Shannon ABM-D 135 User manual

User’s Guide

English

Plastic bending machine

ABM-D 135

ABM-D 135

12-12-2018

-1-

Ruben Rapati

1USER’S GUIDE

Plastic bending machine

ABM-D 135

©2018 SHANNON BV. All rights reserved.

No part of this User's Guide may be photocopied, altered or

translated without prior written consent.

Information contained in this User's Guide is subject to change

without notice

ABM-D 135

12-12-2018

-2-

Ruben Rapati

2TECHNICAL DATA

type

ABM-D 135

Assembly

Control unit

Max.

4

Upper heating profiles

Under heating profiles

Max.

Max.

2

2

Pressure bars

2

Electrical

Control units

Voltage

220 –240 V AC

Power

500 VA (each up)

800 VA (each down)

Fuse

5 AT x1 (each)

Timer unit

Voltage

220 –240 V AC

Power

5VA

Fuse

2,5 AT x2

connection

CEE 7/4 16A 2P+A

Network connection

CEE 7/4 16A 2P+A

Network circuit breaker

Max. 16 A

Pneumatic

Air

Unlubricated clean dry air

Maximum

8 bar

Minimum

6 bar

Operating pressure

6 bar

Coupling

Quick action coupling

Mechanical

Gradation of stop

0 - 500 mm

dimensions

[LxWxH]

850 x 1.510 x 380 mm

weight

200 Kg

Functional

Bending width

1.350 mm

Sheet thickness

0,2 –1,0 mm (with foil bending profile)

1,0 –5,0 mm.

Ambient

Temperature

18-30 C

Humidity of the air

50-80 % (no condensed)

Miscellaneous

set of socket screws keys

1 set [1½, 3, 5 mm]

Spare fuse

2 x [6.3x32 2,5 AT]

4 x [6.3x32 5,0 AT]

ABM-D 135

12-12-2018

-3-

Ruben Rapati

3CONTENTS

2 Technical data 2

3 Contents 3

4 Introduction 4

5 Description of the machine 5

6 Safety instructions 6

7 Safety precautions 8

8 Legend 9

8.1 Summary 9

8.2 Air/Timer Unit 10

8.3 Timer Unit 10

8.4 Control Unit 11

9 Installation 12

9.1 Assembly 12

9.2 Connecting foot switch 12

9.3 Connecting compressed air 12

9.4 Connecting power 12

10 Operation 13

10.1 Preparation 13

10.2 Switching on machine and heating 13

10.3 Setting temperature 13

10.4 Setting cycle time 14

10.5 Foot switch 14

10.6 Setting air pressure 14

11 Adjustment 15

11.1 Safety precautions 15

11.2Pressure bar and upper heating profiles 15

11.3Upper heating profile height 15

11.4 Lower heating profile positioning 16

11.5Parallel Back Stop 16

11.6 Angular stop 16

12 Maintenance 17

12.1Safety precautions 17

12.2 Tensioning and changing Filament 17

12.3 Lubrication points 18

12.4 Profiles 18

12.5 Water separator 18

13 Fuses 19

Annexes 20

A Options 20

Accessoires 20

B Equipment 21

Service and warranty 22

ABM-D 135

12-12-2018

-4-

Ruben Rapati

4INTRODUCTION

Congratulations on purchasing Shannon’s plastic bending machine ABM-D 135. Read

this guide completely before installing and using the machine.

We want to keep in contact and to know how you find the ABM-D 135. We are

always willing to advise on the use of the machine and its accessories.

SHANNON BV

Turfschipper 11

2292 JC Wateringen

P.O. box 84

2290 AB WATERINGEN

the Netherlands (EC)

Tel: +31 (0)174-225240

Fax: +31 (0)174-225249

E-mail: [email protected]l

Website: www.shannon.nl

ABM-D 135

12-12-2018

-5-

Ruben Rapati

5DESCRIPTION OF THE MACHINE

The Shannon ABM-D 135 bending machine is an automatic machine for the production of large

series of items with a single or double bend for the plastic sheet processing industry.

The machine has 4 heating profiles (2 up and 2 down). The temperature of which can be

adjusted by electronic controls.

The heating profiles which are mounted in the pneumatically operated top frame is adjustable

in height in respect of the working surface.

The heating profiles which are mounted in the bottom frame have a heating wire that can be set

in height.

The workpiece can be heated from one or both sides. When used with foil bending profiles in

the top frame it can be heated by contact, making it possible to bend sheets under 1 mm

thickness.

The top frame is switched on independently of the control unit and is controlled by an

adjustable timer.

The heating, and cooling/turning time can be set with the same timer.

The working surface is made of scratch-resistant solid core material to support the plastic

sheet.

When heated, thermoplastics become so flexible that they can be shaped. When a plastic sheet

is heated to its softening point, it can be bent to any angle desired. The bending and cooling is

done by the machine.

The bending radius is determined by the width of the heated zone. The zone is determined by the

thickness of the material and the type of heating element.

When heated, thermoplastics become so flexible that they can be

shaped. When a plastic sheet is heated to its softening point in a

narrow zone, if can be bent to any angle desired.

The bending radius is determined by the width of the heated zone.

The zone is determined by the thickness of the material, the type of

heating element and the distance between the plastic and the

filament.

Every plastic has its specific softening point. By co-ordinating the

temperature, heated zone and heating time all kinds of

thermoplastic can be processed.

ABM-D 135

12-12-2018

-6-

Ruben Rapati

6SAFETY INSTRUCTIONS

To ensure safety when using the machine you should read this

User's Guide carefully and follow the safety instructions closely

Attention!

The machine contains a section where there is a risk of trapping.

Attention!

The machine contains parts, which are hot. Touching them will

cause burns.

Allow hot parts to cool sufficiently (at least 10 minutes) before

touching them.

Never touch the heating elements when the machine is in

operation.

Always wear close-fitting clothing.

Be particularly careful of sleeves and always tie back long hair.

Never leave objects on the working surface after a cycle of the

machine.

The machine may only be used for heating zones in flat plastic

sheet.

Any other use could lead to very hazardous situations or cause

damage to the machine!

The plastic sheets that have to be bent may never be thicker than

5 mm.

Before commissioning and servicing always check the connection

cable and plug for defects.

ABM-D 135

12-12-2018

-7-

Ruben Rapati

When servicing switch off the machine and remove the plug from

the socket.

Before use always check that all the pressure bars and heating

elements in the top frame are firmly attached.

Never operate the machine if anyone is standing close behind or

beside it.

Never introduce objects or material into the machine from the

rear.

Never leave the machine unattended without switching it off.

ABM-D 135

12-12-2018

-8-

Ruben Rapati

7SAFETY PRECAUTIONS

EMERGENCY STOP

There are 2 emergency stops button (C) at the front of the machine, which can be

reached by the operator from the normal working position(s).

Pressing the emergency stop button switches off the machine and the top frame lifts

up. The button remains pushed in.

Resetting of the emergency button comes to pass by turning the button to the right.

The machine is ready to use again.

ONLY USE THE EMERGENCY STOP BUTTON WHEN:

oRisk of trapped limbs.

oDefects in the timer, so the machine fails to open after the pre-set time.

oAn outbreak of fire or situations involving a risk of fire.

oAny situation that might present a risk to people or animals.

oAny other situation, that might present a risk or cause, damage to the

machine and/or objects.

ABM-D 135

12-12-2018

-9-

Ruben Rapati

8LEGENDA

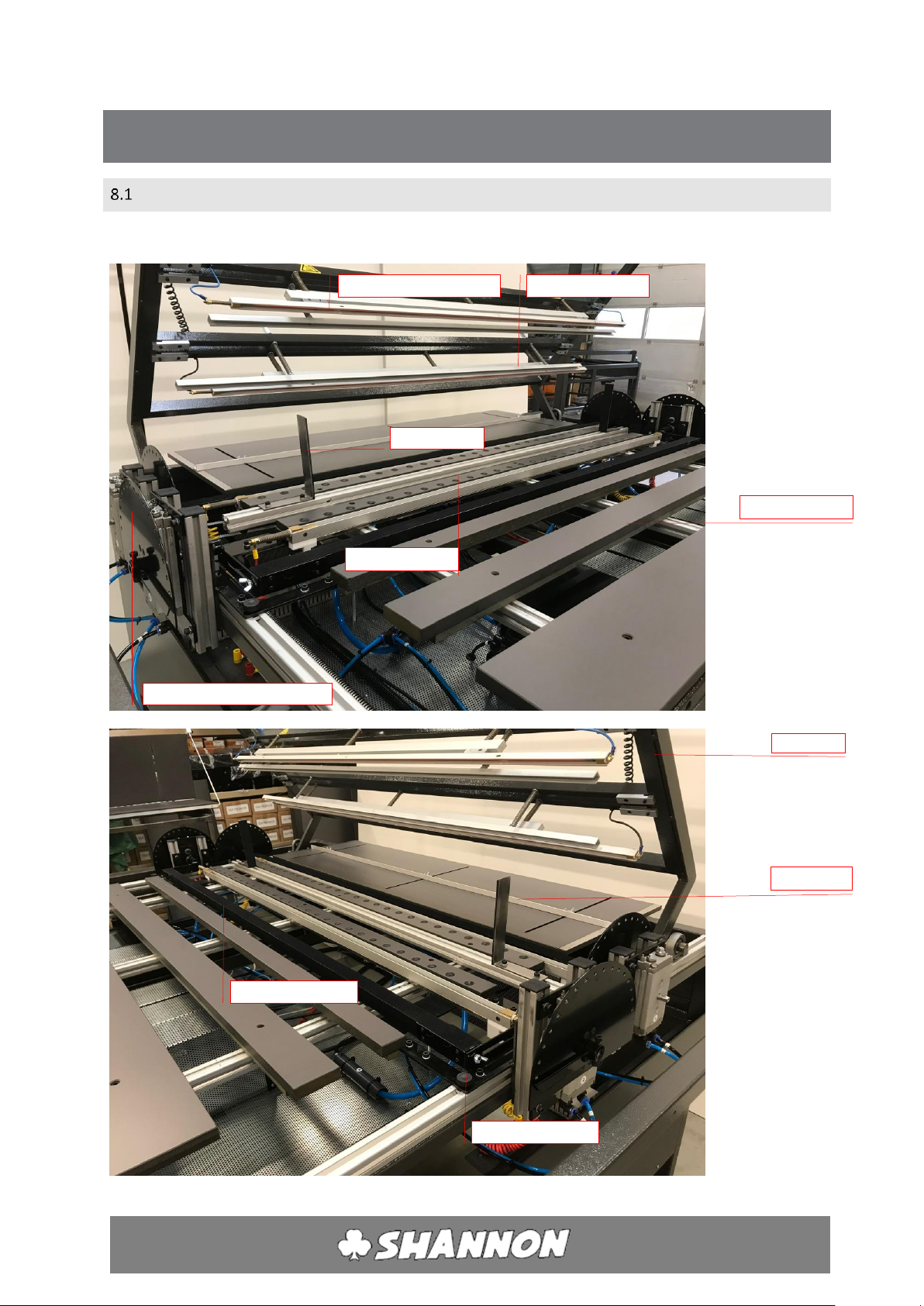

SUMMARY

The legenda of the entire machine.

Topframe

Top Heating profile (2x)

Side stop (2x)

Pressure bar (2x)

Back Stop

Gradation / protractor (4x)

Working surface

Flip over bar (2x)

Vacuüm bar (2x)

Fixing wheel (2x)

ABM-D 135

12-12-2018

-10-

Ruben Rapati

AIR/TIMER UNIT

The air/timer unit is a combined unit for the control of the

topframe and to set the cycle time. The machine closes,

and the vacuum starts when the foot switch is used. The

heating time starts when the machine is closed. The

machine opens when the time reached its value. The

plastic sheet is still held into place by the vacuum system,

and the flip(s) are turned to bend the plastic sheet. The

turning time can be set by the timer unit. The angle in

which the sheet it bent can be set manually. While the

sheet is bent, cool air is blown onto the crease to cool the

sheet. The timer will then reset back to zero

A. Connection foot switch B. On/off switch

C. Switch for 1 or 2 bend. D. Timer unit

TIMER UNIT

Button

Function

Esc

cancel

+

increase value

-

decrease value

OK

confirm

►

move right

▼

move down

▲

move up

◄

move left

There are 4 adjustable digits on the screen. From E to H.

E. The time that counts until the set turning and cooling time is over and the cycle ends.

After this time a loud alarm is heard to notify the operator that flip over bar is moving.

F. The time that the sheets need to be heated and the machine is closed.

G. The time that the sheets need to cool, before the machine resets.

H. The amount of cycles made. Needs to manually put back to zero.

D

C

A

B

G

F

E

H

ABM-D 135

12-12-2018

-11-

Ruben Rapati

CONTROL UNIT

The control unit contains an electronic controller that can be used to set the

temperature of the filament.

The 2 temperature controllers on the left side are used for the top heating profiles.

Marked by the same colors. (black and blue)

The 2 temperature controllers on the right side of the machine are used for the

bottom heating profiles. Marked by the same colors ( red and yellow)

The bottom profiles only heat up after the footswitch has been activated.

I. On/off switch.

J. Temperature adjustment.

K. Fuse.

J

I

K

Front

ABM-D 135

12-12-2018

-12-

Ruben Rapati

9INSTALLATION

ASSEMBLY

1. Remove packaging and blocking of top frame.

2. Place the machine on a level floor with sufficient space around and above the

machine.

3. Ensure there is adequate ventilation and lighting at the workplace.

4. Avoid draughts, in order to prevent uneven heating.

CONNECTING FOOT SWITCH

Connect the plug of the foot switch on the corresponding socket (a) at the front

side of the timer unit. See 10.2

CONNECTING COMPRESSED AIR

1. Check that the heating profiles and pressure bars in the top frame are firmly

attached.

2. Using a quick-action coupling (female supplied with the machine) connect to male

connector situated on the back of machine. Connect to your compressed air

system or compressor. (minimum 6 Bar)

CONNECTING POWER

1. Check that all switches of the control units are in the 0-position.

2. Put the plug into the socket. (single phase)

ABM-D 135

12-12-2018

-13-

Ruben Rapati

10 OPERATION

PREPARATION

1. Check that the air pressure is connected.

2. Clear the working surface.

3. Check that the heating profiles are properly connected to the colored chassis

connectors.

4. Check that all the upper heating element and pressure bars are firmly attached to

the top frame.

SWICHTING ON MACHINE AND HEATING

1. Turn the main switch on the right hand side.

2. Switch on the temperature controllers that are needed (switch I, page 11)

SETTING TEMPERATURE

The temperature of the profiles can be set using the temperature control.

1. To increase the temperature, push right colored button .

(for bottom heaters this is only possible when machine is in cycle)

2. To decrease the temperature, push left colored button.

(for bottom heaters this is only possible when machine is in cycle)

3. Check if the heating element warms up.

ABM-D 135

12-12-2018

-14-

Ruben Rapati

SETTING CYCLE TIME

The heating time during which the machine is closed to heat the plastic sheet can be

set on the timer unit.

See E, F, G and H on page 10

1. Switch between values withe the ▼/▲buttons.

2. Increase of decrease the value with the +/- buttons

3. Cancel the value with the “ESC” button

4. Confirm the value with the “OK” button

FOOT SWITCH

The top frame and vacuum are activated by pressure on the pedal of the foot switch.

SETTING AIR PRESSURE

The pressure for the system is adjusted by the factory on the right value (6 bar).

This can be changed inside the machine by a valve and air pressure indicator.

ABM-D 135

12-12-2018

-15-

Ruben Rapati

11 ADJUSTMENT

SAFETY PRECAUTIONS

Always take the following safety precautions before adjusting the clamp bars:

1. Ensure that the upper heating profiles and pressure bars are firmly attached.

2. Switch off the heating elements (switch I, page 11).

3. Clear the working surface.

4. Allow the heating elements to cool for at least 10 minutes.

PRESSURE BAR AND UPPER HEATING PROFILES

1. Disengage the air connection.

2. The top frame will then slowly lower while air escapes.

3. Loosen the socket head screws on the support bar clamps of the pressure bar or

upper heating profiles one turn.

4. Hold the pressure bar or heating profile at the sides, left and right, and slide it into

the desired position. Move the support bar parallel to the front of the top frame.

5. Tighten the support bar clamps again.

6. Switch on the machine again as in Section 12.

The upper heating elements and pressure bars may fall out of the top frame if they

are loose or not properly attached.

UPPER HEATING PROFILE HEIGHT

1. Set the timer (F, page 10) to at least 160sec. With this time setting the machine

will remain closed for long enough to adjust the element height.

2. Place a test piece of the plastic to be processed on the working surface.

3. Make sure all temperature controllers are switch off (switch I, page 11)

4. Lower the top frame (foot switch).

5. Adjust the height of the profile using the adjusting nuts on the upper heating

profiles.

6. Adjust the height so that the profile just not touches the plastic .

7. Open the top frame by pressing the emergency stop.

8. Reset the emergency stop.

9. Adjust the timer (switch I, page 11) again.

10. Start the machine again as in section 12.

ABM-D 135

12-12-2018

-16-

Ruben Rapati

LOWER HEATING PROFILE POSITIONING

Only the front heating profile can be changed in position.

1Clear the working surface.

2Loosen the fixing wheels left and right (page 9)

3Turn the wheel (K) till the orange indicator shows the correct distance between

the 2 heating wires of the profiles in millimeters.

4Tighten the fixing wheels again. (page 9)

PARALLEL BACKSTOP

1. Loosen the nuts on the stop one half turn.

2. Slide the stop into the desired position.

3. Tighten the nuts.

Always ensure that the stop is placed in such a way that heating elements or

pressure bars cannot hit the stop as they are lowered.

ANGULAR STOP

1. Loosen the nut on the protractor.

2. Put the nut into the desired position.

3. Tighten the nut.

4. Make sure both left and right side are placed in the same position.

5. Run the machine without a piece of plastic, to check if the set angle is accurate

enoug

K

ABM-D 135

12-12-2018

-17-

Ruben Rapati

12 MAINTENANCE

This machine needs little maintenance. Remove loose dirt once in a while.

SAFETY PRECAUTIONS

1. Switch of the main switch (right hand side of machine).

2. Clear the working surface.

3. Allow the heating profiles to cool for at least 10 minutes.

4. Disengage the air connection.

5. Remove the plug from the socket.

TENSIONING AND CHANGING FILAMENT

1. Turn the filament to the lowest position. (Only bottom heating).

2. Hold the end of the wire on the right with pliers and undo screw in the wire

pin. (Use socket screw key no. 1½ or 2 )

3. Pull the wire taut with pliers and tension the spring.

4. Tighten the socket head screw firmly again.

5. Cut off the end of the filament. Always leave 8-10 mm projecting in order to be able to tension the

filament again. Bend the projecting piece down

Attention! The end of the filament is sharp.

10 minutes

Wire

ABM-D 135

12-12-2018

-18-

Ruben Rapati

LUBRICATION POINTS

The following points should be lubricated with a drop of oil or grease once a year:

1. Bearing cilinder: underside.

2. The lubrication point can be accessed from the rear of the machine by removing

back plates.

3. Bearing cilinder: upperside.

4. The lubrication point can be reached by removing the solid core strips on the

middle of the machine.

5. Bearings (left an right of upper frame)

PROFILES

The heating profiles work more effectively when it is clean. Remove dirt and deposits

from the aluminum profiles. Blow away loose dirt and brush them clean.

WATER SEPARATOR

Check if there is water in the water separator and remove it if necessary. The water

separator is situated on the left side of the air/timer unit. If there is water in the glass

holder, it should be drained off.

1. Switch off machine.

2. Remove Trespa working surface from the front of the machine.

3. Hold a small container under the nipple and slowly open the nipple. All the water

will then run out of the glass holder.

4. Close the drain nipple by hand.

5. Switch the machine on again.

ABM-D 135

12-12-2018

-19-

Ruben Rapati

13 FUSES

A maintenance engineer should always be alerted when a fuse blows. Do not replace

the fuse until the short circuit has been corrected.

SAFETY PRECAUTIONS

Before replacing a fuse always take the following safety precautions:

1. Switch the main switch off.

2. Remove plug from socket.

FUSES CONTROL UNIT

1. Open the fuse holder (K, page 11) by pushing it in and turn to the left. The fuse will

come out.

2. Verify and replace the fuse (if necessary) in the reversed order.

N.B. Fuse 6,3x32mm; 5 AT.

Table of contents

Other Shannon Cutter manuals

Shannon

Shannon HRP 220 User manual

Shannon

Shannon HRT 220 User manual

Shannon

Shannon HR 220-300 User manual

Shannon

Shannon AFF/D 135 User manual

Shannon

Shannon HRK 65 User manual

Shannon

Shannon HRT/D 300 User manual

Shannon

Shannon HRP/D User manual

Shannon

Shannon HRP/S User manual

Shannon

Shannon HRT 65 User manual

Popular Cutter manuals by other brands

Jenlis

Jenlis Weed Razer Pro product manual

HERKULES

HERKULES H-FS 618 Original operating instructions

EINHELL

EINHELL TPR 180 operating instructions

THERMACUT

THERMACUT EX-TRACK PA-1 operating instructions

VonHaus

VonHaus 3500079 instruction manual

Reliable Equipment

Reliable Equipment REL-58MC Operator's guide