Newport L Series User manual

Electric Trolling Motor

L Series

User’s Manual

Please read and retain this manual before using product

REACH RoHS

2

Contents

1 General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Find Your Serial Number................................ 4

2 Specications .............................................. 5

3 WiringandBatteryRecommendations ................... 5

3.1 Battery Type............................................ 5

3.2 Circuit Protection....................................... 5

3.3 Cable Size.............................................. 5

4 Safety Information ......................................... 6

5 FirstTimeRunning ......................................... 7

6 TransomMountUsage ..................................... 8

7 BatteryMeterReading..................................... 9

8 MotorOperation........................................... 10

8.1 Battery Connection Method (12 Volt only) ............. 10

8.1.1 Connection With One Battery (12V DC) .............. 10

8.1.2 Connection With Two Batteries in Parallel (12V DC) ... 10

8.2 Battery Connection Method (24 Volt only) .............. 11

8.2.1 Connection With Two Batteries in Series (24V DC) .... 11

8.3 How To Control The Motor ............................. 11

3

8.3.1 On/Off Speed Control ............................. 11

8.3.2 Adjusting Motor Depth ............................ 12

8.3.3 Adjusting Steering Tension ........................ 12

8.3.4 Raising The Motor ................................ 12

8.3.5 Lowering The Motor .............................. 12

9 How to Replace the Propeller ............................ 13

10DailyMaintenance ........................................ 14

11TroubleShooting .......................................... 15

11.1 Loss of Power ......................................... 15

11.2 Motor Makes Excessive Noise or Vibration............. 15

11.3 Motor Fails to Run..................................... 15

11.4 Motor Loses One or More Speeds...................... 16

12AboutCircuitbreaker ..................................... 16

12.1 Function of the circuit breaker......................... 17

13DeclarationofConformityforRecreationalCraft ....... 18

14CustomerSupport......................................... 18

4

1 General Information

Thank you for purchasing our product. We hope that you enjoy it!

Newport Vessels trolling motors are designed and developed by pro-

fessional engineers and the design is continually honed and improved.

There are a wide range of Newport Vessels outboard motors, from 36lbs

to 86lbs, to suit every customer’s requirements and uses.

Please read and retain this manual before using this electric motor. This

manual contains information that describes the procedure for safe op-

eration and daily maintenance of your electric motor. Safe operation will

prevent personal injury and damage to the product.

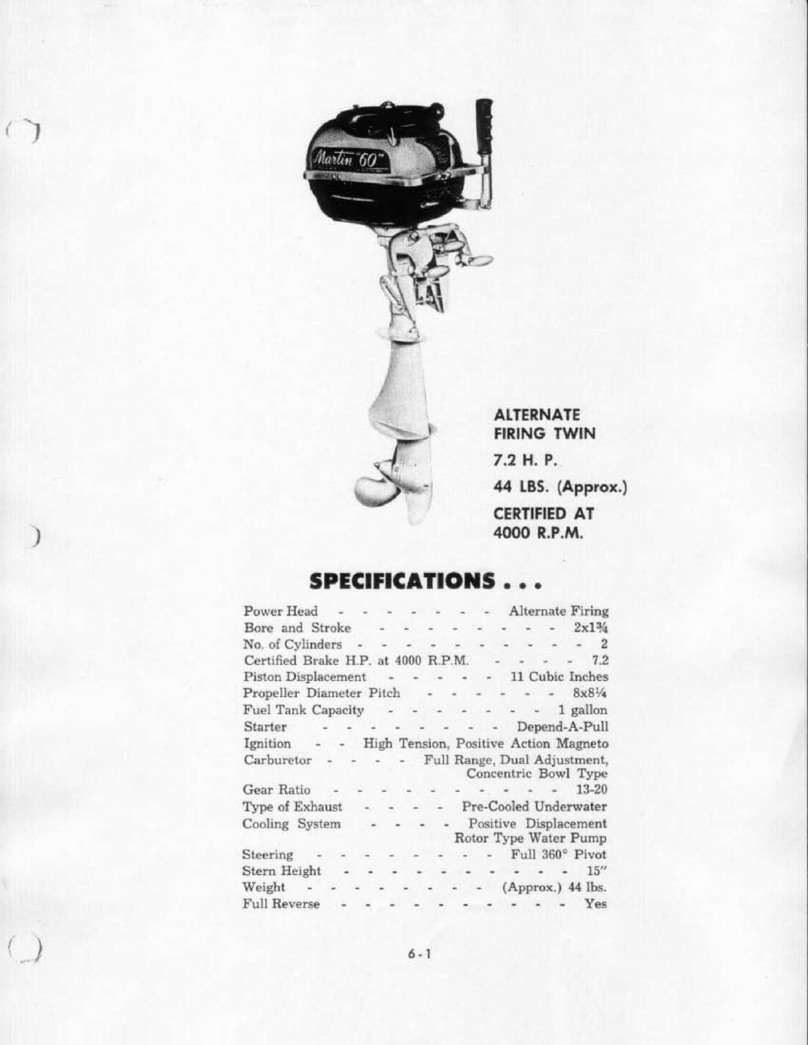

1.1 Find Your Serial Number

Please follow the diagram to nd your product serial number.

US xxxxxxxxx

This is your serial number

5

2 Specications

ItemsNo. Thrust

in LBS

Thrustin

KG Input Input

Power

L-62 62 28.2 12V,58A 696W

L-86 86 37.2 24V, 48A 1152W

Since speed depends on many factors, such as loading, water condi-

tion, hull type, wind speed, etc., it is dicult to give accurate speed

ratings. Instead refer to the thrust and power ratings provided above.

3 Wiring and Battery Recommendations

3.1 Battery Type

Recommended battery(s): 12-volt Deep Cycle battery or Marine battery.

To extend running time, either a larger capacity or an additional battery

can be used. See section on battery connection method.

NOTE: 86lbs model requires a 24-volt battery.

3.2 Circuit Protection

It is recommended to install a manual reset circuit breaker in the electric

outboard motor leads within 72 Inches (1.8m) of the battery(s).

3.3 Cable Size

If extending the standard battery cable supplied with the product, New-

port Vessels recommends the use of 8-gauge wire (13mm2 wire).

Be sure all switches are in the OFF position before

connecting to battery or batteries. Electrical arcing near the battery could

cause an explosion. The battery produces hydrogen and oxygen gases

while charging. This potentially explosive mixture escapes through the

ll vent cell caps and may form an explosive atmosphere around the

6

battery for several hours after it has been charged. Electrical arcing or

ames can ignite the gas and cause an explosion, which may shatter

the battery and could cause blindness or other serious injury.

Batteries contain sulfuric acid, which can cause

severe burns. Avoid contact with skin, eyes and clothing.

4 Safety Information

• Do not allow children to operate the electric outboard motor.

• Do not modify the unit in any way or add accessories not intended

for this product.

• Never fully submerse the unit. If unit is accidentally submersed, dis-

connect battery and leave to dry.

• To prevent accidental damage to the berglass shaft, do not over

tighten the mounting bracket.

• Only use this product between the temperatures -4F° to +113F°

(-20°C to +45°C).

• User(s) should always wear approved life jackets.

Always disconnect power from the motor when

replacing propeller, removing debris around the prop, charging batteries,

transporting boat, or when the motor is not in use.

7

5 First Time Running

1. Place Electric Outboard onto the back of the vessel in the Stow

away position.

2. Loosely tighten the Transom Mounting Screws until they grip the

Transom Mount.

3. Press the Tilt Lever and slowly let the motor enter the water.

4. Use the Depth Adjuster Collar to adjust the height of motor. Recom-

mended running depth is between 6in to 12in (15cm to 30cm) below

the waterline.

5. When you are satised that the motor is at a safe depth, and isn’t

too close, or in danger of hitting the bottom of the water way, you

may proceed to tighten the Transom Mounting Screws.

6. Once this is done it should be safe to connect the battery to the

motor. Ensure that the twist grip is in the neutral position and that

the nuts are tight on the terminals to prevent a poor connection.

7. Select the desired speed and direction using the twist grip on the

tiller arm.

8. Do not go from full forward speed to full reverse speed without let-

ting the propeller stop turning rst or motor damage may occur.

8

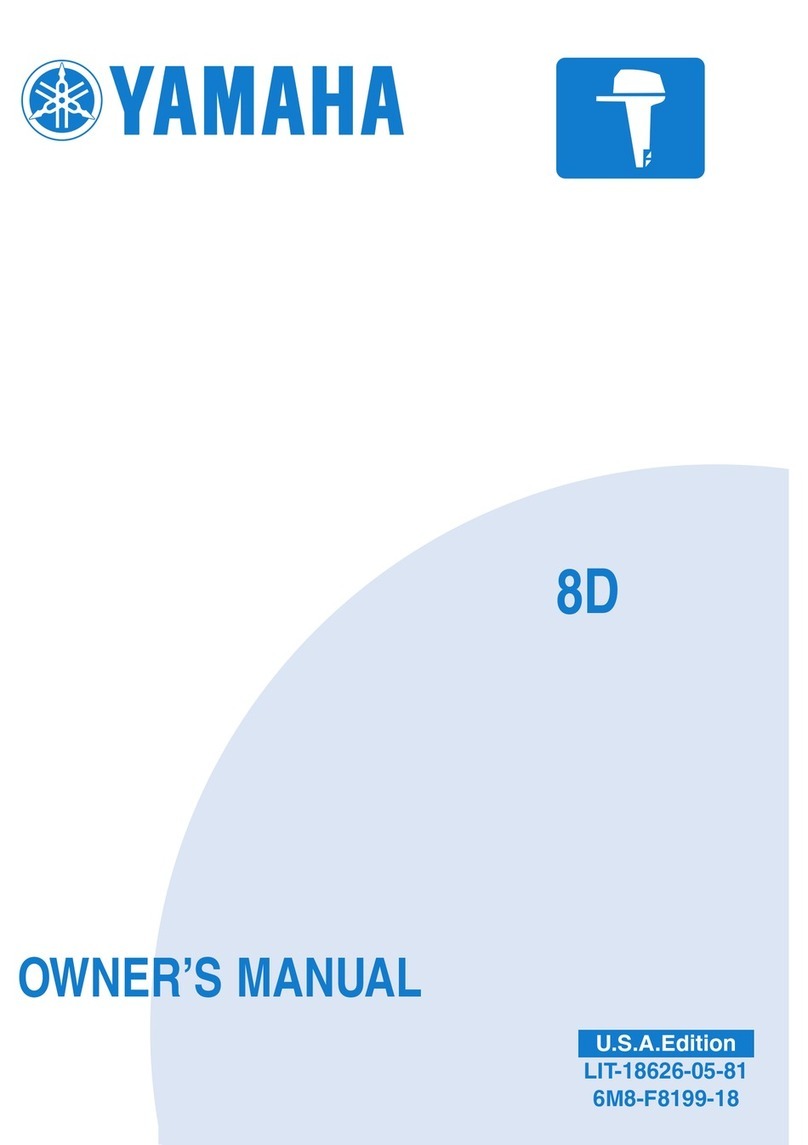

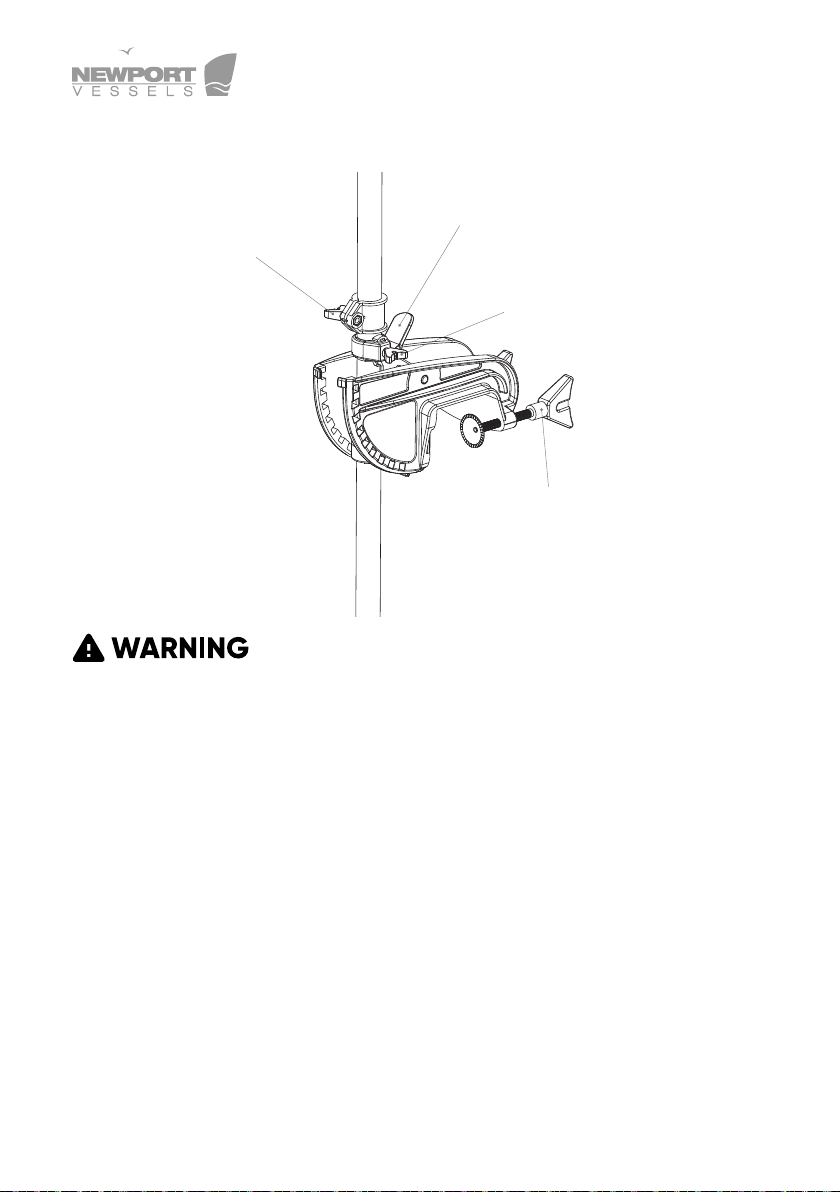

6 Transom Mount Usage

Before the installation, make sure the area between

column and bracket is clear.

1. Tilt Position Lever - This lever allows the user to adjust the tilt (angle)

of the motor. Push tilt position lever, adjust tilt of motor, release lever.

2. Steering Tension Adjustment -To adjust the steering resistance, sim-

ply tighten or loosen the tension knob located on front of the mount.

3. Depth Adjustment Collar -The depth of the motor can be adjusted

up and down by loosening the depth collar tension knob located on

the column directly above the mount. The column can be adjusted

and the motor can be positioned at the desired depth by re-tighten-

ing the tension knob.

4. Transom Screws -The transom clamp screws allow for easy motor

removal and installation. Mount your motor on the transom then

tighten the transom clamp screws securely.

1. Tilt Position Lever

2. Steering Tension

Adjustment

4. Transom Mount

Screw

3. Depth Adjustment

Collar

9

7 Battery Meter Reading

When the motor is connected to the battery, the battery meter will light

up to indicate the amount of power left in the battery. There are ten LED

lights on the top cover. When seven LED’s are out, the meter is indicat-

ing that the input voltage is less than 9.5V (normal voltage draw is 12V).

At this point it is advised to disconnect the motor from the battery to

prevent damage to the battery and recharge.

It is important to pay attention to the remaining power of the battery,

make sure to reserve enough battery power that you can travel back

with motor.

This battery voltage meter is only designed for 12V

deep cycle battery power supply system (24V for the 86lbs motor), not

for lithium battery system. You cannot trust the reading if the motor is

powered by the lithium battery.

Battery Voltage

Meter

10

8 Motor Operation

This product does not include batteries; please choose a battery with

12V (24V for 86LBS motor) output to t this motor. The recommended

type of battery is a deep cycle battery or marine battery, as they will last

much longer and are specically designed for this application.

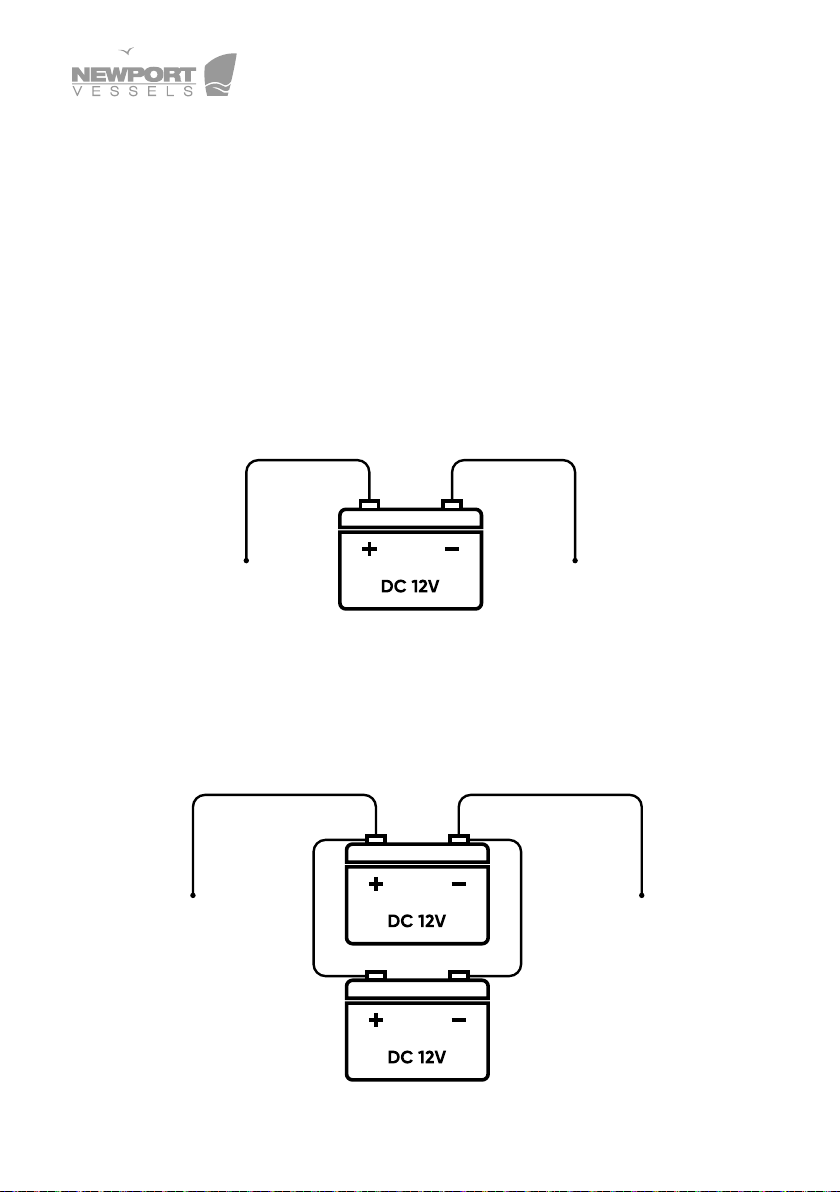

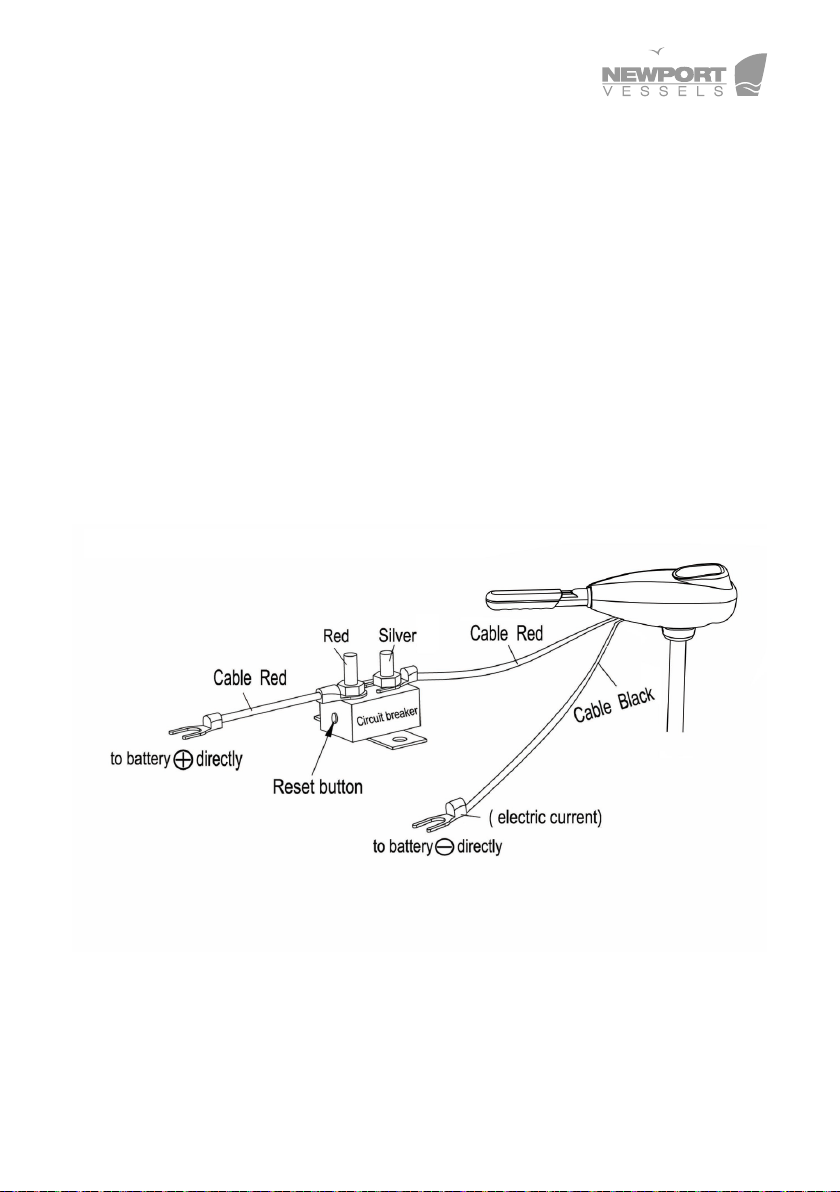

8.1 Battery Connection Method (12 Volt only)

8.1.1 Connection With One Battery (12V DC)

The red wire should connect to positive; the black wire should connect

to negative. (It is recommended to install circuit breaker on the positive

wire.)

8.1.2 Connection With Two Batteries in Parallel (12V DC)

The red wire should connect to positive; the black wire should connect

to negative. (It is recommended to install circuit breaker on the positive

wire.)

11

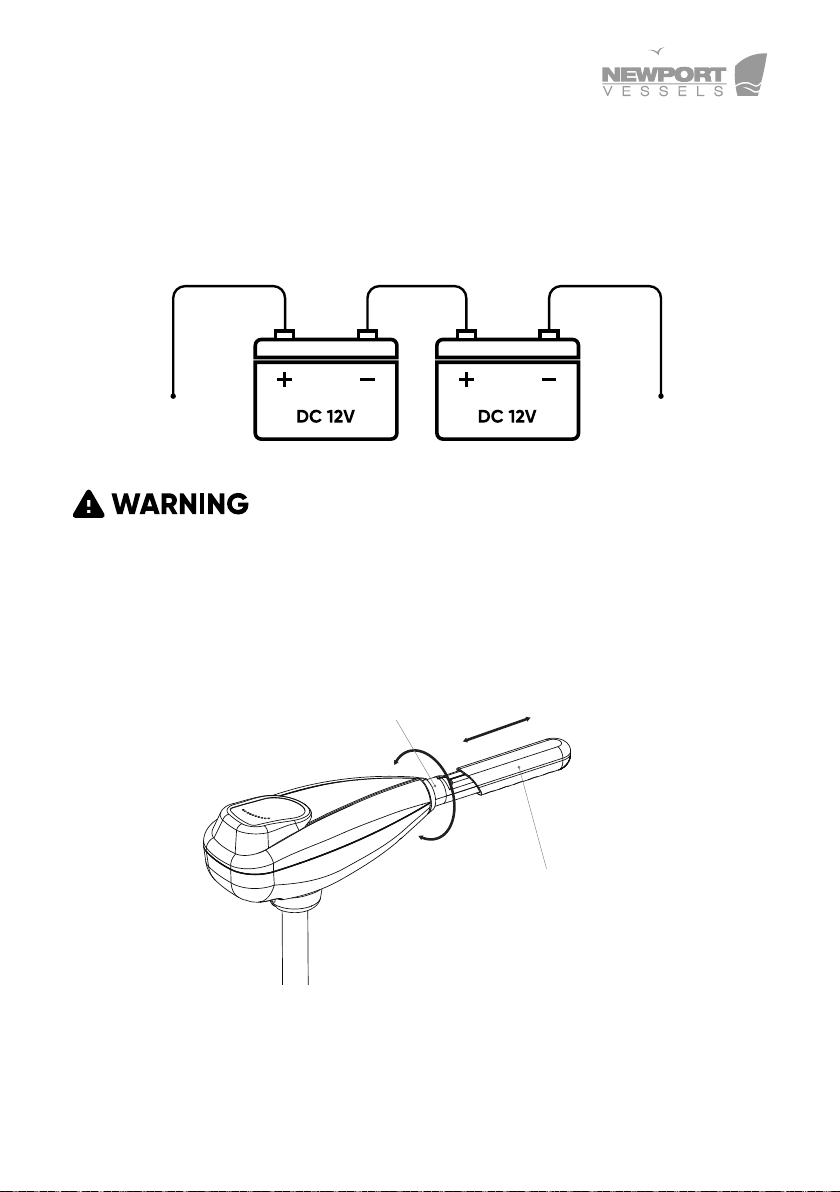

8.3 How To Control The Motor

8.3.1 On/O Speed Control

Rotate handle clockwise to obtain any of the 5 forward speeds. Rotate

handle counter clockwise for any of the 3 reverse speeds. To stop the

8.2 Battery Connection Method (24 Volt only)

8.2.1 Connection With Two Batteries in Series (24V DC)

The red wire should connect to positive; the black wire should connect

to negative. (It is recommended to install circuit breaker in line with pos-

itive lead.)

Remember to always disconnect from the battery(s)

once the motor leaves water as a rotating propeller can cause personal

injury

Rotate the Handle

to Select Gears

Extendable

Telescoping Handle

12

motor from running, position the handle matching the arrow marker on

level 0.

8.3.2 Adjusting Motor Depth

Position the depth adjustment collar so the propeller blades are sub-

merged 6inches - 12inches (15cm - 30cm) below the surface of the

water.

8.3.3 Adjusting Steering Tension

Tighten or loosen the steering tension adjusting knob to increase or

decrease the steering tension. You can also lock the motor direction by

tightening the steering tension adjusting knob rmly.

8.3.4 Raising The Motor

It is recommended to disconnect the battery before carrying out this

procedure to prevent accidental running of the motor. To raise the motor

out of the water push and hold the tilt lever and with the other hand

push down on the end of the handle to bring the motor up and out of

the water. Then release the tilt lever to lock in place.

8.3.5 Lowering The Motor

It is recommended to disconnect the battery before carrying out this

procedure to prevent accidental running of the motor. Press the tilt

lever, while with the other hand; hold onto the end of the handle to

steady the motor into the water. Once lowered release the tilt lever to

lock into position.

Remember to wash the motor with fresh water

after being used in salt water, as it can greatly reduce the possibility of

corrosion.

13

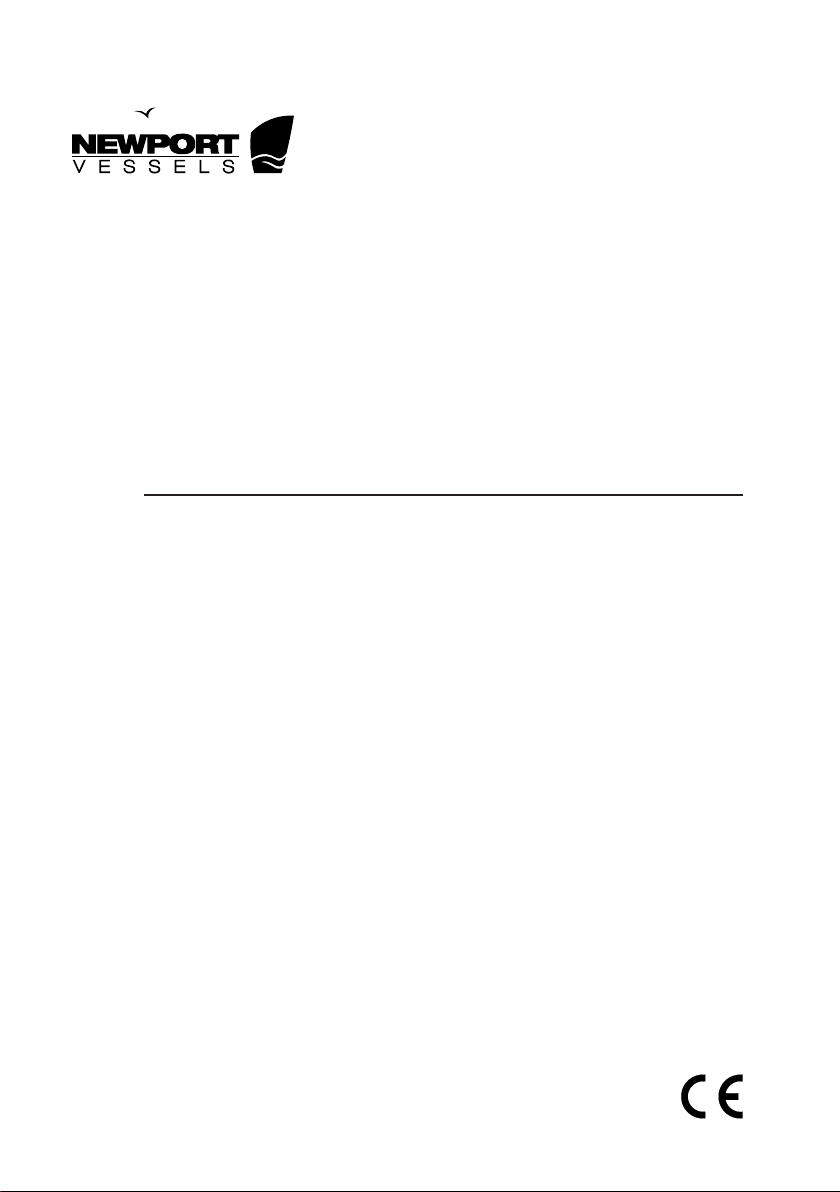

9 How to Replace the Propeller

Make sure that the motor has been disconnected

from batteries before handling the propeller.

Please visit https://newportvessels.com/propeller-installation-

guide/ to get more details.

Hold the propeller blade and loosen the propeller nut using the prop

spanner supplied or a set of needle nose pliers. Remove the propeller

nut. Pull the propeller straight o. If prop is stuck, grasp one blade with

one hand and tap on the backside of the opposite blade lightly with a

rubber mallet, until the propeller comes o. If the propeller pin is bent,

replace it. Align the new propeller with the propeller pin. Reinstall the

propeller nut and tighten rmly by hand, then tighten with spanner an-

other 1/4 turn.

Do not strike bent prop pin with hammer to remove

pin. Damage to motor armature may occur that would not be covered

by warranty.

Motor Drive Shaft

Drive Pin

Motor Propeller

Propeller Washer

Propeller Nut

14

10 Daily Maintenance

1. Check behind the propeller after each day for weeds, shing line or

other debris that may get wrapped behind the propeller.

2. Lubricate all the pivot points with a non-aerosol lubricant. Never

use an aerosol lubricant as many types contain harmful propellants

that can cause damage to various parts of your electric motor.

3. Check tightness of the battery lead connections.

4. Visually check condition of main battery cables.

5. Inspect for loose or corroded wiring connections.

6. Always thoroughly rinse your electric outboard motor with fresh

water after every use in salt water. Only rinse the areas that have

been in contact with salt water, avoid getting the top cover wet as

this may damage the circuitry inside.

7. Inspect tightness of all nuts, bolts and screws.

8. Recharge batteries after each use. Follow the battery manufactur-

er’s recommendations for battery maintenance.

9. During freezing temperatures, when your electric motor is not being

used, it should be stored in an area where it will not freeze.

10. Never connect the wires to the wrong battery terminal. You must

disconnect the battery during maintenance.

15

11 Trouble Shooting

11.1 Loss of Power

• Propeller may be damaged. Remove propeller, clean and replace.

• Battery connections may be corroded.

• Battery has low voltage. Recharge.

• Battery may be faulty, recharge and check.

• Insucient wire size from battery to motor wiring. 6 gauge wire/

13mm2 thickness recommended.

• Bad or faulty connection in boat wiring or electric motor wiring.

• Permanent magnet cracked or chipped. Motor will whine or grind.

11.2 Motor Makes Excessive Noise or Vibration

• Propeller may be damaged or unbalanced.

• Check to see if propeller is secured.

• Bent armature. Remove propeller, set at medium speed, turn unit on

and check for armature wobble.

• Turn propeller by hand. It should turn freely with a slight magnetic

drag.

• Bearing bushes may be worn out.

11.3 Motor Fails to Run

• Check fuse circuit breaker on boat for electric motor.

• Check for loose or corroded connections.

• Check plug for loose or bad connection.

• Test main rotary switch.

• Turn prop by hand. It should turn freely with a slight magnetic drag.

16

• Total battery failure. Recharge and check voltage.

• Propeller damaged.

11.4 Motor Loses One or More Speeds

• Loose wire on rotary switch. Check wiring diagram.

• Lose connection in top housing.

• Rotary switch damaged.

• Speed coils in lower unit may be burned.

12 About Circuit breaker

During the usage of the electric outboard motor, the propeller can some-

times get stuck in weeds, shing lines, or shing nets. Sometimes, due

to the variance of the water depth, the propeller can become covered in

silt. If those situations occur, quickly disconnect the battery and clean

the propeller. (Please DO NOT increase the thrust of electric outboard

motor to solve the problem, or it may cause permanent damage to the

electric outboard motor.)

The characteristics between the electric outboard motor and gasoline

outboard motor are dierent. If the propeller of the motor gets stuck,

the gasoline outboard motor will shut down to not cause any permanent

damage to the motor itself. However, the electric outboard will draw

extremely large current due to the motor stall and can generate large

amounts of heat that can damage important components in the motor

such as switch, rotor and other connecting parts or even cause serious

battery explosions.

In some muddy water areas, it can be hard for the user to recognize

that the motor is stalled. To prevent these situations from occurring, it

is strongly recommended to use circuit breaker to protect the electric

outboard motor. If the current draw of the electric outboard motor ex-

ceeds the limit of normal usage, the circuit breaker will cut o the power

automatically to prevent any possible damage to the electric outboard

17

motor. The circuit breaker has a reset button and is therefore reusable.

To prevent the rotor coil damage from exceeding current, it is highly rec-

ommended to use a circuit breaker to protect electric outboard motor.

12.1 Function of the circuit breaker

During the usage of the electric outboard motor, when the propeller is

stuck by the weeds, small stones, shing lines, etc., the circuit breaker

will cut o the power automatically to prevent the damage of the mo-

tor’s electrical parts.

If the circuit breaker cuts o the power, please disconnect the battery

rst, then check and clear any obstacles. Finally, press the reset button

on the circuit breaker and reconnect the battery. The electric outboard

motor will now be able to continue functioning properly.

18

13 Declaration of Conformity for Recreational Craft

Propulsion Engine with the requirements of Directive

89/392/EEC as amended by 89/336/EEC.

Engine type approved according to: Directives 89/392/EEC, 89/336/EE

Description of Engine(s) and Essential Requirements

Engine Type: Outboard Engine Fuel Type: Electric

This declaration of conformity is issued under the sole responsibility

of the manufacturer. I declare on behalf of the manufacturer that the

motor(s) is (are) in conformity with the type(s) for which above mentioned

EC, EMC and ROHC type-examination or type approval certicate(s)

has (have) been issued and it will meet the requirements of Directive

89/392/EEC, 89/336/EEC as amended when installed in a recreational

craft, in accordance with the manufacturer’s supplied instructions.

14 Customer Support

If you have questions that are not answered in this manual or trouble-

shooting is not successful, please contact Newport Vessels! Our Cali-

fornia based customer service team is standing by to assist you.

Customer Support

Phone: (866)721-0002

E-mail: [email protected]

Hours: 8:30am-4:30pm Pacic Time

19

This manual suits for next models

2

Table of contents

Other Newport Outboard Motor manuals