

The output is always valid because the parallel BCD data updates synchronously

with a single clock pulse. A negative true DATA READY signal goes high,

however, for about 0.2 milliseconds when the parallel BCD data is updated.

3.8 INSTRUMENT SELECT INPUTS (P4-U23, L23, U24 AND L24)

These are TTL-compatible inputs with 47 k Ohms pull-up resistors. When the input

logic levels match the instrument address (set by S1), the outputs are enabled.

When the logic levels do not match, they are in high impedance. Refer to Table 3-1.

3.9 HOLD INPUT

When low, this input freezes the outputs and makes the DATA READY low true.

The internal BCD data continues to update. The updated data replaces the

outputs when HOLD goes high.*

* If the HOLD input goes high during transmission, the output update is postponed in

order to prevent erroneous output. Each transmission requires approximately 10

milliseconds.

6

4.0 JUMPER SELECTION

Pin Group Function

S1 Selects the binary address (Table 3-1).

S2 Jumper installed on A:* Board can be selected by four

address lines on connector P4, pins L24, U24, L23 and U23.

Jumper installed on B: A high or low level on L24 selects

the board when S1-B1 or S1-B1 are installed respectively.

S3 Controls the DATA READY output.

Jumper installed on A:* DATA READY is active low when

the input address matches the board address.

Jumper installed on B: DATA READY is active when P4-L24

matches S1-B1 or P4-U24 matches S1-B2.

S4 Inverts all output logics except DATA READY. S4-A*

corresponds to positive true logic.

S5, S6 Jumpers installed on A and B of S5 and S6: The main board

powers the parallel BCD board. The outputs are not isolated

from the main board. Default setting of these jumpers is open.

S7, S8, S9, S10 Connects Overflow, High, Low and Go signals to connector

P4, pins U22, U1, L1 and U2, respectively. Default setting

of these jumpers is open.

*Default Setting.

7

5.0 CONTROLLER INTERCONNECTIONS

5.1 INTERCONNECTION WITH A PARALLEL BCD PRINTER

If printing the decimal point is not required or if the printer recognizes a positive

true binary address for the decimal point, simply connect the 24 line BCD outputs

(6 digits x 4) to the corresponding inputs of the printer. For negative true BCD and

decimal point address, install S4-B. If the parallel BCD printer accepts more than

6Êdigits, tie the unused inputs (digits 7, 8, etc.) to GND or high level, as required,

to print a BLANK on those positions.

Some printers or data acquisition systems can only accept a binary address of a

left-hand decimal point (001 corresponds to XXXXX.X instead of XXXXXX.). For

interconnection to such a system, connect each digit (4 BCD lines) to the next

more significant digit input of the printer (e.g., D1→D2, D3→D4, . . . D6→D7).

With this method, all of the digits are printed one position to the left;

therefore, the decimal point prints in the correct position. Digit 1 input and

other unused inputs of the printer should be tied to the appropriate level

to print a BLANK or zero.

P6000A/P5000 Parallel BCD Parallel BCD Printer

ISO GND L7 GND

BCD 1 L18 BCD 1

DIGIT 1 BCD 2 U18 BCD 2 DIGIT 1

BCD 4 L17 BCD 4

BCD 8 U17 BCD 8

DIGIT 2 DIGIT 2

DIGIT 3 DIGIT 3

DIGIT 4 DIGIT 4

DIGIT 5 DIGIT 5

BCD 100 k L5 BCD 100 k

DIGIT 6 BCD 200 k U5 BCD 200 k DIGIT 6

BCD 400 k L5 BCD 400 k

BCD 800 k U5 BCD 800 k

d.p. 1 U19 d.p. B1 Decimal point

d.p. 2 L12 d.p. B2 binary address

d.p. 4 U12 d.p. B4 (right-hand

decimal point)

Figure 5-1 Connections with a Parallel BCD Printer

Using Right-hand Decimal Point

1

8

P6000A/P5000 Parallel BCD Parallel BCD Printer

To appro- BCD 1

priate level BCD 2 DIGIT 1

to print BCD 4

BLANK BCD 8

BCD 1 L18 BCD 10

DIGIT 1 BCD 2 U18 BCD 20 DIGIT 2

BCD 4 L17 BCD 40

BCD 8 U17 BCD 80

BCD 10 L16 BCD 100

DIGIT 2 BCD 20 U16 BCD 200 DIGIT 3

BCD 40 L15 BCD 400

BCD 80 U15 BCD 800

BCD 100 L14 BCD 1 k

DIGIT 3 BCD 200 U14 BCD 2 k DIGIT 4

BCD 400 L13 BCD 4 k

BCD 800 U13 BCD 8 k

BCD 1 k L11 BCD 10 k

DIGIT 4 BCD 2 k U11 BCD 20 k DIGIT 5

BCD 4 k L10 BCD 40 k

BCD 8 k U10 BCD 80 k

BCD 10 k L9 BCD 100 k

DIGIT 5 BCD 20 k U9 BCD 200 k DIGIT 6

BCD 40 k L8 BCD 400 k

BCD 80 k U8 BCD 800 k

BCD 100 k L6 BCD 1 M

DIGIT 6 BCD 200 k U6 BCD 2 M DIGIT 7

BCD 400 k L5 BCD 4 M

BCD 800 k U5 BCD 8 M

d.p. 1 U19 d.p. B1 Decimal point

d.p. 2 L12 d.p. B2 binary address

d.p. 4 U12 d.p. B4 (left-hand

decimal point)

Figure 5-2 Connections with a Parallel BCD Printer

Using Left-hand Decimal Point

9

5.2 INTERFACE WITH PROGRAMMABLE CONTROLLERS

If the controller can accept 24 bits of BCD data (32 bits if other data is also

required), the 6-digit parallel BCD mode can be used.

In addressable 3-digit-at-a-time mode, only half of the I/O lines are required. In this

mode, digits 4, 5, and 6, Overflow, High, Low, and Go signals can be accessed on

the same lines of Digits 1, 2, and 3, D.P. 1, D.P.2, D.P. 4 and Polarity signals.

Parallel BCD board can be configured as an addressable 3-digit-at-a-time BCD as

follows:

1. Move U5A and U5B integrated circuits (IC) to U5B and U6B sockets.

2. Install a jumper on S2-B and S3-B.

The outputs can be enabled by an appropriate logic level on U24 and L24 pins of

P4 (see Table 3-1).

10

6.0 PARALLEL BCD DRAWINGS

Figure 6-1 Parallel BCD Board Assembly Diagram

11

12

DUAL 8 A RELAY OPTION

1.0 GENERAL INFORMATION

The relay option provides two Form-C relays corresponding with LO and HI

setpoints of the P6000A/P5000. The inputs are internally connected and the

outputs are available on TB4, a 6-position barrier. TB4J, a mating screw-

clamp connector, is standard.

2.0 MECHANICAL INSTALLATION

The relay board is positioned as an upper board in the P6000A/P5000. Refer

to the exploded view in the main board manual.

To avoid electrical shock be sure to disconnect the unit from its power supply.

To install:

1. Hold the relay board upside-down with components facing the main

board.

2. Position the P5 pins to mate with the J5 connector on the power supply

board.

3. Push the board downward until it rests on the upper rear panel and the

display board.

3.0 ELECTRICAL CONNECTIONS AND JUMPER SELECTION

3.1 RELAY OUTPUTS

These outputs are available on the TB4 connector (Figure 3-1). The relay

board is rated for 8 A current with resistive and 3 A with inductive loads.

Push-on jumpers must be removed from pin groups S1 and S2 (Figure 3-2)

when the P6000A/P5000 is powered by an external battery (connected to

V+ of P2) with a voltage higher than 9 volts.

12345 6

COMMON

NORMALLY

OPEN

NORMALLY

CLOSED

COMMON

NORMALLY

OPEN

NORMALLY

CLOSED

HIGH ALARM LOW ALARM

Figure 3-1 TB4 Connector with Electrical Connections

13

3.2 S3 OF THE RELAY BOARD

If a jumper is installed on the HI position, high relay is energized when high alarm

is active.

If a jumper is installed on HI, the relay is energized when high alarm is not active

(LO or GO active). Also, with the jumper on HI, the high setpoint should be higher

than the low setpoint.

NOTE: Refer to the P6000A/P5000 main board owner's manual for low alarm

polarity reversal.

14

4.0 RELAY BOARD DRAWINGS

Figure 4-1 Relay Board Assembly Diagram

This manual suits for next models

1

Table of contents