0-4

0

How to use this manual

Manual format

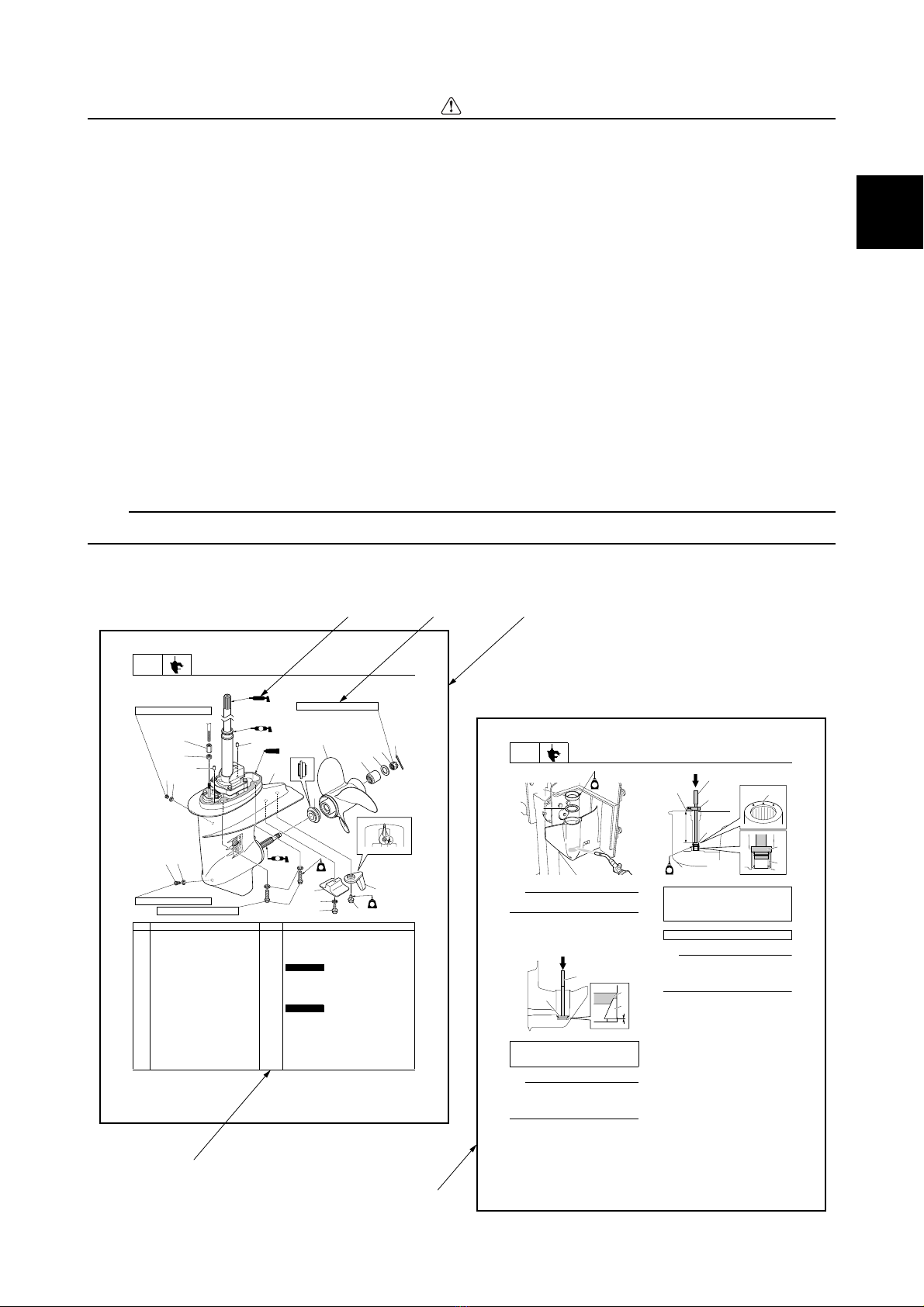

The format of this manual has been designed to make service procedures clear and easy to under-

stand. Use the following information as a guide for effective and quality service.

•Parts are shown and detailed in an exploded diagram and are listed in the component list (see 1

in the following figure for an example page).

•The component list consists of part names and quantities, as well as bolt and screw dimensions

(see 2in the following figure).

•Symbols are used to indicate important aspects of a procedure, such as the grade of lubricant and

the lubrication points (see 3in the following figure).

•Tightening torque specifications are provided in the exploded diagrams (see 4in the following fig-

ure), and in the related detailed instructions. Some torque specifications are listed in stages as

torque figures or angles in degrees.

•Separate procedures and illustrations are used to explain the details of removal, checking, and

installation where necessary (see 5in the following figure for an example page).

TIP:

For troubleshooting procedures, see Chapter 4, “Troubleshooting.”

LOWR Lower unit

8-1

Lower unit

No. Part name Q’ty Remarks

1tungnitsujdA1

1tunkcoL2

2lewoD3

1wercskcehC4

2teksaG5 Not reusable

1wercsniarD6

4rehsaW7

01M4tloB8 ×35 mm

1edonA9

1rehsawlaicepS01 Not reusable

6M1tloB11 ×35 mm

6M1tloB21 ×18 mm

1batmirT31

1tinurewoL41

1recapS51

1relleporP61

1ralloC71

3

1

2

3

65

5

4

20

19

18

17

15

16

14

13

12

11

10

9

8

7

518

M

A

D

LT

572

LT

LT

572

LT

1901

9 N ·m (0.9 kgf ·m, 6.6 ft ·Ib)

9 N ·m (0.9 kgf ·m, 6.6 ft ·Ib) 34 N ·m (3.4 kgf ·m, 25.1 ft ·Ib)

37 N ·m (3.7 kgf ·m, 27.3 ft ·Ib)

LOWR Lower unit

8-17

TIP:

Do not reuse a shim if deformed or

scratched.

3. While holding the special service tool 3,

strike the tool to check that the taper

roller bearing outer race is installed prop-

erly.

TIP:

If a high-pitched metallic sound is produced

when the special service tool is struck, the

taper roller bearing outer race 2is installed

properly.

4. Install a new needle bearing 5to the

specified depth a.

TIP:

• Face the identification mark bon the nee-

dle bearing toward the water pump side.

• Install the stopper conto the driver rod 6

at the specified depth a.

5. Heat the installation area of the taper

roller bearing outer race in the lower

case using a gas torch, and then install

the sleeve 9, the original pinion shims

0, and a new taper roller bearing outer

race A.

NOTICE:

When heating the

lower case, heat the entire installation

area evenly. Otherwise, the paint on

the lower case could be burned.

Driver rod LL 3: 90890-06605

Bearing outer race attachment 4:

90890-06625

1

2G

3

2

1

3

Driver rod SL 6: 90890-06602

Bearing depth plate 7: 90890-06603

Needle bearing attachment 8:

90890-06615

Depth a: 185.0–186.0 mm (7.28–7.32 in)

a

c

5

7

6

G

b

4

7

2

5

34 1

Safety while working / How to use this manual