C&S Electronics CSMPA22-2S User manual

TM

40.26

Electronic Motor Protection Relays

CSMPA (Analog : Electronic Motor Protection Relays)

Features (Inverse Time Characteristics Type - CSMPA22/40/80)

Technical Specification

n

n

n

n

n

n

n

n

n

n

n

n

Multiple protection: Over current / Phase failure / Stall /Asymmetry / Phase reverse.

Current setting upto 80A in 3 frame sizes.

Fault diagnose by LEDs indication.

Time setting 0 - 30 sec.

Accuracy : Current / Time + 5%.

Relays with built-in MCU (Micro Processor Control Unit)

o o

Environment operational temperature (-25 C to +70 C).

Compact design & Elegant outlook.

Common use of the Screw type & Tunnel type.

Applicable to the inverter circuit (20 - 200 Hz).

Mounting options : 35mm Din-rail or Screw.

Fail safe operation.

Model No. CSMPA22-2S CSMPA22- CSMPA40-2S CSMPA40- CSMPA80-2S CSMPA80-

3S/3SR 3S/3SR 3S/3SR

Type Screw Type

No. Of CT 2CT 3CT 2CT 3CT 2CT 3CT

Protection Overcurrent l l l l l l

Phase failure l l l l l l

Stall l l l l l l

Asymmetry – l– l– l

Reverse phase – l(3SR) – l(3SR) – l(3SR)

Current setting range (A) 0.3~1.5

1~5

4.4~22

Operating time characteristics Inverse time characteristics Inverse time characteristics

(CSMPA22-2PD: Definite time

Characteristics)

Time setting Inverse time 0~30 sec

(Sec) Reset time Manual Reset (Prompt); Reset after 1min (optional)*

Tolerance Current +5%

Time +5 (or+0.5sec)

Control Voltage AC 100~260V

Power Frequency 50/60Hz

Aux. Contact Contact 2SPST (When power applied, 1a1b)

Rating 3A/250VAC Resistive load

Operate (95 96Close) (97 98 Open)

Insulation resistance Min 100MW at 500V DC

Surge endurance (IEC 1000-4-5) 1.2 x 50 ms 6kV Apply the standard wave

Fast transient burst (IEC 1000-4-4) 2.5kV / 5min.

o

Environment Operation -25~70 C

o

Temperature Storage -30~80 C

Relative humidity 30~90%RH (No freezing)

Trip indicator Red LED Red/Green LED Red LED Red/Green LED Red LED 2Red LEDs

Dimension (mm) W x H x D) 53 x 68 x87.5 89 x 77.5 x 97.4

Mounting type Separate Mount Direct /Separate Mount

(Screw or DIN-Rail) (Screw or DIN-Rail)

* Auto Reset version available on special request only

4~20

8~40

16~80

10

CSMPA (Analog : Electronic Motor Protection Relays)

1. Check the rated voltage and apply the control supply to A1 and A2

terminal.

CAUTION : Do not apply 220 V to 110 V model.

2. Check the “TEST/RESET” button operation.

Check the operation of the output contact.

Check if the control voltage and wiring method is correct (Refer to the

contact configuration).

When you press the “TEST/RESET” button, the “O.L” LED is turned ON

(Red) and the relay is tripped.

When you press the “TEST/RESET” button under the relay is tripped, the

“O.L” LED is turned OFF and the relay is reset.

Auto reset function : When it is tripped by the over current, it is reset after 1

Min. (Optional).

CAUTION : For safety, when the motor is operating the “Test/Reset”

button do not work.

3. Set the operating time

The operating time is set on the base of 600% of the rated current in the

characteristic curve.

Set the operating time by considering the operating time and start current

according to the types of the load.

(Ex.: If the start current is 600% of the normal operating current and the

starting is 10sec., set the time knob around 11~12sec. with 10~20%

margin)

Operating time range is 0~30sec.

If the time knob is set to 10sec, the relay is tripped when the start current

(600% of the rated current) is applied for 10sec.

CAUTION : The relay with inverse time characteristics can be tripped to

protect the motor when the motor is started a few times continuously.

When a motor is frequently changing the rotating direction (forward and

reverse), set the operating time longer. For the crane and hoist use, select

the relay with definite time characteristics.

4. Set the operating current

Set the current by considering the rated current of a motor to protect from the

over current.

Check if the rated current of a motor is within the current setting range of

relay.

Set the ‘RC(A)’ (Rated current) knob to the maximum value and then start a

motor.

Under normal motor operation, rotate the ‘RC’ knob to the

counterclockwise until the ‘O.L’ LED turned ON&OFF. The current at this

point in the 100% current rating under real load.

At this point, rotate the ‘RC’ knob to the clockwise until the ‘O.L’ LED

turned OFF. In general case the setting value is around 110-120% of the

rated current. (Ex.: When the ‘O.L’ LED flickering at 20A, the setting

current will be 22A (=20x1.1)

Note : The brackets for connection is offered standard.

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

Protection : Over current & phase failure

Time setting : Starting time (0.2-30 sec)

: Operating time(0.2-15 sec)

Accuracy : Current/Time + 5% / (+0.5 sec)

Compact Size, Economical

Realys with built-in MCU (Micro Pressesor Control Unit)

Current setting: 0.5-6A or 5-60A options

Current setting 0.5-6A can be used upto 600A with external CT’s

Looping option is available for FHP Motors

Fault diagonstic by LED indication

Mounting option: 35mm Din-rail or Screw

Features (Definite Time Characteristics Type - CSMPA-6OT)

Operating & Setting of CSMPA22/40/80

O.L LED (2CT)

O.L/FAULT LED (3CT)

TEST/RESET

Button

RC(A) Knob TIME Knob

Indicate the cause of the fault by the LEDs

When it is tripped, you can check the causes of the fault by seeing the LED on it

and you can troubleshoot the causes in a short time

Condition

Operation Trip

Normal Off

Over On &

current Off

Over On

current

R On

Phase

failure S On

(3CT)

T On

Phase On &

failure(2CT) Off

Reverse On &

phase(3CT) Off

Protect 2phases of 3phases,

trips within 3sec.

Off

Off

Off

On &

Off

On &

Off

On &

Off

On &

Off

0.4 second

interval

1 Times for

3 second

2 Times for

3 second

3 Times for

3 second

One after

the other

Red O.L LED Green Fault LED Note

11

1. Tunnel type mounting

Check if the relay operate in overcurrent

Check the “TEST/RESET” button operation

Check if the wiring is correct (Refer to the wiring diagram).

Set the ‘D-time’ and ‘O-time’ knob to the min. ratings.

When the “TEST” button is pressed under tripped condition, the ‘O.L’

LED is turned off.

When you press the “TEST” button again then the lamp turned off and the

relay reset.

In operation, even though you press the “TEST/RESET” button, the

relay do not trip.

2. Set the operating time (Definite time characteristics)

D-TIME (Delay time) : 0.2~30sec.

The motor starting current, which flows when the motor is starting, is

generally 600~800% of the rated current and the delay time varies

according to the load condition. It is the time during which the relay do not

operate by over-current during the starting time.

Set the delay time by use of the ‘D-TIME’ knob.

In case you do not know the delay time, start the motor by setting the ‘D-

time’ knob to the max. position and after checking the time during which

the starting current become stable, set the ‘D-TIME’ (In general pump, the

setting time is 3-5 seconds)

Note : The time delay is forced time delay type, therefore if you make a

mistake to select the time, the motor may burn.

The operating time is the time during which the relay tripped by the over-

current. The relay is tripped after the selected operating time.

Set the operation time by the ‘O-TIME’ knob.

In special case such as for mechanical shock relay, if you set the ‘O-TIME’

to the min value, the relay is tripped at once.

Generally set it to 4~6 seconds.

3. Set the operating current (Similar to that of the screw type)

Set the operation current to protect from over current. Set the current by

considering the rated current

Start the motor by setting the ‘RC (A)’ knob to the maximum position.

Under operating condition, rotate the ‘RC(A)’ knob to the

counterclockwise until the ‘O.L’ LED turned on & off. The current at this

point is the value (100%) under real load condition.

Rotate the ‘RC(A)’ knob to the clock-wise until the ‘O.L’ LED turned off. In

general case the setting is 110~120% of the rated current.

4. Check the LED condition during the operation

Over current

The relay is not tripped during the ‘D-TIME’ under over-current but the

O.L LED turned on and off to indicate that the over-current flows.

If the relay is tripped after ‘D-TIME’ the ‘O.L’ LED turned on.

Phase failure

If a motor does not rotate under phase failure, the high current may flow.

At this time a motor is protected by the over-current protection function.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

n

n

n

n

n

n

Note :

Note :

Operating & Setting of CSMPA-6OT

CSMPA - 60T

CSMPA - 60TE

TM

12

O-Time Knob

O.L LED TEST/RESET Button

D-Time Knob

RC(A) Knob

O-Time Knob

O.L. LED TEST/RESET Button

RC(A) Knob

TM

Technical Specification

Model No. IMC

Operating time characteristic Inverse/Definite time

Current range (A) 0.125~60A (One device)

Time Setting(s) Inverse time 1~60sec/1sec (Class)

Definite time D-Time 1~200sec/1sec

O-Time 1~60sec/1sec

Auto returning time (R-T) 1~20min/1min, OFF (Manual returning)

Control Power Voltage AC 110V or AC 220V (+15%)

Frequency 50/60Hz

Power Consumption Under 6W

Output Contact (9Nos) Capacity 5A/250VAC

Construction Digital contact 3a Direct, Reversing, Y-D, Reactor, Inverter starter

Signal contact 3a Local, Auto, W/L condition

Timer contact 2a ON Delay, OFF Delay

Trip contact 1a Fault output

Output Contact (9Nos) Operation input Local, Auto, Water level, Flow switch

MC condition signal input Monitoring of sequence (LED)

External trip 2a Emergency, Sequence

ZCT Ratings 200mA/0. 1mA

Specification 25Æ, 40Æ, 80Æ

Indication 7-segment 3-phase current, Trip analysis, setting indication

LED Operation, Trip, System fail, Communication, Remote control

Condition

Self supervision System Fail LED, Error indication

Communication MODBUS/RS-485

Installation Panel inside installation/Door mounting

Wlthdrawable cable Basic cable 2m

Weight 0.6kg (MCT 0.35kg)

Dimension Main unit 148(W) x 100(H) x 74(D) mm

MCT 151(W) x 55(H) x 33(D) m

13

Characteristics Curve - CSMPA & CSMPM Series

1000

100

10

1

0.1

100 600 1000

Hot

Cold

10000

1000

100

10

1

100 600 1000

Hot

Cold

20

30

Time(sec)

9

100

Current (%)

150 200 300 400 500 600

1

3

5

7

Analog Relay: CSMPA 22/40/80

Digital Relay: CSMPM 6/60

Class 10 (10 Sec.)

10000

1000

100

10

1

100 600 1000

Hot

Cold

30

10000

1000

100

10

1100 1000

30

20

60

Definite time characteristics-CSMPA-60T/TE

Class 20/30 (20/30sec.)

Definite time characteristics

RST

MC

M

TR

FUSE

MCCB

OFF

(RESET)

MC ON

MC

A1 95 97

TRIP

A2 96 98

Relay

Y

Relay

RST

MC

M

Relay

TR

FUSE

MCCB

OFF

(RESET)

MC ON

MC

A1 95 97

TRIP

A2 96 98

Relay

Y

MC

M

MCCB

Relay

For additional

operational

power

A1 A2 95 96 98

1C

u

u

CSMPA-60TE, CSMPA-60T CSMPA-22/40/80 (2S/3S/3SR)

CSMPA-22 IN 5A (2S/3S/3SR)

With External Current Transformers

CSMPA-22/40/80(2S/3S/3SR)

(For Y-D Wiring)

RST

MCCB

MCD

relay

A1 95 97

A2 96 98

Relay

FUSE

TR

MCMMCS19T MCD

19X

OFF

(RESET)

ON

19X

MCD

19T 19X

MCS

MC

MCM

UVW

M

X Y Z

MCS

Note : When you use the relay inside of the line,

apply the 1/ 3 value of the rated current.

MCM

MCD

MCS

19T

19X

Magnetic Contactors for

Power use

Magnetic Contactors for

motor operation use

Magnetic Contactors for

motor starting use

Timer

Contactor Relays

14

Wiring Diagram of CSMPA Series

17

‘E’ - with extension cable available 1.5~4m length

Technical Specification

u

u

u

u

u

u

u

u

u

u

u

u

u

uu

u

u

u

u

u

53

10.2 11

6-M3.5screw

3-M4screw

7.2

30.5

8.2

51.6

44.8

68

u

u

u

u

u

u

u

u

u

u

87.5

40

72

15.7

27.7

u

u

u

u

97.4

80

u

u

u

u

u

u

u

u

u

u

u

u

u

uu

u

u

u

u

u

6-M6screw

89

57

20

40

23.5

77.5

95 96

11

6-M4screw

20.5

9

u

u

u

u

u

u

u

u

u

u

u

u

u

uu

u

u

u

u

u

6-M6screw

89

57

20

40

23.5

77.5

95 96

11

6-M4screw

20.5

9

u

u

u

u

u

u

u

u

u

u

M4 Mounting hole

17 48

5.5

53 6

54.2

72

5-M3.5

8

52

63

50.5

44

23.7

48.7

2-012

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

55

69

u

u

u

u

47 u

uu

u

9.5

R2.5 05

62.5

15

22

u

uu

u

u

u

u

u

u

u

u

u

44

7

4.5

CSMPA-60T

CSMPA-60TA

CSMPA-22-2S

CSMPA-80-2S

CSMPA-22-3S

CSMPA-80-3S

CSMPA-22-3SR

CSMPA-80-3SR

3 - CT 100~400 500~600

CSMPA-40-2S

CSMPA-40-3S

CSMPA-40-3SR

8-INSERT M4

118

74

22

45

8-Ø5.5

62.5

141

51

141

118

74

14.5 29

22

4-Ø6

63

153

165

75

70

6.3

12

2

Particular

Class

Burden

Insulation Voltage

Insulated impulse Voltage

Insulation Resistance

Mounting

1.0

5VA

600VAC

2kV

10MW (DC 500V Megger)

Panel

Specification

2-Ø5

55

31

161

8

262622 22 22

4-Ø6

43

173

185

55

75

6.3

34 34

17

Product code Range Control Voltage AC Remote Operation

IMC 0.125~60A 110 V/220 V

Product code Range Control Voltage AC Aux. Contact

CSMPM06-S 0.5 - 6 A 110/ 220 V 2a1b

CSMPM60-S 5 - 60 A 110/ 220 V 2a1b

CSMPM06-SI 0.5 - 6 A 110/ 220 V 2a1b

CSMPM60-SI 5 - 60 A 110/ 220 V 2a1b

CSMPM06-SZ 0.5 - 6 A 110/ 220 V 2a/2b/1a1b

CSMPM60-SZ 5 - 60 A 110/ 220 V 2a/2b/1a1b

CSMPA22-2S 0.3 - 1.5A 100 ~ 260 V 1a1b

CSMPA22-2S 1 - 5 A 100 ~ 260 V 1a1b

CSMPA22-2S 4.4 - 22 A 100 ~ 260 V 1a1b

CSMPA22-3S 0.3 - 1.5A 100 ~ 260 V 1a1b

CSMPA22-3S 1 - 5 A 100 ~ 260 V 1a1b

CSMPA22-3S 4.4 - 22 A 100 ~ 260 V 1a1b

CSMPA22-3SR 0.3 - 1.5A 100 ~ 260 V 1a1b

CSMPA22-3SR 1 - 5 A 100 ~ 260 V 1a1b

CSMPA22-3SR 4.4 - 22 A 100 ~ 260 V 1a1b

CSMPA40-2S 4 - 20 A 100 ~ 260 V 1a1b

CSMPA40-2S 8 - 40 A 100 ~ 260 V 1a1b

CSMPA40-3S 4 - 20 A 100 ~ 260 V 1a1b

CSMPA40-3S 8 - 40 A 100 ~ 260 V 1a1b

CSMPA40-3SR 4 - 20 A 100 ~ 260 V 1a1b

CSMPA40-3SR 8 - 40 A 100 ~ 260 V 1a1b

CSMPA80-2S 16 - 80 A 100 ~ 260 V 1a1b

CSMPA80-3S 16 - 80 A 100 ~ 260 V 1a1b

CSMPA80-3SR 16 - 80 A 100 ~ 260 V 1a1b

CSMAP60-T 0.5- 6 A 110/220/415 V 1c

CSMPA60-T 5- 60 A 110/220/415 V 1c

CSMPA60-TE 0.5- 6 A 110/220 V 1c

CSMPA60-TE 5- 60 A 110/220 V 1c

Intellegent Motor Controller with communication

Communication through

Models RS-485/RS-422

Inverse/Definite Time Characteristics - Comprehensive Digital Model

Inverse Time Characteristics - Analog Model

Definite Time Characteristics - Analog Model

NOTE:

2) All above Motor Protection Relay model CSMP06-S/SI/SZ with current range 0.5-6A / 1-5 A &

CSMPA with current range 0.5 - 6 can be used upto 600 A with suitable ratio CTs* having 5A secondary current,class 1 accuracy.

* Refer page (13 for 3CT technical specifications)

1) All auxiliary contacts are standard supply with relays indicated above except CSMPM-06/60 SZ model.

Select one of the three options (2a/2b/1a1b)for this model.

Quick Selection Table

* ‘a' denotes NO,'b' denotes NC & 'c' denotes Changeover Contacts*

18

Range of Motor Protection Relay

We touch your everyday! electricity

36-37, Sai-Dham Commercial Center,

Landewadi,Bhosari, PUNE-411039

Email: [email protected]

Website: www.genuineautomation.net

GENUINE AUTOMATION

This manual suits for next models

8

Popular Relay manuals by other brands

SPEL

SPEL Smart4house RE-00 Series Installation and operating instructions

Velleman

Velleman VMA331 user manual

GE

GE STD15C instructions

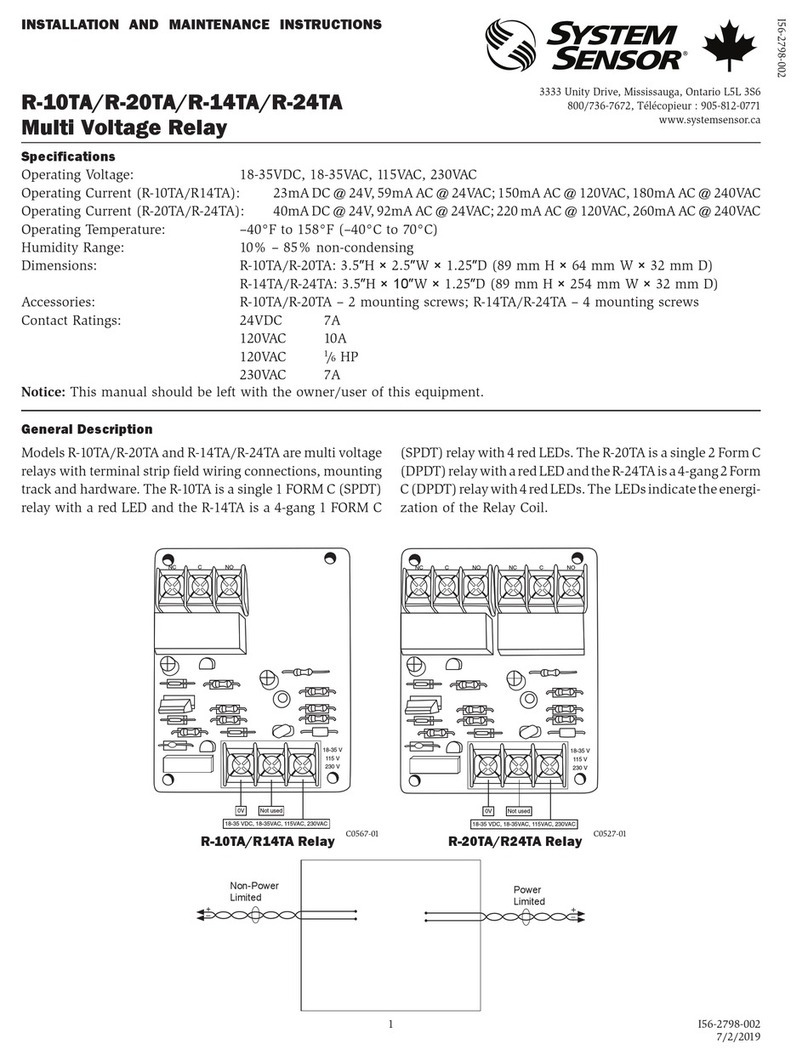

System Sensor

System Sensor R-10TA Installation and maintenance instructions

FANOX

FANOX SIA-F Series Installation & commissioning guide

Schweitzer Engineering Laboratories

Schweitzer Engineering Laboratories SEL-387-0 instruction manual