GL0016P-02 Installation Guidelines for BioDisc®Units BF, BG, NF & NG

4

CONTENTS

Page

Health & Safety ............................................................................................................................................2

Declaration of Conformity ..............................................................................................................................3

1.0 Introduction ............................................................................................................................................4

2.0 Handling & Storage................................................................................................................................4

3.0 Site Planning..........................................................................................................................................4

4.0 Installation - General..............................................................................................................................5

Concrete Specification...........................................................................................................................6

5.0 BioDisc Installation ................................................................................................................................6

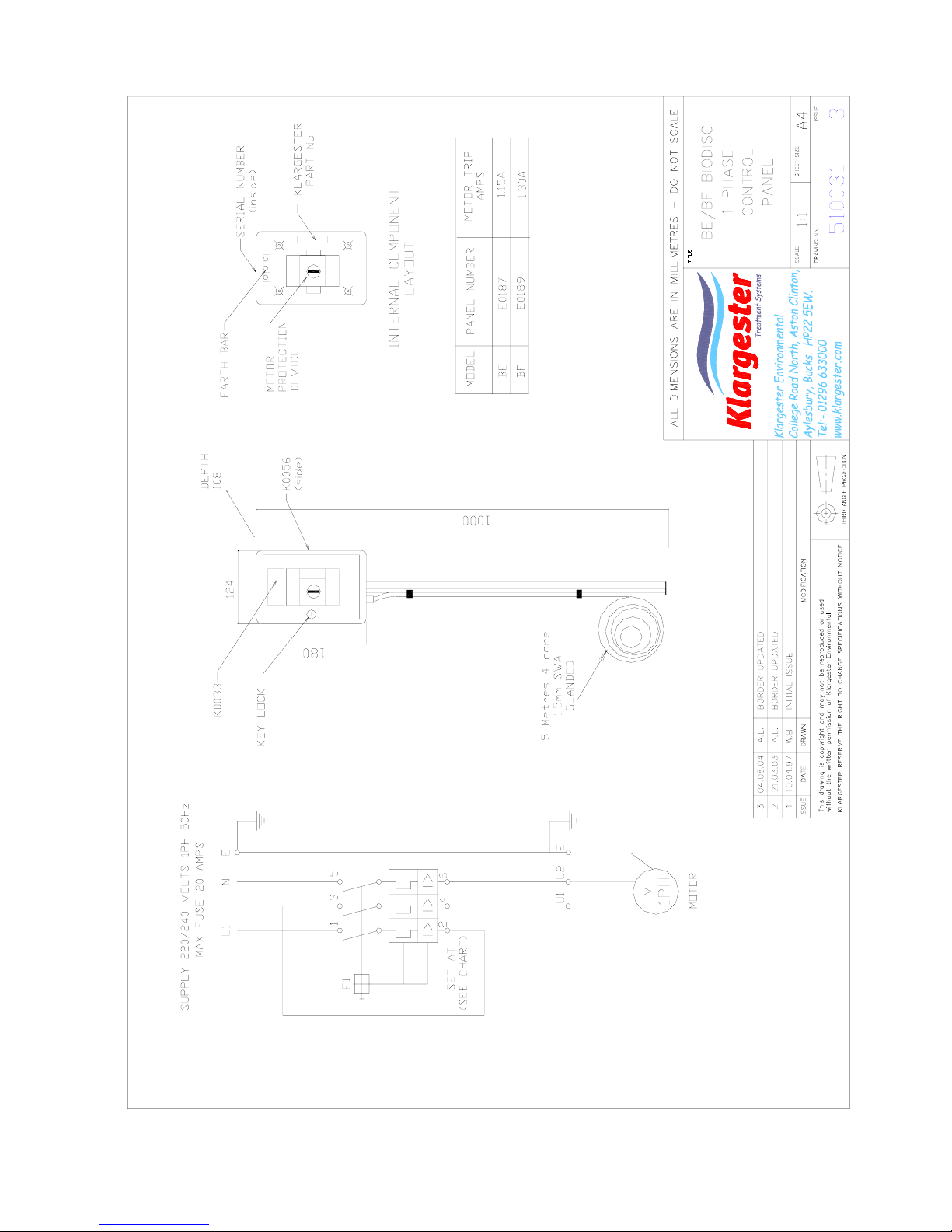

6.0 Control Panel Installation.......................................................................................................................8

7.0 Ancillary Equipment ...............................................................................................................................9

8.0 Start Up ..................................................................................................................................................9

1.0 Introduction

These Guidelines represent Best Practice for the installation of these Kingspan BioDisc Units. Many years

of specialist experience has led to the successful installation of thousands of BioDisc units. It must be noted,

however, that these Guidelines are necessarily of a general nature. It is the responsibility of others to verify

that they are appropriate for the specific ground conditions and in-service loads of each installation.

Similarly, any information or advice given by employees or agents of Kingspan regarding the design of an

installation must be verified by a qualified specialist (e.g. Civil engineering consultant).

2.0 Handling & Storage

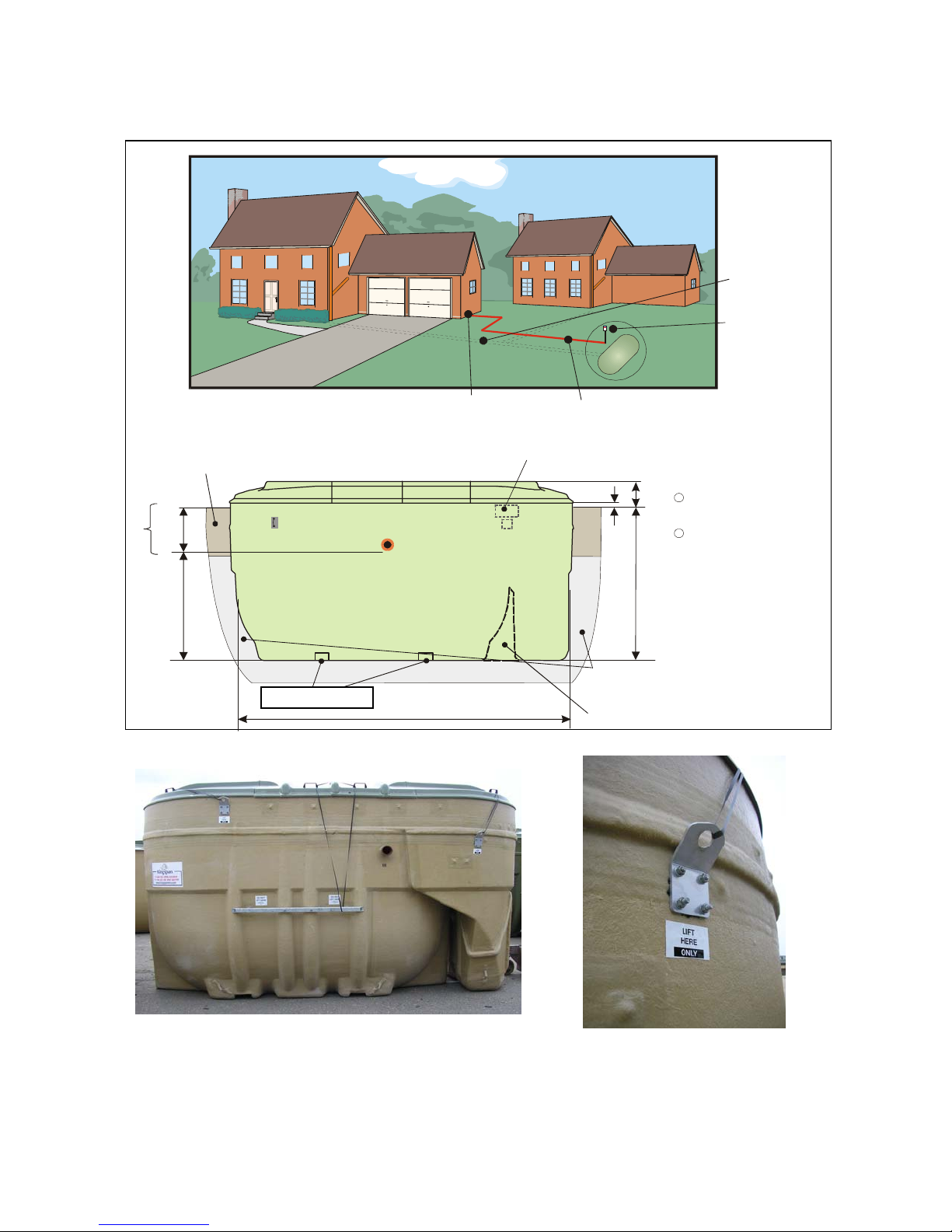

2.1. Care must be taken to ensure that the unit is not damaged during delivery and handling on site.

2.2. Whenever Kingspan BioDisc unit are stored or moved on site, ensure that the storage location is free

of rock, debris and any sharp objects which may damage the unit. The BioDisc must be placed on

ground which is flat and level to evenly support the base of the unit.

2.3. Lifting equipment should be selected by taking into account the unit weight, length and the distance of

lift required on site.

2.4. The design requirements of Kingspan products will frequently mean that the centre of gravity of the

unit is “offset”. Care must therefore be taken to ensure that the unit is stable when lifting. Rainwater

may collect also inside units, particularly if they have been stored on site prior to installation, adding

weight and increasing instability. Check units before lifting and pump out any excess water.

2.5. When lifting units, use webbing slings of a suitable specification. Do not use chains in contact with the

product.

2.6. A suitable spreader bar should be used to ensure that the unit is stable and that loads are evenly

distributed during lifting. When lifting BioDisc units the spreader bar length should be equal to the

width of the BioDisc to avoid compression damage to the covers or sides of the unit.

2.7. BF and NF BioDisc units should be lifted by webbing straps passed through the two channels in the

base of the unit. Do not use the U-bolts on the BioDisc case for lifting.

2.8. BG and NG BioDisc have an off-set centre of gravity and should not be lifted by the base channels as

this would risk tipping over the unit. Lift using 4 the new metal lifting brackets as indicated by labels on

the unit. The old slinging points are still in the bottom of the mould, they are not to be used under any

circumstances.

2.9. Kingspan Environmental accepts no responsibility for the selection of lifting equipment.

3.0 Site Planning

The following points should be considered before installation of the equipment:

3.1. The discharge must have the consent of the relevant Environmental Regulator.

3.2. The installation should have Planning and Building Control approval.

3.3. Ground conditions and water table level should be assessed. If the water table will be above the base

of the unit at any time of the year, adequate concrete backfill must be provided to avoid flotation. In

poorly draining ground, consideration should also be given to the likelihood of flotation due to surface

water collecting in the backfill. It should be borne in mind that the inlet drain trench will act as a land

drain, directing surface water to the backfill around the unit.