LIT-004-198 Page 2 of 4

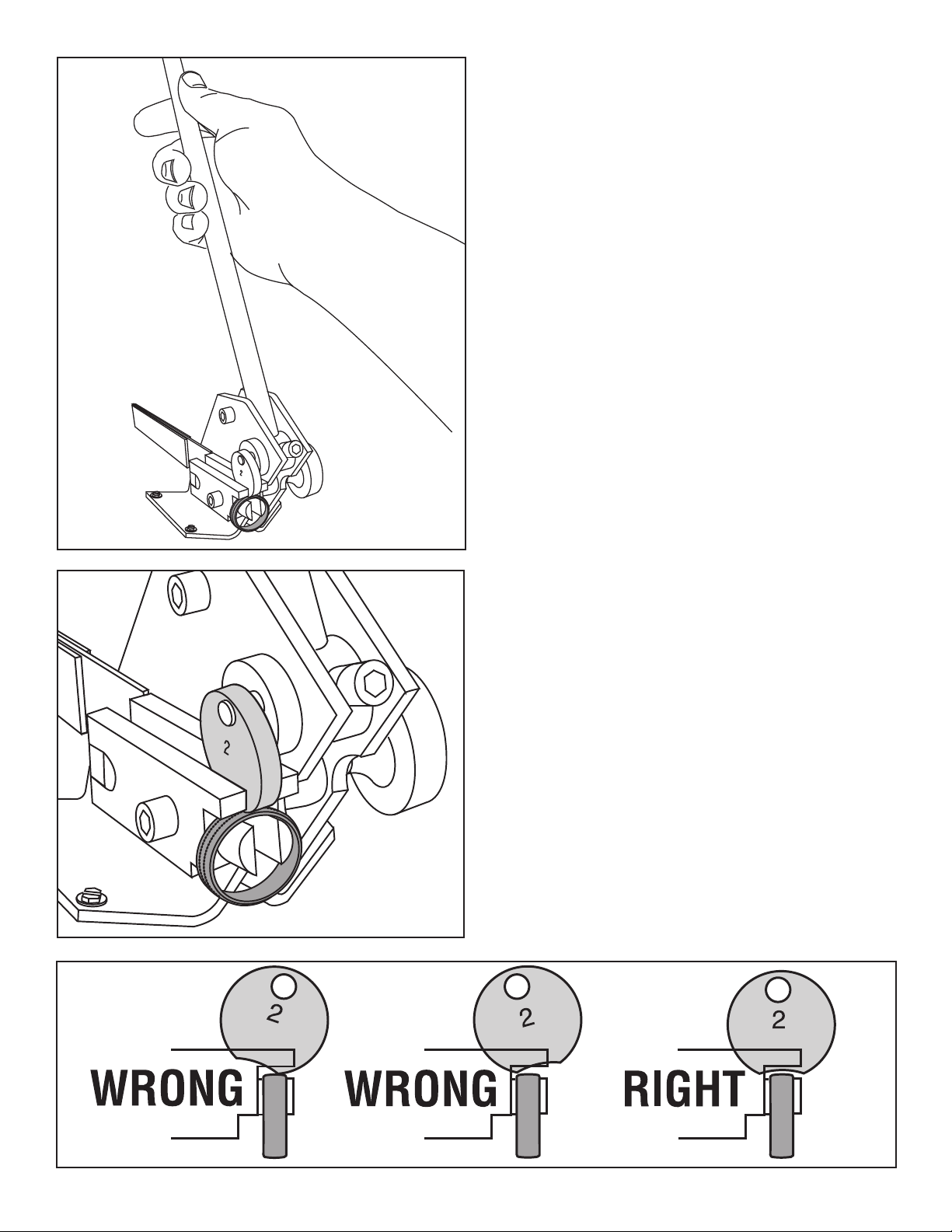

then swinging it down between the two cutter bars (FIG. 5).

If necessary, loosen the adjustment knob further to widen

the space between cutter bars.

You are now ready to set the proper clearance for a clean

shear cut. Visually verify that the cutter is hanging between

the open cutter bars. Now, hold the cutter inward with your

nger (FIG. 6) and simultaneously turn the adjusting knob

clockwise until a light squeeze is felt between the cutter

bars and the cutter. DO NOT OVER TIGHTEN! You have

now set the correct clearance for your cut.

Raise the handle up fully and position your ring over the

cutter bars (FIG. 7 & FIG. 8). Now lower the handle to bring

the cutter in proper contact with the ring. After verifying that

the cutter is correctly positioned over the ring (FIG. 9), pull

smoothly downward on the handle until it stops. Your cut is

complete. Raise the handle, remove the ring. BE SURE TO

REMOVE THE RING SLUG from between the cutter bars.

Once you are familiar with cutter selection and adjustment,

you will nd it to be a fast and simple process. The ring size

cutter has specially shaped cutters that conform to most

convex ring shanks. Notice that the actual cutting area is a

concave notch. This notch must be positioned properly over

the ring shank to make a clean cut. Fig. 9 shows both the

incorrect and correct cutter positions. Although these gures

are somewhat exaggerated, they illustrate an important

point.

INCORRECT CUTTER POSITIONS CAN PRODUCE

ROUGH CUTS AND DAMAGE THE CUTTERS

THEMSELVES!

If you follow the correct procedure for adjusting the cutter

clearance (FIG. 4 to FIG. 9), you will have little trouble with

this problem. Please be sure that the cutter is correctly

aligned before you pull the handle to cut.

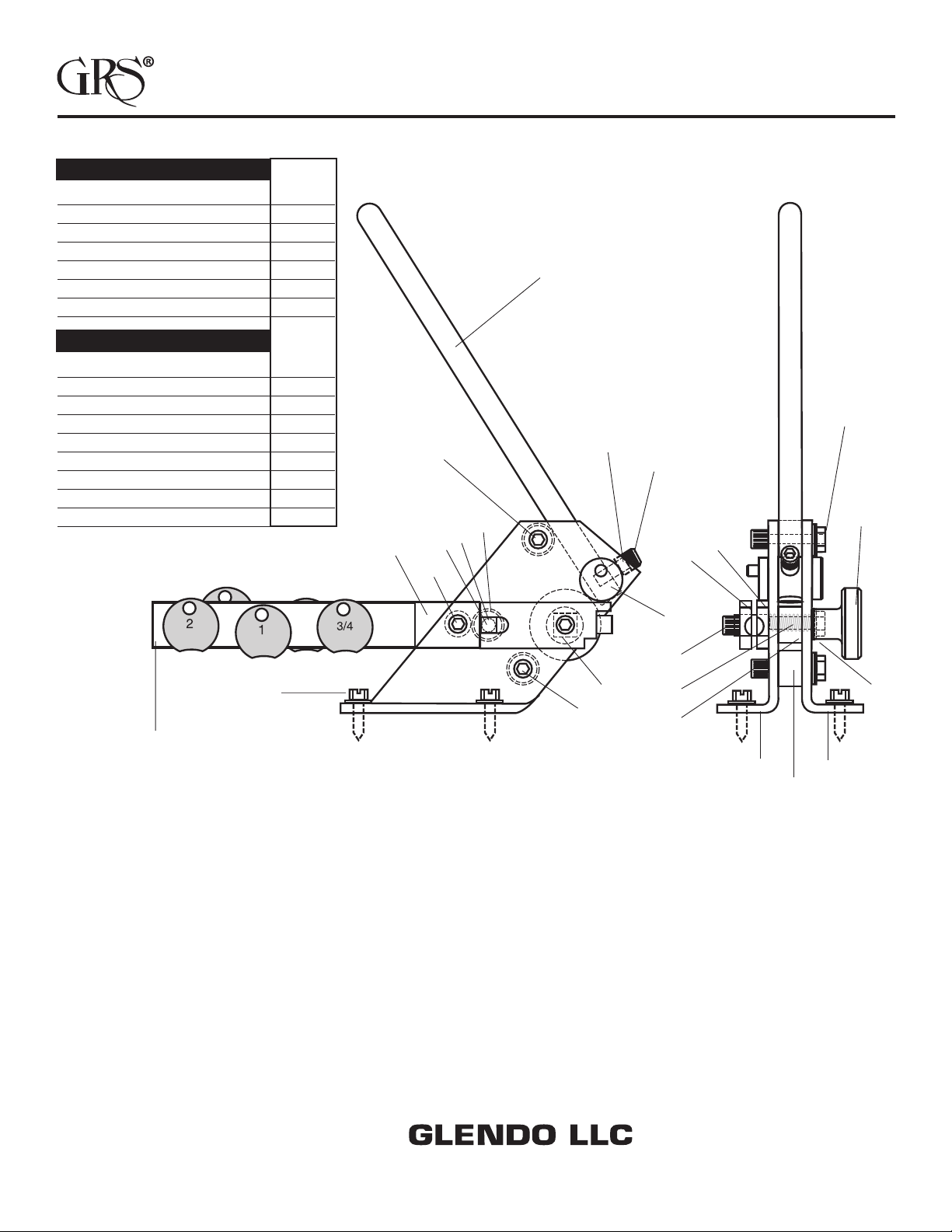

MAINTENANCE

There is very little maintenance required for the ring size

cutter. With proper care, the cutters will provide good

service. This tool is designed to CUT PRECIOUS METAL

ALLOYS ONLY, such as used in jewelry. Do NOT use it

on hard steels, stainless steels, etc. The cutter and cutter

bars are replaceable. You will nd the complete parts listing

on the back of these instructions. Cutters may be ordered

individually or in sets.

The cutter crank may need lubricant from time to time. Most

oils or grease will work. You may nd small amounts of

metal building up on the cutters and inside the cutter bars.

This build-up can hamper correct cutter clearance since

it keeps the cutter bars further apart. If this happens, just

remove this built-up metal with a small le, but be careful

not to round the cutting edges. You should NEVER attempt

to cut anything that does not t across BOTH cutter bars.

This tool is designed to cut a notch from a ring or part that

is supported on both sides. It is NOT a one side shear;

using it this way could cause damage.

FIG. 4

FIG. 5

FIG. 6

TIPS: AVOIDING FRUSTRATION

AND RING DAMAGE

The GRS Ring Cutter cuts by shearing. Some ring shank

shapes and softer alloys may be distorted by this cutting

process. Here are some ways to minimize or prevent this:

1. Observe how the ring shank ts the curved area of

the cutter. Some shanks don’t t the cutter curve well

enough. In a short time you’ll know which rings may

cause problems just by looking at them. You may decide

not to cut some rings with the Ring Cutter. Most jewelers

report using the GRS Ring Cutter well over 80% of

the time. Many tell us they use it virtually 100% once