Nitto ATRA ACE A-100 User manual

The specifications and configurations contained in this document are subject to

change without prior notice due to improvements we are making day in, day out.

Manufactured by :

Nitto Kohki Co., Ltd.

2-9-4, Nakaikegami, Ota-ward,

Tokyo, 146-8555, Japan

Tel : 81 (3) 3755-1111

Fax : 81 (3) 3753-8791

Keep the manual handy – so you can use it whenever necessary.

PORTABLE MAGNETIC DRILLING MACHINE

Read this manual careflly before operating your Nitto Kohki

Portable Magnetic Drilling Machine. Keep this manual with

your machine .All users of the Nitto Kohki Portable Magnetic

Drilling Machine must read this manual.

ATRA ACE Model A-100

Professional Tool For Side-Lock Type Annular Cutter Only

Specifications

Model A-100

Power Supply (Single Phase) 220-240 V AC 50/60 Hz

Drill motor

Rated Power Consumption 1600 W

Rated Current 7.4

No-load Speed 330 min-1

Magnet Power Consumption 80 W

Drilling Capability MAX. Hole diameter φ100 mm (3-15/16”)

MAX. Plate thickness 75 mm (2-61/64”)

Max Magnetic Force 17640 N

Magnet Size 134 x 256 mm (5-1/8”×10-5/64”)

Weight 50 kg (110.20lbs.)

A-100E.indd 1 12.11.28 2:26:01 PM

1

The following Safety notations are used throughout the manual to highlight safety precautions for the user and for

the machine.

DANGER: Indicates an imminently hazardous situation which, if not avoided by following the

instructions given, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided by following the

instructions given, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided by following the

instructions given, could result in injury or material damage.

Caution: Important precautions for machine or tool setup, operation and maintenance.

Thank you very much for your

purchase of Nitto Kohki products.

Before using your machine, please

read this manual carefully so that you

may use it properly to get the most

out of it.

Please keep the manual handy - so

you can use it whenever necessary.

CONTENTS page

GENERAL SAFETY RULES ………………………………… 2

POWER TOOL SAFETY……………………………………… 3

ABOUT YOUR NITTO PORTABLE MAGNETIC

DRILLING MACINE ………………………………………… 4

1. APPLICATION …………………………………………… 7

2. RECEIVING INSPECTION ……………………………… 7

3. PART NAMES …………………………………………… 7

4. FUNCTIONS OF ELECTRONIC CONTROL ………… 8

5. MACHINE SETUP ……………………………………… 8

6. MACHINE OPERATION ……………………………… 10

7. TROUBLESHOOTING ……………………………… 13

8. MAINTENANCE/SERVICE …………………………… 14

9. OPTIONAL PARTS …………………………………… 15

10. EXPLODED DIAGRAM: MACHINE ………………… 16

・English :Please ask your dealer or

distributor for instruction manual

in local language(s).

・German :Bitte fragen Sie lhren Händler

nach eine Betriebsanleitung in

Landessprache.

・French :S'il vous plait, veuillez demandez

á votre foumisseur de manuel

instruction en langue locale.

・Spanish :Por favor, cantacte con su

distribuidor para el manual de

instrucciones en español.

・Portuguese :Por favor pessa ao seo agente

ou distribuidor o manual de

instrucces ih linguagen local.

・Italian :Per Manuale lstruzioni in lingua

locale Vi preghiamo di rivolgervi

al rivenditore o distributore.

・Dutch :Vraag uw handelaar

om een nederladstalige

gebruiksaanwijzing.

・Swedish :Be er lokala Åtreförsäljare eller

distributör om manualer pá

svenska.

・Danish :Venligst henvend Dem til den

danske distributør for instructions

manualer.

・Polish :Prosze pytac swojego dealera

lub dystrybutora o instrukcje

obslugi w jezyku localnym.

・中文 :

A-100E.indd 1 12.11.28 2:26:02 PM

2

GENERAL SAFETY RULES

WARNING

TO OPERATORS

Always Wear Proper Clothing

●Do not wear loose clothing. Loose clothing can

become caught in the drilling machine. This could

cause severe injuries. Be careful that loose clothing

does not come into contact with the machine.

●Wear non-skid footwear. If you lose your footing,

you could contact moving portions of the machine.

This could cause severe injuries. Always wear non-

skid footwear and remain balanced when using the

drilling machine.

●Be careful of long hair. Wear a hat or a hair net to

contain long hair. Long hair can become caught in

the drilling machine. This will cause severe injuries.

Be careful that long hair does not come into contact

with the drilling machine.

Always Wear Safety Glasses

●Always wear safety glasses. The operation of your

drilling machine will cause flying chips and particles.

These will cause severe eye injuries. You must

always wear safety glasses.

● Not all glasses are safety glasses. Wear only safety

glasses that comply with ANSI standards. Not all of

the lenses are shock resistant. Ordinary glasses will

not provide sufficient eye protection.

Always Wear Hearing Protection

●Always wear hearing protection. The operation of

your drilling machine will cause big sound occurs.

These will cause severe hearing loss injuries. You

must always wear hearing protection

Wear respiratory protective equipment (PPE)

●Wear respiratory protective equipment (PPE) when

working in an environment where dust particles are

generated in operation.

Maintain Good Posture

●Always wear non-skid footwear and maintain good

posture. Do not use the drilling machine when you

are tired. Fatigue or loss of balance could cause

you to lose control of the machine. This could cause

severe injuries. Always stay balanced. Always keep

good posture. Stop using the machine if you are

tired.

Never Touch the Cutting Tip

●Never touch the moving or cutting tip. Contact with

the moving tip will cause severe injuries. Always

keep all parts of your body away from the cutting tip.

Always keep your hand and clothing away from the

cutting tip.

ABOUT THE WORK AREA

Keep Work Area Clean

●Always keep your work area clean. Cluttered work

areas cause accidents. Always keep clear of other

objects.

● Never use the magnetic drilling machine when it is

wet. Always use the drilling machine in a dry area.

Do not use the drilling machine in the rain. If you use

the machine when it is wet you can get an electric

shock. If you use the machine in the rain you can

get the electric shock.

● Always use the drilling machine in a well-lighted

area. Do not use the drilling machine in the dark.

● Avoid all flammable materials. Use of the drilling

machine may cause a spark that could ignite a fire

or an explosion. Never use the machine near any

flammable material.

● Keep away from children. Always keep the drilling

machine away from children. Do not operate drilling

machine when children are present.

BEFORE OPERATION

Make sure that all parts are free from damage

● Make sure that the drilling machine is in good

operating condition. Operation of a damaged

machine could result in severe injuries. If there

is any damage to the machine, do not use the

machine. If there is any damage to the machine,

take it to an authorized Nitto dealer for repair.

● Do not attempt service or repair of the drilling

machine. All service or repair should be done by an

authorized Nitto dealer.

Secure Your Work

● Always secure your work piece. Improperly mounted

work can become loose. This can cause severe

injuries. Always secure all work.

● Always use a vice or a clamp. Do not attempt to

hold any work piece with your hand. Attempting to

hold a work piece with your hand may cause severe

injuries. Always use a vice or clamp to hold the work

piece.

● Always secure your drilling machine. Improperly

mounted drilling machine can come loose. This can

cause severe injuries. Always secure the drilling

machine.

Avoid Clutter

● Always stay clear of other objects. Cluttered work

areas cause accidents. Always keep a clean work

area and stay away from other objects.

Always Remove Spanner Wrenches and

Adjustment Tools

● Always remove spanner wrenches and adjustment

tools after adjustments have been made to the

A-100E.indd 2 12.11.28 2:26:02 PM

3

drilling machine. Always remove all adjustment tools

before using the drilling machine.

Always Use a Cutter that is Appropriate for Your

Work

● Always use a Cutter that is appropriate for your

work. Avoid heavy-duty work that is beyond the

capacity of your drilling machine. If the work exceeds

the capacity of your drilling machine, this can cause

accidents and severe injuries. Always use the

drilling machine in accordance with its performance

specifications.

SAFE HANDLING

● Never leave the magnetic drilling machine

unattended while it is running. When the machine

is unattended, disconnect the power source. Do

not leave the work area until the machine comes to

a complete stop. Operating the machine while it is

unattended can case accidents that may result in

severe injuries.

HOW TO STORE YOUR MAGNETIC DRILLING

MACHINE

● Always store the machine in a dry area.

● Always keep the machine out of the reach of

children.

HOW TO CARRY YOUR MAGNETIC DRILLING

MACHINE

● Disconnect the power and turn off the machine

whenever you carry the machine.

MAINTENANCE

Do not take apart or modify your magnetic drilling

machine.

● Do not attempt to disassemble or modify your

magnetic drilling machine.

● Do not modify your magnetic drilling machine.

Modifications can cause accident and severe

injuries.

● All service and repairs must be performed by an

authorized Nitto dealer. Any attempt to service or

repair the machine yourself may result in an accident

and severe injuries.

Check all Parts for Damage.

● Always inspect the magnetic drilling machine before

use.

● Always check that the pilot pin and cutter are in

good condition. Use of the machine with worn pilot

pins or worn cutter can cause accidents and severe

injuries.

● Inspect all cutter before you put them on the

magnetic drilling machine.

● Do not operate the magnetic drilling machine with a

damaged or worn cutter. Do not operate the machine

with a damaged or worn pilot pin. Do not operate the

machine with any damaged accessory. Operating

the machine with any damaged part or accessory

can cause accidents and severe injuries. If there is

any damage to the magnetic drilling machine, do not

operate the machine. Take it to an authorized Nitto

Dealer for repair.

● Always have the magnetic drilling machine repaired

at an authorized Nitto dealer. Always take the

magnetic drilling machine to an authorized Nitto

dealer for service, repair and replacement parts. If

you cannot locate an authorized Nitto dealer near

you, please contact your sales representative.

● Always use Nitto genuine parts. The use of improper

or non-Nitto parts can cause accidents and severe

injuries. Never use unauthorized parts. To obtain

genuine Nitto parts, contact your sales agent.

● Do not remove any nameplate from your magnetic

drilling machine. Do not remove any labels from

your magnetic drilling machine. If any label or

nameplate is damaged contact your sales agent for

a replacement.

POWER TOOL SAFETY

WARNING

● Always make sure that the machine is properly

grounded. If the machine is not properly grounded,

someone can get an electric shock.

● If you have any doubt about the grounding of

the magnetic drilling machine, contact a licensed

electrician.

● Never connect the grounding conductor to a gas

pipe. This will result in an explosion and severe

injuries or death.

● Always check the grounding conductor. If you have

any doubts about the grounding conductor, contact

a licensed electrician.

● Wiring connections to a grounding rod require the

expertise of a licensed electrician. Do not attempt

the wire connections yourself. Always contact a

licensed electrician.

● Do not abuse the power cord. A damaged power

cord can cause an electrocution. A damaged power

cord can cause fires. Always inspect the cord. If the

cord is damaged, do not use the magnetic drilling

machine.

● Do not carry the machine by the cord. Do not pull

the cord to disconnect it from a socket.

● The cord can become damaged from heat, contact

with sharp objects or from being twisted. Always

inspect the cord. Do not use the machine if the cord

A-100E.indd 3 12.11.28 2:26:03 PM

4

is damaged.

● Always use a ground fault circuit interrupter. The use

of a ground fault circuit interrupter may be required

by government regulations. The failure to use a

ground fault circuit interrupter may result in electric

shock.

● Avoid starting the magnetic drilling machine abruptly

or unintentionally.

● Always make sure that the switch is turned off before

connecting the power source.

● Always disconnect the power source and turn off

the switch before setting up for work operations.

Always disconnect the power and turn off the

switch when inspecting work. Always disconnect

the power and turn off the switch before attempting

any maintenance. Failure to disconnect the power

and turn off the switch during set up, inspection

or maintenance can cause accidents and severe

injuries.

About Your Nitto Portable Magnetic

Drilling Machine

DANGER

Do not use your portable drilling machine on the

ceiling and the side.

● Use of the portable drilling machine on the ceiling or

the side is dangerous. The machine could fall. The

falling machine could cause severe injuries or death.

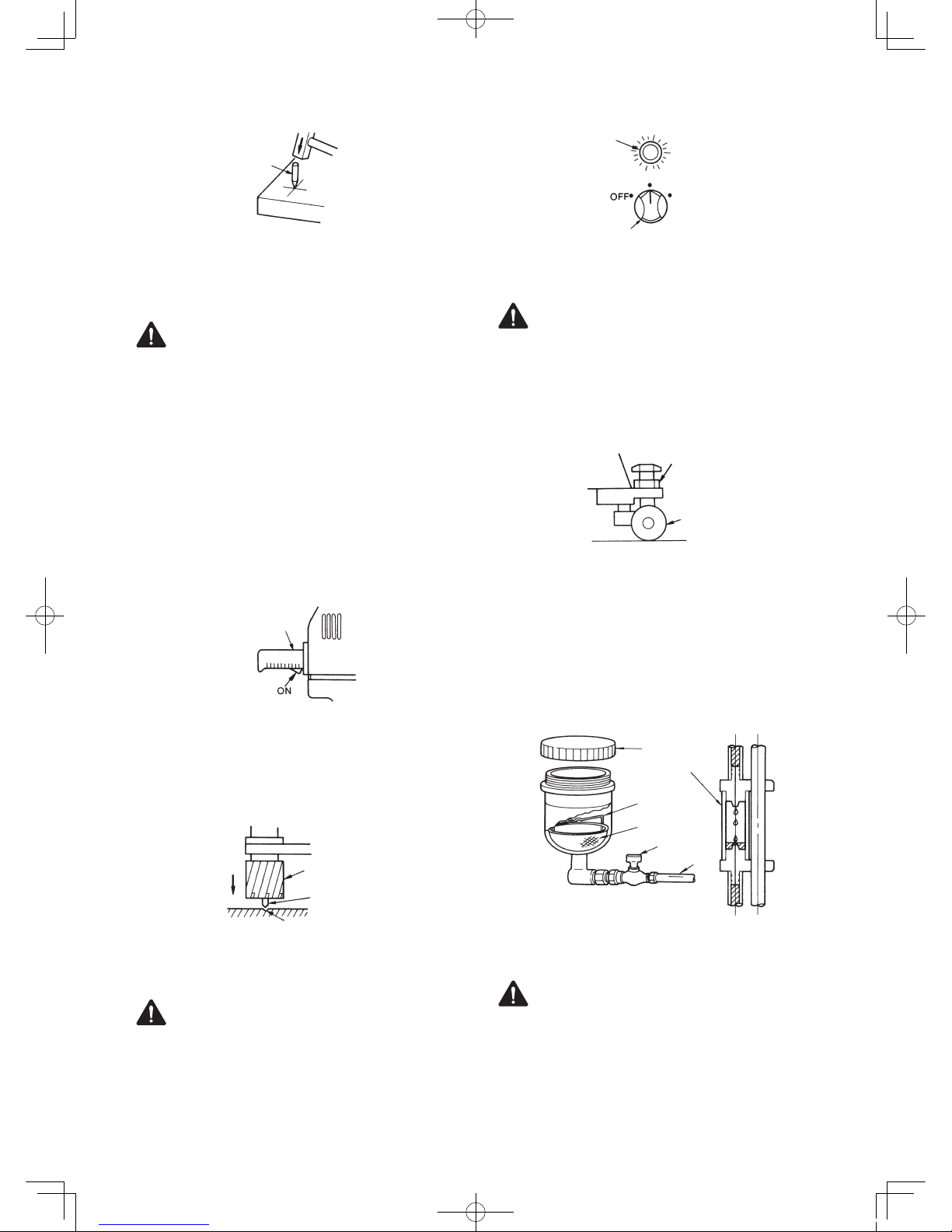

(Fig.1)

Fig. 1

WARNING

Do not use the Magnet for more than five hours.

● More than five hours of uninterrupted operation may

cause a fire. Five hours of uninterrupted operation

generates extreme heat in the Magnet. This heat

can cause a fire. Do not touch the Magnet. When

the Magnet is hot, touching it will cause a severe

burn injury. Never use the Magnet for more than

five continuous hours. When you are not using the

Magnet, turn the switch to the OFF position and pull

the Plug out of the power source.

Do not use the Drill Motor for over 30 minutes.

● Uninterrupted operation of the Drill Motor for over 30

minutes generates heat. This heat can cause a fire.

Never use the Drill Motor for over 30 minutes. When

you are not using the Drill Motor, turn the switch to

the OFF position and pull the Plug from the power

source.

Use only on magnetic materials.

● Your portable drilling machine cannot be used

on non-magnetic materials, such as aluminum,

stainless steel, copper or alloys. The Magnet will not

work on non-magnetic materials. Attempting to use

the Magnet on non-magnetic materials could cause

an accident.

Use caution during wall operation.

● When using your portable magnetic drilling machine

on a magnetic wall, always use caution.

● Never stand under the machine.

* Never allow anyone to stand under the machine.

* Never put any part of your body under the

machine.

* If the machine falls, it could result in severe injury

or death.

Always use a work piece that is at least 13 mm

(33/64”) thick.

● The work piece must be at least 13 mm (33/64”)

thick. If a work piece is too thin, the magnetic power

of your machine will decrease. This will cause the

machine to move during operation. This could result

in an accident. (Fig.2)

Not less than 13mm (33/64”)

Fig. 2

Use an iron back-up plate.

● If the work piece is less than 13 mm (33/64”) thick,

you must use an iron back-up plate that is more

than 10 mm (13/32”) in thickness. The surface area

of the iron back-up plate must he greater than the

surface area of the magnet. An appropriate back-up

plate is necessary to boost the holding power of the

Magnet. (Fig.3)

Use of an inappropriate back-up plate can result in

A-100E.indd 4 12.11.28 2:26:04 PM

5

an accident, If the back-up plate is not thick enough

or big enough, the machine will come loose during

operation. This can result in an accident and severe

injuries.

Place 10mm(13/32”) or

more thick piece iron

Less than 13mm (33/64”)

Fig. 3

Always keep surfaces clean.

● Always keep the Magnet surface clean. Always keep

the work piece surface clean. If there are any foreign

objects between the Magnet and the work piece

surfaces, this will reduce magnetic power. This could

cause the machine to move during operation. This

can result in an accident. Keep all surfaces clean of

rust, chips or other foreign material.

Do not place the machine over a hole.

● Do not attempt to position the Magnet over a hole.

Attempting to straddle a hole will reduce the power

of the Magnet. This will cause the work piece to

come loose during operation and can cause an

accident.

Always use a Chain to secure the machine.

● If the machine falls, it can cause severe injuries.

There is always a possibility that magnetic power

can be lost or reduced because of a power failure.

Magnetic power can be lost on rough surfaces. You

must take precautions to prevent the machine from

falling.

● This machine comes with a Chain. The chain is to

be used to fasten the machine to the work piece.

If you do not use the chain, it is possible that the

machine may fall. (Fig.4)

Fig. 4

Always set the Magnet in the proper position.

● Always set the Magnet parallel to the longitudinal

direction of the material. Failure to set the Magnet in

the proper position may result in reduced magnetic

power. This can cause the machine to move in

operation. This can cause an accident resulting in

severe injuries.

● When using on H-section steel, as shown in the

figure below, set the Magnet in a direction parallel

to the longitudinal direction of the material. This will

ensure that the Magnet is in the best position for

magnetic attraction.(Fig.5)

● Poor magnetic power may result in damage to the

cutter or damage to the work piece.

Wrong Right

Fig. 5

Stabilizer adjustment

The Stabilizer serves as the effective counterbalance

to the adhesive force of the Magnet. After switching

on the Magnet, adjust it so that the Magnet clings to

the work piece evenly without a gap. Make sure the

Stabilizer Wheels are not protruding and lifting the

Magnet off the plate.

Right

Maintain solid contact

Fig. 6

Wrong

Improper contact

Fig. 7

A-100E.indd 5 12.11.28 2:26:06 PM

6

Wrong

Protruding Stabilizer Wheels

lifts up the Magnet

Fig. 8

Be careful about chips.

● Keep your hands away from the cutting area at all

times. During drilling, there will be chips. The chips

are sharp. The chips are rotating with the cutter. Any

contact with the chips can cause severe injuries.

Do not touch the slug.

● Do not touch the slug. The slug is very hot. It will

cause severe burns. Make sure that no one touches

the slug. Make sure that there is no one below the

work area during operation. Hot slugs will fall. Hot

slugs can cause severe burns, other severe injuries,

or even death. Always wear protective equipment,

including protective headgear, eye protection,

hearing protection, and gloves. Do not allow any

person without protective equipment to come near

the machine.

Do not use your hands to remove chips.

● Chips have sharp edges. Use a screwdriver to

remove chips. If you use your hands to remove

chips, you can be injured, even if you are wearing

gloves. Do not use your hands to remove chips

under any circumstances.

The cutting edge is sharp.

● Always wear gloves when changing the cutter. The

cutting edge is sharp. If you do not wear gloves,

you will be cut. Attempting to change the cutter can

result in severe injuries.

Do not use Cutting Oil for other purposes.

● Cutting Oil should be used only for drilling. Please

refer to Section 5-4 of this manual for further

warnings and instructions about Cutting Oil.

CAUTION

Always use a compatible Pilot Pin.

● The Pilot Pin must be compatible with the cutter. An

improper Pilot Pin may result in an accident.

Do not use power that is generated by an engine-

driven welder.

● The use of an engine-driven welder as a power

source may cause your magnetic driven machine

to malfunction, Power from an engine-driven welder

can damage the electronic circuits in your portable

drilling machine.

Use a Proper extension cord.

● Do not use an extension cord that is too thin. Do

not use an extension cord that is too long. Do not

use an extension cord that is wound on a drum. Do

not share an extension cord with other motor-driven

tools. These uses can cause voltage to drop and

can reduce the holding power of the magnetic base,

causing the machine to move during operation. This

can decrease performance and may cause damage

to the machine. (Fig.9)

Extension Cord

Max. length Size (nominal cross-section

area of the conductor)

10 m Min 2 mm2or more

20 m Min 3.5 mm2or more

Fig. 9

Do not use this machine on the steel material

being electrically welded.

● When the electric welder is not properly grounded,

electricity will run through the Atra Ace machine

via its Magnet, causing possible failure or

malfunctioning, which in turn may cause accident.

Do not force to feed cutter.

● Because the Jetbroach has rather thin cutting edges

with less cutting pressure resistance as compared to

twist drill, do not force to feed the cutter.

If you feed it with too much force, the cutter may

break or end up with shorter life than otherwise.

A-100E.indd 6 12.11.28 2:26:07 PM

7

1 APPLICATION

This is a portable drilling machine with a Magnet,

geared to drilling mild steel (mild steel or equivalent)

using One-Touch type Jetbroach or twist drill. The

machine will be mounted on the workpiece to be

drilled with the Magnet securely fastening the machine

to the workpiece while drilling takes place.

2 RECEIVING INSPECTION

Upon unpacking, check to see that the shipment is

complete without damage or oil leakage in transport.

Should you find any damage or short-shipment,

please contact sales agent through which you have

purchased your machine or an authorized dealer near

you for corrective actions.

Part Name Q’ty Check

ATRA ACE 1set

Hex. Socket Screw Key 2 1

Hex. Socket Screw Key 2.5 1

Hex. Socket Screw Key 3 1

Hex. Socket Screw Key 4 1

Hex. Socket Screw Key 5 1

Hex. Socket Screw Key 6 1

Hex. Socket Screw Key 8 1

Spanner 7X8 1

Tool Box 285X125X62 1

Safty Chain Ass'y 1set

Soluble Cutting Oil 0.5 Ass'y 1set

Instruction Manual 1

Feed Handle 3

Oil Cup Ass'y 1

Pilot 12075 Ass'y 1set

3 PART NAMES

Fig. 10

Drill Mortor

Trigger Switch

Set Screw

Lamp

Dial Switch

Magnet

Stabilizer

Plug

Body

Feed Handle

Overload

Warning Lamp

Slide Board

Ajustment Screw

A-100E.indd 7 12.11.28 2:26:08 PM

8

4 FUNCTIONS OF OVERLOAD DETECTOR

● When overload occurs during drilling, the overload

detector puts the following functions to work.

4-1. Overload Warning Light

The lamp on the top of the unit body will be lighted

up in red when the overload detector catches the

overload on the drill feed. As soon as the lamp is

turned on, reduce the drill feed.

4-2. Automatic Stop

If the feed is further increased, the Electric Drill

would stop automatically and the red Overload

Detector Lamp would not go out.

After the Electric Drill stops, return the Main Dial

Switch to the “Magnet ON” position and lift the

Electric Drill up by turning the feed handle inversely

in order to make a thorough check of the unit based

on our checklist.

4-3. Checklist

Check Items Solutions

Feed speed Reduce feed speed

slower as the hole to

be cut comes bigger.

Check if the work piece is

extraordinary hard.

Reduce feed speed

when the work piece

is so hard.

Check if the lubrication is

good enough.

Increase the supply

volume of cutting oil.

C h e c k t o s e e i f

JETBROACH is in good

condition

Clean the blade tips

and re-sharpen them

if they are worn out.

To continue drilling the remaining workpiece after

inspection, eliminaite chips and slowly feed the

handle up to 2 to 3 mm at the beginning of drilling.

5 MACHINE SETUP

5-1. Mounting the accessory to the body

(1) Screw the feed handles into the handle boss

tightly.

(2) Fix the cup holder on the slide plate with the

Hex. Socket Head Cap Screw.

(3) Fix the oil cup on the cup holder.

(4) Couple the oil cup and oil ring to the oil dropper

with the tube and put soluble cutting oil diluted 8

to 10 times into the oil cup.

Handle boss

Oil cup

Cup

holder

Hex. Socket

Head Cap

Screw

Tube

Oil ring

Oil dropper

Feed handle

Fig. 11

WARNING

●When setting up machine, turn off the Magnet

Switch and disconnect the power supply plug

from power source.

5-2. Using Cutter

CAUTION

● Use side lock type cutters only.

●

For better workability and safety, do not use

worn out or damaged cutters.

5-3. Mounting/Removing Cutter

WARNING

●

Wear safety gloves when replacing cutter.

JETBROACH installation.

(1) Put the Pilot Pin into the JETBROACH you will

use.

Pilot Pin

JETBROACH

Fig. 12

(2) Insert the JETBROACH into Arbor shank with the

two flat surfaces are respectively and properly

aligned to the setscrew holes.

Setscrew hole

Flat surfaces

Fig. 13

A-100E.indd 8 12.11.28 2:26:09 PM

9

(3) Initially put 2pcs.of Hex. Socket Setscrews into

each hole tentatively (with careful attention to the

fastening threads), then tighten them firmly with

Hex. Socket Screw Key.

Hex. Socket Setscrews

Hex. Socket Screw Key

Fig. 14

(4) If the JETBROACH is inserted without proper

alignment of Hex. Socket Screws, the Hex. Socket

Screws will contact and clutch other part than flat

surfaces and the JETBROACH may not be taken

off.

Wrong

Right

Fig. 15

5-4. Preparation of Cutting Oil

Cutting Oil Safety Precautions

WARNING

(1) Use

● Use Cutting Oil for cutting purpose only. Don’t use it

for household purposes

(2) Handling Precautions

● The Cutting Oil contains amine. Do not mix it up with

rust inhibitor, etc. containing nitrite.

● Wear safety glasses for eye protection when

handling Cutting Oil: eye injury may results if it gets

into your eyes.

● Wear protective gloves for hand protection when

handling Cutting Oil: skin injury may result if it

comes into contact with your skin.

● Wear respirator when exposure to respiratory

hazards with oil mist or vapor is anticipated.

Inhalation of oil mist or vapor may make you feel sick.

● When diluting Cutting Oil, follow the instructions per

the Operation Manual.

● Keep Cutting Oil out of reach of children.

● Don’t drink Cutting Oil.

(3) First Aid

● If Cutting Oil gets into your eyes, immediately open

your eyelids with your fingers and wash your eyes

with plenty of water for at least 15 minutes. If your

eyes feel irritated, consult with a medical doctor and

follow his/her instructions.

● If Cutting Oil comes into contact with your skin,

immediately wash it away with plenty of water and

soap. Take off contaminated clothes. Clean the

clothes if you need to wear it again. If your skin feels

irritated, consult with a medical doctor for medical

instructions.

● If someone inhales oil mist or vapor, immediately

take him/her to an area where fresh air is abundant

and wrap up his/her body with a blanket, etc. to

keep body temperature. Have him/her take a rest

and consult with a medical doctor for medical

instructions.

● If someone drinks Cutting Oil, immediately make

him/her drink plenty of water and vomit it. Consult

with a medical doctor for medical instructions. When

unconscious, do not pour water into his/her mouth

nor induce him/her to vomit.

(4) Instructions in Case of Fire

● If fire breaks out in the vicinity, wear PPE (personal

protective equipment) and use foam, powder or

CO2fire extinguisher to put the fire out from the

windward.

(5) Storage

● When storing Cutting Oil after use, put it into a

container and put a lid on for tight sealing so

that dust or moisture, which is a catalyst for

contamination, may not get in.

● Avoid direct sunlight, rainwater or the like and store

Cutting Oil a dim cool area.

(6) Disposal

● For disposal of concentrate solution and used fluid,

request a waste-disposal company to dispose them

as industrial waste in accordance with the local laws

and regulations.

● Treat flushing water through pH adjustment,

condensation/sedimentation, activated sludge

process, activated carbon adsorption, etc., and

discharge it in accordance with the regulations of

your local municipal bylaw.

● Residual dross will remain in an emptied container:

be careful when handling an empty container.

(7) Others

● When Cutting Oil is poured into another container

A-100E.indd 9 12.11.28 2:26:09 PM

10

for use, post chemical and label information at the

site where it is kept. At the same time, keep the

Operation Manual handy so that can be referred to

whenever necessary.

● For further details, contact us for product safety data

sheet.

● All the information and descriptions that have been

provided are based on the currently available

documents and information, which may be revised

upon our new recognition and/or discovery.

● The precautions provided apply to regular handling.

If special handling method is used, take safety

measures that are suitable for your applications and

usage.

● The information contained herein is for your

reference purpose only, to which we make no

warranty of any kind and for which we shall not be

held responsible.

Preparation of Cutting Oil

(1-1) Use our genuine-product Cutting Oil (blue).

If other Cutting Oil is used, the cutting

performance and service life of cutter would be

decreased.

(1-2) Use tap water to dilute Cutting Oil by 8- to

10-fold. Do not use well water.

6 MACHINE OPERATION

WARNING

●

Always Wear Safety Glasses.

●

Always Wear Hearing Protection.

●

Wear respiratory protective equipment.

●

Never touch the mounted cutter and the rotating

parts of the machine such as the Spindle Arbor

after the power cable is connected to power

source.

6-1. Start and Stop

●

The Drill Motor will not rotate unless a Magnet

is turned on in operating the Motor Switch.

CAUTION

●

When the Trigger Switch of the Electric Drill

is not turned on, the Electric Drill will not start

even the Main Dial Switch on the side of the

body is turned to the “Drill ON” position. Leave

the Trigger Switch on during the entire drilling

work.

●

When turn on both the Magnet and Electric Drill,

pause momentarily at the “Magnet ON” position

before switching over to the next “Electric Drill

ON” position. Unless the Main Dial Switch is

steadily set to its ON stage once, the Electric

Drill may not start.

(1) Trigger Switch of the Electric Drill ON

Turn on the Trigger Switch. Turning on the Trigger

Switch alone would not let the Electric Drill start.

Trigger Switch

Fig. 16

(2) Magnet ON

First turn the Main Dial Switch to the “Magnet ON”

position. The power lamp will come on and the

Magnet will be activated.

Lamp

Drill Motor

Magnet

Fig. 17

(3) Electric Drill ON

Then set the Main Dial Switch to the “Motor ON”

position. The Electric Drill will start to run.

Drill Motor

Magnet

Fig. 18

(4) All Stop

When the Main Dial Switch is pulled back from

the “Electric Drill ON” position to the “Magnet ON”

position, the Electric Drill will stop. When the Main

Dial Switch is pulled further back from “Magnet

ON” position to the “All OFF” position, the Magnet

will be deactivated and all functions will stop.

6-2. Drilling Procedure

(1) Punching

The punch mark should be stamped quite vertical

to the work piece and rather large in size. Be

careful to get precise punch mark since it serves as

the drilling center guide.

A-100E.indd 10 12.11.28 2:26:10 PM

11

punch

Fig. 19

(2) Keep the Magnet and Workpiece Contacting

Surfaces Clean.

WARNING

●

Always keep surfaces clean.

Always keep the Magnet surface clean. Always

keep the work piece surface clean. If there are any

foreign objects between the Magnet and the work

piece surfaces, this will reduce magnetic power.

This could cause the machine to move during

operation. This can result in an accident. Keep

all surfaces clean of rust, chips or other foreign

material.

(3) Trigger Switch of the Electric Drill ON

Turn on the Electric Drill. Turning on the Trigger

Switch alone would not start the Electric Drill.

Electric Drill

Fig. 20

(4) Align with Punch Mark

Turn the feed handle counterclockwise to slightly

lower the JETBROACH and align the tip of Pilot

Pin to the punch mark.

Punch Mark

JETBROACH

Pilot Pin

Slightly lower

Fig. 21

(5) Magnet ON

WARNING

● Check to see that Magnetic power is activated.

Turn on the Magnet. The Main Dial Switch Lamp

will glow and magnetic power will come on.

Lamp

Drill Motor

Magnet

Fig. 22

(6) Set the Stabilizer properly

WARNING

The Stabilizer serves as the effective counterbalance

to the adhesive force of the Magnet. After switching

on the Magnet, adjust it so that the Magnet clings

to the work piece evenly without a gap. Make sure

the Stabilizer Wheels are not protruding and lifting

the Magnet off the plate.

Stabilizer

Nut

Fig. 23

(7) Cutting Oil Flow Adjustment

When the plug valve to the Oil Cup is open and the

Electric Drill is lowered by turning the Feed Handle

counterclockwise, the Pilot Pin will be pushed up

allowing Cutting Oil to begin to flow. See the oil

flow in the Oil Dropper tube and adjust the oil flow

with the Plug Valve.

Plug Valve

Tube

Oil Cup

Cap

Oil Cleaner

Oil Dropper

Fig. 24

(8) Drill Motor ON

WARNING

●

Don’t touch revolving parts.

Press the Drill Motor ON Switch to start the Drill

Motor

●

Don’t press the Rod Handle strongly or the

Magnet may lift, causing the main body to

swing.

A-100E.indd 11 12.11.28 2:26:11 PM

12

Turning the Main Dial Switch to “Drill Motor ON”

position will let the Electric Drill start running.

Drill Motor

Magnet

Fig. 25

(9) Drilling

To s t a r t d r i l li n g , t ur n t h e F e e d H a n d l e

counterclockwise. Be sure to turn the Feed Handle

slowly for the first 2~3mm depth cutting.

Feed slowly for

2~3mm

Fig. 26

When drilling a hole in an angle, channel or H-section

irons, etc., JETBROACH may be damaged when it

comes to a slanted part of the work on the final cutting

stage. Feed slowly when start and finish cutting.

Slanted part

Fig. 27

(10) Finishing the hole cutting

WARNING

● Be careful about chips.

● Do not touch the slug.

● Do not use your hands to remove chips.

When drilling is finished, raise the Electric Drill and

set the Main Dial Switch back to the “Magnet ON”

and “Motor OFF” position. When the Electric Drill has

stopped, then quickly pull the Main Dial Switch back

to the “Power OFF” position. If you fail to do this, the

Magnet will remain activated, which will shorten its life

Drill Motor

Magnet

Fig. 28

(11) Removing Slug

Don’t proceed to the next operation without

removing the slug from the operation just finished.

At the end of drilling operation slug will pop out

automatically ejected by the spring-operated Pilot

Pin. Should a slug left in the hold sticking, remove

it from the hole by tapping the collar of the slug

with a needle stick or something. (fig.29)

Cutter

Pilot pin

Slug (chips) Needle pin Slug

Fig. 29

6-3. Drilling Oblong Hole

CAUTION

Always drill oblong hole slowly.

Drill oblong hole in the order of ①, ②, ③. For the

steps ②and ③, take care so that the cutter may

not be fed into the workpiece with too much force.

Spacing between each step of drilling operations

should be so arranged that the Pilot Pin will always

hit the material yet to be machined. (fig.30)

File away any excesses

Fig. 30

6-4. Drilling Stacked Plates

CAUTION

●

Remove slug as each plated is finished:

otherwise, being blocked by the slug left

unremoved, the cutter cannot cut into the next

layer of plate, which results in the Magnet base

being pushed up possibly causing accident.

●

For stacked plates drilling, always feed and

drill slowly and carefully.

●

Before drilling stacked plates, securely clamp

the plates together in place.

●

When drilling stacked plates, retract the cutter

as each layer of plate is finished in order to

remove slug from the drilling area, then put

another hole in the next layer of plate.

A-100E.indd 12 12.11.28 2:26:12 PM

13

7 TROUBLESHOOTING

WARNING

●Never attempt to repair machine yourself: injury or damage to equipment may result.

●Please feel free to consult the sales agent through which you have purchase your machine or an

authorized dealer, when the following symptoms appear or when you have any questions about our

products.

Problem Causes Solutions

Switch lamp doesn’t come on

when Magnet Switch is turned

on.

Power supply plug is not connected to

socket.

Connect power plug to socket.

Drill Motor stops during drilling.

(Magnet is not working with

Magnet lamp not illuminating.)

Power failure has occurred or power

supply plug is disconnected.

After power failure is restored or power

supply plug is re-connected, turn on

Motor Switch again.

Magnet does not adsorb. Magnet is disconnected. Request for repair.

Drill Motor doesn't start when

Motor Switch is turned on.

Switch is broken. Request for repair.

Lateral shifting of Magnet is

detected by lateral position

sensor, bringing machine to a

compete stop.

Workpiece too thin. Use back-up plate: thickness 10 mm

(13/32”) or more.

Chips under Magnet base. Clean it up.

Worn cutting edge. Regrind or replace with new one.

Effective magnetic force too weak. Request for repair.

A-100E.indd 13 12.11.28 2:26:13 PM

14

8 MAINTENANCE/SERVICE

WARNING

●Always disconnect the power and turn off the

switch before attempting any maintenance.

Failure to disconnect the power and turn off the

switch during set up, inspection or maintenance

can cause accidents and severe injuries.

8-1. Tighten Set Screw When Machine is Not Used

For the purpose of safety, when you don’t use the

machine temporally or on a long-term basis, raise the

Drill Motor and set it in position with the Set Screw

so that it will not come down on its own weight. If

you leave the machine alone with the Drill Motor in a

lowered position, the Pilot Pin and/or cutter may be

damaged when the machine is relocated.

Before tightening the Set Screw, make sure that the

slide section in the Gearbox is properly aligned to

the head of the Set Screw.

8-2. Grease the Sliding Surfaces from Time to Time

Grease the machine body and Slide Board from time

to time.

8-3. Gearbox Clearance Adjustment

Excessive clearance between the machine body

and Gearbox would deteriorate not only drilling

performance but also cutting tool life to a substantial

degree. If you find excessive clearance, make

adjustment by tightening 5 Slide Board Adjusting

Screws on the side of the machine using the same

torque all round so that Drill Motor will not come

down on its own weight.

8-4. Keep the Tip of Pilot Pin Sharp

When the tip of Pilot Pin gets dull, it sometimes fails

to seat into punched hole, causing drilling accuracy to

deteriorate. See that the tip is sharp from time to time.

If you find it too dull, regrind or replace as required.

When regrinding do so carefully, for grinding with too

much force may cause the tip to get dull or soften

the material to such a degree that it is no longer

usable. (Fig.31)

Pilot Pin

Sharpen

the tip

Optimal angle

Fig. 31

8-5. Recovery Measures When Pilot Pin Gets

Jammed

When you change cutting tool you also change

Pilot Pin, which acts as a guide for the cutting tool.

However there are times when the pin does not

come off easy with cutting chips in the clearance

between the cutting tool and pin, causing jamming.

In such case, tap the tip of Pilot Pin with wooden

hammer, etc., pull it off. (Fig.32)

Cutter

Pilot Pin

Cutting chips

Fig. 32

8-6. Cutter Regrinding

When you need to regrind cutter, please contact

sales agent through which you have purchased your

machine or an authorized dealer near you.

Inner cutter

Outer cutter

Inner

cutter

Outer

cutter

Inner

cutter

Outer

cutter

Fig. 33

8-7. Carbon Brushes Inspection and Replacement

Check Carbon Brushes for wear periodically.

When the length of Carbon Brushes gets as short

as 6mm, replace it with a new one, for, if you don’t,

chances are that you’ll have a rectification problem

which may cause machine failure. (Fig.34)

Check – machine failure.

(1) Remove the Brush Cap with a straight slot

screwdriver.

(2) Remove the worn-out Carbon Brush and replace

it with a new one. Then reattach the Brush Cap.

(3) After replacing the Brush, operate the unit for

about ten minutes with no load.

A-100E.indd 14 12.11.28 2:26:13 PM

15

5mm

Fig. 34

9 OPTIONAL PARTS

9-1. Nitto-Brand Cutting Oil

CAUTION

Use Nitto-brand Cutting Oil for Atra Ace.

Part No. Part Name

TB01507 Cutting Oil 2ℓ (Light Blue)

9-2. Chane Ass’y

Part No. Part Name

TA99027 Chane Ass’y

9-3. Cutter

Part No Part Name Part No Part Name

TJ17709 50x75L TJ16676 76x75L

TJ16651 51x75L TJ16677 77x75L

TJ16652 52x75L TJ16678 78x75L

TJ16653 53x75L TJ16679 79x75L

TJ16654 54x75L TJ16680 80x75L

TJ16655 55x75L TJ16681 81x75L

TJ16656 56x75L TJ16682 82x75L

TJ16657 57x75L TJ16683 83x75L

TJ16658 58x75L TJ16684 84x75L

TJ16659 59x75L TJ16685 85x75L

TJ16660 60x75L TJ16686 86x75L

TJ16661 61x75L TJ16687 87x75L

TJ16662 62x75L TJ16688 88x75L

TJ16663 63x75L TJ16689 89x75L

TJ16664 64x75L TJ16690 90x75L

TJ16665 65x75L TJ16691 91x75L

TJ16666 66x75L TJ16692 92x75L

TJ16667 67x75L TJ16693 93x75L

TJ16668 68x75L TJ16694 94x75L

TJ16669 69x75L TJ16695 95x75L

TJ16670 70x75L TJ16696 96x75L

TJ16671 71x75L TJ16697 97x75L

TJ16672 72x75L TJ16698 98x75L

TJ16673 73x75L TJ16699 99x75L

TJ16674 74x75L TJ16700 100x75L

TJ16675 75x75L

A-100E.indd 15 12.11.28 2:26:14 PM

16

1

2

3

4

5

6

7

8

9

9

10

11

12

13

14

15

16

88

89

90

91

87

17

18

19

20

21

14

22

23

24

25

26

27

28

29

30

31

32

37 38

39

39

73

40

41

42

43

44

45

46

86

47

35

48

49

54

55

50

51

52

35

51

51

53

56

54

51

57 58

59

56

35

61

63

35

64

65

66

67

68

68

69

70

71

72

74

75

76

77

78

79

80

81

82

83

84

84

85

82

13

92

93

94

95

96

97

98

60

33

133

35

134

36

62

10 Exploded Diagram: Machine

WARNING

This diagram is for reference only. Do not attempt service or repair the Nitto Portable Magnetic Drilling Machine. Do not take the machine apart. Contact an authorized

Nitto dealer for all service and repair of the machine. Improper service and repair can cause accidents and severe injuries. Never attempt to modify the machine. Never

attempt to service or repair the machine youself.

A-100E.indd 16 12.11.28 2:26:24 PM

17

No. Part No. Part Name Q'ty Price

1 TA9A686 Arbor Body Ass'y 1set

2 (TP17596) Arbor Body 1

3 (TP17597) Hex.Socket Set Screw 16x9 2

4 (TP16720) Spring 1.6x11x177 1

5 (TP16721) Pilot Spacer 1

6 (TP16722) Spacer 16x31.8x12 1

7 (TP07623) Internal Retaining Ring C-32 2

8 TA9A193 Oil Ring Ass'y 1set

9 (TP14499) Oil Seal GD38x48x4 2

10 (TP14964) Oil Ring 1

11 (LP10496) Hex.Nut M6 1

12 (TP05469) Hex.Socket Head Cap Screw

6x45 1

13 (TP14500) Hose Nipple 2

14 TP12773 Washer 38.5x54x1 2

15 TB00732 Bush 1

16 TP16725 Bracket 1

17 TB00564 Electric Drill Ass'y 1set

− (TA9A388) Brush Ass'y 1set

− (TB00953) Armature Ass'y 1set

18 TP15637 Hex.Head Bolt 16x40 1

19 TP15638 Spring Washer M16 1

20 TP00802 Washer M16 1

21 TP14969 External Retaining Ring

ISTW-38 1

22 TA9A527 Slide Board 1

23 TP05882 Hex.Socket Head Cap Screw

5x35 5

24 TP06141 Hex.Socket Set Screw 6x6 1

25 TP02862 Hex.Socket Head Cap Screw

5x15 6

26 TP08584 Hex.Nut M8 3

27 TP04531 Hex.Head Bolt 8x30 2

28 TP16284 Hex.Socket Head Cap Screw

8x45 2

29 TP02260 Hex.Socket Head Cap Screw

8x35 1

30 TP03261 Spring Pin 4x26 1

31 TP02575 Cap 1

32 TP02638 Pan Head Screw 4x12 4

33 TB09296 Lamp Holder Ass'y 1set

35 TP02618 Pan Head Screw 4x8 24

36 TP16737 Lamp Holder Plate 1

37 TP17636 Stopper Plate 1

38 TP01644 Hex.Socket Head Cap Screw

6x12 3

39 TP02936 Hex.Nut M5 7

No. Part No. Part Name Q'ty Price

40 TP00021 Hex.Socket Head Cap Screw

5x10 1

41 TP02937 Hex.Socket Set Screw With

Cup Point 5x20 6

42 TP02931 Set Screw 1

43 TP02578 Retaining Ring CE-22 1

44 TP02571 Pinion Shaft 1

45 TP09853 Spring Pin 5x34 1

46 TP02572 Handle Boss 1

47 TP16738 Spacer 4

48 TB09202 Spare Laod Detecting Device

Sub Ass'y 1set

49 TP00067 Hex.Head Nut M3 2

50 TP15957 Sensor Transformer 1

51 TP00056 Pan Head Screw 3x6 10

52 TP16740 Laod Detecting Device Board 1

53 TP16741 Holder 4

54 TP02639 Hex.Nut M4 5

55 TQ10920 Solid Relay G3NA220B DC5-24 1

56 TP16739 Transfomer 2H2403 1

57 TB01396 Print Board Ass'y 1set

58 TP14698 Cable Connector 2

59 TA97849 Cabtyre Cable Ass'y (1.25 3-core) 1set

60 TQ01511 Spacer 2

61 LP08489 Binding Head Screw 4X6 1

62 TB07298 Lamp Holder Ass'y 1set

63 TP12781 Knob MY-30 1

64 TQ00776 Switch Plate 1

65 TP12780 Rotary Switch 1

66 TP13813 Spring Pin 5x30 1

67 TB00006 Square Magnet Sub Ass'y 1set

68 TP00045 Hex.Socket Head Cap Screw

8x25 6

69 TP16717 Pole Plate 1

70 TP01460 Hex.Socket Head Cap Screw

8x20 4

71 TA94059 Stabilizier Ass'y 1set

72 TP16724 Dust Cover 1

73 TP04519 Hex.Socket Set Screw With

Dog Point 5x18 4

74 TB01180 Body Sub Ass'y 1set

75 TP13832 Slide Plate 2

76 TP16735 Rack 1

77 TP06526 Spur Gear B 1

78 TP02567 Gear Shaft 2

79 TP02570 Retaining Ring E-140 2

80 TP06525 Spur Gear A 1

No. Part No. Part Name Q'ty Price

81 TA99688 Oil Dropper Ass'y 1set

82 (TP15965) Tube 4X7X190 1

83 (TA9A390) Oil Dropper Sub Ass'y 1set

84 (TP15964) Tube 4X7X150 1

85 TP15156 Oil Ring Stopper 1

133 TQ13777 Spacer 16x20x4 1

134 TQ13776 Lamp Holder Cover 1

ACCESSORIES

No. Part No. Part Name Q'ty Price

86 TP00118 Feed Handle 3

87 TA9A207 Pilot 12075 Ass'y 1set

88 (TP06158) Hex. Screw 8x8 1

89 (TJ16748) Pilot 12075A 1

90 (TP16750) Spring 1x5.3x120 1

91 (TP16749) Pilot 12075B 1

− TA98903 Oil Cup Ass'y 1set

92 (CP21947) Seal Packing 1

93 (TP14495) Two-Port Cock 1

94 (TP11916) Cover 1

95 (TP15823) Oil Cleaner 1

96 (TA98909) Oil Cup Sub Ass'y 1set

97 (TP14497) Cup Holder 1

98 (TP16193) +Screw 5x15 1

TP13892 Hex. Socket Screw Key 2 1

TP04305 Hex. Socket Screw Key 2.5 1

TP04696 Hex. Socket Screw Key 3 1

TP01939 Hex. Socket Screw Key 4 1

TP04004 Hex. Socket Screw Key 5 1

TP00170 Hex. Socket Screw Key 6 1

TP03249 Hex. Socket Screw Key 8 1

TP14091 Spanner 7X8 1

TQ07167 Tool Box 285X140X70 1

TA99027 Safty Chain Ass'y 1set

TB02145 Soluble Cutting Oil 0.5 Ass'y 1set

TQ12569 Instruction Manual 1

The part numbers with ( ) are include in the Ass'y part

wrriten above them.

A-100E.indd 17 12.11.28 2:26:25 PM

A-100E.indd 18 12.11.28 2:26:26 PM

Printed in JAPAN

TQ12569-2

READ ALL INSTRUCTIONS BEFORE OPERATING THIS TOOL

ATRA ACE Model A-100

PROFESSIONAL TOOL

Overseas Affiliates / Offices

NITTO KOHKI U.S.A., INC.

46 Chancellor Drive, Roselle, IL 60172 U.S.A.

Tel: (1)-630-924-9393 Fax:(1)-630-924-0303

NITTO KOHKI EUROPE CO., LTD.

Unit 21, The Empire Centre Imperial Way,

Watford Herts, WD24 4TS, U.K.

Tel: (44)-1-923-239668 Fax:(44)-1-923-248815

NITTO KOHKI DEUTSCHLAND GMBH

Lerchenstr.47 D-71144 Steinenbronn, Germany

Tel: (49)-7-157-22436 Fax:(49)-7-157-22437

NITTO KOHKI CO., LTD., SINGAPORE BRANCH

10 UBI CRESCENT #01-62,

UBI TECHPARK LOBBY D, SINGAPORE 408564,

Tel: (65)-6227-5360 Fax:(65)-6227-0192

NITTO KOHKI CO., LTD.,

BANGKOK REPRESENTATIVE OFFICE

M&A Business Center 38Q. House Convent Bldg.,

7th Floor, Unit 7A, Convent Rd., Silom, Bangrak,

Bangkok 10500 Thailand

Tel: (66)-2-632-0307 Fax:(66)-2-632-0308

NITTO KOHKI AUSTRALIA PTY. LTD.

77 Brandl St., Brisbane Technology Park,

Eight Mile Plains QLD 4113 Australia

Tel: (61)-7-3340-4600 Fax:(61)-7-3340-4640

NITTO KOHKI (SHANGHAI) CO., LTD.

Room1506, suite C, Orient International Plaza,

NO85 LouShanGuan Road,Shanghai, 200336, CHINA

Tel: (86)-21-6415-3935 Fax:(86)-21-6472-6957

NITTO KOHKI CO., LTD.,

SHENZHEN REPRESENTATIVE OFFICE

Rm.#0726, 7F International Culture Bldg., 3039, Shennan

Zhong Rd., Futian District, Shenzhen, China Post Code:518033

Tel: (86)-755-8375-2185 Fax:(86)-755-8375-2187

A-100E.indd 19 12.11.28 2:26:26 PM

Table of contents

Other Nitto Drill manuals

Popular Drill manuals by other brands

Worx

Worx WXI 60 Safety and operating manual

Ingersoll-Rand

Ingersoll-Rand IR17JV Operation and maintenance

Cornwell Tools

Cornwell Tools CAT350HD operating instructions

Cleco

Cleco 5 Series Operation & service manual

Hitachi

Hitachi FDV16VB - 5/8" Reversible Hammer Drill Disassembly & reassembly procedures

Neilsen

Neilsen CT3142 manual