Application Guide PumpDrive 2 Eco

2016-11-11 PDrv2-Eco_Application_Guide_rev_1_4.docx

1. Pre-Conditions..............................................................................................................................3

1.1.1 Pump characteristc curve ...................................................................................................................................... 6

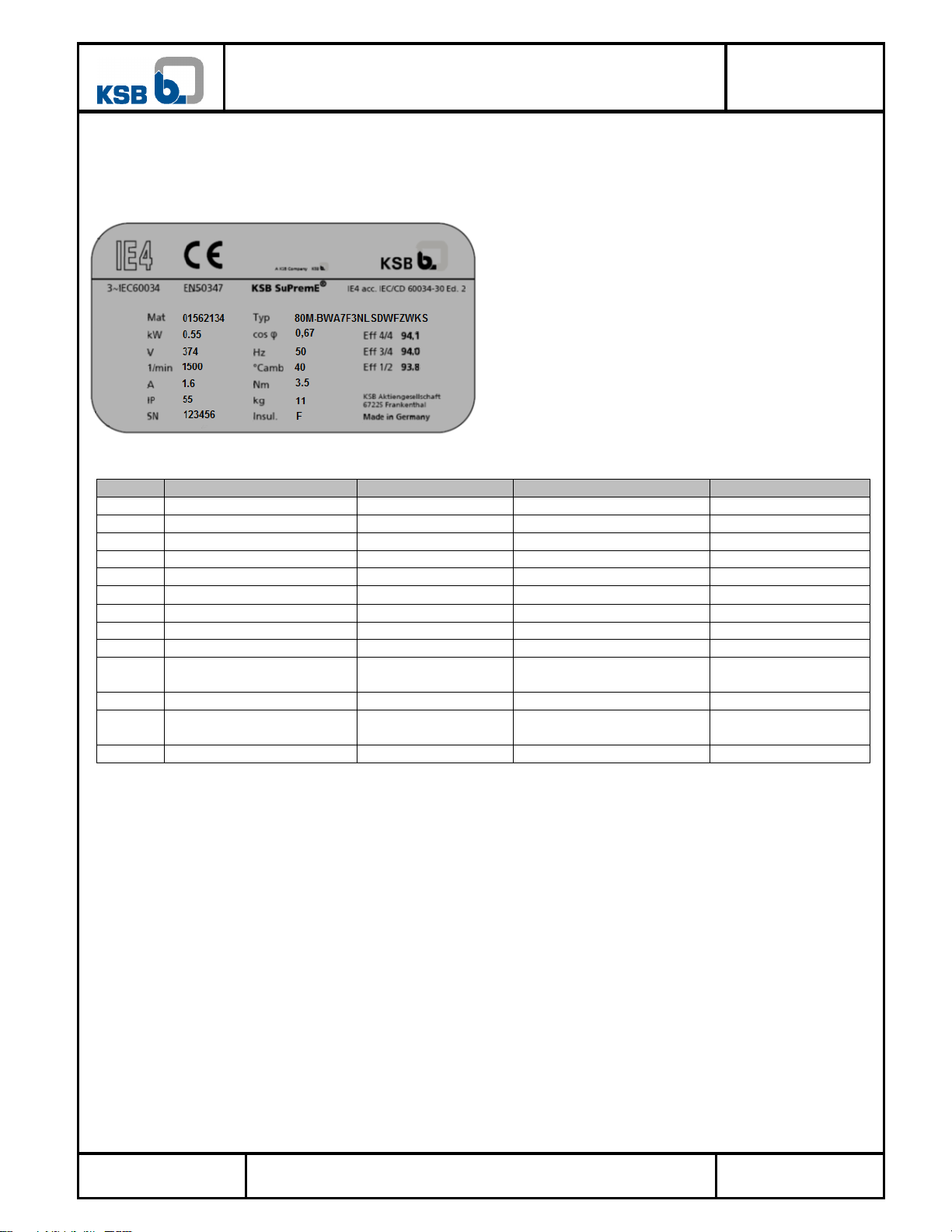

1.1.2 Parameterization of Motor data............................................................................................................................. 7

2. Single pump..................................................................................................................................8

2.1 Single pump –Open loop control...........................................................................................................8

2.1.1 Open loop control: control value at display.......................................................................................................... 8

2.1.2 Open loop control: control value by external signal 0…10V ............................................................................... 9

2.1.3 Open loop control: control value by external signal 4…20mA ...........................................................................10

2.1.4 Open loop control: digital motor potentiometer...................................................................................................11

2.2 Single pump –closed loop control........................................................................................................12

2.2.1 Closed loop control: Differential pressure with PumpMeter (Modbus)...............................................................12

2.2.2 Closed loop control: differential pressure with sensor 4…20mA ........................................................................13

2.2.3 Closed loop control: differential pressure with sensor 4…20mA set point via analog input ...............................14

2.2.4 Closed loop control: differential pressure with 2 pressure sensors 4...20 mA .....................................................15

2.2.5 Closed loop control: Sensorless differential pressure control..............................................................................16

2.2.6 Closed loop control: pressure with pressure sensor 4...20 mA ............................................................................17

2.2.7 Closed loop control: Pressure with PumpMeter (Modbus)..................................................................................18

2.2.8 Closed loop control: Pressure with Pressure sensor 0...10 V...............................................................................19

2.2.9 Closed loop control: Pressure, Set point (closed loop) at analog input 0…10V ..................................................20

2.2.10 Closed loop control: constant level at low pressure side with submersible sensor 4…20mA.........................21

2.2.11 Closed loop control: temperature with thermometer 4…20mA ......................................................................22

2.2.12 Closed loop control: Flow rate with flow rate sensor 4…20mA .....................................................................23

3. Double pump...............................................................................................................................24

3.1 Double pump –Open loop control.......................................................................................................24

3.1.1 Open loop control: control value at display.........................................................................................................24

3.1.2 Open loop control: control value with external signal.........................................................................................26

3.2 Double pump –closed loop control......................................................................................................28

3.2.1 Closed loop control non redundant: differential pressure with PumpMeter (Modbus) –typical application ......28

3.2.2 Closed loop control redundant: differential pressure with PumpMeter (Modbus)...............................................30

3.2.3 Closed loop control redundant: Discharge pressure with sensor 4…20mA and PumpMeter each pump ............32

3.2.4 Closed loop control redundant: Discharge pressure with pressure sensor 4…20mA via M12 ............................35

4. Pump functionality......................................................................................................................38

4.1 Closed loop control................................................................................................................................38

4.1.1 Closed loop control: dynamic differential pressure set point compensation based on flow rate estimation ........38

4.1.2 Closed loop control: dynamic differential pressure set point compensation based on speed...............................40

4.1.3 Open loop control: 1 fix speed selected by digital switches or variable speed via analog signal ........................41

4.1.4 Closed loop control: sleep Mode .........................................................................................................................42

5. M12 Cable....................................................................................................................................43

5.1 Bus cable for connecting PumpMeter to the M12-Module................................................................43

5.2 Bus cable for Double- and Multi Pump Operation.............................................................................44

5.3 Crosslink cable.......................................................................................................................................45

5.4 M12 Cable for fieldbus module Modbus RTU....................................................................................46

6. Project .........................................................................................................................................47

7. Other documents........................................................................................................................48