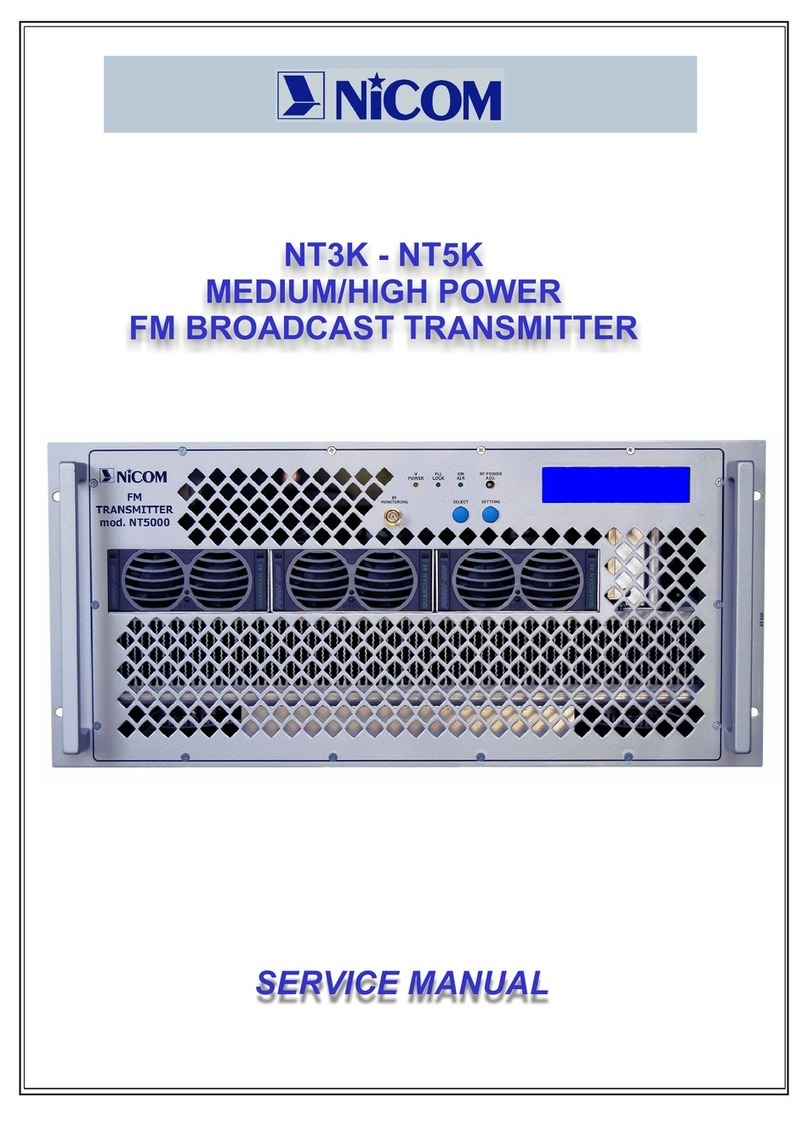

NiCom NTi 300 User manual

NTi 300/600 FM BROADCAST TRANSMITTER

1

INSTALLATION

The installation of any electrical equipment should be made by trained

technicians who know the risks related to handling electrical supplies.

Before proceeding with the installation, it is necessary to verify that the

equipment is in compliance with the rules of the Country where the unit will

operate. Before connecting the transmitter to the AC source, it is necessary to

verify that the voltage range reported in the back of the unit matches the

voltage of the AC supplied. Here are some important details about electrical

systems.

ELECTRICAL SYSTEM

Depending upon the exact location of the site, electricity is subject to more or

less fluctuations in power. Fluctuation in voltage is not the only issue you can

have with electricity. Most of the time, you can have spikes and peaks of

power that last for very short intervals but that are sufficient to destroy your

device. There are many devices on the market that protect the AC line and

they are all useful (surge suppressors, stabilizers etc.). However, only one is

really mandatory to avoid disasters caused by the AC. It is called an

ISOLATION TRASFORMER. The isolation transformer creates a physical

separation from the input of your AC line to the trasmitter. Anything

destructive that would come through the AC, stops in the transformer and

cannot reach the transmitter.

This device is indispensable because, in the last 10 years, the broadcast

industry has developed new smaller power supplies that are very light. They

did this to allow the units to be lighter for easy trasportation. Unfortunately,

the side the downside is that the big transformers that were located inside

the units protecting them, have been removed. The new AC-DC power

supplies do not give any sort of protection. The isolation transformer is

necessary to give that protection. A big isolation transformer installed where

the AC enters the site protect not only one specific device, but all of the

equipment that are in the same building.

If you want to protect only one specific device and you want to know what

size of tranformer you will need, you can multiply the output watt power of

your device by 2.5 and you will have the Watts needed by your isolation

transformer. (Example: for a 1000 W transmitter you need at least a 2.5

2

KWatt isolation transformer). If you want to protect more devices you should

add the wattage of every unit and multiply by 2.5.

Once you have your transformer installed, you need to verify how good your

ground system is. Every good electrician should have a proper device to

measure the ground. Money invested in measuring your ground can fix

problems and avoid bigger expenses in the future. Every rack and every unit

must be connected to ground.

Once that the electrical connections have been verified, you need to connect

the antenna to the transmitter through the coaxial cable. Verify that the

connector is properly tighten and, in case you have a rigid coaxial cable

feeding the transmitter, install a pigtail with proper power capability and more

flexibility so that you do not put too much pressure on the connector.

Before proceeding to operate, we strongly recommend that you make double

sure an adequate grounding system has been set. Nicom will not be held

responsible for damages to persons and materials if these guidelines are not

followed.

The positioning of the transmitter inside the room is equally important. If the

unit is placed in a rack, make sure there is enough space around for the air to

circulate. Remember that fresh air is positioned lowest in the room. Place

your transmitter as low as possible, but not too close to the floor to avoid

damages due to humidity. Leave at least 2 feet of space behind the

transmitter to allow the warm air flow to circulate without obstruction. We

highly recommend to keep the room cool with an air conditioning system, so

that the unit can work at a constant temperature without excessive humidity

(between 60 and 75 degrees); a temperature over 75 degrees causes the unit

to work in a stressed environment which can negatively impact the life and

performance of the unit.

3

CONNECTION AND OPERATION

1. First, connect the transmitting cable coming from the antenna to the

corresponding connector placed in the rear panel of the unit; check that

it is tightened properly.

2. Then connect the plug to the AC mains and also make a good ground

connection.

3. Once these procedures have been performed, you can turn the power

on. The transmitter requires about 20 to 30 seconds to perform the

internal checks and lock onto the frequency. After that, it will start

delivering power.

4. Always start with low power and keep an eye on the reading of the

reflected power to be sure that your system (antenna, cables etc.) is

performing well.

5. Allow the unit to warm up for about 30 minutes and then you can

increase the power to the desired level.

6. Wait another 30 minutes to verify that everything is working properly.

7. Check the air coming out from the rear fans and verify that it is just

warm air not overly hot. At this point, if everything looks good, you can

consider your installation successful.

4

SAFETY SUGGESTIONS

Thank you for your business. We at Nicom appreciate our partnership with you and your

broadcasting team. We proudly stand behind our products. Regardless of how well our

electrical equipment is designed; personnel can be exposed to dangerous electrical shock

when protective covers are removed for maintenance or other activities. Therefore, it is

incumbent on the user to see that all safety regulations are consistently observed and that

each individual assigned to the equipment has a clear understanding of first aid related to

electrical shocks (see next pages).

In addition, these safety practices must be followed:

•Do not attempt to adjust unprotected circuit controls or to dress leads with the

power on.

•Always avoid placing parts of the body in a series between ground and circuit

points.

•To avoid burns, do not touch heavily loaded or overheated components without

precaution.

•Remember that some semiconductor cases and solid-state circuits carry high

voltages.

•Do not assume that all danger of electrical shock is removed when the power is off.

Charged capacitors can retain dangerous voltages for long periods of time after the

power is turned off. These capacitors should be discharged through a suitable

resistor before any circuit points are touched.

•Do not take chances. Be fully trained. Nicom equipment should be operated and

maintained by fully qualified personnel.

•Do not service equipment alone and do not perform internal adjustments to this unit

unless another person is capable of rendering first aid and resuscitation is present.

•Some components used in the construction of this equipment contain Beryllium

Oxide (BeO). This substance is harmless as it is, but becomes highly dangerous if it

is ground to powder. Special procedures of disposal must be observed in case of

failure of these devices.

NOTE: This section is not intended to contain

a complete statement of all safety

precautions that should be observed by personnel in using this electronic

equipment or others.

Nicom shall not be responsible for injury or damage resulted from improper

procedures or from using it by improperly trained or inexperienced personnel.

5

GENERAL INFORMATION FOR SAFETY

When connecting the equipment to power, please follow these important

recommendations:

•This product is intended to operate from a power source that will not apply more

than 10% of the voltage specified on the rear panel between the supply conductors

or between either supply conductor and ground. A protective- ground connection by

way of the grounding conductor in the power cord is essential for safe operation.

•This equipment is grounded through the grounding conductor of the power cord. To

avoid electrical shock, plug the power cord into a properly wired socket before

connecting to the product input or output terminals.

•Upon loss of the protective-ground connection, all accessible conductive parts

(including parts that

may appear to be insulating) can render an electric shock.

•To avoid fire hazard, use only the fuse of correct type, voltage rating, and current

rating. Refer fuse

replacement to qualified service personnel.

•To avoid explosion, do not operate this equipment in an explosive atmosphere.

•To avoid personal injury, do not remove the product covers or panels. Do not

operate the product without the covers and panels properly installed.

GOOD PRACTICE

In maintaining the equipment covered in this manual, please keep in mind the following

standards for good safety practice:

•At regular intervals, the condition of the equipment and the correct functioning of

protective and safety devices shall be checked by a skilled person approved by the

appropriate authority for this duty. Functional checks shall be carried out on

interlocking systems of doors, mechanical interlocks, isolating switches, earthing

switches, parallel resistances and protective devices against overvoltage and over-

currents. The above checks shall not be carried out after the protective and safety

devices have operated under faulty conditions. The safety devices shall not be

altered or disconnected except for replacement, nor shall the safety circuit be

modified without specific approval of the appropriate authority in each case.

•When connecting any instrument (wattmeter, spectrum analyzer, etc.) to a high

frequency output, use the appropriate attenuator or dummy load to protect the final

amplifiers and the instrument input.

6

•When inserting or removing printed circuit boards (PCBs), cable connectors, or

fuses, always turn off power to the affected portion of the equipment. After power is

removed, allow sufficient time for the power supplies to bleed down before

reinserting PCBs.

•When troubleshooting, remember that FETs and other metal-oxide semiconductor

(MOS) devices may appear defective because of leakage between traces or

component leads on the printed circuit board. Clean the printed circuit board and

recheck the MOS device before assuming it is defective.

•When replacing MOS devices, follow standard practices to avoid damage caused

by static charges and soldering.

•When removing components from PCBs (particularly ICs), use care to avoid

damaging PCB traces.

PROCEDURE TO ESTABLISH THE ABSENCE OF VOLTAGE

Follow these simple steps for establish the absence of voltage:

•Before starting work on the equipment, it shall be isolated from the main power

supply. This disconnection shall always be checked by visual inspection. Further

precautions shall be taken to ensure that the main supply cannot be restored while

work is being carried out. After the main supply has been disconnected, all other

lines such as the control, interlocking and modulation lines shall be disconnected if

they carry dangerous voltage. Moreover, the antenna or the antenna transmission

line shall be disconnected from the antenna terminal device to prevent the

introduction of dangerous voltage due to antenna pick-up. When disconnection of

the antenna or antenna transmission line is not possible, other suitable precautions

shall be taken, for example, earthing, when necessary at several places, to

establish absence of voltage. These earthing connections shall be very short

compared with the wave-length.

•Capacitors, which are connected to a circuit isolated from its supply, shall be

discharged (and have their terminals permanently short-circuited, and the casing

earthed) during the whole period of the work.

•The electrical charge retained by electrical machinery when stopped may, in certain

cases, be sufficient to cause a severe shock. This shall be taken into account when

making connections to an apparently "dead" machine. Therefore, all machinery

shall be discharged and earthed using an adequately insulated lead for this

purpose. The discharge operation shall be repeated several times.

7

•Before any maintenance work iscarried out on automatic or remote-controlled

equipment, the remote switching circuits shall be made inoperative.

PROCEDURE FOR DETERMINATION OF THE ABSENCE OF

VOLTAGE

After the equipment has been isolated according to the standard EN60215, the absence of

voltage shall be determined at the work place. This may be done by the use of voltage

indicators, measuring instruments, glow discharge lamps for indicating radio-frequency

voltage or other suitable means.

ELECTRIC SAFETY PRECAUTIONS

All parts making up the equipment have danger identification tags (with a yellow

background) to highlight the parts dangerous for the operator that has access to the

system

. Presence of hazardous energy levels

A hazardous energy level is defined as a stored energy level of 20 J or more, or an

available continuous power level of 240 VA or more, at a potential of 2 V or more.

Precautions for Handling Components Containing Toxic Material

The Beryllium (Beryllium Oxide) is used in the construction of some components of the

apparatus.

This material, when in the form of fine powder or vapor if inhaled into the lungs can cause

respiratory problems. In its solid form, as used herein, can be handled quite safely, but it is

prudent to avoid conditions that favor the formation of dust due to abrasion of the surfaces.

Because of this risk, you should be very careful in the removal and disposal of these

components.

Do not throw them in containers for generic waste material, industrial or domestic, or send

via mail. They must be packed separately and clearly identified in safety and to show the

nature of the risk and then safely disposed by authorized personnel for toxic waste.Before

you remove or replace any RF COMPONENT, make sure that all precautions comply with

the recommendations of SAFETY.

This warning label is used for components containing

Beryllium Oxide.

8

ELECTROSTATIC PRECAUTIONS

Before removing or replacing any PCB assembly within the equipment, make sure that all

precautions comply with ESD protections (ESD = Electro Static Discharge). Make sure that

electrostatic discharge protections are reset after maintenance and/or measurement

operations.

The tag of CAUTION is used for the majority of electronic

devices that are subject to electrical shocks.

If electronic parts have to be touched during installation or repair, please observe the

following precautions.

Operators must be equipped with anti-static protection devices such as:

Elastic wristband: to be fixed on the operator’s wrist.

Flexible cords: to be connected to the elastic wristband and

the

special plug on the shelf highlighted with the ESD

warning label.

9

RULES OF FIRST AID

Personnel engaged in the installation, use and maintenance of the equipment must be

familiar with the theory and practice of first aid.

FIRST AID IN CASE OF ELECTRIC SHOCK

If someone seems unable to free themselves when they receive an electric shock,

disconnect the power before trying to help. A muscle spasm or unconsciousness may

render the victim unable to free themselves from the power source.

If power cannot be turned off immediately, very carefully loop a length of dry non-

conducting material (such as a rope, insulating material, or clothing) around the victim and

pull him free of the power. Carefully avoid touching him or his clothing until free of power.

DO NOT TOUCH VICTIM OR HIS CLOTHING BEFORE POWER IS DISCONNECTED

OR YOU CAN ALSO BECOME A SHOCK VICTIM.

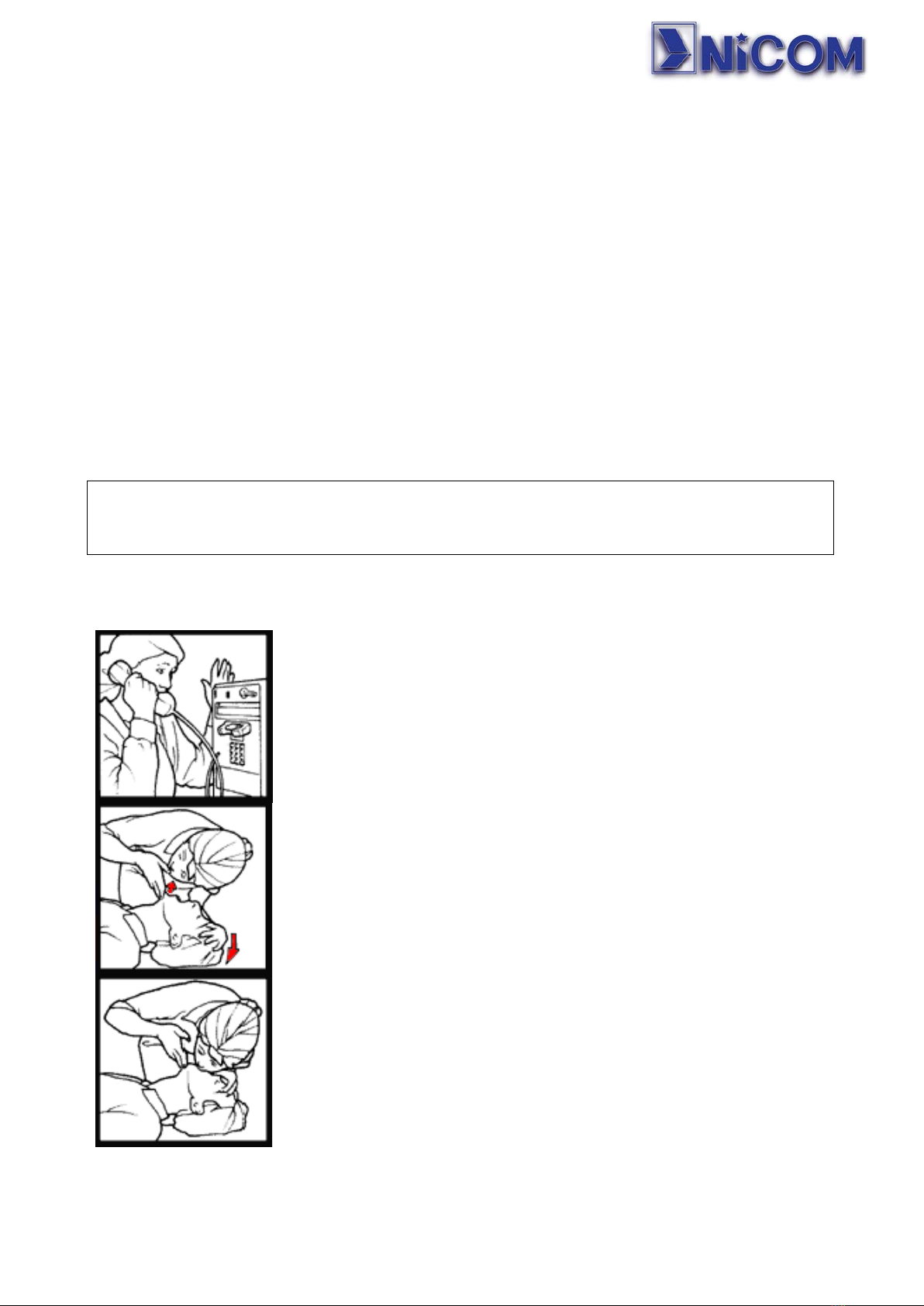

EMERGENCY RESUSCITATION TECHNIQUE

Step 1

Check the victim for unresponsiveness. If there is no response,

immediately call for medical assistance and then return to the

person.

Step 2

Position the person flat on their back. Kneel by their side and

place one hand on the forehead and the other under the chin. Tilt

the head back and lift the chin until teeth almost touch. Look and

listen for breathing.

Step 3

If not breathing normally, pinch the nose and cover the mouth with

yours. Give two full breaths. The person's chest will rise if you are

giving enough air.

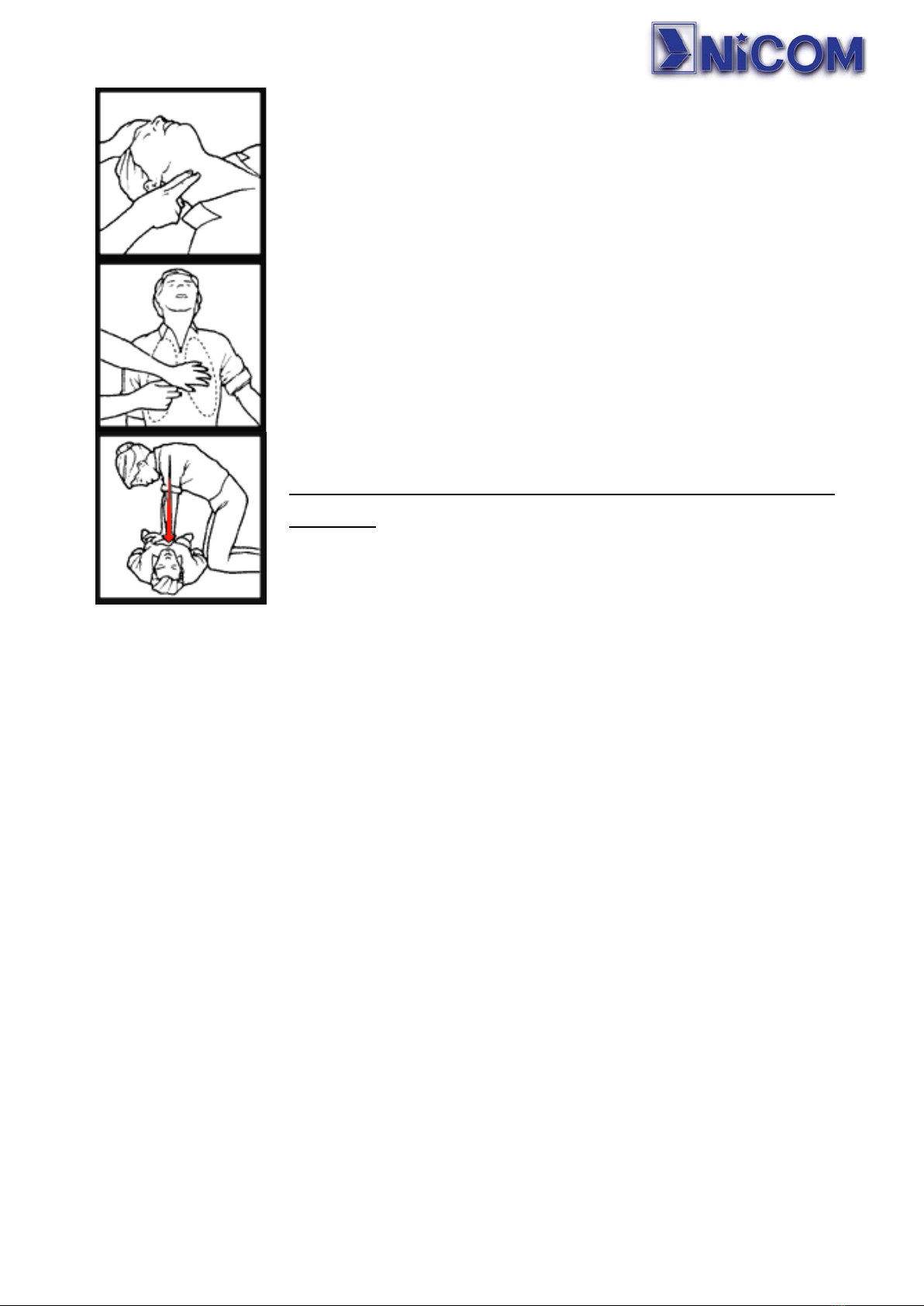

10

Step 4

Put the fingertips of your hand on the Adam's apple; slide them

into the groove next to the windpipe. Feel for a pulse. If you

cannot feel a pulse or are unsure, move on to the next step.

Step 5

Position your hands in the center of the chest between the

nipples. Place one hand on top of the other.

Step 6

Push down firmly two inches. Push on chest 15 times.

CONTINUE WITH TWO BREATHS AND 15 PUMPS UNTIL HELP

ARRIVES.

TREATMENT FOR BURNS

Extensive burns and broken skin

•Cover area with clean sheet or a clean cloth.

•Do not break blisters, remove tissue, remove any clothing that is stuck to the skin,

and apply an ointment.

•Treat victim according to the type of accident.

•Arrange transportation to a hospital as quickly as possible.

•If arms or legs are affected, keep them elevated.

If medical help is not available within an hour and the victim is conscious and not vomiting,

give a solution of salt and baking soda: 1 teaspoon of salt and half of baking soda every

250 ml of water. Make slowly drink half a glass of solution four times and for a period of 15

minutes.Stop at the retching.Do not administer alcoholic beverages

Less severe burns

•Apply cold gauze compresses (not iced) using a cloth as clean as possible.

•Do not break blisters, remove tissue, remove any clothing that is stuck to the skin,

and apply an ointment.

•If necessary, put on clean clothes and dry.

•Treat victim according to the type of accident.

•Arrange transportation to a hospital as quickly as possible.

11

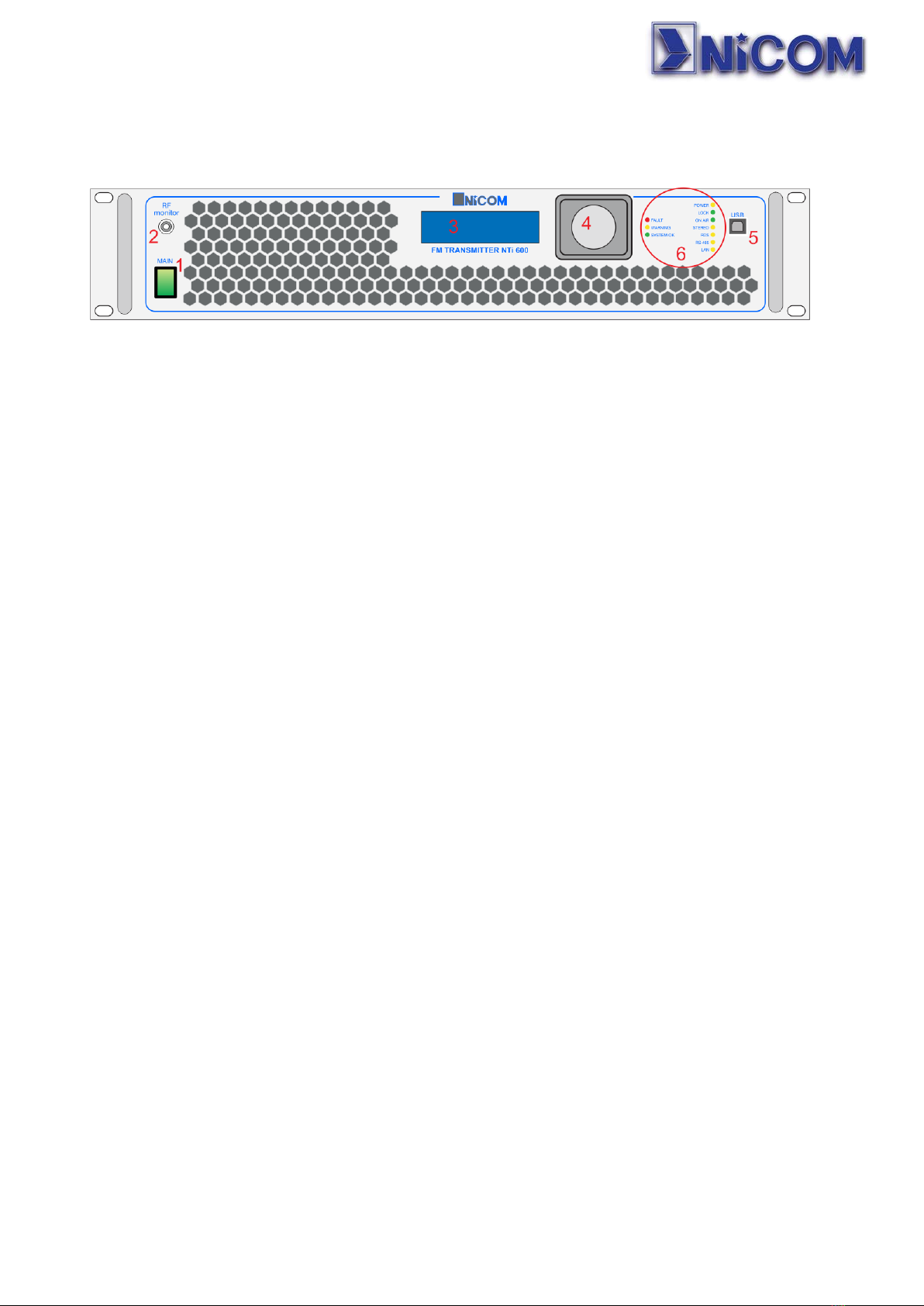

NTi 300-600 TRANSMITTER FRONT PANEL

The NTi 300 and 600 front panel presents:

1. ON – OFF SWITCH

2. RF MONITOR - RF output of approx.. -50 dBm

3. OLED GRAPHIC DISPLAY

4. ROTARY SWITCH

5. RDS programming input

6. LEDs reporting the status of the unit.

The 3 LEDs close to the rotary switch are like a traffic signal:

•Green indicates regular operation;

•Yellow is a caution alert for a possible issue;

•Red signal stops the machine to protect electronic parts from any damage. After

few minutes the microprocessor will make a second attempt to check if the alarm

condition is still present, if not the unit will resume the power. If not it will try up to

five times and then it will lock the unit in a protection status.

The LEDs on the right give the following indications:

•Internal power supply is running;

•PLL lock status;

•Activation of the final RF module (ON-AIR mode);

•Activation of the STEREO CODER module;

•Activation of the RDS module;

•Activation of RS-485 management

•Activation of the LAN

12

NTi 300-600 TRANSMITTER REAR PANEL

1. POWER SOCKET

2. FUSE HOLDER

3. 80x80x38 48 VDC FANS

4. RF OUTPUT N TYPE CONNECTOR

5. RIGHT CHANNEL STEREO XLR- INPUT

6. LEFT CHANNEL STEREO XLR- INPUT OR MONO (if stereo coder not activated)

7. S/PDIF DIGITAL INPUT

8. MPX INPUT

9. SCA SUBCARRIER 1 INPUT

10.SCA SUBCARRIER 2 INPUT

11.RS485 COM PORT IN-OUT

12.LAN CONNECTION REMOTE CONTROL

13.DB9 TELEMETRY DATA CONNECTOR

13

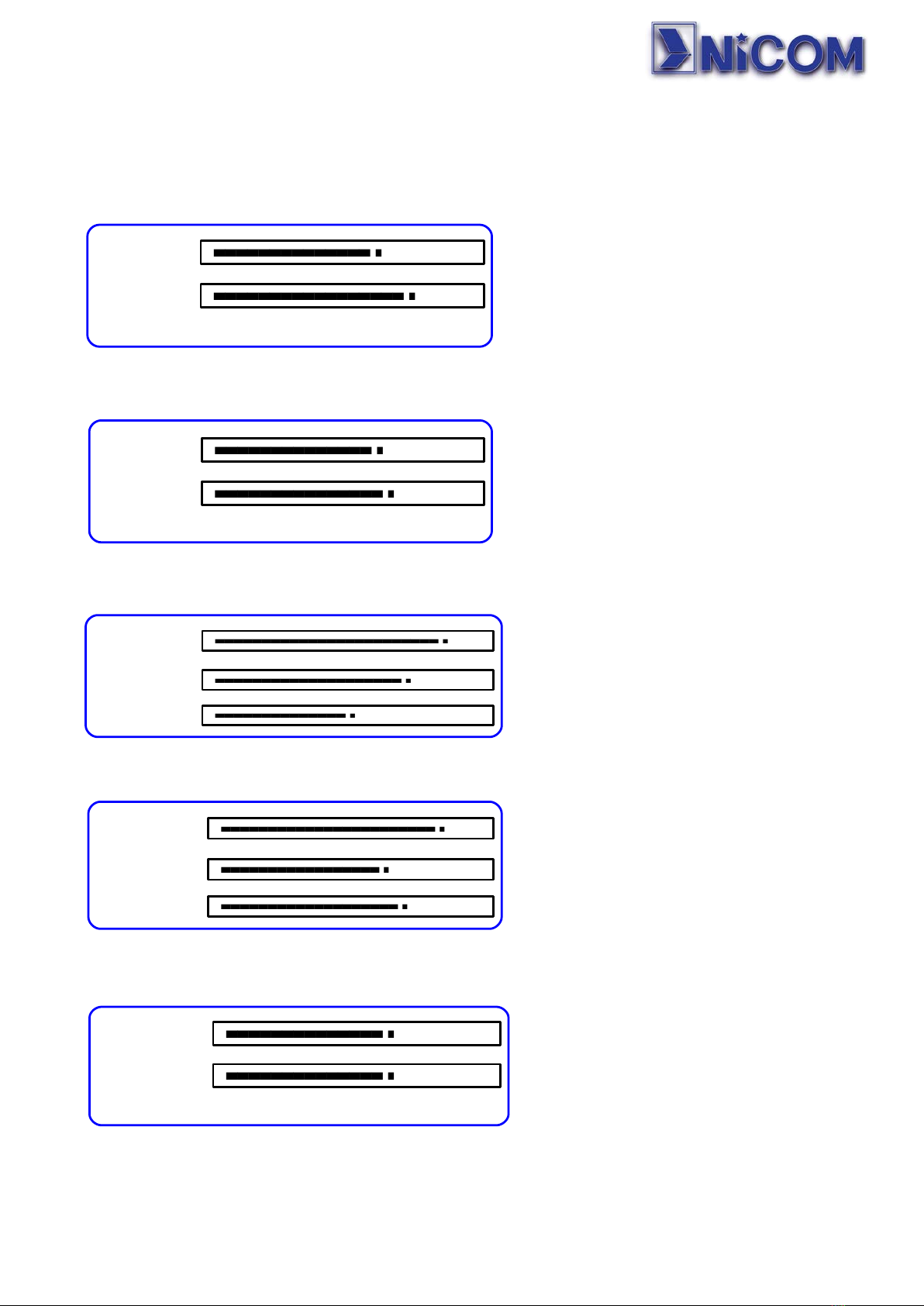

TURNING ON THE EQUIPMENT

After the unit is switched on the display will show the logo, as it does this, the unit is

performing a test on the signal lights by lighting them for a few seconds.

Then the traffic light LED turns yellow, while the model name is displayed with the

firmware version at the bottom, at the top left you will see the date and on the top right the

time:

During a waiting time of approximately 15 seconds, the PLL module is locking the

programmed frequency

If the lock process is successful, the working frequency is displayed, the traffic light

becomes green, while the LOCK and ON AIR lights indicate that the PLL module and the

RF module are OK:

If a RF power was previously set, the unit will slowly increase the output power until it

reaches the memorized value.

05-01-2016 13:06

Model NTi 5000

Firmware Version 1.02

WAIT

PLL LOCK IN PROGRESS

Frequency 100.000 MHz

RF FWD 250 W –RF RFL

MOD. :

██████████████▐

KHz 0 10 20 30 40 50 60 70 ▲ 80 90

14

Rotating the knob clockwise the reading goes to the main modulation and the MONO

input:

Then it goes to the MPX one:

Then it goes to the STEREO CODER

Then it goes to the SCA1 e SCA2:

Then it goes to the MONO input and to the digital S/PDIF signal.

MOD.:

MONO:

KHz 0 10 20 30 40 50 60 70 ▲ 80 90

dBV -30 -19 -14 -11 -9 -7 -6 -5 -4 -3 -2 -1 0 +1

██████████████▐

█████████████████▐

MOD.:

MPX :

██████████████▐

██████████████▐

██████████████▐

███████████████▐

KHz 0 10 20 30 40 50 60 70 ▲ 80 90

dBV -30 -19 -14 -11 -9 -7 -6 -5 -4 -3 -2 -1 0 +1

MOD.:

RIGHT:

████████████████████████▐

████████████████████▐

██████████████▐

LEFT:

KHz 0 10 20 30 40 50 60 70 ▲ 80 90 100

dBV -30 -19 -14 -11 -9 -7 -6 -5 -4 -3 -2 -1 0 +1 +2

MOD.:

SCA2:

███████████████████████▐

█████████████████▐

███████████████████▐

SCA1:

KHz 0 10 20 30 40 50 60 70 ▲ 80 90 100

dBV -30 -19 -14 -11 -9 -7 -6 -5 -4 -3 -2 -1 0 +1

MOD.:

S/PDIF:

██████████████▐

██████████████▐

KHz 0 10 20 30 40 50 60 70 ▲ 80 90 100

dBV -30 -19 -14 -11 -9 -7 -6 -5 -4 -3 -2 -1 0 +1 +2

15

Then it goes to the digital S/PDIF signal related to the LEFT and RIGHT channels

Then to the RF VOLTAGE and CURRENT module;

Finally, it goes to the internal temperature and the RF module

MOD.:

S/PDIF R:

████████████████████████▐

████████████████████▐

██████████████▐

S/PDIF L:

KHz 0 10 20 30 40 50 60 70 ▲ 80 90 100

dBV -30 -19 -14 -11 -9 -7 -6 -5 -4 -3 -2 -1 0 +1 +2

TEMPERATURE

INTERNAL31.7 °C

RF MODULE 45.5 °C

RF VOLTAGE: = 48.3 V

RF CURRENT:I1 = 24.6 A

I2 = 25.1 A

I3 = 25.3 A

16

SETTING PARAMETERS (PASSWORD DEFAULT: 0 0 0 0)

To access the settings, please press and hold the rotary encoder for a few seconds:

After that you enter the password by selecting the desired number rotating the encoder

and confirming it by pressing the same encoder:

The password is always four digits, at the end of which the unit will ask to confirm by

pressing “ENTER” or exit.

5 attempts are allowed; after that you must turn the machine off and on again to resume

the procedure described above.

ENTER PASSWORD

ENTER PASSWORD

* * * *

ENTER PASSWORD

******

EXIT

ENTER

17

FREQUENCY SETTING

The first line allows you to set the frequency:

Pressing the rotary switch you can choose the frequency steps between 100 KHz or 10

KHz. Then turning the rotary knob you can reach the desired frequency. Confirmation is

done by pressing the rotary encoder for a few seconds.

After confirmation, the RF module is turned off processing a new PLL frequency locking;

The PLL and ON-AIR LEDs are switched on after the locking time is complete. During the

locking time, the traffic light turns yellow and then turns green once the procedure is

complete.

MENU SETUP

3) MONO INPUT

4) MPX INPUT

1) FREQUENCY SETUP

2) RF POWER SETTING

MHz 98.000

FREQUENCY SETUP

100KHz

10KHz

PUSH

FREQUENCY:MHz 88.000

FREQUENCY SETUP

100KHz

10KHz

PUSH

CONFIRM? YES NO

YES

FREQUENCY SETUP

RF FORWARD: 0 W RF FEFLECTED: 0 W

WAIT

PLL LOCK IN PROGRESS

18

OUTPUT POWER SETTING

The second line allows you to set the output RF power:

Rotary encoder rotation allows you to increase or decrease the value of the output RF

power, short rotary pressure allows you to switch from one movement being 10W to many

movements being 100W.

Once the power has been set, it is possible to save it so that in the event of a network

power blackout the system will return to the set value when it is restored:

MENU SETUP

1) FREQUENCY SETUP

2) RF POWER SETTING

3) MONO INPUT

4) MPX INPUT

RF POWER SETTING

RF FWD: 250 W RF RFL: 5 W

POWER: 250 W

RF POWER SETTING

RF FWD: 245 W RF RFL: 5 W

100W

10W

PUSH

100W

CONFIRM? YES NO

10W

This manual suits for next models

1

Table of contents

Other NiCom Transmitter manuals