08 09

W W W . D Y E P A I N T B A L L . C O M W W W . D Y E P A I N T B A L L . C O M

RIZE ™BOARD

SE T TI NGS A ND F UNC T IO NS

BOARD SETTINGS AND CONF IGURATION MODE

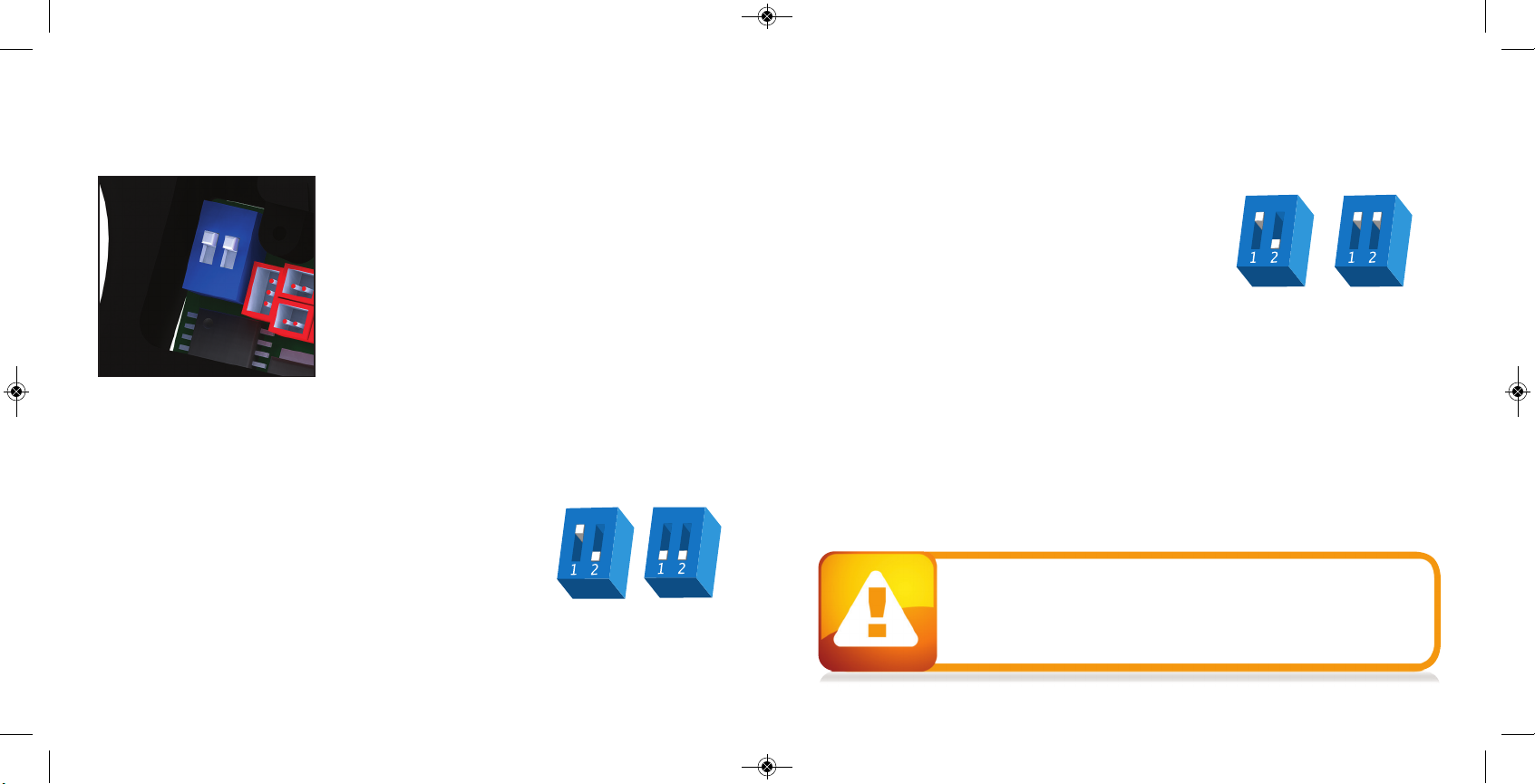

There are five settings yo u can alter o n the RIZE ™board with

the DIP switches inside the g rip frame ( see figure 1) :

ABS A nti Bo lt Stick.

Trigger Sensitivity This setting adjusts the d elay

between two trigg er pulls.

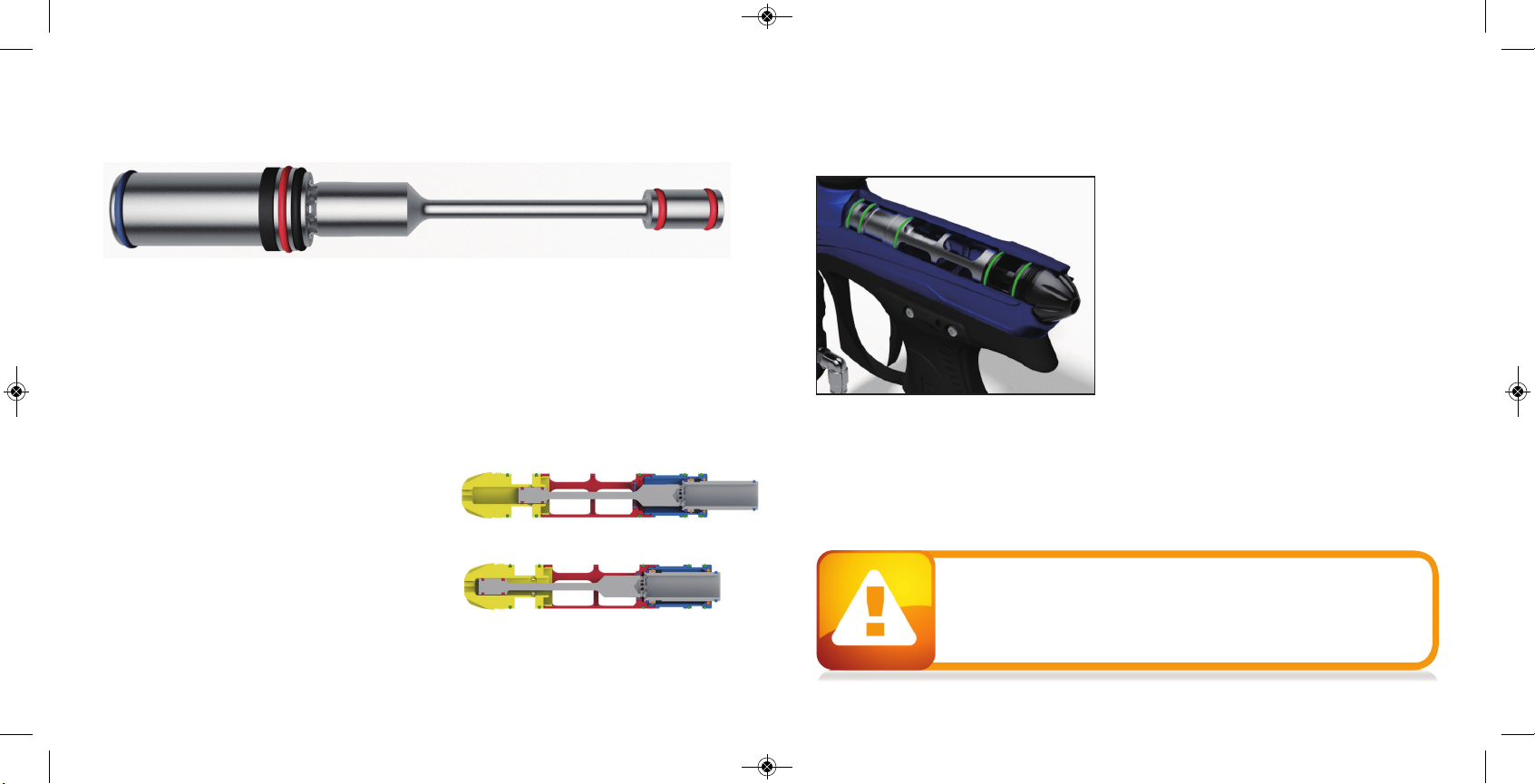

Dwell This is the time the solenoid is

activated for.

Rate Of Fire This setting is for ad justing the

maximum rate of fire

Firing Mode This is the firing mod e the RIZE ™uses.

There are two DIP switches mounted o n the b o ard o f the RIZE ™( See fig ure 1) . The first one is

used for the A BS setting and the second one is used to access a config uration mo d e which

changes the other four settings.

Anti Bolt Stick -W hen A BS is activated , the dwell is increased after

15 second s of no n- use for the next sho t fired . This help s to prevent

bolt- stick, b ut may result in hig her velocity for the first shot.

FIGURE 1

ABS ON

(DEFAULT)

ABS OF F

CONFIGURATION MODE - The following settings can only b e

modified in configuration mode. To activate the co nfiguration

mode, turn yo ur marker off and set DIP switch 2 to the ON

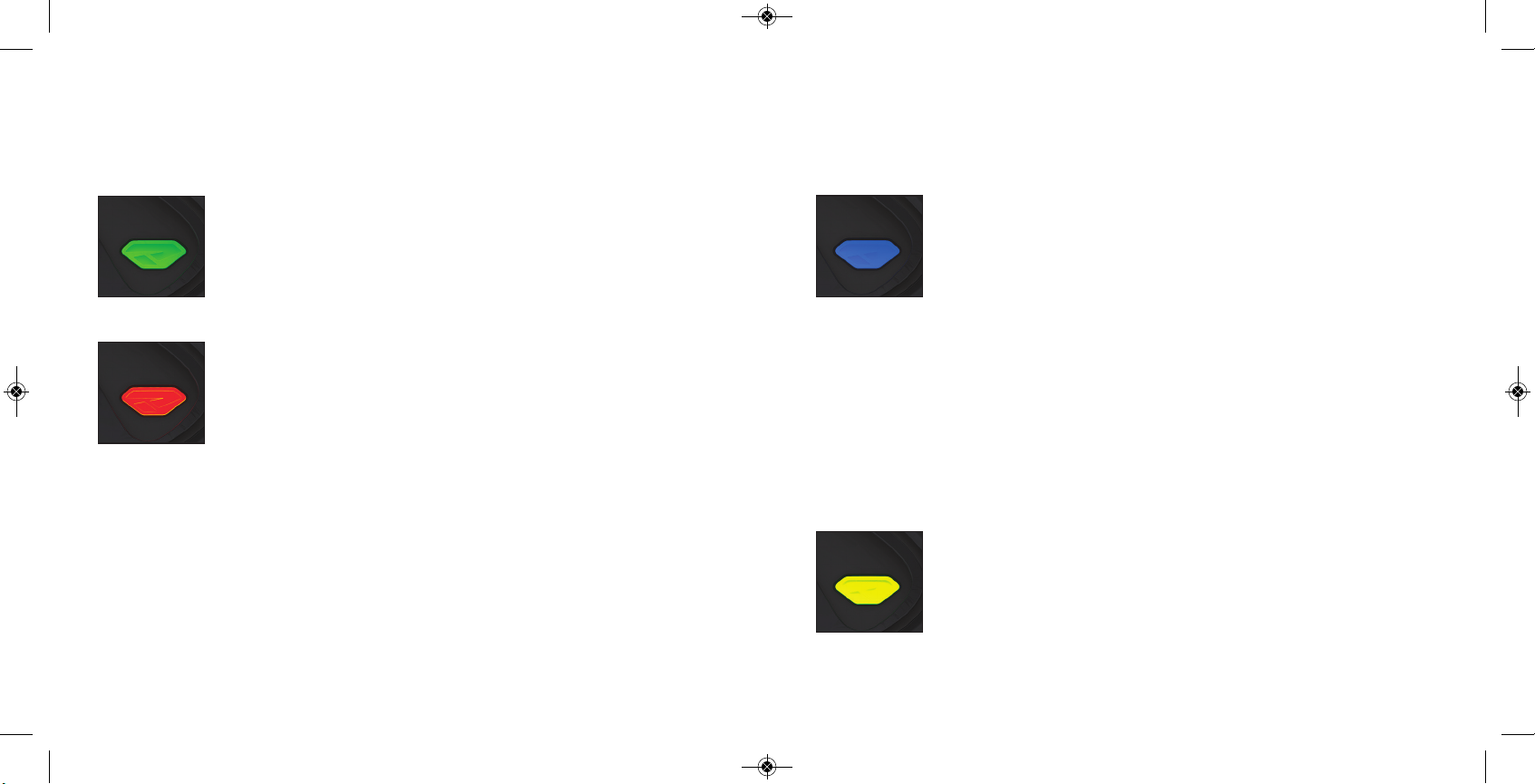

position. Next, turn yo ur marker on. The LED's cycle throug h

all colors for one seco nd to ind icate that yo u have entered

the config uration mod e.

To cycle throug h d ifferent settings, p ull and release the trigg er.

Config uration mode has 4 settings that can b e chang ed.

TO CHANGE A VALUE OF A SETTING

1. While in the config uration mo d e, choose the setting yo u wish to chang e by p ulling the trigger

to cycle throug h d ifferent op tions.

2. W hen the LED indicates the color of the setting you wish to chang e, p ull and hold the trig g er

until the LED starts to flash.

3. The LED will flash as many times as the previous setting was and it will then turn o ff. Now pull

the trigg er as many times as you wish the new setting to b e. Note: You must enter a value at this

point, if yo u d o not wish to alter the setting then re- enter the prev ious value.

4. W hen d o ne, the LED will cycle throug h all the co lors again to indicate setting was saved and

turn b ack to g reen. You can now chang e ano ther setting o r q uit the configuration mod e.

5. To exit configuration mode, set DIP 2 to the off p osition.

NORMAL

MODE

CONF IGURATION

MODE

RIZE ™BOARD

SE T TI NGS A ND F UNC T IO NS

•The RIZE™ is not water resistant. Excess moisture can cause damage

to electronic parts.

•Keep the board and all electrical components clean of dirt, paint and moisture.

•To clean the board, use canned air. If a more aggressive cleaning method

is needed, lightly scrub the components with a soft, dry brush.

Heavy scrubbing will damage the board.