EN

English - 3

•Install the product exclusively indoors or in a sheltered place; do not allow it to

get wet and protect it from excess moisture.

3.1 –Preliminary checks

Carefully check that the parameters for use correspond to the figures appearing in the

“Technical Features” section. In the event of doubt, do not use the product, and ask the

Nice technical assistance service for clarification.

3.2 –Choice of coil geometry

The loop, constituting the detector’s sensitive element, is an inductor which, in combina-

tion with a condenser in the detection circuit, forms a type LC oscillator. The circuit’s res-

onance frequency depends on the loop inductance value. When a vehicle passes over

the loop, its metal parts (body, wheels, suspensions, etc.) change the inductance value

and therefore the frequency of the oscillator. The detector checks this frequency and

trips the relay when the variation exceeds the threshold specified for the established level

of sensitivity. To improve sensitivity and prevent false switching, it is essential to construct

the loop according to the following simple rules:

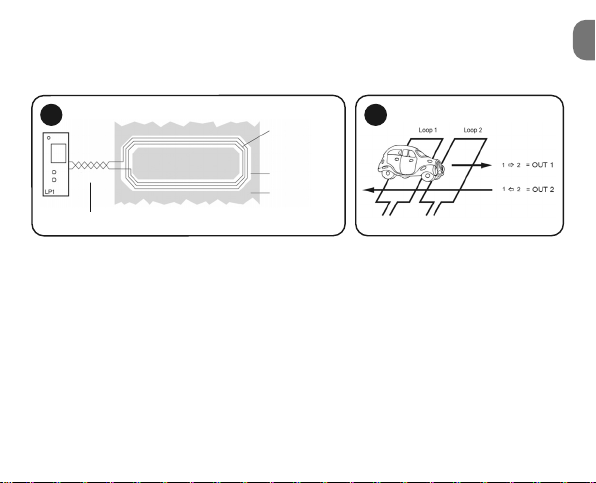

01. The rectangular loop is the simplest, most effective shape (fig. 1); it is suitable for

cars, trucks and buses. The 45° shape (fig. 2) is recommended for detecting motor-

cycles and bicycles, while the 8 shape (fig. 3) is for use in applications requiring

reduced sensitivity at the sides, such as when the loop is close to the gate.

02. Loop size must not exceed the size of the object to be detected; for instance, if the

car to be detected has an average width of 2 m, the loop must be 2 m wide.

03. If the loop is located near the gate or other moving metal parts, it is important to

comply with the minimum distance of 1 m between the loop and the moving parts.

04. Fixed metal parts close to the loop (such as concrete reinforcements, streetlight

poles, etc.) may reduce the detector’s sensitivity; make sure that this cannot hap-

pen by moving these parts, as a variation could result in false tripping.