Ningbo RD610 User manual

RD610/RD620

Paper Shredder Operation Manual

Ningbo R.D.C Office Equipment Co.,Ltd

Preface

The operation manual will guide you how to operate and maintain paper shredder, and also

include security guides. The paper shredder could keep in a good performance and work condition

which is closely related to right operation and maintenance. So please read the manual and

security guides carefully and take it with you .If you operate as the manual, it can be in working

order to avoid accident.

R .D. C company focus on improving the quality of products. Our company have the right of

modification and improvement for performance and specification ,but it doesn’t mean we are

under obligation to modify the machine which have been sold out .to improve the quality of paper

shredder ,it is necessary to improve the technology, but our company keep the right!

Copyright of this manual belongs to R.D.C company. The manual show the information about

installation, operation, maintenance for the machine. The information about technology

specification and drawing are not allowed to copy, spread, use in unfair competition and retransfer

to the third parties.

Notice: If you have any question after reading the manual, please contact with the local distributor.

1

Catalog

Preface——————————————————————————————1

Paper shredder nameplate ———————————————————------4

1.Security

—————————————————————————-----5

1.1 Points for attention on safety———————————————————--5

1.1.1 Security symbols——————————————————————------5

1.1.2 Attention symbols——————————————————————-----5

1.2 Safe operation guides—————————————————————-----5

1.3 Operation as manual——————————————————————---7

1.4 Inspecting security device——————————————————--------7

1.4.1 Inspecting process —————————————————————-------8

2. Technology parameter———————————————————----10

2.1 Assembly summary—————————————————————-----10

2.2 Specification and feature—————————————————-----------11

2.3 Shred data—————————————————————————----11

2.4 Motor————————————————————————————-12

2.5 Power supply specification and fuse protection———————---------------12

2.6 Size————————————————————————————---12

2.6.1 Machine Size————————————————————————---12

2.6.2 Paper feed table——————————————————————------12

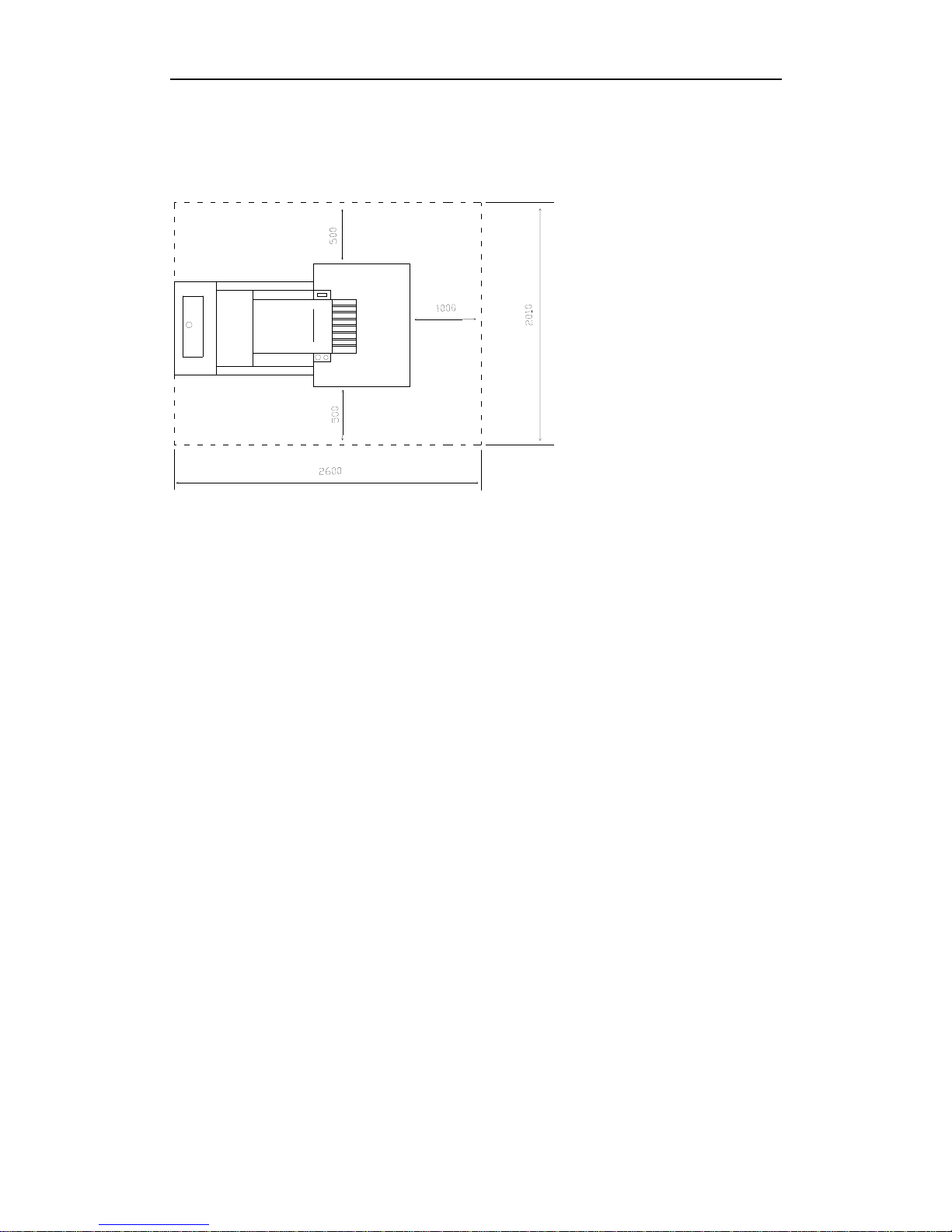

2.7 Space demand————————————————————————---13

2.8 Noise index————————————————————————------13

2.9 Machine size(drawing)———————————————————----13

3.Installation————————————————————————------14

3.1 Space demand—————————————————————————-14

3.2 Power supply connection————————————————————---14

3.3 Transfer paper shredder to installation location———————----------------14

3.3.1Installation of paper feed table——————————————---------------14

3.4 Installation of paper shredder ————————————————---------15

4.Start ————————————————————————————--15

4.1 Control and display——————————————————————----15

4.1.1 Main supply switch—————————————————————-------15

4.1.2 Emergency stop switch————————————————————------15

2

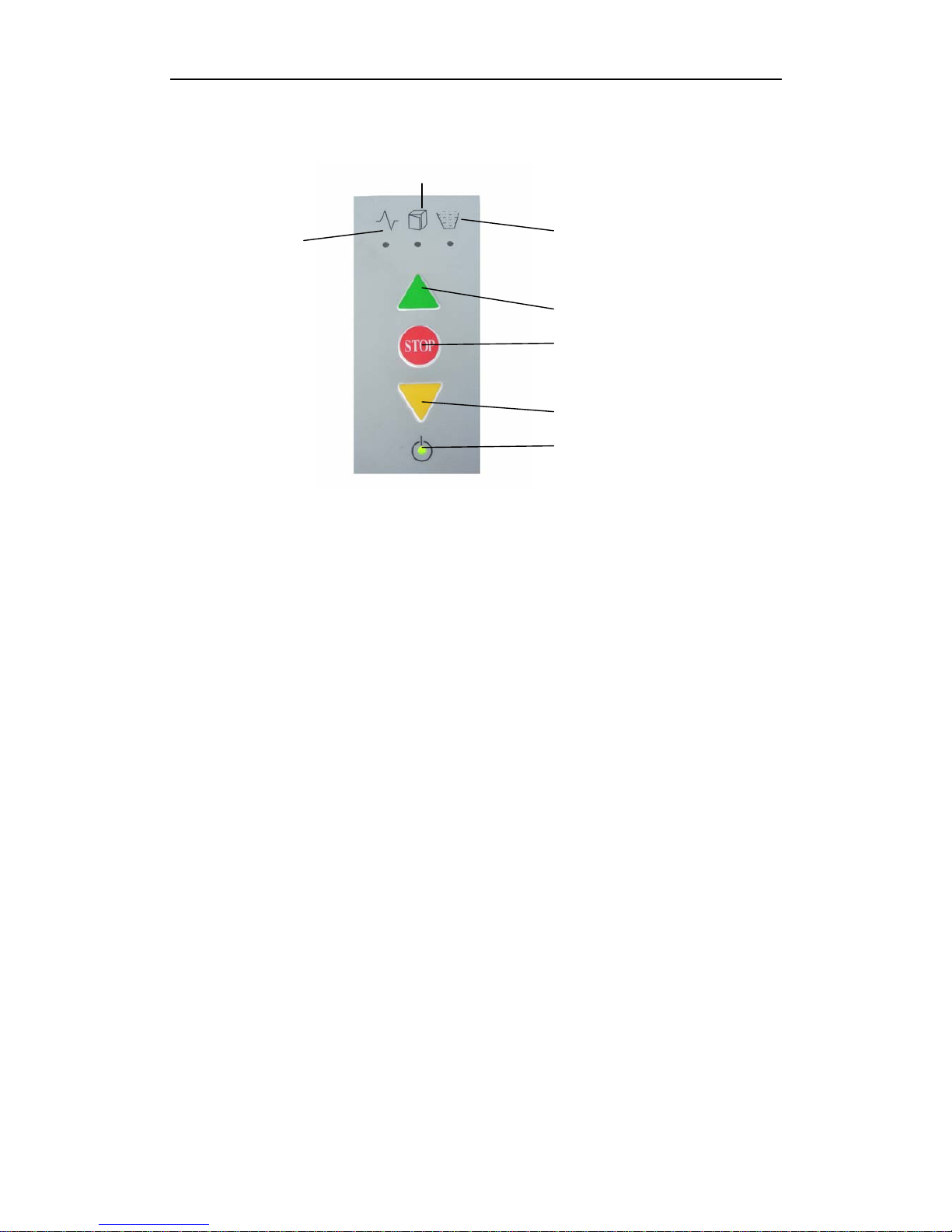

4.1.3 Control panel———————————————————————------16

4.2 Paper delivery ————————————————————-------17

4.3 Deliver paper too much—motor overload————————————------17

4.4 Shut down——————————————————————————-18

4.5 Replace shred bag——————————————————————----18

5.Inspection and maintenance——————————————————--19

5.1 Maintenance of delivery belt—————————————————--------19

5.1.1 Inspecting the tightness of delivery belt——————————----------------19

5.1.2 Inspecting the abrasion of delivery belt———————————--------------20

5.1.3 Cleaning the delivery belt—————————————————------------20

5.2 Inspecting the tightness of chain belt—————-----------------------------------20

5.3 Lubricating paper shredder——————————————————-------21

5.3.1 Paper shredder system————————————————————-------21

5.3.2 Drive———————————————————————————------21

6.Replacing parts—————————————————————--------22

6.1 After-service department address———————————————---------22

6.2 Maintenance—————————————————————————---22

7.Circuit diagram———————————————————————--23

3

RONGDA

Paper shredder

Model:RD610/RD620

serial No:

Motor:

voltage:

current:

结构:

If you couldn’t offer the serial No, you will not get the right of claim and guarantee for all repairs

The serial No is showed on nameplate as indicated above

Once you receive the goods, please mark the serial and related data on right place immediately

4

1. Security

1.1 Points for attention on safety

1.1.1 Security symbol

The symbol means dangerous, it may cause serious harm to health and

even life if ignoring it .Please pay attention to it and inform of other

users.

1.1.2 Attention symbol

You should pay much attention to the symbols .make sure to operate the machine

as manual guide to avoid damaging the machine and other devices.

1.2 Safe operation guides

Please notice below security operation ways:

The machine have passed the security certificate, but it will cause following harm by

incorrect operation

zUser’s health and life

zMachine and other precious devices

zUsing effort of paper shredder

The machine utilize the national advanced technology to guarantee the security,

but it will cause the dangerous by incorrect operation and the operation which is

not apply to our machine design

zThe curled materials are not apply to be shredded by the machine

zLong hair, clothes, belt, Scarves must be far from the paper feeding Portal

--- It is not allowed to operate it for the people under 16 years old

--- The operation worker who is engaged in the assembly, disassembly, reinstallation

5

and maintenance (including inspection, maintenance and repair) must read and

understand the manual totally, especially the contents involve “security”

--- The person who is engaged in operation, maintenance, repairing for the machine

should be trained and guided and know potential danger of the machine.

--- The procedure of installation, disassembly, reassembly, operation and maintenance

should clearly know the responsibility of each other to avoid potential danger.

--- Make sure to cut the power before installation, disassembly, reassembly, operation,

maintenance. These operations should be done when power off

--- Before using the machine, avoid driving the machine by touching switch

unconsciously. Please turn the main switch to “off” to lock the power.

--- After repairing and before using, please inspecting all protection devices

----When operating machine, all operations which will threaten to your security will

be forbidden

---If the situation which will threaten to your security happened, please report

principal. It is not allowed to start the machine before solving the danger

---Make sure the machine could work normally before starting to use

--- Make sure to keep machine in a clear and safe place

---All the modifications that will decrease security index are forbidden. Forbid

removing or rejecting security devices

--- When the machine leave unused, please continuously do the maintenance work.

--- Forbid opening the door or cover of the machine when the machine is working,

please notice the symbol

--- Please inspect the security system after installing and repairing the machine.

---When using the paper shredder, please pay attention to the local safety regulation

--- Don’t put the machine on the stand or salience surface object which will affect

security index

--- Keep all connection wire well

--- Inspecting the wear parts of the mechanism every half year

--- Inspecting the electron parts by qualified electrician every half year.

6

1.3 Operate as manual

The paper shredder is apply to shred paper, cardboard, CD, and card. But it is not

apply to shred loose-leaf book, paper clip and staple.

The operator will take on after effect by incorrectly using the machine.

Manufacturer will be derelict of duty

Operating as manual and working conform to factory’s instruction of installation,

disassembly, reassembly, operation. The person who is engaged in operation,

maintenance, repairing for the machine should be trained and guided and know

potential danger from the machine

Take attention to related security rules and other occupational disease preventing rule

1.4 Inspecting security devices

Please inspect the security devices as below:

zWhen Change the function of machine ,it should be inspected

zWhen the machine continuous work, it should be inspected at least once a

week .

zInspect after maintenance and repair

Please make security inspecting as following aspects:

zSpecific environment

zSpecific position

zAttached security devices

zSpecific function

Once the error happened when the machine is working, Please stop the machine

and eliminate the error

Don’t modify and remove the protection devices. When the danger happened,

please don’t cut down the protection devices.

To be on the safe side, it is not allowed to modify the machine

Caution symbol

Error security devices may cause serious accident, so when the security devices

have problem, should stop using the machine immediately. Forbid putting you hands

7

into paper feed system, otherwise it will be grievously hurt.

Please start shredding after all the security devices is checked normally

Please inspect as all the following points. Eliminate the error first before using the machine

1.4.1 Inspection List

Please inspecting all the following points before using the machine

1. Inspecting “emergency stop” switch on paper

feeding table

When you press down “emergency stop” switch,

please shut down the machine immediately, then the

“on” light will be off.

When the “emergency stop” switch is locked.

Please don’t start the machine. The “on” light will be

on after release the “emergency stop” switch.

2. Inspecting the top cover of delivery belt.

When the top cover open, machine stop

immediately. ”security top cover open” light is

on. When the top cover open, please don’t start

the machine. ”security top cover open “light is

off after closing the top cover.

3. Inspecting the security switch of shred box

The machine will stop immediately, when you

take out the shred box. ”security top cover open”

light is on. Please do not start the machine, when

you are taking out the shred box. The “security

top cover open” light will be off after you

reinsert the shred box.

8

4. Inspecting security switch of checking door

When open the checking door, the machine stop

immediately. ”shred box full” light is on, close it, the

light is off.

5. Install all security cover and tighten them.

record:

Date:________________

note:_________________

9

2. Technology parameter

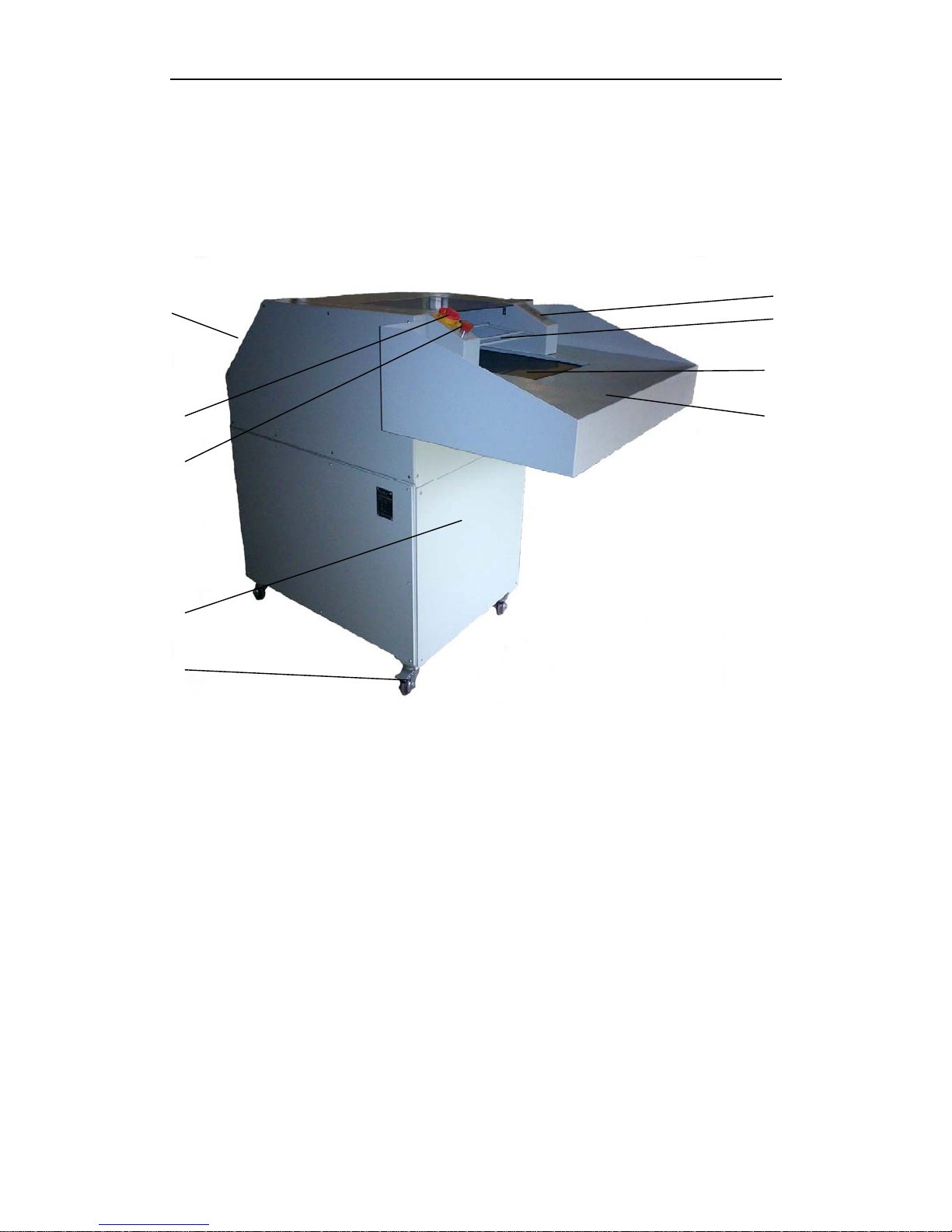

2.1 Assembly summary

5 4

3

2

6 1

7

8

9

(Picture)

The model with shred box

1.Paper feed table

2.Paper delivery belt

3.Security top cover

4.Control panel

5.Checking door

6.Switch

7.Emergency switch

8.Machine frame

9.Moving wheel

10

2.2 Machine specification and feature

Body design:Deliverybelt

Model:

Net weight:360KG

Color:

zMachine frame: gray and white RAL 9002

zPaper feeding table and box: gray and white RAL 9002

Technology devices

zLarge paper feed table

zPaper feed delivery belt

zFeed roller

zAutomatic reversing control

zMoving wheel

zShred box

2.3 Shred data

Shred type:strip slight

Shred size:5.8mm 5.8*50mm

Security index (din std):2 3

German industry standard:32757 32757

Max.sheetcap

Every time :appvox:100sheets appvox:100sheets

German industry standard:A4,70g/㎡A4,70g/㎡

Shred speed:373mm/s 354mm/s

Paper width:390mm 390mm

Power:4kw 4kw

Power supply:380v/50Hz 380v/50Hz

11

2.4 Motor

Model: Motor with transmission box

Rated power: 4.0kw

Frequency: 50Hz

Rated current: 8.7A (voltage=380v)

Output speed: 177circle/min

Frametype:

Pole quantity:Inductionmotor3pole

2.5 Power supply specification and fuse protection(400V/50Hz)

Total rated power: 4.0KW

Total rated current: 8.7A

Fuse total current: 2.5A(coil in)

Powerbolt: 32A(IEECRC)

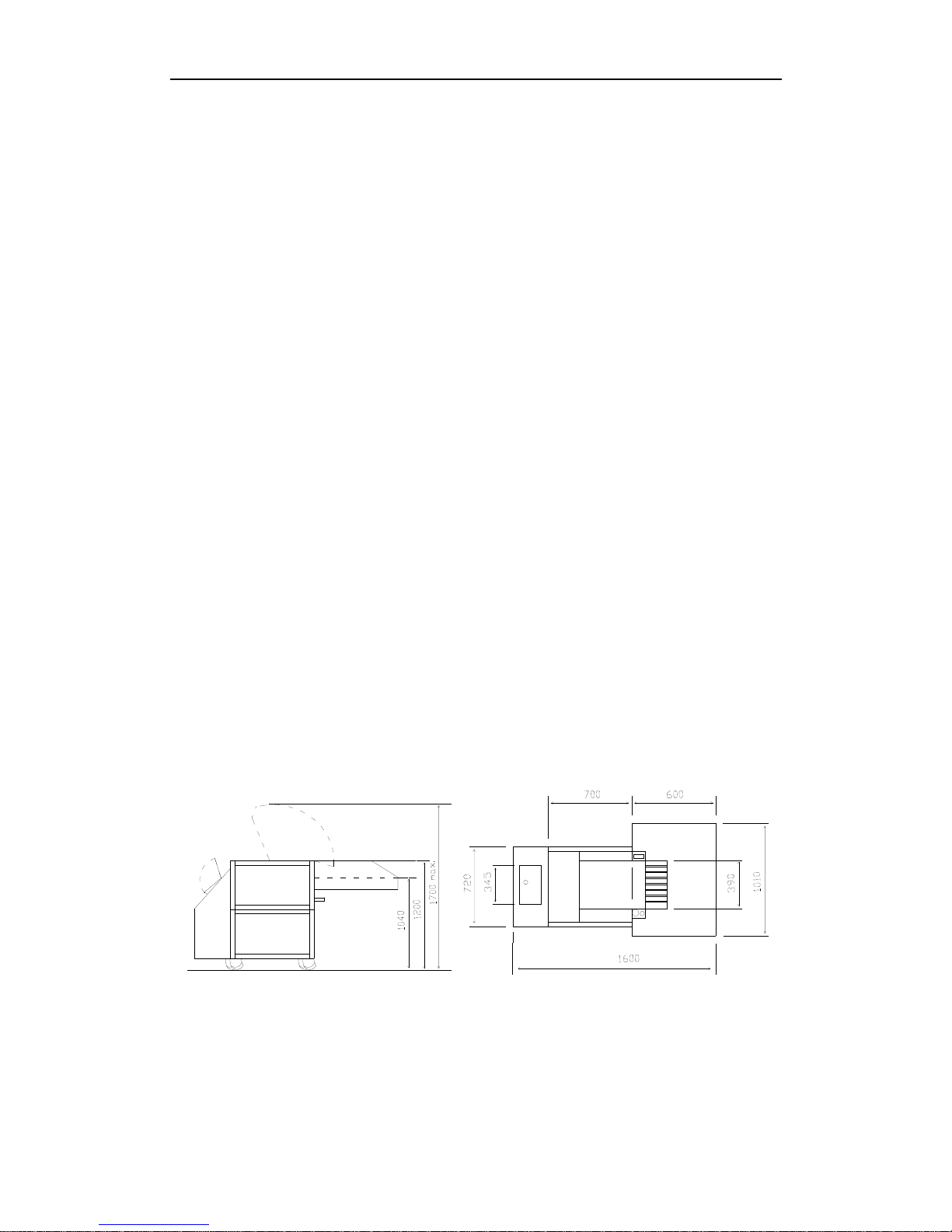

2.6 Size

2.6.1 Machine size

Width:1010 mm

Length:1600mm(the model with shred box)

Height:1200mm

2.6.2 Paper feed table

Width:1010mm

Length:600 mm

Paper feeding height:1040mm

12

2.7 Space demand

Width:Min.2010mm

Length:Min. 2600mm

Height:Min.1700mm

2.8 Noise index

Operating the machine as manual, the noise index as follows:

zMachine working but not shredding:63DB (A)

zShredding:87DB (A)

The above data is applied to the machine in correct installation without another

noise condition

The data will change if the machine work over 8 hours or have extra noise

When the machine continuous loading 50% document quantity, the noise can

reduce: 3DB

When the machine continuous loading 25% document quantity, the noise can reduce: 6 DB

2.9 Machine size(drawing)

13

3. Installation

3.1 Space demand

3.2 Power supply connection

The installation location must offer the socket of A32 CEE

3.3 Transfer paper shredder to installation location

The paper shredder that sent out from factory is not installed totally. The paper

feeding table has removed from the machine and must be installed to the machine on

installation location

--- When transfer the machine, please pay attention to the center of gravity of the

machine

--- Put the machine on a level and steady place

---Open the packing

--- The machine is convenient to be pulled with moving wheels, if it needs to deliver to the

installation location by lift cart, please using appointed cart.

3.3.1 Installation of paper feed table

zOpen the packing

zRemove the belt which is fixed with screw on paper feeding table.

14

zFix the paper feeding table on machine frame with six M8 screws

zRefix the belt to paper feeding table(The rubber of belt must touch delivery

belt)

zFix the protection cover under paper feeding table with four M5 screws

3.4 Installation of paper shredder

--- Put the machine on a level and steady place (without carpet)

The model with shred box:

zLock the brake roller;

zPlug of shredder connect with 380V socket

4. Start

4.1 Control and display

4.1.1 Main switch

---Turn the main power switch 90°clockwise to start the machine

---The main power switch is locked on “off” location

4.1.2 Emergency stop switch

--- Lift emergency stop switch to release

--- Press down emergency stop switch to cut off the power

--- The switch can be used to stop the machine

15

4.1.3 Control panel

2

1 3

4

5

6

7

1. Paper jam ---Motor overload

Red light

2. Security top cover open

No shred box or put wrong shred box

Redlight

3. Shred box full –checking door open

Red light (it is apply to the model with shred box)

4. Start key

---- Shredder start—shred system run towards paper feeding direction

5. Stop key

—Shred system stop---paper shredder in spare using condition

6. Reversing key(micro)

Shred system reverse moving

7. Start

Green light

16

4.2 Paper delivery

---Turn on main switch “on”

---Release “emergency stop “switch

---Make sure security top cover is closed

---Make sure shred box put in the right position, checking door is closed (it is

apply to the model with shred box)

---Checking the “on” light

--- Press “start” key

If the paper shredder reverse

Attention:

Turn off the power. It needs to change two of the three phase wires by

Technician!

Please check the circuit diagram

--- According to above process to run the machine

--- When the shredder runs forward you can start to deliver the paper

--- Put the paper on paper receiving table, and the paper will deliver orderly.

--- If you put the useful document on the delivery belt. Don’t take out direct use

your hand. You could do as follows:

zFirst press the “stop” key .when the machine stop ,and press reversing

button.

zShredder reverse

zRelease the reversing button, and the shredder stop.

Now you could get back the useful document, then press start key to use the shredder

again.

4.3 Deliver paper too much—motor overload

When the shred system overload, the delivery belt will turn back automatically.

--- Paper shredder stop

---“Paper jam” red light is on

17

---The paper shredder reverses and stops automatically

---“Paper jam” red light is off

--- Detach the paper and press start key again

--- Paper shedder run

--- Put a little paper again

Notice:

If the automatic reserving can’t take out the paper, please press the

manual reserving button . If the paper can take out by press the

manual reserving button, please press the button until paper were delivered to

paper receiving table, and the paper jam red light is “off”. If it fails to do it,

please contact with repair person

Attention:

In order to make the machine working continuously and keep in a good situation.

Please do not put too much paper in one time to shred which can avoid reversing and

improve work efficiency.

4.4 Shut down

--- Press “stop” key

--- Turn the main switch 90° anti-clockwise to stop the machine

--- Lock the main switch if it is necessary

4.5 Replace the shred bag

It is applied to the model with shred box

If the shred box is full, the shred paper will knock the checking door, and the

machine stop

---Paper shredder stop

---“Shred box full” light is on

--- Turn the main switch 90°anti-clockwise to stop the machine

--- Press down “emergency stop” button if it is necessary

18

--- 0pen checking door

--- Press the jam paper into the shred box

--- Close the checking door

--- Pull out the shred box totally

--- Take out the shred bag

--- Insert new shred bag, and make sure the shred bag is high 5cm than the

frame.

--- Insert the shred box

--- Open the main switch “on”

--- Loosen “emergency stop” switch

--- Make sure close the checking door and security top cover.

--- Make sure the shred box in right location

--- Press the green start button

5. Inspecting and maintenance

5.1 Maintenance of delivery belt

5.1.1 Inspecting the tightness of delivery belt

The delivery belt could not skid when the paper on it. The paper on the belt

should be delivered steadily,

The delivery belt skid, please adjust as follows:

--- Shut down, take out the paper feed table, then will see the tightness of the

delivery belt

--- Loosen the screw of tightness pulley

--- Tighten the screw to adjust the tightness of delivery belt

19

This manual suits for next models

1

Table of contents

Other Ningbo Paper Shredder manuals