Nipro PHOENIX ONE DS User manual

Operator´s Manual

Reverse Osmosis

TYP: PHOENIX ONE DS

Datum: 13.01.2021 |Version: 3

Written by: Nipro Pure Water

Table of Contents

1 General .............................................................................................. - 2 -

Shipment ........................................................................................... - 2 -

Unit combinations ............................................................................... - 2 -

Accessories and Consumables............................................................... - 2 -

Notes for the Operator.........................................................................- 2 -

Laws and Standards ............................................................................- 2 -

Symbols used in this Manual ................................................................ - 3 -

Transport and Storage ......................................................................... - 3 -

Model Plate ........................................................................................ - 4 -

Warning on the Unit ............................................................................ - 5 -

Shutdown .......................................................................................... - 5 -

Disposal............................................................................................. - 5 -

Further Documentation ........................................................................- 5 -

2Intended operation ................................................................................ - 7 -

3Safety .................................................................................................. - 8 -

Risk Assessment ................................................................................. - 8 -

EMC .................................................................................................. - 8 -

Emissions...........................................................................................- 8 -

4Technical Data....................................................................................... - 8 -

5Description of the unit .......................................................................... - 10 -

Flow-Chart ............................................................................................11

Operation Sequence Permeate Production .................................................12

Assembly groups ...................................................................................13

6Installation ..............................................................................................14

Environmental Conditions .......................................................................14

Assembly ..............................................................................................14

Electrical installation .....................................................................................15

Installation plan (Example) .....................................................................16

7Operation ................................................................................................17

Control Panel.........................................................................................17

Emergency operation..............................................................................18

Manual On / Off .....................................................................................19

Quick access keys ..................................................................................20

Main menu ............................................................................................21

Menu Info .............................................................................................22

|3 |13.01.2021 |Seite 3

Menu Notification ...................................................................................23

Menu Statistics ......................................................................................24

Menu Functions .....................................................................................25

Set clock...............................................................................................26

Timer ...................................................................................................27

8Maintenance and cleaning..........................................................................28

External Cleaning...................................................................................28

Maintenance Intervals ............................................................................28

Primary Filter Replacement .....................................................................29

Chemical Disinfection .............................................................................30

Microbiological Inspection .......................................................................31

9Malfunctions.............................................................................................32

Technical Appendix..........................................................................................34

10 Fuses ......................................................................................................35

Labelling ...............................................................................................35

Micro Fuses in Control Cabinet.................................................................36

11 Settings...................................................................................................37

Setting Ring Pressure (Permeate Pressure) ...............................................37

Setting Concentrate Pressure ..................................................................38

12 Replacement of the reverseosmosis membrane ............................................39

13 switch over only „Step 1“ or only „Step 2“ ..................................................40

Emergency operation only „2. step“..........................................................41

14 Disinfection..............................................................................................42

Disinfection Protocol ...............................................................................43

15 Service/Limits ..........................................................................................45

16 EMC MANUFACTURER’S DECLARATION ........................................................47

Electromagnetic emissions and electromagnetic immunity .................................47

Warning ......................................................................................................48

Requirements...............................................................................................48

Recommended minimum distances between portable and mobile HF

communicationunits and PHOENIX ONE ....................................................51

Nipro Pure Water Operator’s Manual Reverse Osmosis Phoenix One DS

- 1 -

Stand 3 as at 13.01.2021

The reverse osmosis model Phoenix One DS has been declared

conform in accordance with EC directives.

Foreword

This Operator’s Manual includes all information required for the installation and operation for

the reverse osmosis model Phoenix One DS.

Please keep this Operator’s Manual readily available and near the unit.

This Operator’s Manual applies fort the units with the serial number:

© Copyright 2020

Nipro Pure Water GmbH

Werner-von-Siemens-Str.2-6

76646 Bruchsal –Germany

Tel.: 0049 7251-32 19 7810

Fax: 0049 7251-61 89 943

Rev#

Date / Name

Description

0

28.02.14 / N.Bürkle

First edition

1

27.07.16 / N.Bürkle

Nipro

2

08.09.20 / N.Bürkle

EN60601

3

13.01.21 / R.Tille

60 Hz Version

0297

Nipro Pure Water Operator’s Manual Reverse Osmosis Phoenix One DS

- 2 -

Stand 3 as at 13.01.2021

1 General

Shipment

The following parts are included in the shipment:

▪1 Reverse osmosis

▪1 Connector set

Unit combinations

The unit model Phoenix DS may be combined with the following devices:

▪Hot cleaning system Phoenix One +

▪Hot cleaning system Phoenix One +FH

Accessories and Consumables

▪1 Prefilter 20‘‘ 10 µm

Notes for the Operator

The operator is responsible for:

▪Competent and intended operation

▪Compliance with work safety and accident prevention provisions

▪Competent instruction or operating personnel

Laws and Standards

The following laws and standards are adhered to:

▪Guidelines of the Medical Devices Directive (Council Directive 93/42/EEC)

▪EN 60601

▪DIN EN 1717 protection against pollution of potable water

Nipro Pure Water Operator’s Manual Reverse Osmosis Phoenix One DS

- 3 -

Stand 3 as at 13.01.2021

Symbols used in this Manual

Stands for a dangerous situation. Disregard can result in personal injury or

material damage.

Stands for information and valuable tips.

Transport and Storage

Protect unit against frost and moisture.

Protect against strong jolting and collisions.

Only move unit upright and with an appropriate lift.

Nipro Pure Water Operator’s Manual Reverse Osmosis Phoenix One DS

- 4 -

Stand 3 as at 13.01.2021

Model Plate

Attention! Adhere for the

accompanying documents

CE-Sign with labeled area.

Here DQS

IPX 4

Protection of liquid entry.

Here splash guard

Drinking water protection

according to EN 1717. Here

free outlet

Serial number

Year of construction

manufacturer

pay attention to manual

Nipro Pure Water Operator’s Manual Reverse Osmosis Phoenix One DS

- 5 -

Stand 3 as at 13.01.2021

Warning on the Unit

Caution! Hot surface. Attached to the tank.

Caution voltage. Turn mains switch off before opening housing. Fixed on

control cabinet.

Shutdown

In a unit shutdown for more than 5 days, conservation will be necessary.

Please contact Nipro Pure Water before performing conservation.

Disposal

Regarding the WEEE guidelines of the European Union, the disposal of electronic devices

and electronical sub-assemblies and parts into the general garbage is not lawful. These parts

must be disposed environmentally appropriate:

If not appointed otherwise and no private disposal management is available, these devices or

possibly other environmental hazardous items can be sent back.

The filters and membrane can be disposed via the general garbage

Further Documentation

The using personnel must be warned against the hazards during operation and must be

warned against the hazards of misusing the product.

The personnel gets the instruction of operation and the specialties of usage.

Instructed adult only are allowed to operate this device.

t

Further trainings ate not necessary for this device.

For qualified personnel the following documents can be made available upon request

Circuit diagrams

Spare parts list

Nipro Pure Water Operator’s Manual Reverse Osmosis Phoenix One DS

- 6 -

Stand 3 as at 13.01.2021

Technical manual

There are additional manuals if the system is operated in combination with the hot

cleaning system Phoenix One + or the hot cleaning system Phoenix One +FH.

Duration of usage

The device is designed for a use of 10 years

Nipro Pure Water Operator’s Manual Reverse Osmosis Phoenix One DS

- 7 -

Stand 3 as at 13.01.2021

2Intended operation

The unit is designed for the preparation of potable water. The pure water (permeate) thus

produced may be used for dialysis treatment.

Other applications are only possible after consulting the manufacturer and receiving their

approval.

The unit can only be maintained by the manufacturer or technicians trained by

the manufacturer.

Only original replacement parts may be used for maintenance and repairs.

Installation operations, modifications or reparations, are only allowed to be

performed by persons authorised by the manufacturer and may only be done

with original replacement parts. Improper performed reparations or

modifications can lead to hazards to the user and/or may damage the system

The device may only be operated in perfect condition.

Before operating, check the following:

- Lose or defect parts

- Defect cables and/or isolations

- Serious soiling

The device may only be operated with the appropriate ring line.

The system does not produce water for injections.

The device has pressurized parts.

During failure of the temperature sensor, the temperature might increase. (60

°C)

The water treatment system Phoenix One may only be used for permeate

supply of dialysis devices, which have a temperature measurement (permeate

temperature).

The device does not have direct patient contact and no patient application.

Nipro Pure Water Operator’s Manual Reverse Osmosis Phoenix One DS

- 8 -

Stand 3 as at 13.01.2021

3Safety

Risk Assessment

If the operating instructions are adhered to there are no dangers associated with the reverse

osmosis model Phoenix One D.

The unit can automatically start by way of an auto-start.

EMC

The unit was developed and tested in accordance with current standards. Nevertheless,

influence through electromagnetic fields cannot be completely excluded.

Emissions

The unit does not produce dust or vibrations. The noise level is under 609 dB (A)

4Technical Data

Permeate performance

Permeate

performance l/h

[15°C]

700

1050

1400

1750

2100

2450

2800

3500

Inlet quantity

max. at 3 bar

dynamic

1500

2500

3000

3500

4000

4600

5200

6000

Feed water

Quality

Potable Water

Hardness

< 1 °dH

Silicate

< 25 mg/l

Chlorine

< 0,1 ppm (mg/l)

Iron

< 0,1 ppm (mg/l)

SiO2

< 30 ppm

Fouling Index (S.D.I)

< 3

Temperature

5-30°C

Nipro Pure Water Operator’s Manual Reverse Osmosis Phoenix One DS

- 9 -

Stand 3 as at 13.01.2021

Conductivity

<1500µS/cm

pH

6,5-8,5

Pressure

3-6 bar

Connections

Water feed

G 1” external

Permeate

connection

TriClamp d50,5 DIN

Drain

HT 50

Electrical data

Phoenix ONE DS

Supply voltage

400 V, 3 Phases, 50 Hz

400 V, 3 Phases, 60 Hz

Fuse

Automat 25 16 A-K, Fi ΔI

30mA

Energy consumption

11A

Degree of pollution

1

Phoenix One DS+ (with hot water tank)

Supply voltage

400 V, 3 Phasen, 50 Hz

400 V, 3 Phases, 60 Hz

Fuse

Automat 25 A, Fi ΔI 30mA

Energy consumption

23A

Degree of pollution

1

Display system

Conductivity

0-1000 µS/cm ±5%

Pressure sensor

0-20 bar ±5%

Water meter

1impl/l ±1%

Flow

0-3000 l/h ±1%

Ambient temperature

Storage / transport

1-40°C

Operation

10-35°C

Relative humidity

< 90% at 20°C not

condensing

Air pressure

795-1062 hPa

Size

Size in

(LxWxH in mm)

1830x1000x1800

- 10 -

5Description of the unit

3

N

6

D

P

P

D

D

4

7

8

1

26 25 27

28

22

23

D L P T

LF

D

M

M

2

5

9

10

11 12

13

14

15 16 17 18

19

20

21

24

29

30

31

32

33

34

Raw water

Permeate

Concentrate

3 |13.01.2021 |Seite 11

Flow-Chart

1

Water meter

2

Membrane valve input

3

Fine filter

4

Float valve

5

Dry running protection

6

Pressure increasing pump

7

Pressure sensor pump pressure

8

Reverse osmosis membrane 1.step

9

Conductivity probe 1.step

10

Three way valve with motor

11

Pump 2.step

12

Manometer pump pressure 2.step

13

Reverse osmosis membrane 2.step

14

2 x Return valve permeate

15

Through flow display permeate

16

Conductivity probe 2.step

17

pressure sensor ring pressure

18

Temperature sensor permeate

19

Connection ring flow

20

Connection ring back flow

21

Through flow display permeate back flow

22

Three way valve permeate to drain

23

Permeate pressure retaining valve

24

Concentrate restrictor 1. step

25

Manometer concentrate pressure

26

Concentrate pressure retaining

27

Through flow display concentrate to drain

28

Concentrate valve to drain

29

Concentrate restrictor 2.step

30

Through flow concentrate 2.step

31

Adjustment concentrate flow 2.step

32

Return valve concentrate return 2.step

33

Magnetic valve emergency operation

34

Ball valve emergency operation with motor

3 |13.01.2021 |Seite 12

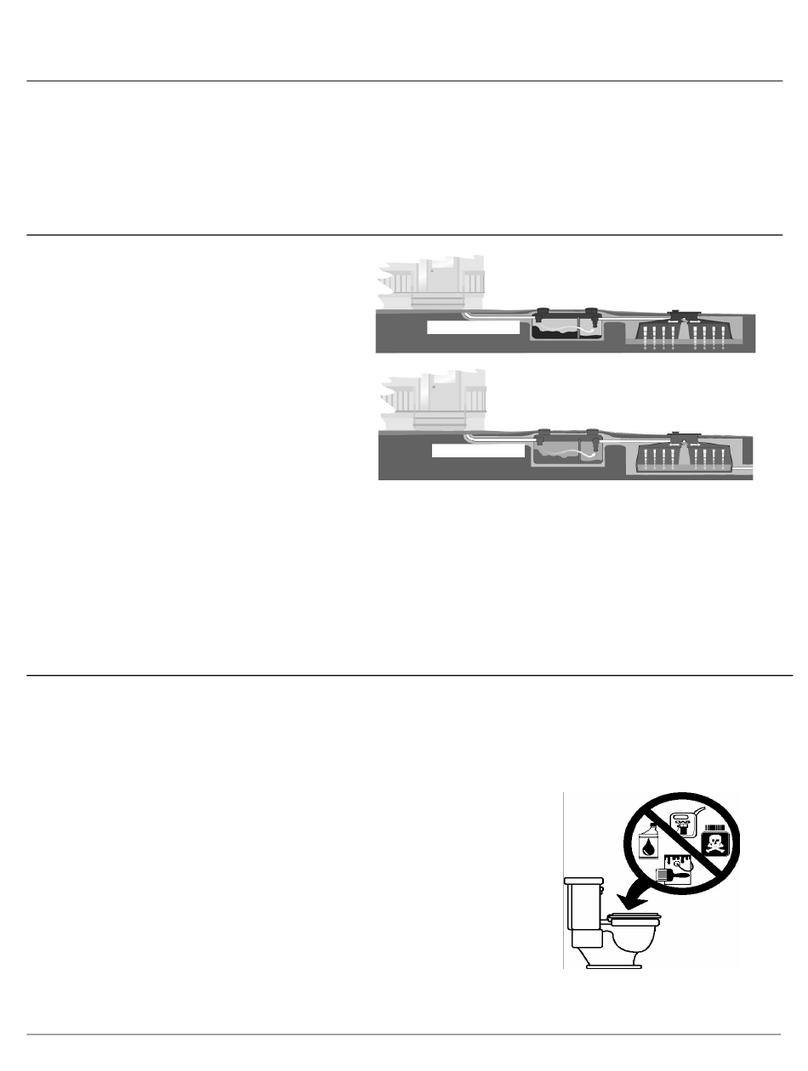

Operation Sequence Permeate Production

Untreated water flow the main through the water line (1) and the fine filter (3) into the break

tank. The float valve (4) mounted in the break tank regulates the water level in the tank.

The pressure increasing pump (6) draws the water out of the tank and then presses it into the

reverse osmosis membrane (8). At the reverse osmosis membrane the water stream separates

into the permeate stream (pure water) and the concentrate stream.

The Quality of the produced permeate will be tested with the temperature probe (10) and the

conductivity probe (11). Afterwards it will flow into the ring line to the consumption points.

Unused permeate will be returned to the break tank over the permeate pressure valve (23).

A portion of the concentration will flow through the concentrate valve (26) back into the cycle.

The rest will leave the unit through the proportional valve (28) to the drain. The ratio of

concentrate return to concentrate drainage is regulated by the proportional valve (28) based on

consumption.

3 |13.01.2021 |Seite 13

Assembly groups

Main switch

Ball valve

Permeate to drain

Pressure

retaining valve

permeate

Prefilter

Pressure increasing

pumps 1. step

Break tank

DIN EN 1717

Concentrate valve

Through flow display

Permeate back flow

Through flow display

Permeate flow

Pressure sensor

permeate

Conductivity probe

permeate

Temperature

sensor

permeate

Pressure increasing

pumps 2. step

Ball valves with Motor

(emergency operation)

Through flow display

Concentrate to drain

Through flow display

concentrate 2. step

Water meter

3 |13.01.2021 |Seite 14

6Installation

The installation must be conducted by the manufacturer or by personnel trained

and authorized by the manufacturer.

Environmental Conditions

Conditions for the osmosis room:

▪Relative air moisture < 90% at 20°C

▪Room temperature between +10°C und +35°C (frost proof)

▪Equipped with floor drain, water supply and electrical supply

Assembly

▪Set up unit appropriate position

▪Adjust machine feet until the unit stands level and secure on the floor.

Do not store easily flammable or explosive materials in the vicinity of the unit.

Do not store chemicals in the vicinity of the unit.

Only operate the unit with the necessary water pre-treatment.

Room of osmosis may not be freely accessible. (Access for instructed personnel

only)

3 |13.01.2021 |Seite 15

Electrical installation

6.2 Assembly

The installation may only be performed by a qualified electrician

The system must be supplied by a permanent connection, connectors are not

valid. The disconnection via the main switch at the control cabinet.

Main switch

Main switch.

For protection against a re-start of the unit, the main switch

can be locked with a padlock.

Safety class I

The device is equipped with a Protective earth terminal for

prevention against high touch current

For prevention of the hazard of an electric shock, this device

may only be connected to a power supply with protective

earth.

The power cord is fixed to the system and cannot be replaced.

3 |13.01.2021 |Seite 16

Installation plan (Example)

AUS

Ball valve

Pipe seperator

Back flow filter

Water alarm with

magnetic valve Softener

Soft water monitoring

system

Reverse osmosis

Phoenix One DS

230V, 16A

3 Phases, 400V, 32A,6h

Potable water intake 1"

min. 3000l/h bei 3 bar

Ring flow

Ring back flow

Drain HT50

Provided by the

customer Phoenix Pure Water

Pressure reducer

Local water works regulations and DIN EN 1717 must be adhered to

The water pre-treatment must be adapted to the local potable water quality

3 |13.01.2021 |Seite 17

7Operation

Control Panel

Unit start

Button

Starts the permeate production

Control light unit in operation

Light

If the unit is in operation, this will be

signalled with a green light

Switch manual operation

Switch

Hand, 0, Auto

Switch with three positions:

1 Hand: If the controls fail the

unit can be switched to

emergency operation.

2 0 : Unit off (no clean, no time

start)

Auto: The unit will be operated over

by the controls

Horn

Signal

Horn will activate if an alarm is present.

Horn cancel

Button

Turns off the horn (tone off)

Unit stop

Button

Turns off the unit.

Keyboard

Call up operation value and settings for

service.

Display

2 lines display

Display operation value and

notifications.

Horn

Keyboard for settings and

call up operation values

Unit stop

Horn off

Display

Unit start

Control light unit in

operation

Switch to manual

operation (emergency

operation)

This manual suits for next models

1

Table of contents

Popular Water Filtration System manuals by other brands

sanebio

sanebio SaltLine 040 manual

Philips

Philips Saeco BRITA INTENZA+ user manual

Hozelock

Hozelock Aquaforce 1683 quick start guide

ENEKA

ENEKA Greasly-A Installation, operation and maintenance manual

Vortec

Vortec VORTEX COOLER Series Operation & Safety Instructions

Pentair

Pentair IntelliChlor IC20 Installation and user guide

KENT

KENT Ace Star Mineral RO Instruction handbook

Everpure

Everpure H-54 Installation and operation guide

entegris

entegris Chemlock PFA Installation and use manual

Selecto

Selecto SP20-1 use and care manual

Whirlpool

Whirlpool WHED20 Installation and operation manual

Pond One

Pond One ClariTec 3000UV instruction manual