1

operating the pump in accordance with the nature of the transfer fluid and industry

have the experience and ability to carry out related work.

When pumping dangerous liquids, please follow safety precautions.

The staff responsible for the installation or maintenance of this equipment should

Please determine whether you need to wear personal protective equipment when

specifications.

Do not refit this product by yourself. If you need to repair it, please contact the

office of Chuang Rui.

personal injury.

For hazardous fluids, a dedicated operation process must be specified to prevent

Precautions

Precautions

>>

Tube precautions

In the event of a tube failure, ensure that the fluid in the pump tube of the pump

head can be discharged to a suitable container or drain.

and Accessories.

When disassembling the tube, it is necessary to drain the medium and cut off the

power supply to ensure that the pipeline is pressure-free.

Ensure that the chemicals to be handled are compatible with the pump head, tubes

A ruptured tube may cause fluid to splash. Please take appropriate protective.

Roller recautions

the tube to run out or the pump head shell to corrode.

Do not lubricate the pump head rollers by yourself. Improper operation may cause

Do not touch the rollers while the pump is running.

Keep the rollers clean and dry to reduce tube wear.

Knob adjustment

The pump head has an Adjustable knob to fine-tune the pressure. But it is not

recommended to adjust at will when there is no special requireme

Product storage

The product should be placed in a well-ventilated, non-corrosive storage

environment, which can be stored for a long time, but before putting it into

installation and operation, please confirm that the pump head nails, rollers and

other parts can be used normally.

Please read the operating instruction manual carefully before operating this

equipment.

INTRODUCTION

>>>

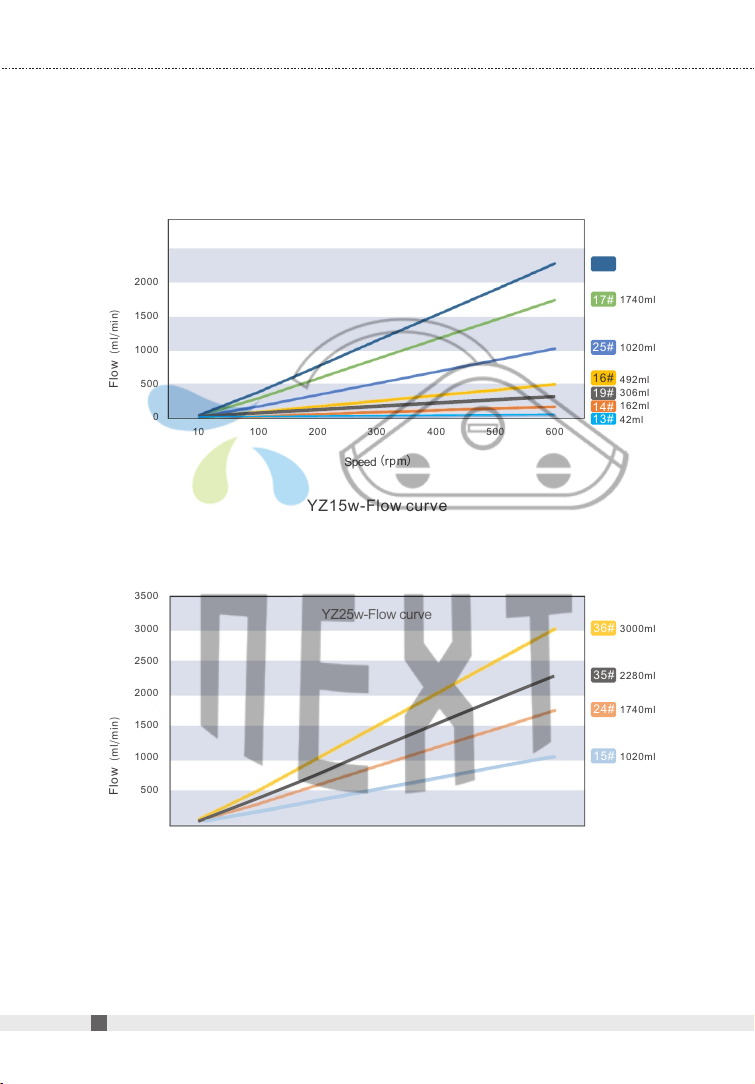

YZ-w SERIES