cyber®reaction wheel 2 Project planning guide

Revision: 02 Doc. no.: 5022-D060586 en-1

Contents

1About this manual 1

1.1 Signal words 2

1.2 Safety symbols 3

1.3 Structure of the safety information

3

1.4 Information symbols 3

2Product characteristics 4

2.1 cyber®reaction wheel 2 5

2.1.1 Type code 5

2.1.2 Name plate 6

2.1.3 Packaging and scope of delivery 6

2.1.4 System characteristics 7

2.1.4.1 DC power, torque and speed 7

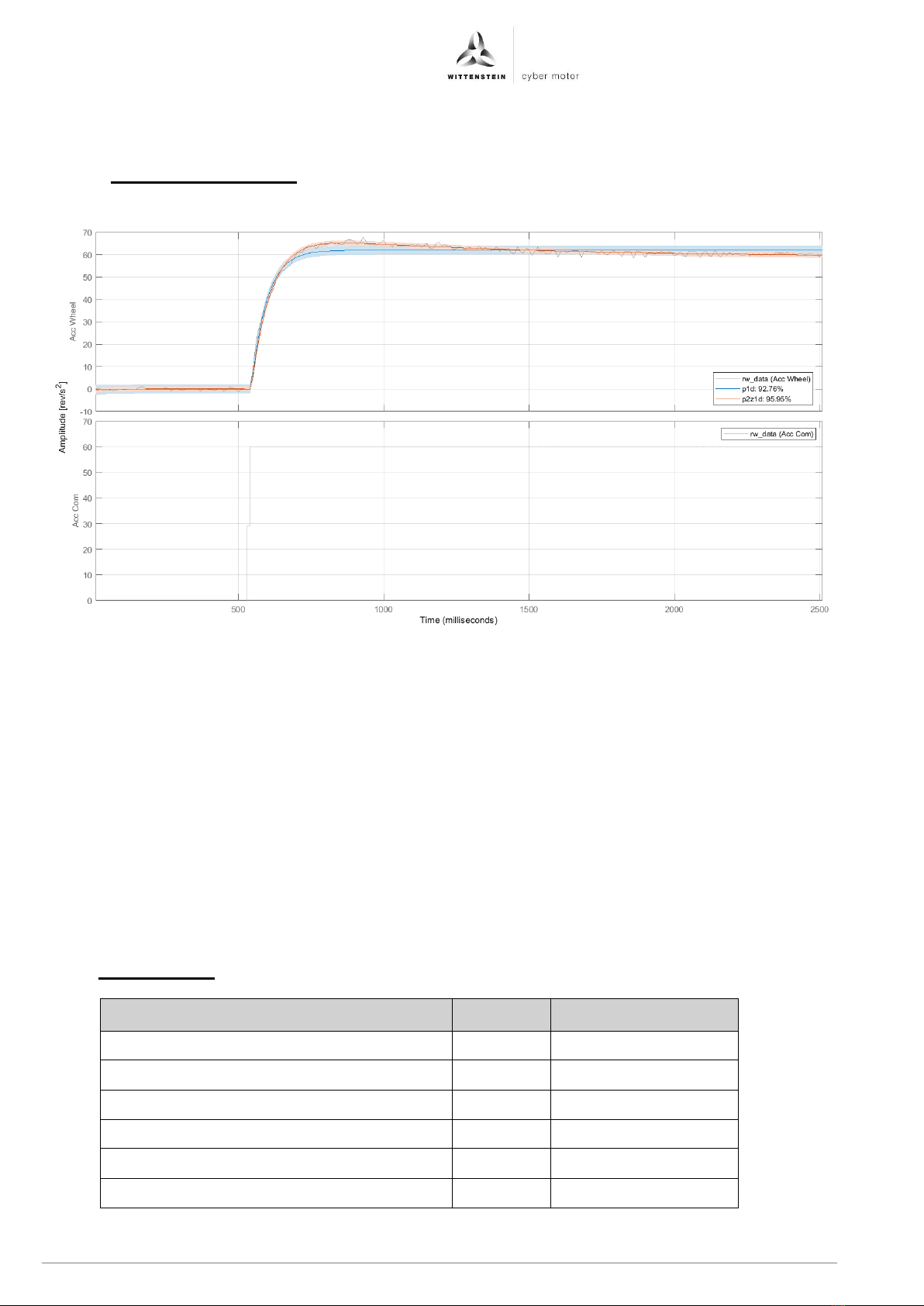

2.1.4.2 Control characteristics 8

2.1.5 Electrical data 8

2.1.5.1 Pin assignment of connector A 9

2.1.5.2 Pin characteristics of connector A 9

2.1.5.3 Use of digital IOs 10

2.1.6 Control and setpoint selection of

the reaction wheel 11

2.1.7 Ensuring availability of the

reaction wheel 11

2.1.8 Environmental conditions 12

2.1.9 Vibration/shock 12

2.1.10 Electromagnetic Compatibility

(EMC) 12

2.2 cyber®reaction wheel starter kit

13

2.2.1 Type code 13

2.2.2 Intended use 13

2.2.3 Packaging and scope of delivery 14

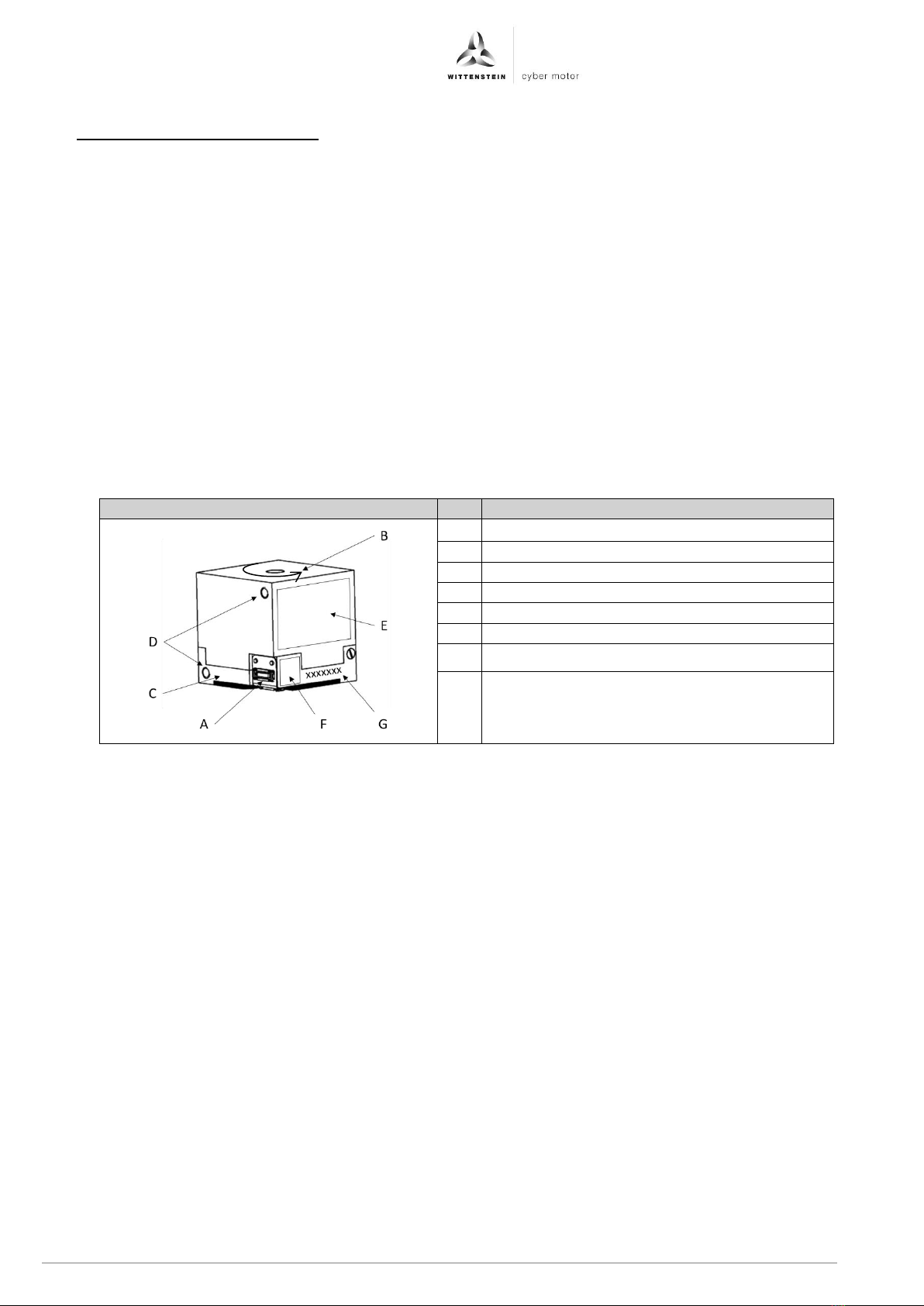

2.2.4 Structure 15

2.2.5 Electrical interfaces 16

2.2.5.1 A: USB port 16

2.2.5.2 B: Application interface 17

2.2.5.3 D: Interface to reaction wheel 18

2.2.5.4 E: Supply voltage 18

2.2.6 LEDs 19

2.2.7 Application notes 19

2.2.7.1 Setting the supply voltage 20

2.2.7.2 Provision of V-IO for the logic

blocks on the starter kit 20

2.2.7.3 Integration of digital IOs 20

2.2.7.4 UART switching 21

2.2.7.5 Brake chopper: Dissipation of

recuperation energy 21

2.2.8 Environmental conditions 22

2.3 Graphical user interface cyber®

reaction wheel assistant 23

2.3.1 Installation of the cyber®reaction

wheel assistant 23

2.3.2 CHM-Help 23

2.3.3 Oscilloscope 23

2.3.4 Setting of communication

parameters 24

2.3.4.1 Setting the I2C address 24

2.3.5 Changing important system

parameters 25

2.3.5.1 Setting the voltage limits 25

2.3.5.2 Setting speed and current limits 26

3Startup of the cyber®reaction

wheel 2 27

3.1 Safety instructions 27

3.2 Preparations 27

3.3 Startup with the cyber®reaction

wheel assistant 27

3.3.1 Installation at cyber® reaction

wheel starter kit 28

3.3.2 Establishing the power supply 28

3.3.3 Establishing a connection 28

3.3.4 Speed setting 29

3.4 Prototypical integration of the

cyber®reaction wheel 2 into an

ADCS environment 30

3.4.1 Preparations at the cyber® reaction

wheel starter kit 30

3.4.2 Example of an integration of a

reaction wheel for startup via SPI

with a Nucleo board from ST 30

3.4.3 Communication interfaces 32

3.4.3.1 I2C interface 33

3.4.3.2 SPI interface 33

3.4.3.3 UART interface 34

3.4.4 Wittenstein software stack for

integration of the reaction wheel 35

3.5 Diagnostics using the cyber®

reaction wheel assistant 35

3.6 Firmware update 36

3.6.1 Firmware update with the cyber®

reaction wheel assistant 36

3.6.2 Firmware update with ADCS 36

4Integration of the cyber®reaction

wheel 2 into a satellite 37

4.1 Electrical integration of the

cyber®reaction wheel 2 37

4.2 Mechanical integration of the

cyber®reaction wheel 2 38

4.3 Installation of the cyber®

reaction wheel 2 38

4.4 Requirements for power

adapters and supply voltage 39

4.5 Installation space 39

4.6 Mounting position 39

4.7 Cooling 39

4.8 Maintenance 39

4.9 Software-side integration in

ADCS 39