Ninja Paintball Proudly made in the USA 815-477-0007

4

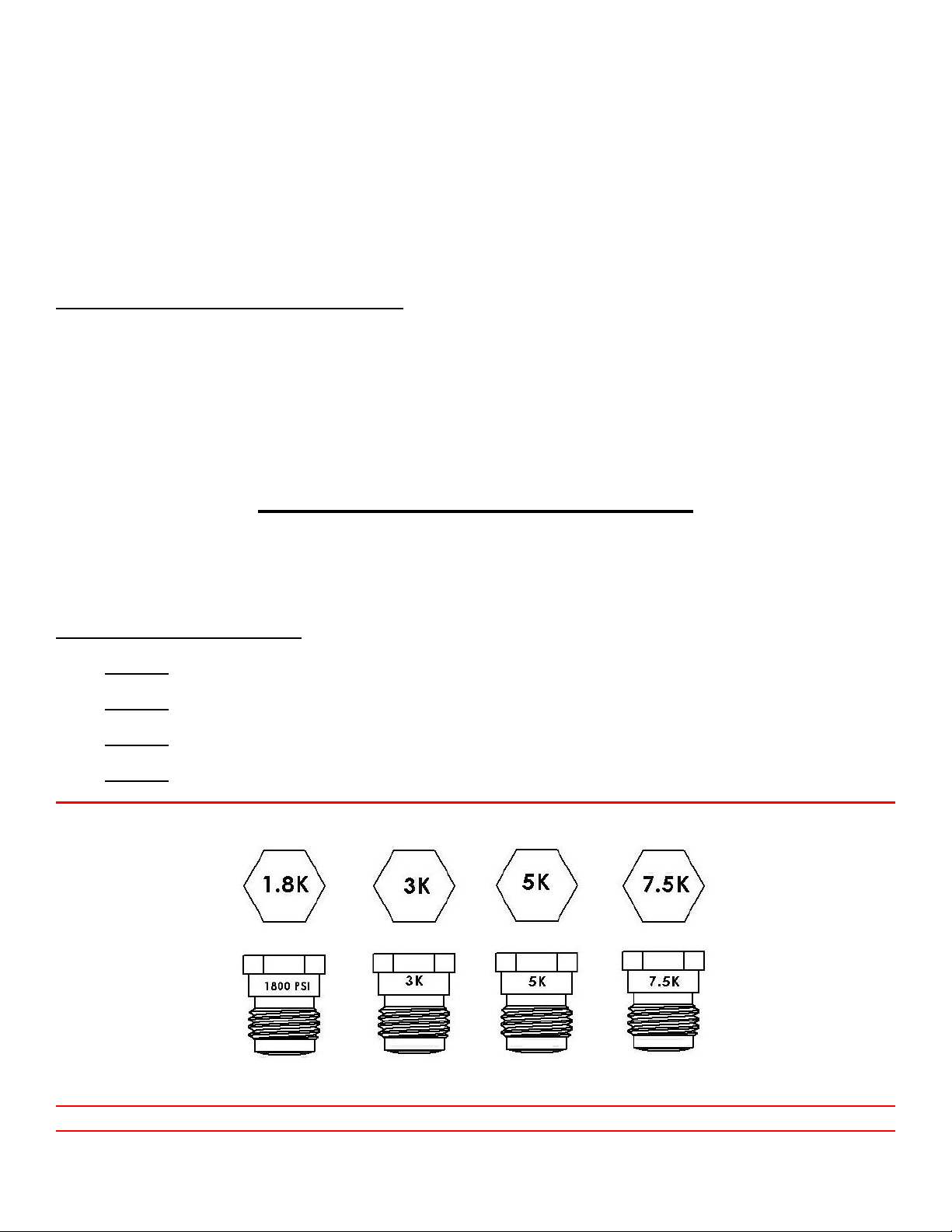

The next piece of information you want is the Working Pressure Rating.

As you can see, this information is also present in the data line on the bottle.

oREFER TO THE LABEL ON THE BOTTLE FOR PRESSURE RATING AND TEST DATES.

oUNDER NO CIRCUMSTANCES SHOULD YOU FILL AN OUT-OF-DATE BOTTLE!

oNEVER EXCEED THE PRESSURE RATING OF THE BOTTLE!!!

oEXAMINE THE BOTTLE FOR DENTS, GOUGES OR OTHER SIGNIFICANT DAMAGE. DO NOT FILL A BOTTLE

THAT HAS BEEN ABUSED OR DAMAGED.

For more information, consult the Compressed Gas Association pamphlets C-6, C-6.1, & C-6.2.

These are available online at WWW.CGANET.COM.

WARNING

IF YOU FIND THAT THERE IS NO MARKING ON THE BOTTLE OR THE LABEL HAS BEEN OBSCURED, DO NOT FILL

THE BOTTLE!

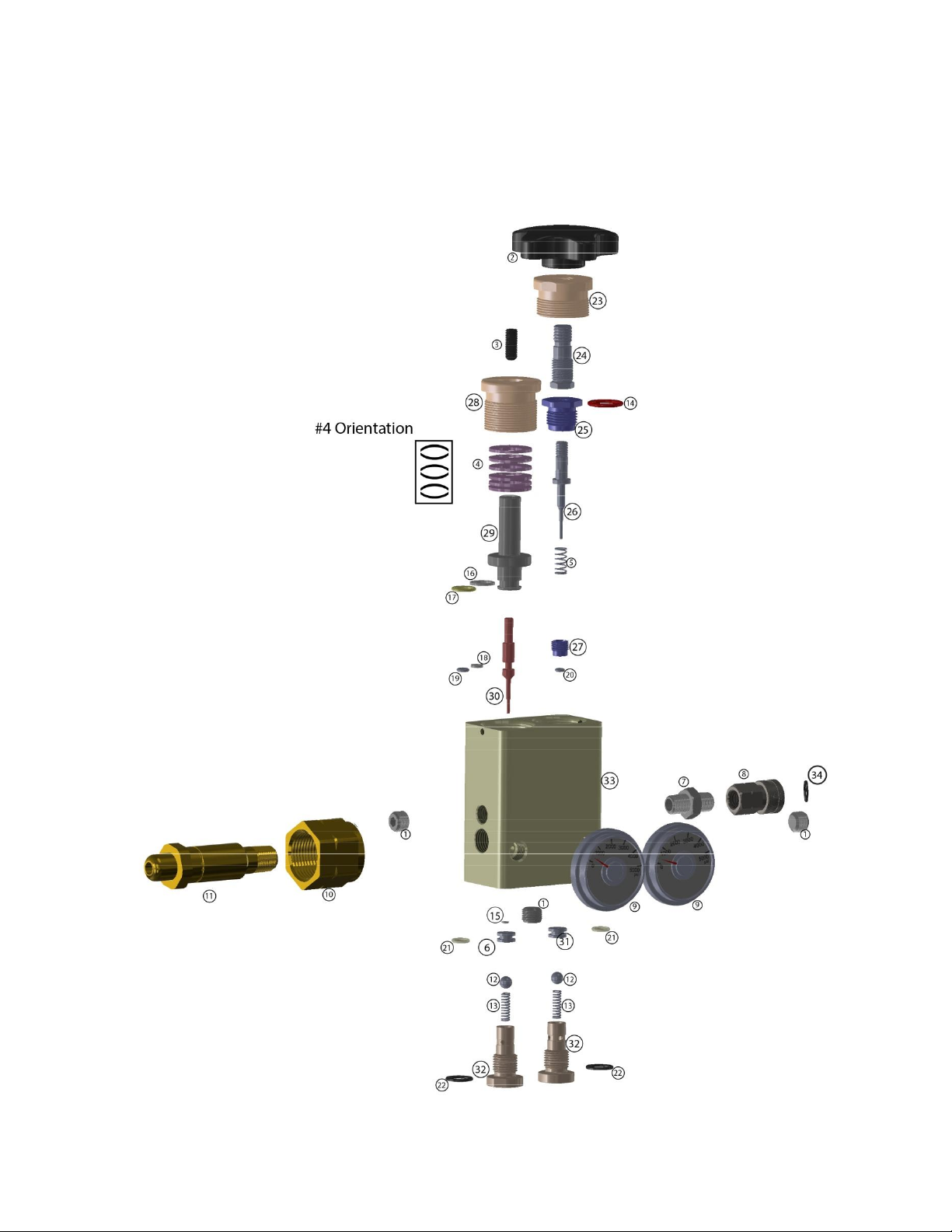

THE OPERATING CONTROLS

A DESCRIPTION OF THE OPERATING CONTROLS FOLLOWS. DO NOT HOOK UP YOUR HIGH PRESSURE FILL

STATION UNTIL YOU HAVE READ AND UNDERSTOOD THE SETUP PORTION OF THIS MANUAL.

THERE ARE TWO USER CONTROLS ON THE FILL STATION.

Output Pressure Adjustment

Control Knob.

YOUR FILL STATION IS EQUIPPED WITH TWO GAUGES

DELIVERY PRESSURE (Labeled “OUTPUT ” on the Fill Station body)

How Much Gas Is Left In Your Supply Cylinder (Labeled “BULK ” on the Fill Station body.)

OUTPUT PRESSURE ADJUSTMENT:

The Output Pressure Adjustment allows the operator to set the pressure that will be dispensed.

It is located on the top of the Fill Station, next to the control knob, and is set with a 1/8 inch Allen key.

THE CONTROL KNOB:

The Control Knob is a single control that manages both the gas delivery to the system to be filled, and the

purging of the fill line to allow disconnection.

NOTE: DO NOT OVER-RANGE THE CONTROL KNOB! DAMAGE TO THE CONTROL VALVE CAN RESULT!

THE MAXIMUM PRESSURE DELIVERED BY THE FILL STATION IS ALWAYS DETERMINED BY THE PRESSURE IN THE

BULK TANK. THE BULK TANK PRESSURE MUST BE GREATER THAN THE OUTPUT SETTING ON THE FILL STATION.

ONCE YOUR FILL STATION HAS BEEN CONNECTED TO THE BULK TANK AND PRESSURIZED, YOU CAN NOW SET THE

DELIVERY PRESSURE.

Using a 1/8 Allen key, slowly turn the Delivery Pressure Adjustment clockwise until the output gauge shows the

desired fill pressure. DO NOT EXCEED THE PRESSURE RATING ON THE BOTTLE YOU ARE FILLING