Lindner URRACO 75 D Operating and maintenance instructions

S h r e d d i n g S y s t e m s

1

1.

.7

7

M

MA

AI

IN

NT

TE

EN

NA

AN

NC

CE

E

I

IN

NS

ST

TR

RU

UC

CT

TI

IO

ON

NS

S

LINDNER

Shredder Type URRACO 75 D

Date 2013.11.29

© Copyright LINDNER Mobile Shredder GmbH 2012-2013

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 2 - of - 38 -

1.7.-1 General.............................................................................................................. - 3 -

1.7.-2 Important Advice for Welding Work.................................................................... - 5 -

1.7.-3 Filling Liquids ..................................................................................................... - 7 -

1.7.-4 Initial Maintenance Work.................................................................................. - 10 -

1.7.-5 Maintenance Intervals...................................................................................... - 13 -

1.7.-6 Inspecting / Changing the Hydraulic Oil Filters................................................. - 18 -

1.7.-7 Replacing the Tank Aeration Filter ................................................................... - 19 -

1.7.-8 Checking the Hydraulic Oil Level / Changing the Hydraulic Oil......................... - 20 -

1.7.-9 Checking the Gearbox Oil Level / Changing the Gearbox Oil........................... - 23 -

1.7.-10 Checking / Changing Engine Oil and Filter....................................................... - 24 -

1.7.-11 Checking the Coolant Level / Changing the Coolant ........................................ - 25 -

1.7.-12 Changing the Air Filter ..................................................................................... - 26 -

1.7.-13 Maintaining the Water Sprinkler Filter (Option)................................................. - 28 -

1.7.-14 Adjusting the Belt Tensioning and Alignment ................................................... - 30 -

1.7.-15 Assembly and Disassembly of the Discharge Conveyor Belt Rollers................ - 33 -

1.7.-16 Tilting Hopper 1 up........................................................................................... - 35 -

1.7.-17 Dismounting the Overbelt Magnet (Option) ...................................................... - 36 -

1.7.-18 Welding in new Knives, Breakers and Blocks................................................... - 37 -

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 3 - of - 38 -

1.7.-1 General

General maintenance schedules must be observed, otherwise, our warranty for

your shredder will cease to apply.

The first maintenance and any necessary repairs may only be executed by our

service staff. Please refrain from executing any maintenance repair work

yourself or assigning any third parties with such works, since otherwise our

warranty will cease to apply.

All maintenance work may only be executed by trained and instructed

personnel. Before carrying out any maintenance work, carefully read the

instructions contained in the "Safety instructions" section.

The following must be done before entering the machine and before taking up

and maintenance or repair work:

set the key switch (Start) to the centre position and remove the ignition key,

set the key switch (Manual-0-Automatic) to "0 " and remove the key,

turn battery disconnecting switch out,

keep keys and the battery disconnecting switch in a safe place.

The shredder must always be secured against accidental or unauthorised

restarting.

It is strictly forbidden to climb into or onto the machine during operation,

particularly onto the shredding tools and the tilting hopper!

For servicing the drive engine, it is essential to follow the manufacturer’s

operating and maintenance manual!

Dispose of replaced filling liquids according to the manufacturer's instructions in

order to avoid endangering people or the environment.

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 4 - of - 38 -

The maintenance schedule contains recommended maintenance intervals for the main

components. However, please note that this maintenance schedule may have to be adapted

to the actual conditions in your plant.

If you are working under particularly difficult conditions, it may be necessary to shorten the

recommended intervals. The following maintenance schedule should therefore be used as a

basis for preparing your own schedule, which should take into account your individual

operating conditions.

Thanks to their special training, the staff of LINDNER

GmbH are able to provide first class

technical assistance as well as all maintenance services and spare parts which you require.

If you require spare parts or are encountering any problems, please do not hesitate to

contact us.

Phone: + 49 (0) 36920 - 7269 - 600

The contact details of our

Service Department are: Fax: + 49 (0) 36920 - 7269 - 99

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 5 - of - 38 -

1.7.-2 Important Advice for Welding Work

Before any welding work is carried out, the earth switch must be set to "off" and

all electronic parts and components (remote control system, engine electronics)

must be disconnected from the power supply). Turning out the battery

disconnecting switch does not provide sufficient safety. Considerable damage

to the electronics is possible in the case of nonobservance.

All material residues must be removed from the shredder before each welding

procedure. Risk of fire!

For performing welding work, prepare the shredder as follows:

1. Switch off the drive engine.

2. Turn out battery disconnecting switch and secure it against being switched (lock it).

3. Disconnect the two plugs from the electronic engine control (ECM; Put the cable away

such that the contact pins of the plugs cannot make any contact.

4. Connect the earth cable of the welding apparatus directly to the part to be welded

(connect the earth cable of the welding apparatus as closely as possible to the welding

point).

Before you start welding, the cable and other combustible parts must be covered so that they

cannot be damaged by weld spatters.

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 6 - of - 38 -

Battery disconnecting switch

Plug of the electronic

engine control (ECM)

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 7 - of - 38 -

1.7.-3 Filling Liquids

R

Re

ec

co

om

mm

me

en

nd

de

ed

d

f

fi

il

ll

li

in

ng

g

l

li

iq

qu

ui

id

ds

s

f

fo

or

r

y

yo

ou

ur

r

L

LI

IN

ND

DN

NE

ER

R

s

sh

hr

re

ed

dd

de

er

r

Total filling capacity including filters as required Changing interval

Fuel

1

approx. 450 litres Diesel oil according to DIN 51601 as required

Coolant1

1

approx. 55 litres coolant mix of distilled water and

antifreeze according to

ASTM D4985-89

(ethylene glycol basis)

every 3000 hours

or annually

1

1

Refer to the drive engine operating and maintenance manual

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 8 - of - 38 -

Engine oil

2

32 litres Select the lubricant viscosity according to the

ambient temperature:

Required oil viscosity

Ambient temperatureDiesel engine

multigrade oil

EMA LRG-1 API

CH-4 APICG-4

and APICF-4

Degree of

viscosity

min. maximum

SAE 0W / 20 -40 °C (-40 °F) 10 °C (50 °F)

SAE 0W / 30 -40 °C (-40 °F) 30 °C (86 °F)

SAE 0W / 40 -40 °C (-40 °F) 40 °C (104 °F)

SAE 5W / 30 -30 °C (-22 °F) 30 °C (86 °F)

SAE 5W / 40 -30 °C (-22 °F) 40 °C (104 °F)

SAE 10W / 30 -20 °C (-4 °F) 40 °C (104 °F)

SAE 15W / 40 -15 °C (5 °F) 50 °C (122 °F)

Factory-filled: SAE 10W / 40

every 250 hours or

every 6 months

ATTENTION:

Mandatory!

After 100 – 200

operating hours, the

customer must order

an inspection to be

performed by

LINDNER.

After 100-200

operating hours, the

engine inspection has

to be performed by the

responsible, authorised

dealer or OEM dealer

to ensure the warranty

for the engine. The

customer must order

this inspection

independently.

Gearbox

oil

60 litres (depending on sight glass level)

Types of oil: Oils with characteristics as per API GL-5

Ambient temperature: -10°C to +30°C SAE 80W/90

+20°C to +45°C SAE 85W/140

Factory-filled: CLP 220

after first

100 hours,

then every 500

hours

or twic

e yearly

Greases Standard multipurpose grease for antifriction and plain

bearings (e.g. MARSON L2),

Operating temperature range from -30 to + 120 °C

see lubrication

chart in the manual

2

Refer to the drive engine operating and maintenance manual

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 9 - of - 38 -

Hydraulic

oil

approx. 120 litres Hydraulic oil according to DIN 51524

part 2, select the viscosity class from the

diagram according to the climatic

conditions

Purity class 18/13 according to ISO 4406 or better.

Factory-filled: HLP 46

every 500 to 1000

hours

or twice yearly

(depending on

contamination level)

Auswahldiagramm Selection diagram

A = arktische Verhältnisse oder für extrem lange Leitungen A = arctic conditions or for extremely long lines

W = winterliche Verhältnisse in Mitteleuropa W = winterly conditions in Middle Europe

S = sommerliche Verhältnisse in Mitteleuropa oder geschlossene

Räume

S = summerly conditions in Middle Europe

T =tropische Verhältnisse oder Räume mit starkem Wärmeanfall T =tropical conditions or rooms with high heat exposure

U = übermäßig starker Wärmeanfall (z.B. durch

Verbrennungsmaschinen)

U =excessively high heat exposure (e.g., by combustion engines)

Max. zul. Viskosität (kurzzeitig) max. permissible viscosity (short-term)

Optimaler Betriebsviskositätsbereich optimaler Wirkungsgrad Optimal operating viscosity range, optimal efficiency

min. zul.. Viskosität (kurzzeitig) min. permissible viscosity (short-term)

min. zul. Viskosität (kurzzeitig) min. permissible viscosity (short-term)

Temperatur t in °C Temperature t in °C

1) Druckflüssigkeitstemperaturbereich 1) Pressure liquid temperature range

Produkt- bzw. nenngrößenabhängig gelten folgende

Viskositätsbereiche:

The following viscosity ranges apply, depending on product or

nominal size:

(Der max. zul. Viskositätsbereich ist den Katalogblättern der

einzelnen Produkte zu entnehmen)

(For the maximum admissible viscosity range, refer to the

catalogue sheets of every product.)

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 10 - of - 38 -

The oil change intervals for the gear and hydraulic oil can be extended subject to written

approval of our Service Department if the results of an oil analysis (laboratory report) have

been submitted.

You can have the oil analysis

conducted yourself in a certified laboratory and then send us the laboratory report, or

further advice and information concerning the oil analysis can be found at

www.wearcheck.de.

The maximum oil change intervals are 1000 h and must on no account be exceeded.

1.7.-4 Initial Maintenance Work

When servicing the drive engine, observe the separately enclosed operating

and maintenance manual of the engine manufacturer!

ATTENTION: Mandatory!

After 100 operating hours, the customer must order an inspection to be

performed by LINDNER.

After 100 -200 operating hours, the engine inspection has to be performed by

the responsible, authorised CAT dealer or OEM dealer to ensure the warranty

for the engine. The customer must order this inspection independently.

All maintenance work may only be executed by trained and instructed

personnel. Before carrying out servicing work, you must always read the safety

instructions.

The initial maintenance tasks are performed 16 hours (2 working days) and 100 - 200 hours

(1 month) after installation and commissioning of the machine.

The daily and the regular maintenance tasks are carried out according to section 1.7-5.

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 11 - of - 38 -

M

Ma

ai

in

nt

te

en

na

an

nc

ce

e

a

af

ft

te

er

r

1

16

6

h

ho

ou

ur

rs

s

o

or

r

2

2

w

wo

or

rk

ki

in

ng

g

d

da

ay

ys

s

(

(t

to

o

b

be

e

e

ex

xe

ec

cu

ut

te

ed

d

b

by

y

t

th

he

e

c

cu

us

st

to

om

me

er

r)

)

Filter

elements

Hydraulic

system

Conveyor

belt

Cooler Gearbox Others

Daily

maintenance

tasks to be

executed

Daily

maintenance

tasks to be

executed

Daily

maintenance

tasks to be

executed

Daily

maintenance

tasks to be

executed

Daily

maintenance

tasks to be

executed

Daily

maintenance

tasks to be

executed

Retighten

all

fastening

bolts

Retighten

all bolts,

especially

on the

rakes,

shaft

bearings,

hoppers

and engine

fastening

bolts.

Inspect the

V-belts of

the fans

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 12 - of - 38 -

M

Ma

ai

in

nt

te

en

na

an

nc

ce

e

a

af

ft

te

er

r

1

10

00

0

h

ho

ou

ur

rs

s

o

or

r

o

on

ne

e

m

mo

on

nt

th

h

(

(b

by

y

a

an

n

L

LI

IN

ND

DN

NE

ER

R

G

Gm

mb

bH

H

e

en

ng

gi

in

ne

ee

er

r)

)

Filter

elements

Hydraulic

system

Conveyor

belt

Cooler Gearbox Others

Daily

maintenance

tasks to be

executed

Daily

maintenance

tasks to be

executed

Daily

maintenance

tasks to be

executed

Daily

maintenance

tasks to be

executed

Daily

maintenance

tasks to be

executed

Daily

maintenance

tasks to be

executed

Replace

suction filter.

Replace

suction/return

filter

Replacing the

tank aeration

filter

Check main

air filter

element

Change

gearbox oil.

Commission-

ing inspection

of the drive

engine

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 13 - of - 38 -

1.7.-5 Maintenance Intervals

When servicing the drive engine, observe the separately enclosed operating

and maintenance manual of the engine manufacturer!

All maintenance work may only be executed by trained and instructed

personnel. Before carrying out servicing work, you must always read the safety

instructions.

The long-term maintenance tasks always include the performance of all more frequent

maintenance tasks.

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 14 - of - 38 -

D

Da

ai

il

ly

y

m

ma

ai

in

nt

te

en

na

an

nc

ce

e

t

ta

as

sk

ks

s

Filter

elements

Hydraulic

system

Conveyor

belt

Cooler Gearbox Others

Check and

clean the

main air

filter

element

Check oil

level and

refill if

necessary

Visual

check for

damage

Check

alignment

and

functioning

of the

rollers

Check the

belt

support

and clean if

necessary.

Remove

any

jammed

material

from the

conveyor

belt

Check belt

tensioning

and

alignment

Check

coolant

level and

refill if

necessary.

Check if

clean.

Visual

check for

damage

and leaks.

Check oil

level and

refill if

necessary.

Visual

check for

damage

and leaks

Check

engine oil

level and

refill if

necessary.

Functional

test of all

(Emergency

Stop)

buttons and

safety

devices

Overall

visual check

of the entire

machine for

damage,

leaks, loose

connections,

loose or

worn belts

and take any

remedial

action

necessary

Check tire

pressure

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 15 - of - 38 -

M

Ma

ai

in

nt

te

en

na

an

nc

ce

e

e

ev

ve

er

ry

y

2

25

50

0

h

ho

ou

ur

rs

s

o

or

r

q

qu

ua

ar

rt

te

er

rl

ly

y

Filter

elements

Hydraulic

system

Conveyor

belt

Cooler Gearbox Others

Check the

main air

filter

element

and clean if

necessary

(max. six

times) or

replace.

Replace

the safety

elements

after every

third

cleaning of

the main

element

Check oil

and filters

Change oil

of the main

gearbox

Engine

mainten-

ance (in

accordanc

e with the

engine

manual)

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 16 - of - 38 -

M

Ma

ai

in

nt

te

en

na

an

nc

ce

e

e

ev

ve

er

ry

y

5

50

00

0

h

ho

ou

ur

rs

s

o

or

r

e

ev

ve

er

ry

y

s

si

ix

x

m

mo

on

nt

th

hs

s

Filter

elements

Hydraulic

system

Conveyor

belt Cooler Gearbox Others

Replace

suction

filter.

Replace

suction/ret

urn filter

Replace

the tank

aeration

filter

Check

preset

pressure

settings.

Change

the

hydraulic

oil + filters

Check belt

tension

and adjust

if

necessary.

Change oil

of the main

gearbox

Functional

test of all

safety

devices

Check

shredding

tools and

scrapers

for wear.

Check all

bolted

connection

s.

Engine

mainten-

ance (in

accordanc

e with the

engine

manual)

M

Ma

ai

in

nt

te

en

na

an

nc

ce

e

e

ev

ve

er

ry

y

1

10

00

00

0

h

ho

ou

ur

rs

s

o

or

r

a

an

nn

nu

ua

al

ll

ly

y

Filter

elements

Hydraulic

system

Conveyor

belt Cooler Gearbox Others

Change oil

of the main

gearbox

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 17 - of - 38 -

A

An

nn

nu

ua

al

l

m

ma

ai

in

nt

te

en

na

an

nc

ce

e

Filter

elements

Hydraulic

system

Conveyor

belt Cooler Gearbox Others

Replace

the main

air filter

element

M

Ma

ai

in

nt

te

en

na

an

nc

ce

e

e

ev

ve

er

ry

y

3

30

00

00

0

h

ho

ou

ur

rs

s

o

or

r

a

an

nn

nu

ua

al

ll

ly

y

Filter

elements

Hydraulic

system

Conveyor

belt

Cooler Gearbox Others

Check and

clean the

cooling

system and

change the

coolant

M

Ma

ai

in

nt

te

en

na

an

nc

ce

e

e

ev

ve

er

ry

y

6

6

y

ye

ea

ar

rs

s

Filter

elements

Hydraulic

system

Conveyor

belt

Cooler Gearbox Others

Replace

all

hydraulic

hoses

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 18 - of - 38 -

1.7.-6 Inspecting / Changing the Hydraulic Oil Filters

A suction/return filter and a suction filter are installed in the shredder. The filter cartridges

have to be replaced when the <Oil filter> indicator light lights up or at least every 500

operating hours.

Although hydraulic oil filters are electronically monitored, maintenance still must

be carried out at regular intervals. Therefore, replace the filters after 500

operating hours at the latest.

When changing the filter, pay attention to the hydraulic oil temperature. Danger

of scalding.

All installed filter elements are also listed in the enclosed machine data sheet.

Suction/return filter of the hydraulic oil tank

The integrated suction/return filter is equipped with a return and a suction connector. It is

equipped with an integrated oil temperature control device. Furthermore, it is equipped with

intelligent valve technology to control the oil temperature exceeding 50°C. To prevent air

from being drawn into the suction pipe, an oil guiding system has been installed.

To replace the suction/return filters, proceed as follows:

1. Have the new filter cartridge to hand. To find out which type of filter cartridge you have to

choose, please refer to appendix "Modules and Spare Parts".

2. Remove the complete cap using an appropriate tool by turning it counter clockwise.

3. Pull the cap with the filter element out of the hydraulic tank.

4. Replace the old filter cartridge by a new one.

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 19 - of - 38 -

Suction filter

To replace the suction filter, proceed as follows:

1. Have the new filter(s) to hand. Filter cartridge type: see Appendix "Modules and spare

parts".

2. Unscrew the old filters from the filter head.

3. Clean the filter head sealing surface. The old sealing ring may still be sticking to the filter

head. If this is the case, remove it carefully.

4. Fill the oil filter with clean hydraulic oil.

5. Apply a thin hydraulic oil film on the filter seal.

6. Screw the filter onto the filter head. Tighten the filters until the seal touches the surface of

the filter head.

7. Tighten the filter by about another half to three-quarters of a turn.

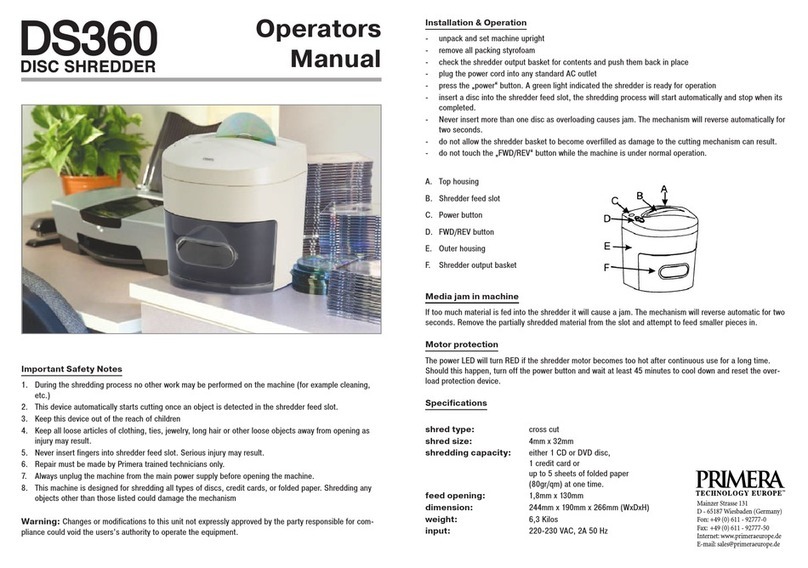

1.7.-7 Replacing the Tank Aeration Filter

The tank aeration filter on the hydraulic tank must be replaced every 500 operating hours.

The type of filter to be used is listed in the Appendix "Modules and Spare Parts”.

Tank aeration filter

URRACO 75 D

S

ERVICE GUIDELINES

Managing director

LINDNER

Mobile Shredder GmbH

Industriestrasse 1A

D-99820 Hörselberg / Eisenach

Service hotline:

+49 (0) 36920 - 7269 - 600

Manuel Lindner

Gerhard Buhl

Walter Geiger

Page - 20 - of - 38 -

1.7.-8 Checking the Hydraulic Oil Level / Changing the Hydraulic Oil

Maximum oil filling is only permissible with retracted hydraulic cylinders.

Checking the oil level

If the oil drops below the minimum level, the <Hydraulic oil level> indicator light lights up on

the control panel. In this case, the machine switches off immediately.

The hydraulic oil level must be checked daily via the sight glass; the oil should be

approximately in the upper third of the sight glass. Ensure that the shedder is standing

horizontally.

Oil drain plug

Sight glass

Hydraulic oil tank

Other manuals for URRACO 75 D

1

Table of contents

Other Lindner Paper Shredder manuals

Popular Paper Shredder manuals by other brands

Aurora

Aurora ShredSafe AU740XA user manual

Talex

Talex LEOPARD 320/O PROFESSIONAL Instruction Manual-Catalogue of Parts-Warranty

Retsch

Retsch BB200 operating instructions

Hyundai power products

Hyundai power products HBT420 Original instructions

Ativa

Ativa DQ60M operating instructions

UNITED OFFICE

UNITED OFFICE UAV 380 A1 - 2 operating instructions