TRIGGER

ADJUSTMENT

SLG™ BOARD

SETTINGS AND FUNCTIONS

BATTERY

The 9V battery will last for about

20,000 shots. Please be aware that

there are substantial differences in

performance between different brands of

batteries. Use of high quality alkaline or

lithium ion batteries is recommended for

maximum battery life. If you plan not to

use your marker for a long period

of time (a month), it is

recommended that you remove the

battery from the marker. When the

battery voltage starts to go too low, the

marker will not fire with every trigger pull.

For tournament use, it is recommended to

change the battery for each tournament.

CHANGING THE BATTERY

The battery is housed on the right side of the grip

frame. To access the battery, remove the three screws holding the right side

grip panel down. Use a 3⁄32” allen key. When inserting a new battery notice the

+ and - marks on the frame. The positive lead of the 9V battery goes to the left and the negative

lead to the right.

NOTE: If the marker will not

function with the eye on,

there is a good chance the

battery needs to be

changed.

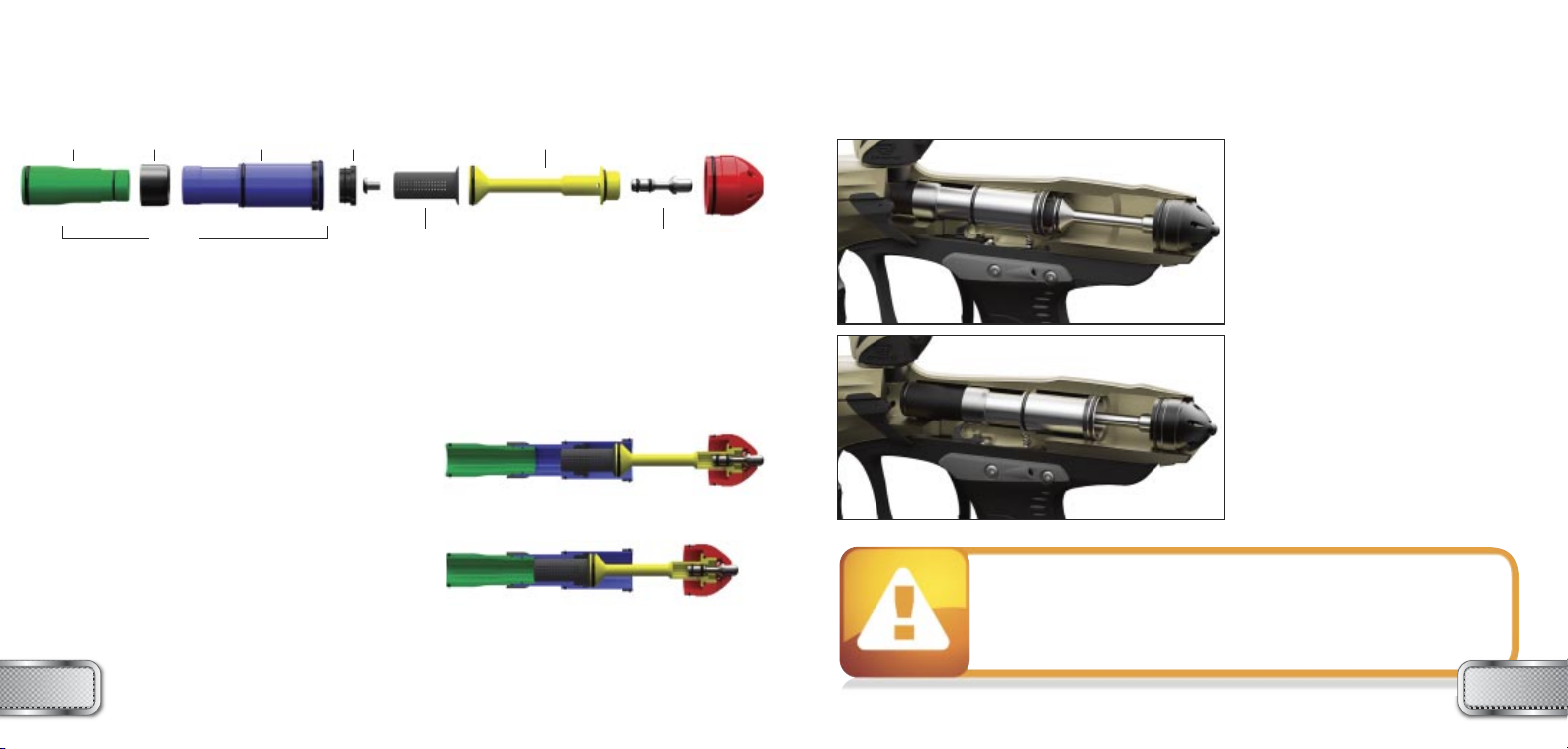

ADJUSTING YOUR TRIGGER

The trigger’s forward travel, over travel and spring tension

are fully adjustable so that the user can fine-tune the

trigger to his or her exact liking. You do not need to remove

the frame from the gun in order to adjust the trigger pull.

• There are two adjustment screws located on the right side

of the Ultralite frame and one adjustment screw behind the

trigger. The two screws on the side of the frame adjust the

travel of the trigger. The one located behind the trigger is

used to change the tension of the trigger spring.

• Use a 5⁄64” allen key to make all desired adjustments.

TO ADJUST TRIGGER TRAVEL (SEE FIGURE 1)

• The screw toward the front of the trigger (1) controls the trigger’s length of pull. NOTE: If this

screw is adjusted too far, the switch will be held down at all times and the marker will not fire.

•The screw toward the rear of the trigger (2) controls how far the trigger will travel after it

reaches the firing point. NOTE: If this screw is adjusted too far, the trigger will not be allowed to

travel far enough to depress the switch and fire the marker.

TO ADJUST SPRING TENSION (SEE FIGURE 1)

• Turn the screw located through the hole in the trigger (3) in or out to reach the desired tension.

Fig. 1

2

1

3

• Be sure the trigger is not adjusted to the point where it is too sensitive

and may cause accidental discharge of the marker.

• Removing the trigger spring will cause premature wear on the microswitch,

resulting in failure.

•Be sure you do not pinch the wires between the frame and body when

reattaching the frame to the body.

• A low battery will not be able to

power both the ACE eye and the

trigger switch, causing ACE eye failure.

• If the battery is low, the marker will

not fire with every trigger pull.

WWW.PROTOPAINTBALL.COMWWW.PROTOPAINTBALL.COM

10 11

FIGURE 1