Nitronic ST215 User manual

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

1

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

Operating instructions

High precision stripping machine

ST215 / ST215W / Polystrip

V3.0 (based on V3.0 German)

Please read through these operating instructions carefully before starting work.

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

2

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

General

We thank you or your trust and or choosing our high precision stripping machine!

In order to achieve optimum performance, please read the operating instructions carefully. Damage caused

by not following the instructions will invalidate the warranty. We accept no liability for consequential

damage.

Table o Contents

Table o Contents .......................................................................................................................................... 2

Symbols ........................................................................................................................................................... 3

Product description ...................................................................................................................................... 3

Centering unit (ST215 and ST215W) ........................................................................................................ 3

Connecting the machine ............................................................................................................................. 4

Control Elements ........................................................................................................................................... 4

Placing in operation ..................................................................................................................................... 5

Setting the centering unit........................................................................................................................ 5

Setting the Diameter ................................................................................................................................. 5

Setting the Wayback (ST215W only) .................................................................................................... 6

Setting the Length ..................................................................................................................................... 6

Setting the rotation duration / inci ion rate ....................................................................................... 7

Counterclockwi e or clockwi e rotation / no rotation .................................................................... 7

Maintenance ................................................................................................................................................... 9

Lubrication .................................................................................................................................................. 9

Cleaning ....................................................................................................................................................... 9

Changing the tripping blade .............................................................................................................. 9

Di mantling the centering unit ............................................................................................................ 11

A embling the centering device ....................................................................................................... 12

Fit the tripping blade and calibrating the centering unit ......................................................... 14

Error sources ............................................................................................................................................... 15

Fault on cable ......................................................................................................................................... 15

Basic Equipment, Spare Parts, Options ............................................................................................... 16

Ba ic Equipment ST215 ........................................................................................................................ 16

Spare Part ............................................................................................................................................... 16

Option ....................................................................................................................................................... 17

Technical Data ............................................................................................................................................. 17

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

3

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

Symbols

The following symbols draw attention to the different danger levels in the individual chapters:

Please follow the work and procedures marked with this pictogram exactly. Failure to do so may result

in damage to the machine or the cable.

This pictogram refers to working and operating procedures that must be followed, as well as important

information on the functioning of the system.

Product description

In this document the designation ST215 refers to all machine types ST215 / ST215W and Polystrip!

The ST215 is a high-precision stripping and twisting machine especially designed for stripping small

diameter cables. The high processing quality paired with high-quality materials make the ST215 a robust

production machine.

The ST215 is a real all-rounder; it masters stripping of standard cables in short cycle times as well as

micro-coaxial cables with highest precision. The absence of grippers allows the ST215 to process shortest

cable ends, crushes on the outer jacket are excluded. The patented blade system enables an absolutely

precise and repeatable stripping of cable ends.

The jacket is removed by a rotary incision with subsequent pulling-off in a single operation. The ST215 can

be infinitely adjusted to another diameter or length in seconds using a scale.

System overview:

Rotary incision

Stripping head with a blade system in one plane

Knife changing performed without tools

Stepless adjustment of diameter and length via a scale

The ST215 is suitable exclusively for stripping copper conductors. Make sure that no

metallic objects (e.g. screwdrivers, tweezers) come into the vicinity of the blades, otherwise

the blades will be damaged.

Centering unit (ST215 and ST215W)

The infinitely adjustable centering unit ensures that the cable is precisely aligned with the center of the

blades. If your ST215 was delivered without centering device, you can easily retrofit it.

The advantages of the centering unit are as follows:

Influencing of the stripping quality by the user is practically ruled out.

The stripping diameter can be set very close to the conductor, enabling very thin walled insulations to

be stripped without problem.

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

4

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

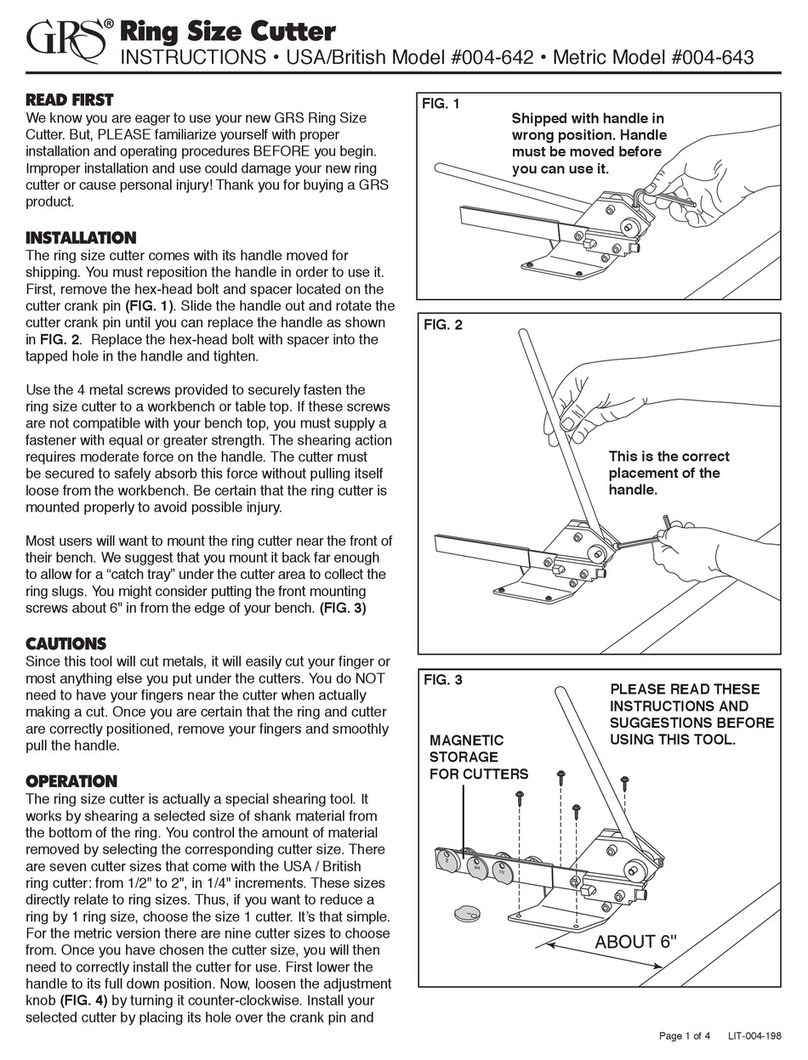

2

5

30

31

17 32

Connecting the machine

Connect the machine with the supplied power supply unit to the mains supply and to the "2 V DC"

connection. If the power plug is not compatible with your power outlet, please contact your Nitronic

partner or contact us directly.

Connect the machine to your compressed air installation. The supplied compressed air hose is provided

with a coupling on the machine side, the other side is free. On the free side you must fit a coupling that

is compatible with your compressed air installation. The outer hose diameter is 6 mm.

The machine is internally equipped with a pressure regulator, but the inlet pressure must be between

5 and 8 bar. Under no circumstances must the pressure exceed 8 bar!

Connect the foot pedal switch (optional) to the connection „Foot Pedal“.

With the foot pedal connected, the activation sensor is inactive! The machine can only be activated

with the foot pedal!

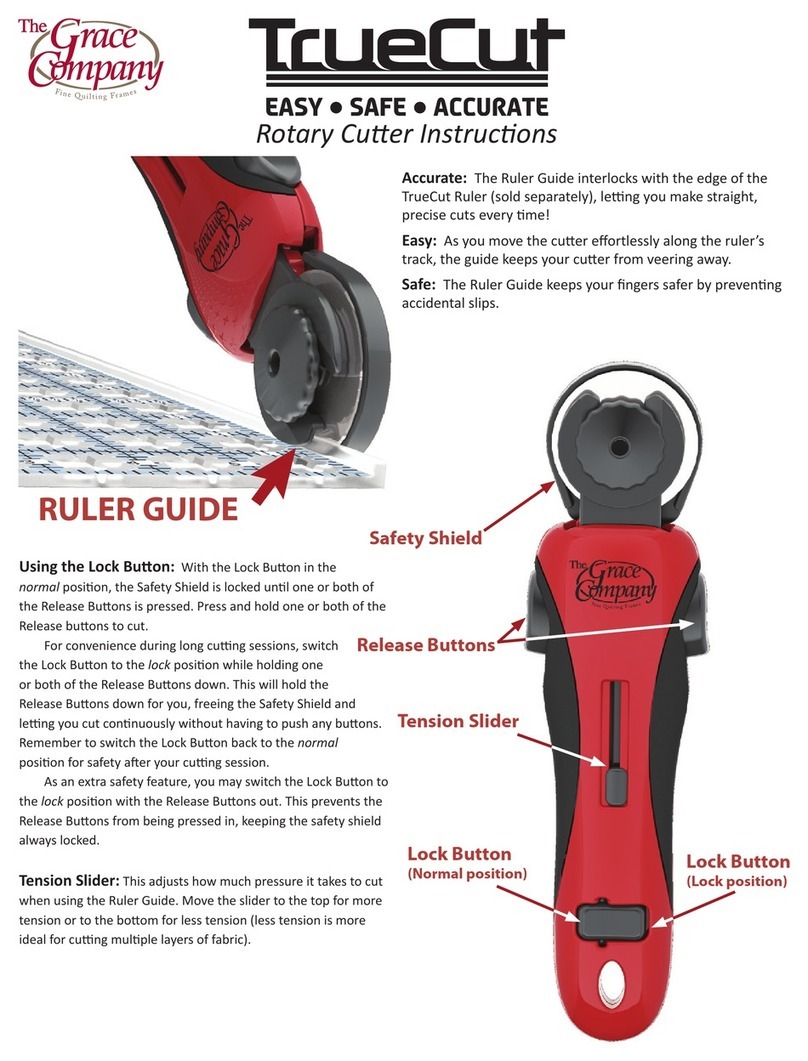

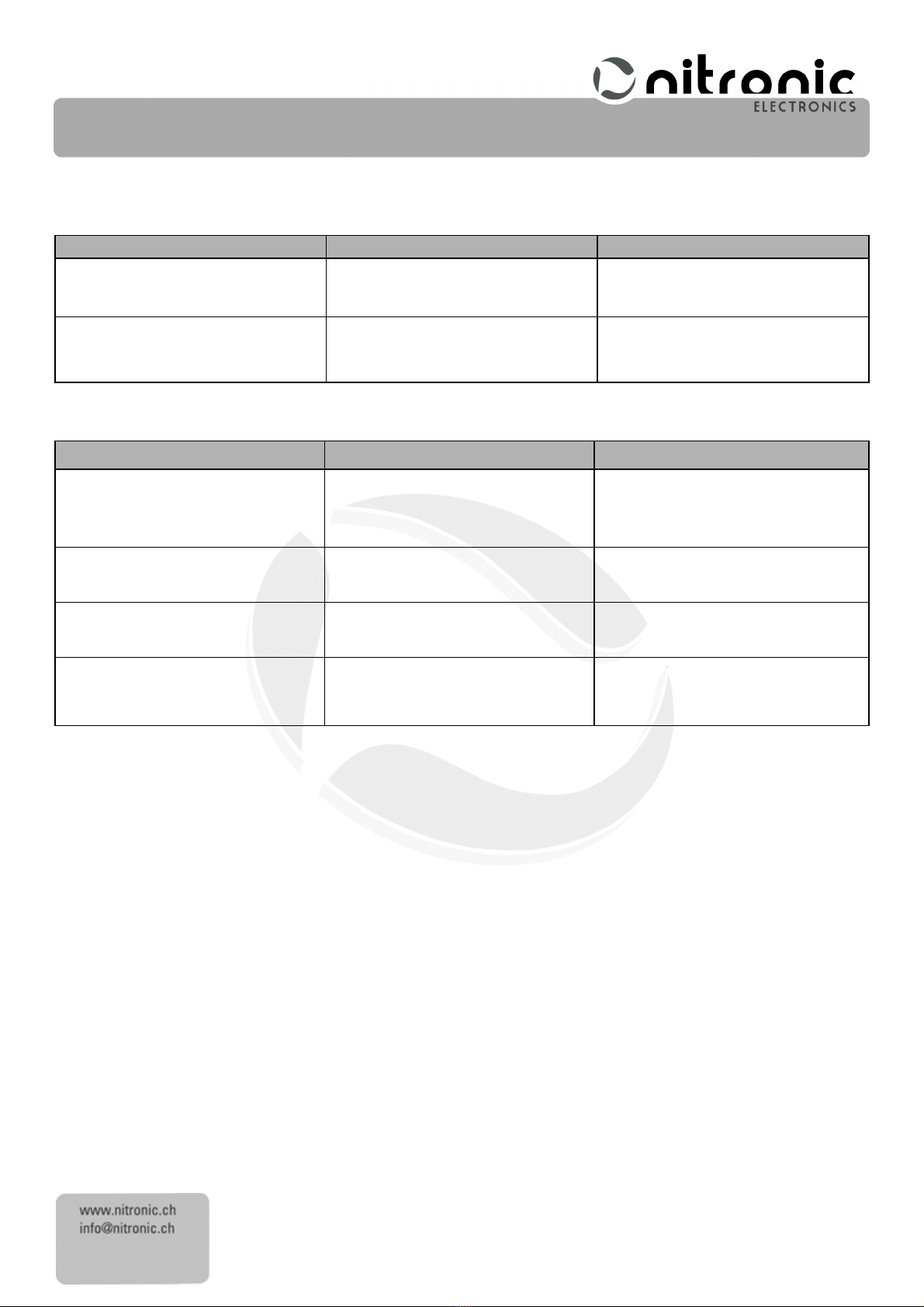

Control Elements

. Diameter 31.Rotation time / diameter feed rate

5. Stripping head with length scale 30. Counterclockwise / no rotation /

clockwise

2. Length 32. Wayback (ST215W only)

17. Centering (ST215 and ST215W)

Fig. 1

Fig. 2

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

5

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

Placing in operation

The sequence of the settings should be observed, since changes to the stripping diameter, due to

the design, require adjustments to the stripping length!

For adjustments on the stripping head, i.e. the centering unit or the stripping diameter, the protective cover

must be removed. It can be removed or reinstalled by simply pulling it out or pushing it in. The protective

cover must be pushed up to the front panel, remove any cable residues between protective cover and front

panel.

For safety reasons the machine cannot be started without the protective cover in place!

The blue LED flashes 3 times if an attempt is made to start the machine without the protective cover.

Setting the centering unit

Measure the external diameter, e.g. with the slide gauge or centering device open; introduce the

cable and close the centering device.

The cable must in no event be clamped but should be movable in the centering device without play.

Special regulations (e.g. military) require a blocking of the centering unit. This can be done with the

light-coloured Allen screw, use the supplied Allen key.

Do not confuse the light-coloured Allen screw with the black one. If you loosen the black Allen screw,

the centering device will be displaced and must be recalibrated.

Setting the Diameter

Evaluate the cable conductor diameter, e.g. with the sliding gauge.

Check that the Wayback is set to 0 (ST215W only).

Then set a slightly larger value on the diameter scale (about + 0.1mm or 0.01 Inch). The division of

the diameter scale is 0.01mm (0.001 Inch).

When setting the diameter, always turn from a larger diameter to the desired value. For example, if

0.95mm is set and 1.00mm is to be set, then first open to approx. 1.50mm and then turn to 1.00mm

If the stripping diameter is set too small, the blades cut into the conductor and the insulation can only

be removed with high tensile force. This can damage the blades.

If desired, the diameter adjustment can be blocked with the supplied stud bolt. Remove the existing

stud screw on the side of the diameter adjustment with the supplied Allen key and carefully screw in

the longer stud screw until it stops.

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

6

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

Setting the Wayback (ST215W only)

The Wayback is an opening of the blades before pulling off the jacket. This allows a slightly deeper cut

without touching the conductor or shield during the pull-off.

The Wayback is only active when pulling off without rotation. The Switch 30 must be in the middle

position.

Set the Wayback to 0.00mm firstly

Raise the Wayback until the desired stripping results are reached.

The Wayback scale is graduated in 0.01mm (0.0005 Inch). That means that with a full turn the

Wayback will be 0.2mm (0.008 Inch) in diameter.

Setting the Length

Set the desired stripping length with the length setting knob and read off the length at the length

scale.

Fig. 3

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

7

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

Setting the rotation duration / inci ion rate

The rotation duration and the incision rate are selected with the same switch. The longer the setting of the

rotation duration, the shorter the incision rate. At step 0, i.e. the shortest rotation duration, the blades close

very quickly. At step 9, the longest rotation duration, the blades close very slowly.

The stripping head may not be externally braked whilst running. Otherwise there is no guarantee that

the blades will close to the set diameter, particularly with step 9.

Counterclockwi e or clockwi e rotation / no rotation

The desired rotation direction can be set with the changeover switch. This is especially important for the

twisting of stranded wires. The correct choice of rotation direction can also positively influence stripping

quality when stripping micro-coaxial cables.

ST215W only:

In the middle position the stripping head stops before the stripping, i.e. no twisting of the stranded wire

takes place. The cable must be pulled out while the blue LED is ON. A cleaning cycle follows.

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

8

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

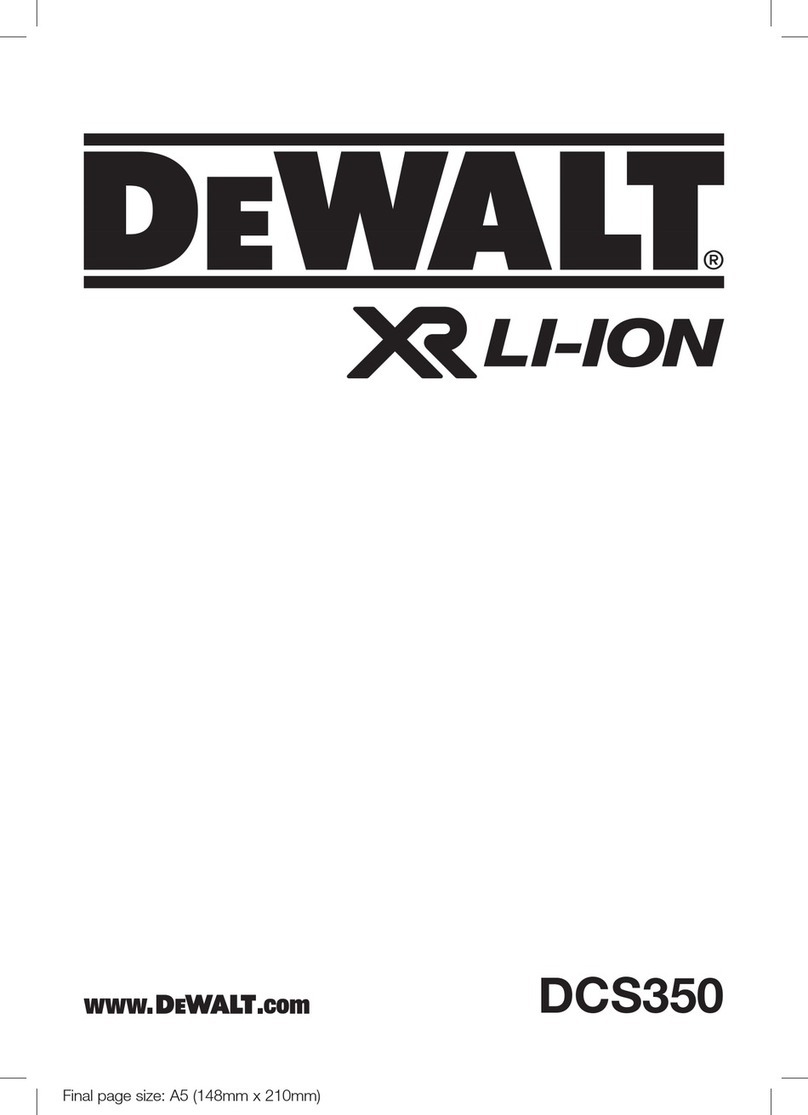

Fig. 4

Adjust

machine

Insert the cable end to the sensor

With

foot

pedal

Without foot pedal

When the cable touches

the

activation sensor, the machine

will automatically start the

stripping cycle.

Start the stripping cycle with

the foot pedal

Full strip?

No

Yes

Wait until the stripping

head stops before pulling

out the cable

Wait until the

LED is on or the

solenoid air valve is activated

(you hear the air blowing out

the air nozzle). Now pull out the

cable while the LED is on!

End of

stripping

cycle

Twisting

?

(ST215W only)

No

Cleaning

cycle

(starts automatically)

Yes

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

9

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

Maintenance

Maintenance is limited to cleaning the stripping head.

Lubrication

The ST215 is designed so that no grease or oiling is required. In order to ensure good function and a

long service life, no greasy or oily substances may get into the device!

Cleaning

The stripping residues should be automatically removed from the stripping head by the compressed air jet

after each stripping operation. If this is not the case, start the machine again without the cable using the foot

pedal. If there is no foot pedal, insert the next cable. This is often sufficient to push stripping residues

away.

Clean the surface of the stripping head using a dry, clean brush only.

Dirt on the housing, the protective hood and the stripping head can be removed with a cloth lightly

moistened with benzine.

Do not use solvents such as nitro thinner!

Changing the tripping blade

The stripping blades may only be checked and replaced by

appropriately trained persons.

Remove the power cord, foot pedal and compressed air.

To facilitate the handling with the machine, arrange the machine

with aid of the bench clamp. See

Fig.

5

.

Set the diameter setting to 0.2mm (0.008 Inch).

Set the length setting to the hindmost position.

Fig. 5

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

10

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

Insert the position retainer into the stripping head as shown in

Fig.

6

by pushing the large Allen screw at the longitudinal scale to the rear. This makes it easier to insert

the new blades.

If the centering unit is blocked, loose the bright and small Allen screw.

Loose the black and small Allen screw of the centering unit.

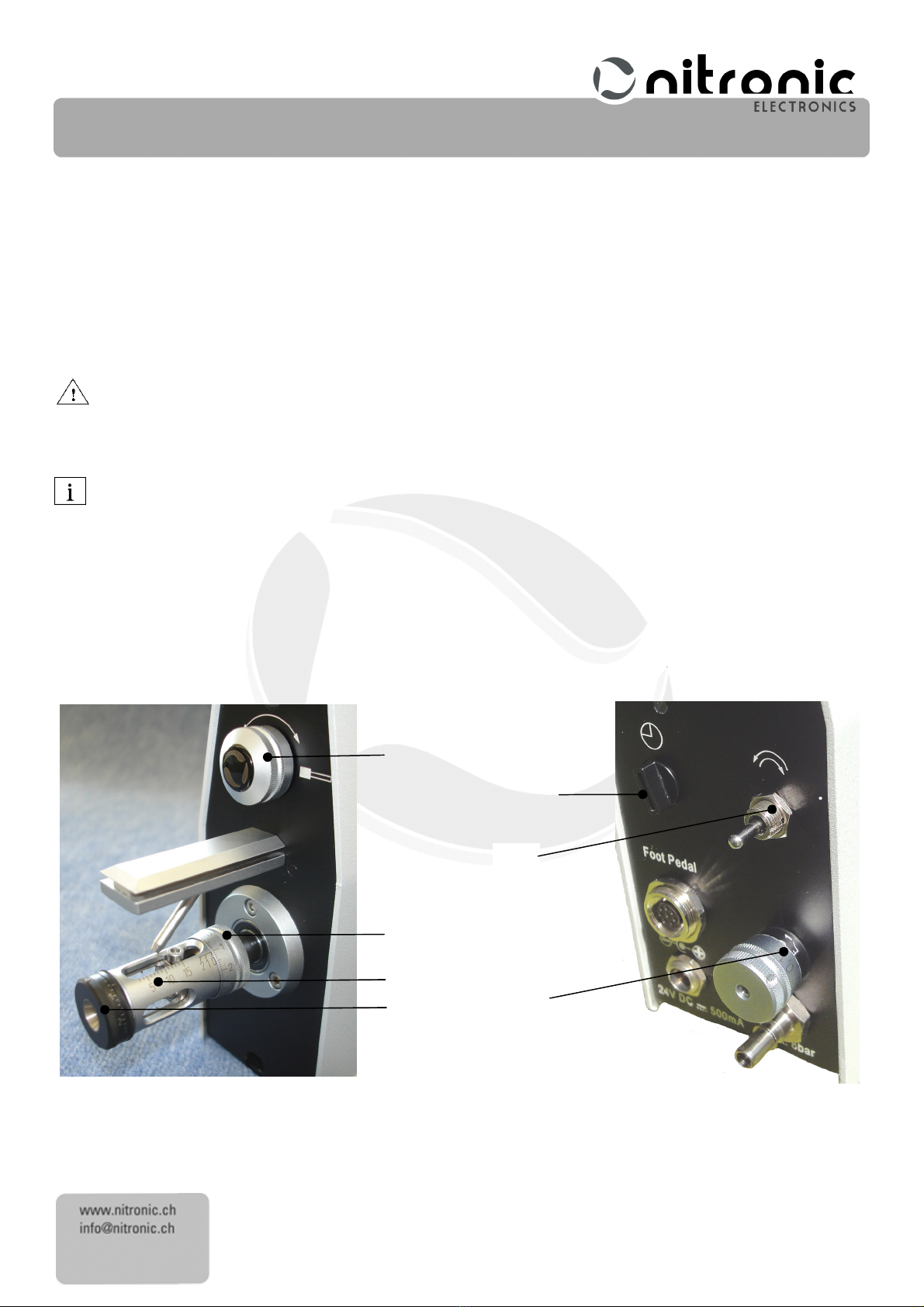

Loose the entire centering unit and pull it out Fig.

7

.

Fig. 6 Fig. 7

Now you can see the four stripping blades Fig.

8

In order to avoid losing the very small stripping blades, we recommend that you put down a dark-

colored, smooth mat and use a pair of tweezers.

All four stripping blades must be changed at the same time in order to maintain a consistent

stripping quality.

Remove each stripping blade (8) individually from the guide

plate (9).

If necessary, carefully clean the guide plate (9) with a dry

brush

Insert new stripping blades (8) individually. As far as possible,

align the stripping blades accurately with the track so that the

blades do not subsequently jam.

Insert the centering unit carefully, but do not yet tighten it.

Remove the position retainer.

Set the diameter scale to 0.0mm (0.0 Inch).

Fig. 8

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

11

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

17

30

19

6

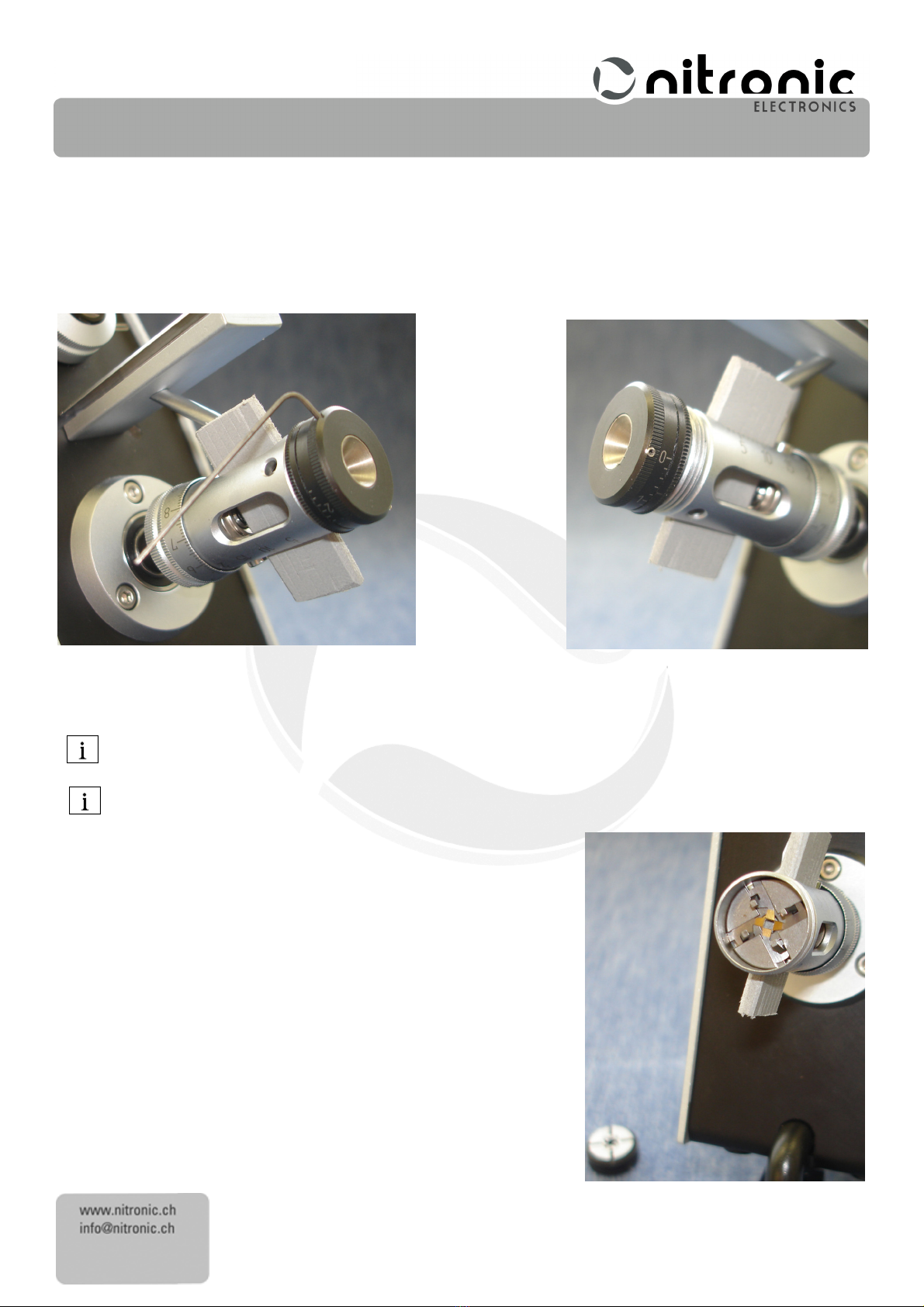

Slowly push the big Allen screw (6) back and forth. This will cause the four stripping blades to

automatically fit into the tracks on the guide plate Fig. 9.

Only now tighten the centering unit.

Fig. 9 Fig. 10

Tighten a bit the screw (19) (black)

By rotating the centering scale (17), fully open the centering jaws (25) and insert the calibrating pin (30).

Then by rotating the centering scale (17) close the centering jaws as far as the calibrating pin (30)

Fig.

10

.

Loosen screw (19) (black) and turn the centering scale (17) clockwise to diameter 2.0 mm. Retighten

screw (19) (black) and remove calibrating pin (30).

The ST215 is now ready for use.

Di mantling the centering unit

Loosen screw (19) (black) and remove centering scale (17) with a slight turning movement Fig. 11.

Lift off the O-ring (20) and take it out Fig.

12

.

Fig. 11

Fig. 12

19

20

17

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

12

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

23

25

26

22

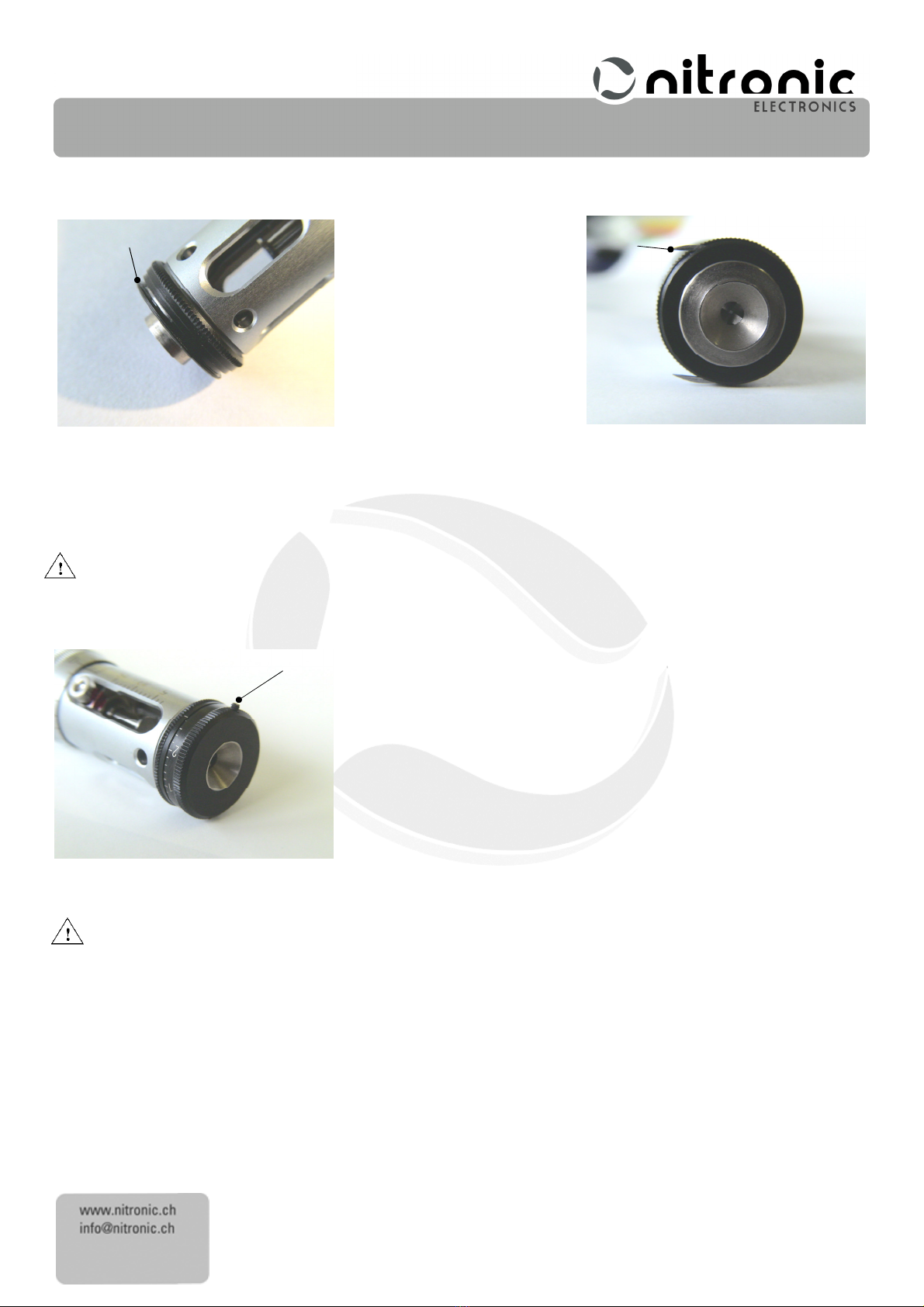

Push the two keys (22) out of the guides with a pair of tweezers and remove them Fig. 13.

The guide plate (23), the centering jaws (25) and the helixes (26) can now be removed together Fig. 14.

Fig. 13

Fig. 14

A embling the centering device

Reinstall guide plate (23) and insert the centering jaws (25) individually Fig. 15.

Push all four centering jaws (25) outwards to the stop on the stripping head and carefully put the helixes

(26) in place Fig. 16.

Fig. 15 Fig. 16

By rotating the helixes (26) check that the centering jaws can close smoothly and simultaneously. If

necessary repeat the procedure.

23

25

26

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

13

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

Screw on nut (18) and tighten up Fig. 17.

Fig. 17

Fig. 18

Insert the two keys (22) and install the previously-greased O-ring (20) Fig.

18

.

The two keys (22) must be inserted flush with the inside diameter of the slot.

Push centering scale (17) with a slight turning movement to the stop but do not yet tighten screw (19)

(black) Fig. 19.

Fig. 19

If the centering scale (17) cannot be pushed over the O-ring the two keys (22) are not properly.

The centering device must now be calibrated in the next operating step.

22

18

19

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

14

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

17

30

19

6

Fit the tripping blade and calibrating the centering unit

Loosen the centering unit so that it is not tightened.

Set the diameter scale to 0.0mm (0.0 Inch).

Slowly push the big Allen screw (6) back and forth. This will cause the four stripping blades to

automatically fit into the tracks on the guide plate Fig. 20.

Now tighten the centering unit.

Fig. 20 Fig. 21

Tighten a bit the screw (19) (black)

By rotating the centering scale (17), fully open the centering jaws (25) and insert the calibrating pin (30).

Then by rotating the centering scale (17) close the centering jaws as far as the calibrating pin (30) Fig.

21.

Loosen screw (19) (black) and turn the centering scale (17) clockwise to diameter 2.0 mm. Retighten

carefully screw (19) (black) and remove calibrating pin (30).

The ST215 is now ready for use.

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

15

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

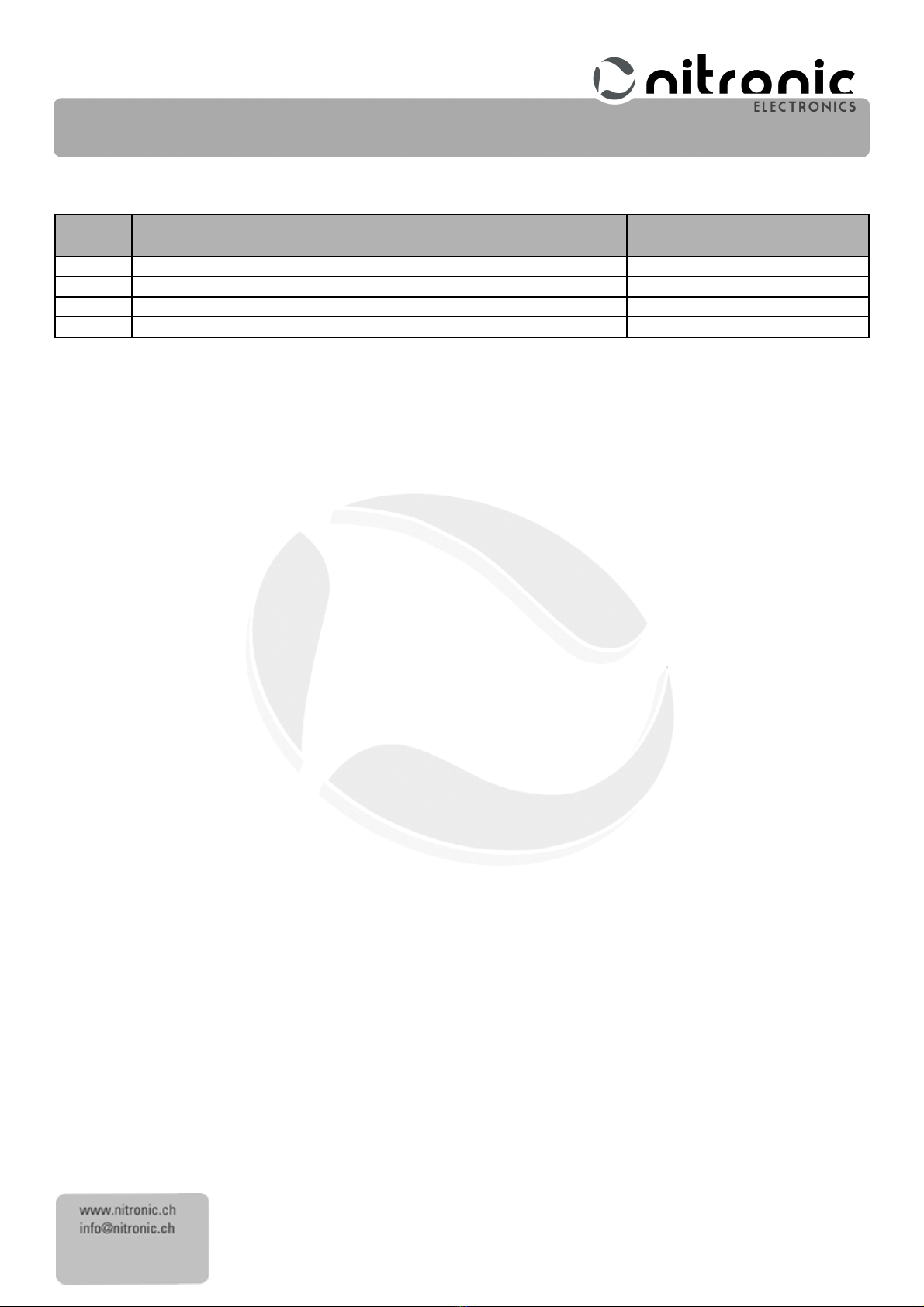

Error sources

Fault on cable

Fault

Diagnos

is

Fault

recti ication

Inside co

nductor, screen or

dielectric cut into

Cable

is

very

eccentric

Reduce centering diameter in

steps

Jacket

cannot be stripped off

Very small difference in diameter

between Jacket and conductor.

Reduce centering diameter in

small steps

Fault on machine

Fault

Diagnos

is

Fault

recti ication

Can not insert the cable

Cable rests in the stripping head

Clean, with startin

g

the stripping

cycle several times.

Bad stripping quality

Strippi ng blades are

broken

or

used

Change the stripping blades

T

he

blue L

ED is blinking 3 times

The safety shield is not mounted

Insert the safety shield

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

16

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

Basic Equipment, Spare Parts, Options

Ba ic Equipment ST215

Qty

.

Description

Article

N

umber

1

Stripping machine

ST215

/ ST215 Inch

010083

/

010307

1

Stripping mac

hine ST215

W

/ ST215

W

Inch

010305 / 01031

1

Stripping machine Polystrip / Polystrip Inch

010520 / 010535

1

Bench

clamp

010177

1

Power

supply

with Adapter Set

010113

1

C

oupler

for air hose

010151

1

Allen key

for diameter blocking

EN

-

7 11

1

Stud screw

for diameter blocking

BN

-

617 M2x8

010569

1

Position retainer

ST

-

0900

1

Operating

Instructions

English

or

Operating Instructions German

EN

-

7120

E

EN-7120D

1

Allen key for centering unit

(ST215 / ST215W only)

E

N

-

7 12

1

Calibrating

mandrel

(ST215 / ST215W only)

BN

-

1208

1

Set (3pcs)

Set of

Centering I

nsets, diameter 1.0 / 0.5 / 0.2mm

(Polystrip only)

010591

Spare Part

Qty

.

Description

Article

N

umber

1

S

et

( pcs)

Stripping

blades HSS

(

ST215 / ST215W only)

010075

1 Set

( pcs)

Stripping blades Titanium coated carbide

(Standard for ST215 / ST215W)

01007

9

1 Set

( pcs)

Stripping blades carbide Polystrip

(Polystrip only)

010520

1 Set

( pcs)

Input connectors for power supply ( EU,

USA

, UK,

SAA

)

010115

1

Cover

010322

1

Length

button

010 0

1

Guide

plate

010225

1

Solenoid

air

valve

0101 9

1

Stud screw, centering b

locking

M1. x

2.5

chrome

010566

1

Stud screw, centering

M1. x

black

010567

1

Stud screw for diameter blocking

BN

-

617 M2x8

010569

1

Sealing Cap with Nitronic Logo

010216

Sdasdasdsdfdsdcdscsdcdcd

cdcsc

17

Nitronic

AG

Mattenstrasse 11

2555 Bruegg Email: info@nitronic.ch

Switzerland Phone: + 1 32 373 70 70

Option

Qty

.

Description

Article

N

umber

1

Foot

pedal

01008

1

Micro Filt

er

0103 6

2

Port for Micro Filter straight

0103 7

Technical Data

Wire size range 0.08 mm (0.003”) to 2.00 mm (0.08“) (12 – 0 AWG)

Outer cable diameter max. 2.5 mm (0.1“)

Stripping length up to 13mm

Cycle time 0.3 sec. up to 6.2 sec. (stripping cycle), 10 different steps

Rotation / Twisting Clockwise / Counter clockwise

Diameter Scale 0.01 mm (0.001 Inch)

Wayback Scale (ST215W only) 0.01 mm (0.0005 Inch)

Length scale 1.0 mm (.06 Inch)

Dimensions LxWxH 210 x 5 x 126 mm (10 x 2.2 x 5 Inches)

Weight 850g

Stripping blades pcs. Carbide, Titanium coated

Power supply (Primary) 100-230 VAC, < 0.6A RMS, 7-63 Hz

Power supply ST215 (Secondary) 2 VDC

Compressed air 5 to max.8 Bar

Outer hose diameter 6mm (0.2 “)

We reserve the right to make technical changes at any time!

This manual suits for next models

2

Table of contents