Nielsen CT2142 User manual

Industrial Direct Diesel Heater 30KW CT2142

This product is not suitable for primary heating purposes.

Direct-fired

Diesel/Kerosene Heaters

ORIGINAL INSTRUCTIONS

Cannon Tools Limited

Address:20 Station Road, Rowley Regis, West Midlands, B65 0JU.UNITED KINGDOM

SAVE THESE INSTRUCTIONS AND PRECAUTIONS.

READ ALL PRECAUTONS AND INSTRUCTIONS BEFORE USE.

Introduction

Thank you for choosing a BGE product. Read this manual carefully before using the unit and save it for

future reference.

Disclaimer

Cannon Tools

reserves the right to make alterations to specifications, quantities, dimensions etc.

for production or other reasons, subsequent to publication.

While we believe the information is accurate and complete, we make no warranty or representation for

any particular purposes. The information is offered in good faith and with the understanding that any

use of the units or accessories in breach of the directions and warnings in this document is at the sole

discretion and risk of the user.

Disposal guidelines (EU)

Do not dispose of this product with general household waste. This product must be

disposed according to the laws governing Waste Electrical and Electronic Equipment.

If required, contact your local authorities for information regarding the available disposal

facilities.

EC DECLARATION OF CONFORMITY

We CANNON TOOLS LTD

20 Station road, Rowley Regis, West Midlands,B65 0JU.U.K.

Declare that the following machine complies with the appropriate basic safety and health requirements

of the EC Directive based on its design and type, as brought into circulation by us.

In case of alteration of the machine, not agreed upon by us, this declaration will lose its validity.

Product description: Industrial Direct Diesel Heater 30KW

Model: CT2142

Applicable EC Directives:

EC Low Voltage Directive 2014/35/EU

EC Directive of Electromagnetic Compatibility 2014/30/EU

Harmonized standards

EN 55014-1:2006/+A1:2009/+A2

EN 55014-2:1997/+A1:2001/+A2

EN 61000-3-2

EN 61000-3-3

EN 60335-2-30:2009+A11

EN 60335-1:2012+AC:2014+A11

EN 62233

20 Station Road, Rowley Regis, West Midlands, B65 0JU.U.K.

Mr. Gurcharan Tony Singh Sanghera

Managing Director

CANNON TOOLS LTD

2018-08-07

1. General Safety Rules

READ INSTRUCTIONS CAREFULLY. READ AND FOLLOW ALL INSTRUCTIONS. PLACE

INSTRUCTIONS IN A SAFE PLACE FOR FUTURE REFERENCE. DO NOT ALLOW ANYONE

WHO HAS NOT READ THESE INSTRUCTIONS TO ASSEMBLE, LIGHT, ADJUST OR

OPERATE THE HEATER.

IF THE INFORMATION IN THIS MANUAL IS NOT FOLLOWED EXACTLY, A FIRE OR

EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS

OF LIFE.

SERVICE MUST BE PERFORMED BY A QUALIFIED SERVICE AGENCY.

UNVENTED PORTABLE HEATERS USE AIR (OXYGEN) FROM THE AREA IN WHICH IT IS

USED. ADEQUATE COMBUSTION AND VENTILATION AIR MUST BE PROVIDED. REFER TO

INSTRUCTIONS. WARNING

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

FIRE, BURN, INHALATION, AND EXPLOSION HAZARD. KEEP SOLID COMBUSTIBLES, SUCH

AS BUILDING MATERIALS, PAPER OR CARDBOARD, A SAFE DISTANCE AWAY FROM THE

HEATER AS RECOMMENDED BY THE INSTRUCTIONS. NEVER USE THE HEATER IN

SPACES WHICH DO OR MAY CONTAIN VOLATILE OR AIRBORNE COMBUSTIBLES, OR

PRODUCTS SUCH AS GASOLINE, SOLVENTS, PAINT THINNER, DUST PARTICLES OR

UNKNOWN CHEMICALS.

WARNING

DIRECT-FIRED HEATERS MAY CAUSE CARBON MONOXIDE (CO) POISONING WHEN

INCORRECTLY USED, E.G INDOORS WITHOUT ADEQUATE AIR CIRCULATION, OR IF NOT

PROPERLY WORKING. CO POISONING MAY LEAD TO DEATH.

GENERAL HAZARD WARNING

FAILURE TO COMPLY WITH THE PRECAUTIONS AND INSTRUCTIONS PROVIDED WITH

THIS HEATER, CAN RESULT IN DEATH, SERIOUS BODILY INJURY AND PROPERTY LOSS

OR DAMAGE FROM HAZARDS OF FIRE, EXPLOSION, BURN, ASPHYXIATION, CARBON

MONOXIDE POISONING, AND/OR ELECTRICAL SHOCK. ONLY PERSONS WHO CAN

UNDERSTAND AND FOLLOW THE INSTRUCTIONS SHOULD USE OR SERVICE THIS

HEATER. IF YOU NEED ASSISTANCE OR HEATER INFORMATION SUCH AS AN

INSTRUCTIONS MANUAL, LABELS, ETC. CONTACT THE MANUFACTURER.

WARNING

NOT FOR HOME OR RECREATIONAL VEHICLE USE

WARNING

YOUR SAFETY IS IMPORTANT TO YOU AND TO OTHERS,

SO PLEASE READ THESE INSTRUCTIONS BEFORE YOU OPERATE THIS HEATER

THE ELECTRICAL SYSTEM TO WHICH THE APPLIANCE IS CONNECTED MUST COMPLY

WITH CURRENT LEGISLATION. INSTALLATION REQUIRES A RESIDUAL CURRENT

CIRCUIT BREAKER (RCCB) IN THE MAIN ELECTRICAL DISTRIBUTION BOARD.

UNPLUG THE APPLIANCE BEFORE PERFORMING ANY MAINTENANCE OPERATIONS.

ALWAYS CHECK THE POWER CABLE BEFORE USING THE APPLIANCE. IT MUST NOT

BE BENT, TAUT, STRETCHED, CRUSHED OR ANY WAY DAMAGED.

THE POWER CABLE MUST BE REPLACED BY QUALIFIED PERSONNEL ONLY. USE AN

ORIGINAL POWER CABLE ONLY WITH A 3-PIN APPROVED PLUG.

THE FRONT OUTLET IS VERY HOT DURING OPERATION. DO NOT TOUCH! BURN

DANGER.

2. Product Description

•Diesel or Kerosene direct-fired mobile/portable space heater with open combustion chamber

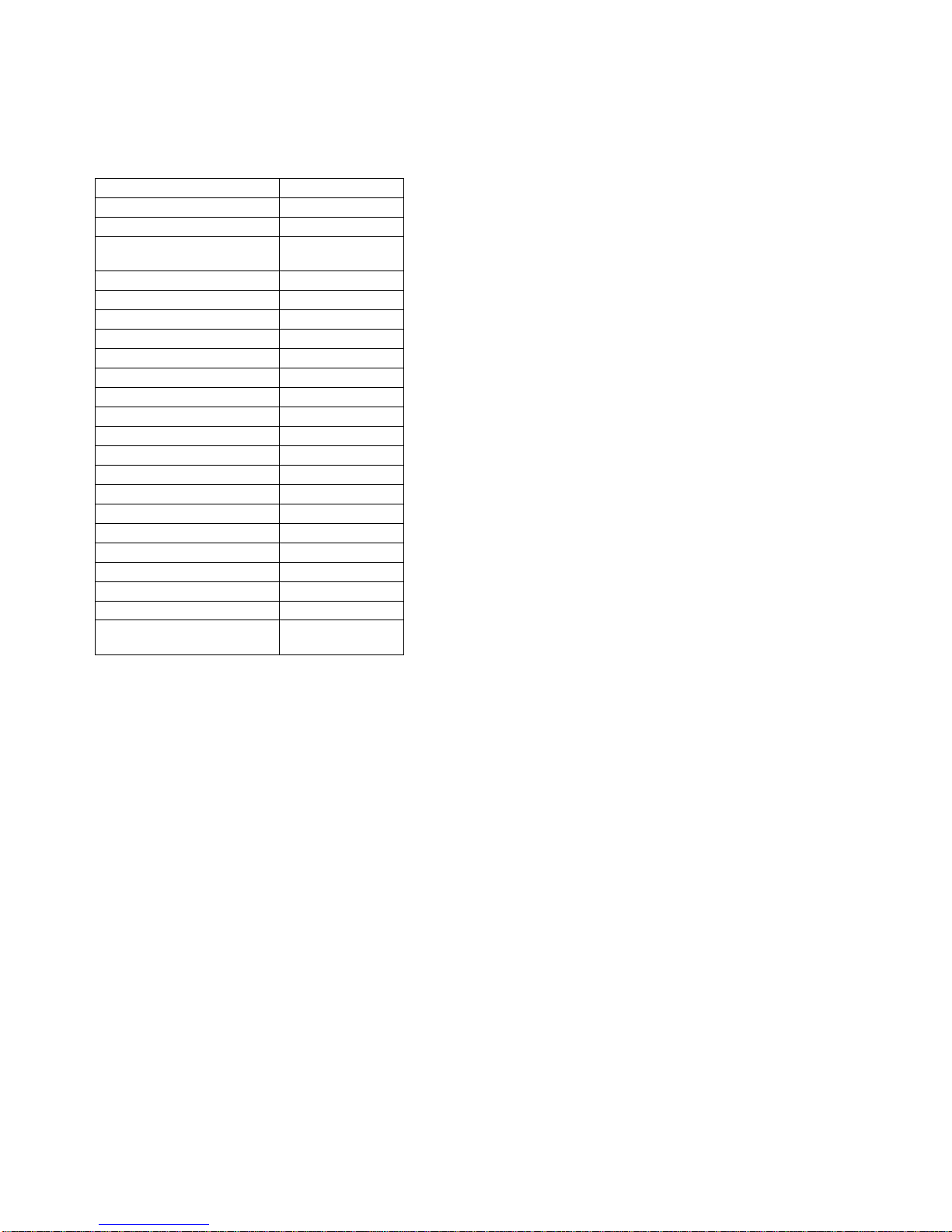

3. Technical Specifications

Model CT2142

Heat Input [kW] * 30

Air Flow Rating [m³/h] 720

Fuel Type Diesel -

Kerosene

Fuel consumption [Kg/h] 2.4

Fuel Nozzle Size [gph] 0.80

Voltage [V/Hz] AC220-240V/50

Air Pressure Setting [bar] 0.31

Current Rating [A] 1.1

Electrical Power [W] 230

Fuse Rating T3.15A

Dimensions

Net Weight (kg) 21

Length (mm) 880

Width (mm) 456

Height (mm) 590

Tank Capacity (l) 38

Operating range (h) ~13

Standard Accessories

Fuel gauge yes

Handle 1

Ambient thermostat built-in

Malfunction detection

light built-in

* Based on Gross Calorific Value [Hrs]

4. Assembling Instructions

Extract the heater from its carton. If the unit is anyhow damaged, do not use it and contact your dealer.

CT2142

The following accessories are supplied in the shipping carton.

Fig.2

To assemble the heater, proceed as follows (see Fig. 2):

1、insert the wheel shaft J to the corresponding hole of feet pipe E,insert the cotter K to the

corresponding holes; put plain washer I to the two sides of shaft, slide the wheel H over the wheel

shaft J,screw the nut G to fix the wheel on the shaft.

2、Put the heater body on the feet pipe assembly, make sure the 4 holes of handle A point towards the

corresponding 4 holes on the feet pipe respectively.

3、Using the screw B ,spring washer C, plain washer C and nut 4 to fix the feet pipe assembly and

handle to the tank.

5. Installation Instructions

Position the heater on a flat, level, non-flammable, solid surface.

Direct-fired heaters are intended for use in outdoor open areas or in indoor well

ventilated areas. For indoor use, provide permanent ventilation openings of at least 25

cm²/kW, equally distributed between floor and high level, with a minimum of 250 cm².

•Only install the heater in normal

upright position.

•Do not place the heater near walls, corners or low ceilings.

•Do not place the heater below a socket outlet.

•Do not place the heater on moving vehicles or where it can tip over.

•Keep the heater away from flammable, combustible, explosive or corrosive materials.

•Keep the heater away from curtains or similar materials that could block the air inlet and

outlet.

•Never block or restrict the air inlet and outlet for any reason.

•Keep the power cable away from heat sources, sharp edges, cutting and moving parts.

•Do not expose directly to the weather or to excessive humidity.

•Do not place the heater in the immediate surroundings of a bath, shower or swimming

pool.

Pos. Description Qty

A Handle 1

B Screw 6or8

C Spring washer 6or8

D Plain washer 6or8

E Feet pipe 1

F Nut M5 6or8

G Nut M12 2

H Wheel 2

I Plain washer ø12 2

J Wheel shaft 1

K Cotter 2

CT2142

Minimum Opening Size 800 cm²

•Follow general and special fire safety regulations in force in all fields of applications. In

any case ensure the following minimum safety clearances from materials or objects in

the surroundings of the heater:

•Side: 0.6 m

•Air inlet side: 1 m

•Top: 1.5 m

•Hot air outlet side: 3 m

•Floor: 0 m

•Floors and ceilings must be made of fireproof materials in the place where the heater is

operated.

•Do not connect direct-fired heaters to air ducts.

6. Instructions for Use

6.1. Start-up

Fill tank with clean fuel. Only use Diesel or Kerosene.

The fuel gauge on top of the tank allows to check fuel level

Connect the power cord plug to a 230 V 50 Hz earthed electrical supply system.

Earthing is mandatory.

Models CT2142:

When complete “start-up” above, the power indicator will light, the display window will show the

ambient temperature value.

Push the power switch to “on” position.

If the thermostat control knob setting temperature is higher than the ambient temperature, the

electrodes start sparking and after 7 seconds, the heater starts.

If the thermostat control knob setting temperature is lower than the ambient, turn thermostat control

knob to desired temperature setting, the electrodes start sparking and after 7 seconds, the heater

starts.

Model BGO1601-50

When complete “start-up” above, the left display window shows “--”, the right display window shows

ambient temperature value.

Push the power switch to “on” position.

The default temperature setting is 20 , be showed on the left display window.℃

If the ambient temperature is lower than default temperature, the electrodes start sparking, after 7

seconds, the heater starts.

If the ambient temperature is higher than default temperature, turn thermostat control knob to desired

temperature, the electrodes start sparking, after 7 seconds, the heater starts.

COLD START-UP: at low temperature keep the air vent hole (see Fig. 6) closed by a finger during

ignition to make start-up easier.

ABNORMAL OPERATION: in case of malfunction (flame failure, reduced air flow, bad combustion,

etc.) the heater stops and the indicator light starts FLASHING (THE LOCK-OUT MODE code will be

showed on the display window).

6.2. Manual reset/restart

If the heater is in lock-out mode, check and remove the cause of lock-out before restarting the heater.

To reset, turn the ON/OFF switch to 0 and then again to I. In case of repeated malfunction, call

technical service. Turning the thermostat control knob will NOT reset the heater.

6.3. Shut-down

Move switch to "OFF" (O) position. Unplug the unit when not used for a long time.

Never disconnect the heater from mains to stop it while in operation. Always allow the

cooling sequence to be completed (BGO1601-50), otherwise the residual heat could

damage internal components.

Do not cover the heater. Do not block the air inlet and outlet.

The heater outlet is very hot during operation and after use. Do not touch! Use personal

protecting equipment if needed.

Children should be supervised to ensure that they do not play with the appliance.

The appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge.

Unplug the heater before moving it. Never pull the cable to unplug or move the unit.

Do not leave the heater unattended when in use.

Never use the appliance with wet hands or when either the heater or the power cable is

wet.

If the supply cable is damaged, it must be replaced by the manufacturer, by a service

agent or a similar qualified person.

7. Cleaning, Maintenance and Storage

Regularly wipe the enclosure using a soft sponge or cloth. For very dirty parts, use a sponge wetted

with lukewarm water and a mild detergent, then dry using a clean cloth.

Keep air inlet and fan free from dust and dirt. To clean inner parts, gently blow compressed air through

air inlet.

Regularly inspect the power cable: if worn, cracked or damaged have it replaced by technical service.

Before storing the heater, make sure it is perfectly cool and dry. Cover the unit with a plastic bag, put it

in its packing box and store it in a dry, ventilated place.

Before starting any maintenance task, shut down, unplug and let the heater cool down

for at least 15 minutes.

Do not attempt any electrical repair yourself. If the heater needs service or repair,

contact a qualified technician.

Do not use a faulty unit unless a qualified technician has inspected and repaired it.

When cleaning, make sure that water does not enter the unit.

Do not open the enclosure to clean the inner parts. Do not spray water into the heater.

Never use solvents, gasoline, toluene and similar aggressive chemicals to clean the

heater.

The following checks BY QUALIFIED PERSONNEL ONLY are recommended before every

seasonal use:

Nozzle

Carefully unscrew nozzle from nozzle fitting. Blow compressed air through nozzle orifice to free it from

dirt. Replace nozzle if necessary.

Air Filters

Clean air filters. Remove filter end cover (11), wash air intake filter (10) using a light detergent and dry

it thoroughly before re-installing. Replace air delivery filter (9) once a year (Fig.3)

Fig.3

Ignition Electrodes

Clean, adjust and if necessary replace ignition electrode. For electrode gaps see Fig. 4-5 (dimensions

in mm).

Fig.4 Fig.5

Compressor Pressure Adjustment (Fig. 6)

The compressor pressure is factory set and must be checked and adjusted by qualified

technicians only. Tampering with the unit may be dangerous.

Remove pressure gauge cap. Connect a pressure gauge on the pressure measuring port on the rear

guard. Start heater and read air pressure value. If necessary adjust pressure to the correct value

turning the adjusting screw (the air vent hole in the adjusting screw middle) clockwise to increase,

anticlockwise to decrease the pressure:

Fig.6

Electrical

Inspect cables, electrical parts and connections.

Model Air Pressure (bar)

CT2142 0.31

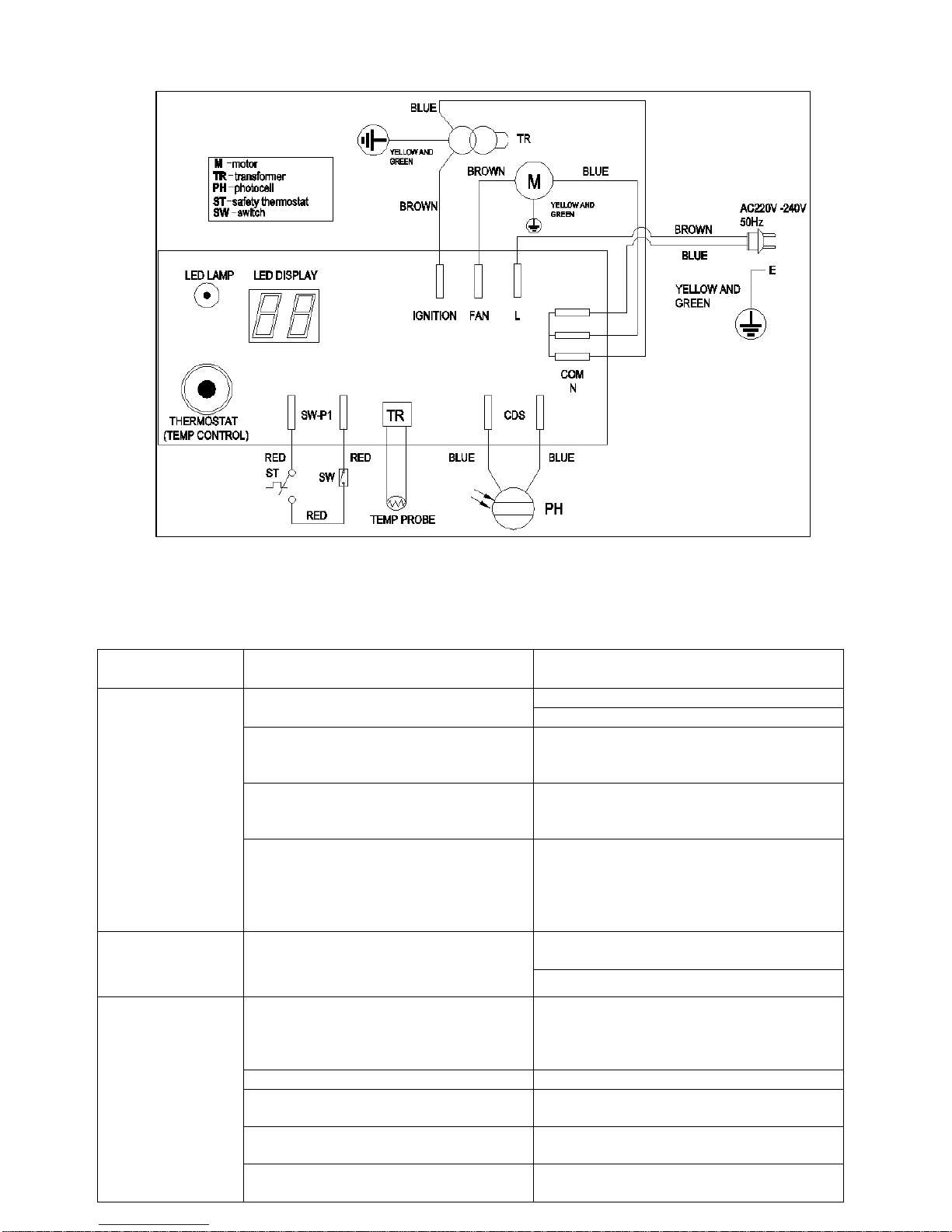

8. Wiring Diagram

Wiring diagram for CT2142

9. Troubleshooting

PROBLEM

CAUSE REMEDY

Motor does not

start

E1 displayed on the

screen

No power or low voltage

Check power line and voltage

Check fuse and replace if necessary

Faulty or damaged power cord

Check and replace if needed

Faulty motor/capacitor

Check and if necessary replace

Lock-out of appliance due to previous

overheating

Detect the cause of overheating

Shut the appliance down

Check air inlet and outlet

Wait some minutes and restart the

appliance

E2 displayed on the

screen The temperature probe is faulted or the

connector for temperature probe is

loosen

Check and replace if the temperature

probe if needed

Check and replace the PCB if needed

Motor runs, but the

heater does not

ignite and locks

out after a short

time

E1 displayed on the

screen

Empty fuel tank, dirty or wrong fuel Remove wrong or dirty fuel

Fill the tank with clean Diesel or kerosene

Fuel filter clogged Clean or replace fuel filter

Air leaks in oil line Check hoses, tighten connections, if

necessary replace

Burner nozzle clogged Clean nozzle blowing compressed air,

replace if necessary

Fuel viscosity increased at low

temperature Mix Diesel with 10-20% kerosene

Flames come out

of flue outlet

E1 displayed on the

screen

Insufficient airflow into combustion

chamber

Check air inlet, fan, motor

Compressor pressure too high Check air pressure, adjust if needed*

Heater stops

during operation

Ambient temperature

displayed on the

screen

The room temperature set on room

thermostat has been reached Normal operation

To start turn the temperature control knob

clockwise on a higher setting

Heater stops

during operation

E1 displayed on the

screen

Flame failure

Check and remove the cause(s) of

malfunction

To reset, turn On/Off switch to 0 and then

to I

Call technical service if the problem

persists

Bad combustion

Reduced airflow

Overheating

Model identifier(s): CT2142

Indirect heating functionality: [no]

Direct heat output: 30(kW)

Indirect heat output: N/A (kW)

Fuel

Space heating emissions (*)

NOx

Select fuel type [liquid] Kerosene 69[mg/ kWhinput] (GCV)

Item Symbol Value Unit

Item Symbol Value Unit

Heat output Useful efficiency (NCV)

Nominal heat

output

Pnom 30

kW

Useful efficiency at nominal

heat output ηth,nom

100

%

Minimum heat

output (indicative)

Pmin N/A

kW

Useful efficiency at minimum

heat output (indicative)

ηth,min

N/A

%

Auxiliary electricity consumption Type of heat output/room temperature control (select one)

At nominal heat outpu

t

elmax 0.002

kW

Single stage heat output, no room temperature

control

[no]

At minimum heat

output

elmin N/A

kW

Two or more manual stages, no room temperature

control

[no]

In standby mode

elSB N/A

kW

with mechanic thermostat room temperature control

[no]

with electronic room temperature control [yes]

with electronic room temperature control plus day

timer

[no]

with electronic room temperature control plus

week timer

[no]

Other control options (multiple selections possible)

room temperature control, with presence detection [no]

Room temperature control, with open window

detection

[no]

with distance control option [no]

with adaptive start control [no]

with working time limitation [no]

with black bulb sensor [no]

Permanent pilot flame power requirement

Pilot flame power

requirement (if

a

pp

lica

b

le

)

Ppilot

0

kW

(*) NOx = nitrogen oxides

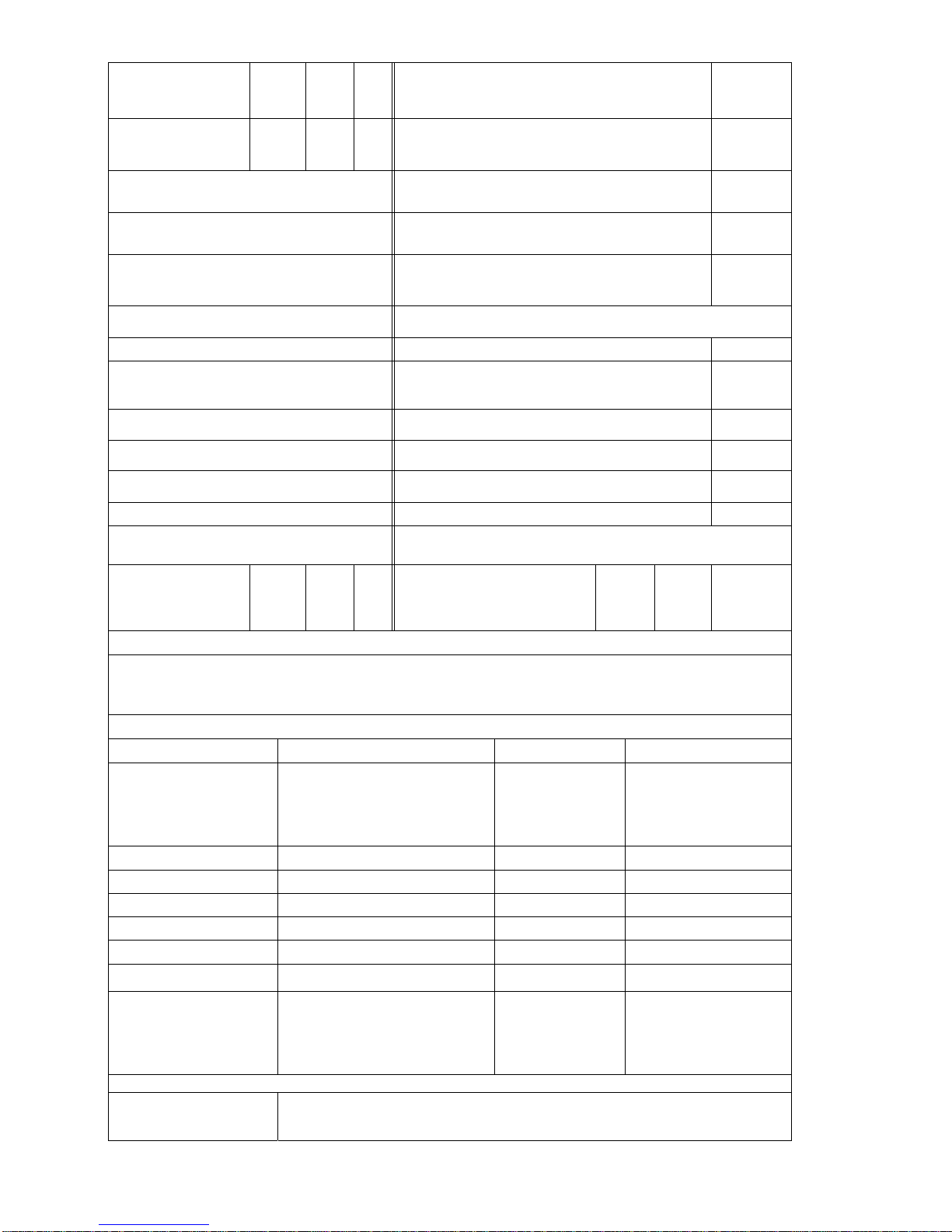

The seasonal space heating energy efficiency ηS

Item Symbol Value Unit

The seasonal space heating

Energy efficiency in active

mode

ηS,on 100 %

Correction factor (F1) / 0 %

Correction factor (F2) / 7 %

Correction factor (F3) / 0

%

Correction factor (F4) / 0

%

Correction factor (F5) / 0

%

Biomass label factor BLF 1 /

The seasonal space heating

energy efficiency ηSηS97

%

Energy efficiency classes A

CANNON TOOLS LTD

Add: 20 station road, Rowley Regis, west midlands,B65 0JU.U.K.

Made in China

Table of contents

Popular Heater manuals by other brands

Aerotech

Aerotech BT 400-46 Installation and operation maintenance

scandia

scandia 12240 Installation instructions & user manual

Dru

Dru COLOURLINE G31 Instructions for installation and operation

Timberk

Timberk TFH T20MDR instruction manual

Winterwarm

Winterwarm DXB Series instruction manual

Schwank

Schwank novoSchwank D 20S U Technical manual

NADklima

NADklima NAC Series Maintenance and installation guide

Eraser

Eraser Luxtherm HL2 operating manual

MrHeater

MrHeater MH60CLP Operating instructions and owner's manual

Warmtech

Warmtech WTCHMO2003TL-WI Original instructions

Soler & Palau

Soler & Palau EMIBLUE-A installation manual

VOGEL&NOOT

VOGEL&NOOT NERO Assembly and operating manual