Planning your Installation

3NEWTEAM 1500-XT

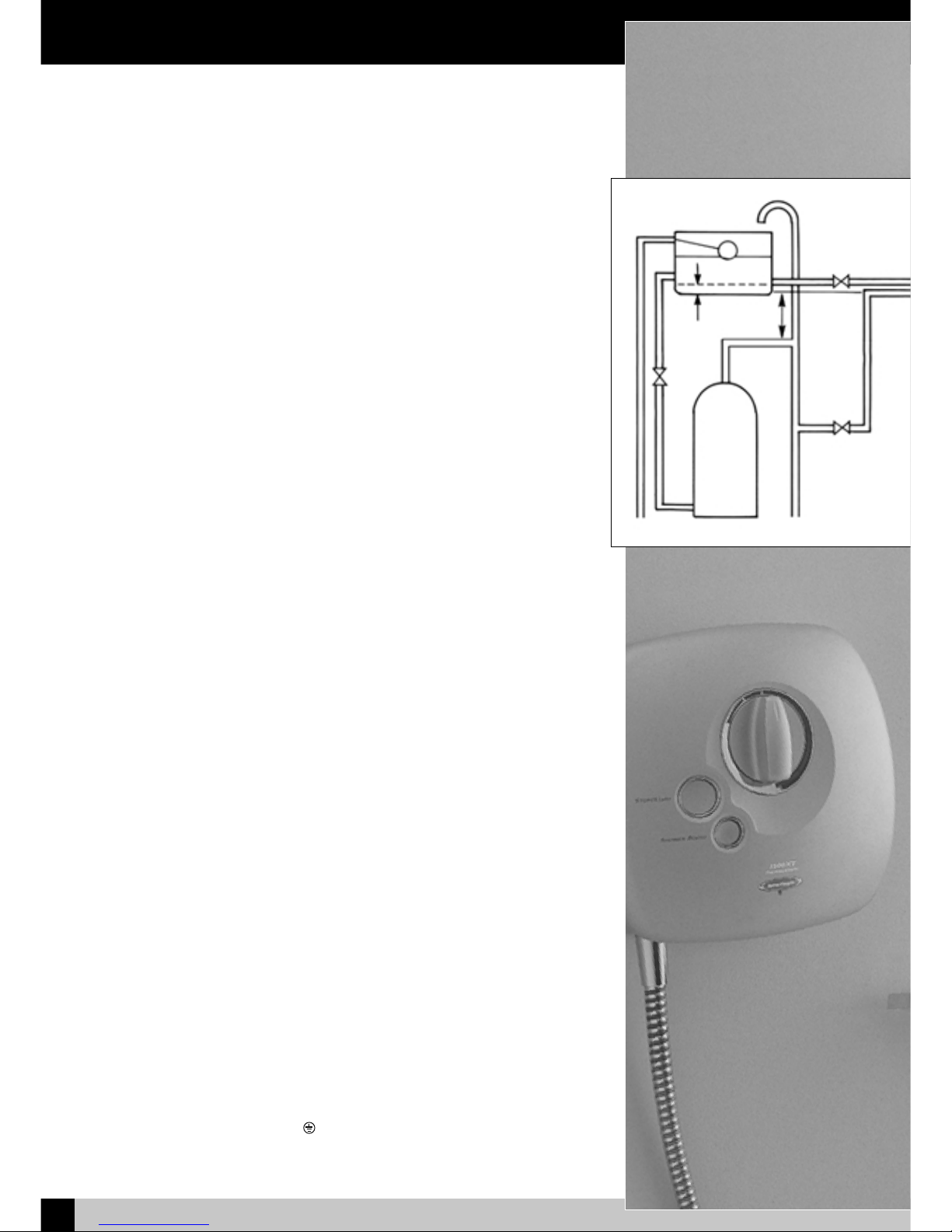

Plumbing

Under no circumstances should the unit be connected directly to the mains

cold water supply, or to a combination boiler, or pressurised hot water system.

For correct operation of the NewTeam 1500-XT power shower, both hot and cold

water supplies must be gravity fed, at nominally equal pressures, from a cold water

storage tank, and a hot water storage cylinder.

We recommend a minimum of 115 litres (25 gallon actual) of cold water

supplied by a storage tank. Please ensure compliance with all Water

Regulations. Under no circumstances must the Power Shower be connected to the

mains cold water supply.

Please ensure maximum supply head of 10 metres, minimum 1 metre.

It is recommended that the hot water supply is at a temperature of 60ºC, in line with

British Standard 6700, British Water Regulations, and Plumbing Code of Practice.

Do not use jointing compounds when connecting, and do not solder within 300mm

of the unit.

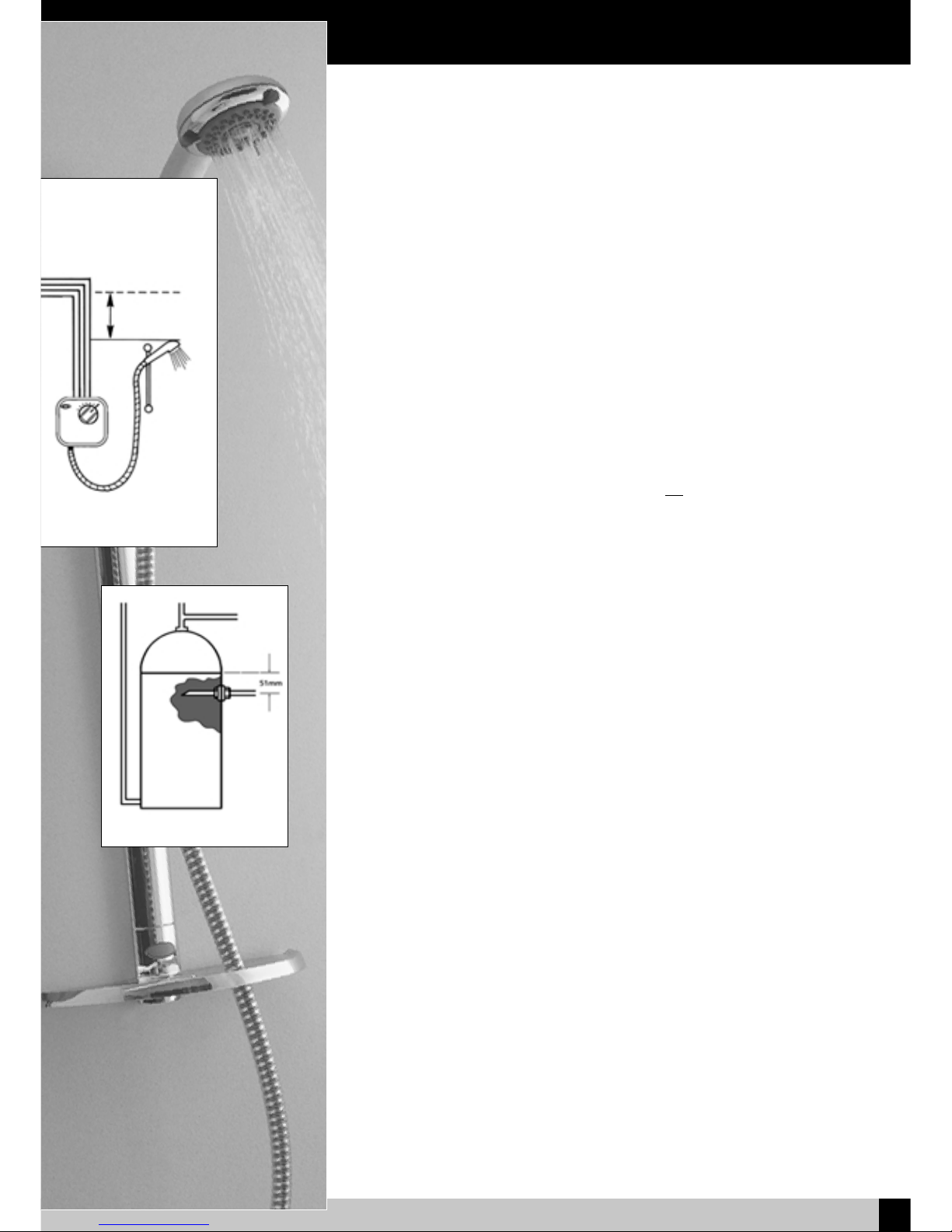

Before proceeding with the installation of this unit, check that your site requirements

allow the handset to be a minimum of 1 metre below the bottom of the cold water

storage tank to allow the 1500-XT to also operate on gravity.

WARNING: THIS APPLIANCE MUST BE EARTHED.

All electrical wiring for the shower must comply with the current

I.E.E Regulations which includes earth-cross bonding to all metal pipework.

IMPORTANT:

All plumbing should be completed before final electrical connections are made.

The shower must be connected to a 230/240 volt A.C electrical supply from a

13-amp ring main, via a fused double pole switch with at least 3mm contact

separation. The switch is to be clearly identifiable, a minimum distance of 2.5m from

a fixed tap or shower, i.e. mounted in an adjacent room or via a ceiling-type pull cord

switch. The unit should be fused at no more than 3 amps.

This appliance must be earthed, and all associated metal pipework earth

crossbonded in line with current I.E.E regulations.

As the colours of the wires in the cable (not supplied) used to connect to this

appliance may not correspond with the coloured markings identifying the terminals

in your switch, please follow the procedure below:

Please use the cable entry point provided. Failure to comply will eliminate any

BEAB approval.

Procedure:

•The wire, which is coloured Blue or Black, must be connected to the terminal that

is marked with the letter N.

•The wire, which is coloured Brown or Red, must be connected to the terminal that

is marked with the letter L.

•The wire which is coloured Yellow/Green must be connected to the terminal which

is marked with the earth symbol .

•The installation and wiring must comply with I.E.E regulations.

Electrics

Fig. 1 –Gravity Power Shower Installation

1m

Minimum

60mm