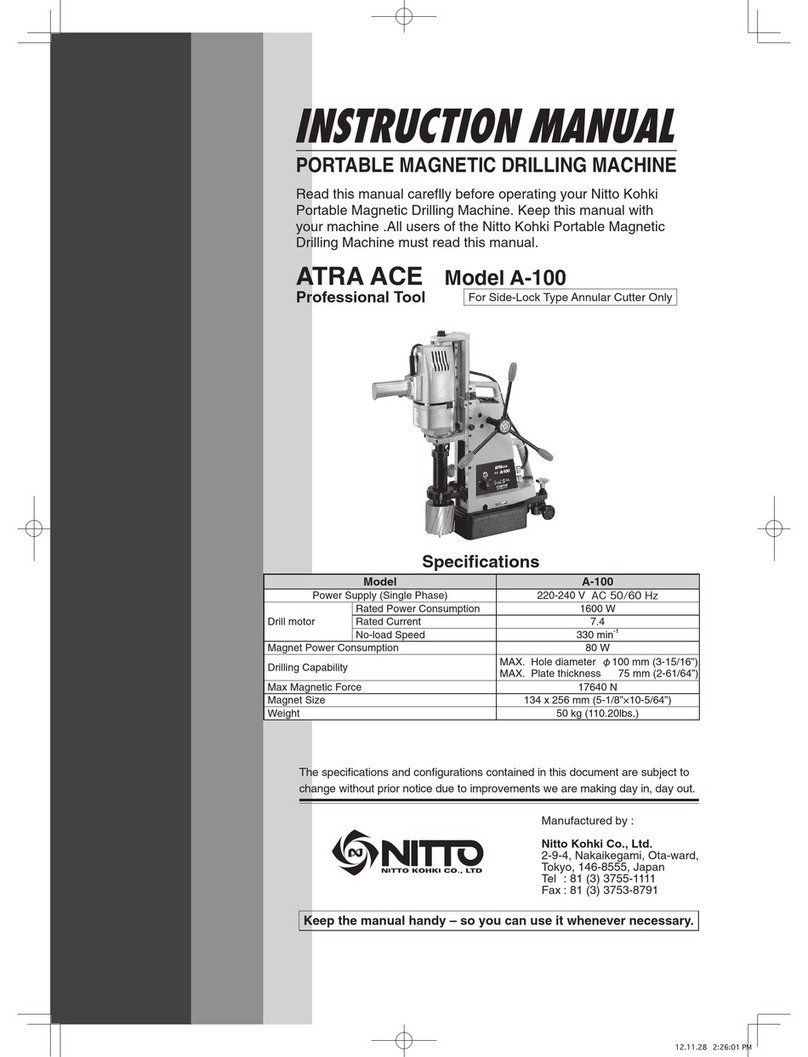

Nitto ATRA ACE CLA-2720 User manual

2

GENERAL SAFETY RULES

WARNING

TO OPERATORS

Always Wear Proper Clothing

●Do not wear loose clothing. Loose clothing can

become caught in the drilling machine. This could

cause severe injuries. Be careful that loose clothing

does not come into contact with the machine.

●Wear non-skid footwear. If you lose your footing,

you could contact moving portions of the machine.

This could cause severe injuries. Always wear non-

skid footwear and remain balanced when using the

drilling machine.

●Be careful of long hair. Wear a hat or a hair net to

contain long hair. Long hair can become caught in

the drilling machine. This will cause severe injuries.

Be careful that long hair does not come into contact

with the drilling machine.

Always Wear Suitable Eye Protection

●Always wear suitable eye protection. The operation

of your drilling machine will cause flying chips and

particles. These will cause severe eye injuries. You

must always wear suitable eye protection.

●Not all glasses are suitable eye protection. Wear

only suitable eye protection that comply with ANSI

standards. Not all of the lenses are shock resistant.

Ordinary glasses will not provide sufficient eye

protection.

Glasses only for visual correction are not appropriate

to be used as safety glasses.

Always Wear Suitable Hearing Protection

●Always wear suitable hearing protection. The

operation of your drilling machine will cause big sound

occurs. These will cause severe hearing loss injuries.

You must always wear suitable hearing protection.

Always Wear respiratory protective equipment (PPE)

●Always Wear respiratory protective equipment

(PPE) when working in an environment where dust

particles are generated in operation.

Maintain Good Posture

●Always wear non-skid footwear and maintain good

posture. Do not use the drilling machine when you

are tired. Fatigue or loss of balance could cause

you to lose control of the machine. This could cause

severe injuries. Always stay balanced. Always keep

good posture. Stop using the machine if you are tired.

Never Touch the Cutting Tip

●Never touch the moving or cutting tip. Contact with

the moving tip will cause severe injuries. Always

keep all parts of your body away from the cutting tip.

Always keep your hand and clothing away from the

cutting tip.

ABOUT THE WORK AREA

Keep Work Area Clean

●Always keep your work area clean. Cluttered work

areas cause accidents. Always keep clear of other

objects.

●Never use the magnetic drilling machine when it is

wet. Always use the drilling machine in a dry area.

Do not use the drilling machine in the rain. If you

use the machine when it is wet you can get electric

shock. If you use the machine in the rain you can

get an electric shock.

●Always use the drilling machine in a well-lighted

area. Do not use the drilling machine in the dark.

●Avoid all flammable materials. Use of the drilling

machine may cause a spark that could ignite a fire

or an explosion. Never use the machine near any

flammable material.

●Keep away from children. Always keep the drilling

machine away from children. Do not operate drilling

machine when children are present.

BEFORE OPERATION

Make sure that all parts are free from damage

●Make sure that the drilling machine is in good

operating condition. Operation of a damaged

machine could result in severe injuries. If there

is any damage to the machine, do not use the

machine. If there is any damage to the machine,

take it to an authorized Nitto dealer for repair.

●Do not attempt service or repair of the drilling

machine. All service or repair should be done by an

authorized Nitto dealer.

When a failure is observed with the switch, request

for repair to the sales agent where the product was

purchased or your nearest authorized Nitto dealer.

When a damage is observed with the power cord of

the battery charger, request for repair to the sales

agent where the product was purchased or your

nearest authorized Nitto dealer.

Do not use the machine that cannot be started or

stopped by the start switch.

Secure Your Work

●Always secure your work piece. Improperly mounted

work can become loose. This can cause severe

injuries. Always secure all work.

●Always use a vice or a clamp. Do not attempt to hold

any work piece with your hand. Attempting to hold a

work piece with your hand may cause severe injuries.

Always use a vice or clamp to hold the work piece.

●Always secure your drilling machine. Improperly

15.+/2+..]AJ?+050.]C,glbb0 /2,7,/.28.582.NK

3

mounted drilling machine can come loose. This can

cause severe injuries. Always secure the drilling

machine.

Avoid Clutter

●Always stay clear of other objects. Cluttered work

areas cause accidents. Always keep a clean work

area and stay away from other objects.

Always Remove Spanner Wrenches and

Adjustment Tools

●Always remove spanner wrenches and adjustment

tools after adjustments have been made to the

drilling machine. Always remove all adjustment tools

before using the drilling machine.

Always Use a Cutter that is Appropriate for Your

Work

●Always use a Cutter that is appropriate for your

work. Avoid heavy-duty work that is the beyond the

capacity of your drilling machine. If the work exceeds

the capacity of your drilling machine, this can cause

accidents and severe injuries. Always use the

drilling machine in accordance with its performance

specifications.

SAFE HANDLING

●Never leave the magnetic drilling machine

unattended while it is running. When the machine

is unattended, disconnect the power source. Do

not leave the work area until the machine comes to

a complete stop. Operating the machine while it is

unattended can case accidents that may result in

severe injuries.

●How to store the machine and battery pack.

Store the machine and battery pack at a dry area

under 50°C when not in use. Also, keep the machine

and battery pack out of the reach of children.

●Pay attention when carrying the machine.

Keep your hands away from the start switch when

carrying the machine.

Do not hold parts other than the handle to carry the

machine.

MAINTENANCE

Do not take apart or modify your magnetic drilling

machine.

●Do not attempt to disassemble or modify your

magnetic drilling machine.

●Do not modify your magnetic drilling machine.

Modifications can cause accident and severe

injuries.

●All service and repairs must be performed by an

authorized Nitto dealer. Any attempt to service or

repair the machine yourself may result in an accident

and severe injuries.

Check all Parts for Damage.

●Always inspect the magnetic drilling machine before

use.

●Always check that the pilot pin and cutter are in

good condition. Use of the machine with worn pilot

pins or worn cutter can cause accidents and severe

injuries.

●Inspect all cutter before you put them on the

magnetic drilling machine.

●Do not operate the magnetic drilling machine with a

damaged or worn cutter. Do not operate the machine

with a damaged or worn pilot pin. Do not operate the

machine with any damaged accessory. Operating

the machine with any damaged part or accessory

can cause accidents and severe injuries. If there is

any damage to the magnetic drilling machine do not

operate the machine. Take it to an authorized Nitto

Dealer for repair.

●Always have the magnetic drilling machine repaired

at an authorized Nitto dealer. Always take the

magnetic drilling machine to an authorized Nitto

dealer for service, repair and replacement parts. If

you cannot locate an authorized Nitto dealer near

you, please contact your sales representative.

●Always use Nitto genuine parts. The use of improper

or non-Nitto parts can cause accidents and severe

injuries. Never use unauthorized parts. To obtain

genuine Nitto parts, contact your sales agent.

●Do not remove any nameplate from your magnetic

drilling machine. Do not remove any labels from

your magnetic drilling machine. If any label or

nameplate is damaged contact your sales agent for

a replacement.

●When a damage is observed with the power cord of

the battery charger, request for replacement at your

nearest authorized Nitto dealer to avoid accidents.

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

●Read all safety warnings and all instructions. Failure

to follow the warnings and instructions may result in

fire and serious injury.

●Save all warnings and instructions for future

reference.

●The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-

operated (cordless) power tool.

<Work area safety>

●Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

●Do not operate power tools in explosive

15.+/2+..]AJ?+050.]C,glbb1 /2,7,/.28.582.NK

4

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

●Keep children and bystanders away while

operating a power tool. Distractions can cause you

to lose control.

<Electric safety>

●Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

●Do not expose power tools to rain or wet

conditions. Water entering a power tool will increase

the risk of electric shock.

<Personal safety>

●Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

●Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will

reduce personal injuries.

●Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to battery

pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch or

energizing power tools that have the switch on

invites accidents.

●Remove any adjusting wrench before turning the

power tool on. A wrench left attached to a rotating

part of the power tool may result in personal injury.

●Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

●Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

<Power tool use and care>

●Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it was designed.

●Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

●Disconnect the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

●Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

●Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tool’s operation. If damaged, have the power tool

repaired before use. Many accidents are caused

by poorly maintained power tools.

●Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

●Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for operations

different from those intended could result in a

hazardous situation.

<Battery tool use and care>

●Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used

with another battery pack.

●Use power tools only with specifically designated

battery packs. Use of any other battery packs may

create a risk of injury and fire.

●When battery pack is not in use, keep it away

from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects,

that can make a connection from one terminal

to another. Shorting the battery terminals together

may cause burns or a fire.

●Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact

accidentally occurs, flush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation or

burns.

<Service>

●Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

●Hold power tool by insulated gripping surface,

15.+/2+..]AJ?+050.]C,glbb2 /2,7,/.28.582.NK

5

when performing an operation where the cutting

accessory may contact hidden wiring. Cutting

accessory contacting a “live” wire may make

exposed metal parts of the power tool “live” and

could give the operator an electric shock.

Drill safety warnings

- Wear ear protectors when impact drilling.

Exposure to noise can cause hearing loss.

- Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal injury.

GENERAL SAFETY RULES FOR

CORDLESS MACHINE

WARNING

●Do not use the battery pack other than for the

cordless machine of Nitto.

Use the battery charger and battery pack specified

by Nitto described in the instruction manual and

catalog. Use of a battery pack not specified by Nitto

may cause machine failure, injury or damage.

●Do not use deteriorated battery pack.

Use of deteriorated battery pack may cause liquid

leak, heat generation or explosion of the battery.

●Use proper method for charging.

Use a power source appropriate for the rated

voltage of the battery charger. Do not use power

source of direct current or engine generator. It may

cause failure or fire.

Do not charge the battery pack when the

temperature is less than 0°C or over 40°C. It may

cause explosion or fire.

Charge the battery pack at a well-ventilated area.

Do not cover the battery pack or battery charger with

a cloth, etc. It may cause explosion, smoke or fire.

When not in use, unplug the power supply plug of

the battery charger from the electric outlet. Leaving

the machine plugged may cause electric shock,

smoke or fire.

●Do not use or charge at an area where there is

flammable liquid or gas.

It may cause smoke, ignition or explosion.

●Do not use or charge in rain or at damp or wet

areas.

It may cause electric shock or smoke.

●Do not short circuit between terminals of the

battery pack.

Short circuit by water, cutting chips and other

conductive materials may cause smoke, ignition or

explosion.

●Be careful of electric shock.

Do not touch the power supply plug, terminals or

their peripheral areas of the battery pack and battery

charger with wet hands. It may cause electric shock.

●Turn the switch of the machine off and disconnect

the battery pack from the machine in cases

described below.

When not in use or when repairing.

When replacing accessories such as a drill.

When work is finished and storing the machine.

When other dangerous situation is assumed.

●Avoid abrupt starting.

Check that the switch is turned off before attaching

the battery pack. Do not touch the arbor or drill when

attaching the battery pack.

●Use specified accessories and attachments.

Use specified accessories and attachments

described in this instruction manual and Nitto

catalog. Use of other accessories and attachments

may cause an accident or injury.

●Do not place the battery pack in fire.

It may cause ignition or explosion.

●If the liquid of the battery pack leaks and gets into

your eyes, do not rub your eyes but immediately

wash your eyes with plenty of clean water such

as tap water and consult with a medical doctor.

●If the liquid of the battery pack leaks and comes

into contact with your skin or clothing,

immediately wash with plenty of clean water and

consult with a medical doctor since it may cause

skin infection or injury.

●Pay attention that the battery pack is clean from

chips and dust.

Prevent chips to fall on the battery pack when

working.

Do not leave the battery pack where chips or dust

accumulate when the battery pack is not in use.

Clean off chips and dust when storing the battery

pack and store it separately from metal parts.

Do not stick a nail or apply strong impact to the

battery pack.

●Do not apply heat or high pressure to the battery

pack by putting it in a microwave or in a

pressurized container.

●Immediately move the battery pack away from fire

when any leaking or smell is identified.

●Do not use the battery pack for other devices.

●Stop charging the battery pack when charging is

not completed even after the specified charging

time is significantly exceeded.

●Do not use the battery pack that has external

damage or significant deformation.

●Do not use at areas where strong static electricity

is generated.

15.+/2+..]AJ?+050.]C,glbb3 /2,7,/.28.582/NK

8

●Do not discard the battery pack with normal

garbage or place in fire.

●Keep the battery pack out of the reach of children.

●Use the battery pack properly following the

indicated specifications.

WARNING

This machine is not water proof.

Use the machine following the description below.

●Immediately wipe the electric drill or the machine

when any liquid such as cutting fluid or water is

applied.

●Do not operate with wet hand.

●Do not use in rain.

CAUTION

●Do not force feed the cutter while driling

manually.

Jetbroach and Hi-Broach cutters use a reduced wall

thickness to minimize cutting resistance, resulting in

faster hole productivity and less shavings. Pressure

required to feed a Jetbroach or Hi-Broach cutter

is far less than that of a twist drill bit; if too much

pressure is applied to the cutter, life and or breakage

may result.

●The color of LED changes according to the load

of the electric drill. Use it with LED in green or

yellow.

LED turns green or yellow when the load of the

electric drill is in normal condition and turns or blinks

in red when it is in overload condition. Decrease

the feeding rate of the drill when LED is turned or

blinking in red since the electric drill is in overload

condition and obtain a load with LED in green or

yellow when drilling.

●The power of the electric drill drops when

excessive load is applied to the electric drill

and LED starts blinking rapidly in red. When

load is applied continuously, the machine will

automatically stop and LED will start blinking in

white.

When further load is applied to the electric drill even

when LED is turned or blinking in red, the power

of the electric drill drops to protect the electric drill

and battery pack. The electric drill returns to normal

operation when the load is decreased before it stops

automatically due to overload. If the electric drill

stops automatically, turn the switch off and then turn

the switch back on to continue the operation.

●Store the machine by keeping the electric drill at

lowered position when not in use.

The machine may fall when stored with the electric

drill at a lifted position.

●When energized, the magnet may exhibit a

buzzing sound or a slight hum.

15.+/2+..]AJ?+050.]C,glbb6 /2,7,/.28.68/5NK

9

1 USAGE

This is a machine tool which attaches magnetically to mild steel and uses the power of Drill Motor to drill holes

with JETBROACH One-touch type or HI-BROACH One-touch Type.

2 CHECK THE CONTENTS OF THE PACKAGEKAGE

Check the contents and make sure that the tool is not damaged due to an accident during the transportation, if any.

The contents should correspond to the list as follows. Just in case there are some damaged or missing parts, contact

the sales agent from whom you purchased the tool or an authorized dealer.

THE CONTENTS OF THE PACKAGE AND ACCESSORIES

CLA-2720

Package Contents Q'ty check

ATRA ACE 1set

Hex. Socket Screw Key 3 1

Hex. Socket Screw Key 4 1

Spanner 8×10 1

Battery Charger 1set

Battery Pack 2set

TUBE 4×7 1

Package Contents Q'ty check

Cutting Oil 0.5ℓCan 1

Handle Assʼy1

Lashing belt 1

Jet Oiler (No.3013) 1

Instruction Manual 1

Guard 1

Hex. Socket Set Screw 8×28 1

Hex. Socket Head Cap Screw 5×12 1

Blade 1

Jet Oiler (No.3013) Lashing belt Guard

(Fig. 6) (Fig. 7) (Fig.8)

3 NAME OF PARTS

LED

Magnet switch

Lock screw

Blade Hex. Socket Head Cap Screw 5x12

Universal elbow

Motor cover

Battery pack

Battery cover

Electric drill switch

Belt attachment plate

Sleeve

Plug cushion rubber

Handle Ass’y

(Fig. 9)

15.+/2+..]AJ?+050.]C,glbb7 /2,7,/.28.681.NK

12

6-2 Cutter Usage

CAUTION

●Cutters other than one-touch type can not be used.

●For better working and greater safety, do not use

worn or broken cutters.

●When you need one-ouch type cutters or

accessories, refer to 10. Ordering Service Parts.

6-3 Cutter and Pilot Pin Combinations

WARNING

You must use a Pilot Pin which matches the cutter.

Pilot Pins differ according to cutter type, diameter, and

length (depth). An accident may be caused if the cutter

and Pilot Pin combination is wrong.

6 PREPARATIONS

WARNING

●Turn the magnet switch off and detach the battery pack from the machine when preparing.

6-1 Attaching handle Ass’y

<Attachment and detachment of handle Ass’y >

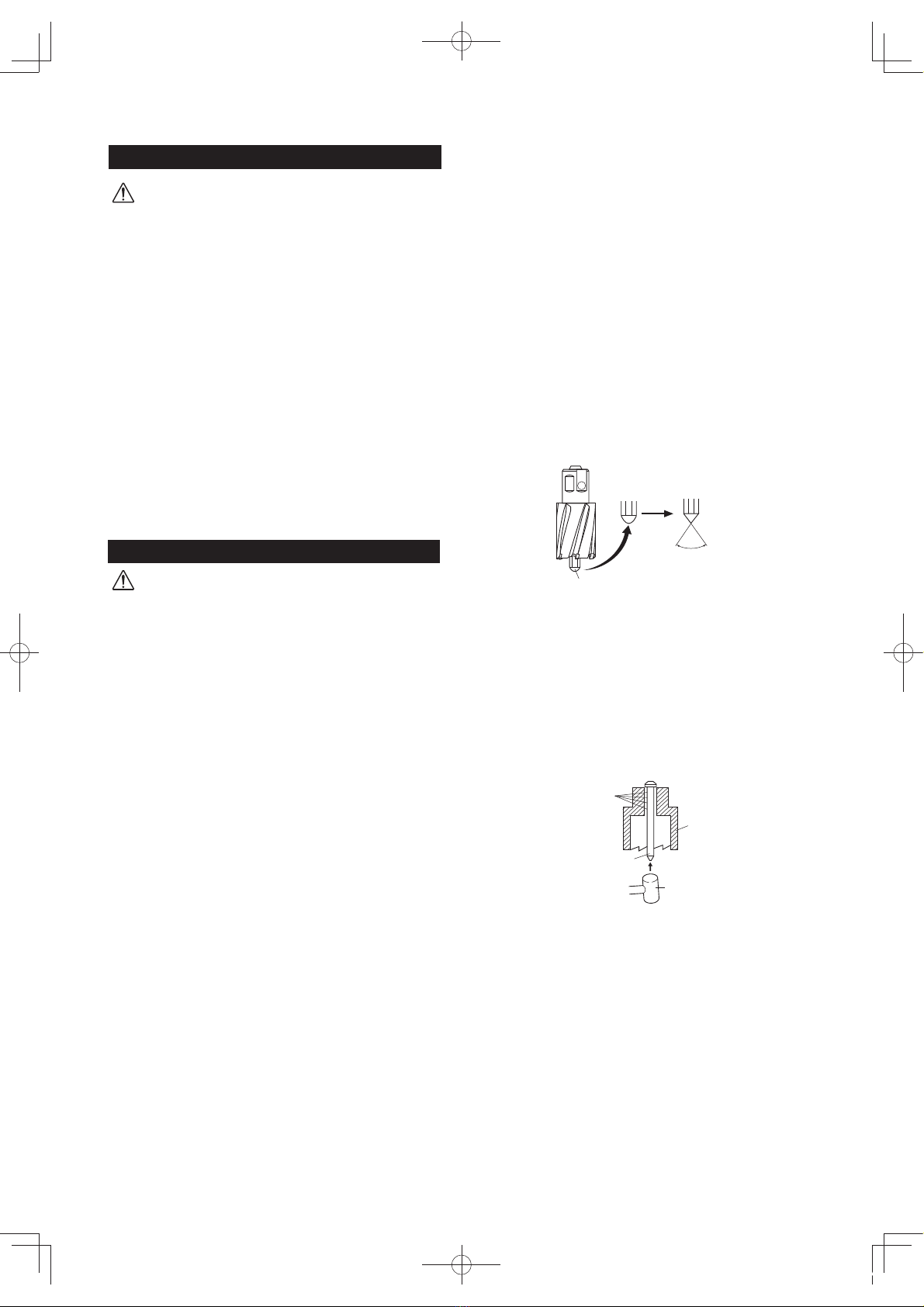

1. How to attach the handle Ass’y

- Insert the sleeve of the handle Ass’y in the pinion shaft while the sleeve is pulled toward the handle. (Fig. 13)

- After it is attached, check that the handle Ass’y will not be detached before use.

* The handleAss’y can be attached on either right or left of the machine. (Fig. 14)

* When the handle Ass’y interferes with the lock screw, attach the lock screw on the opposite side of the handle

Ass’y. Refer to 7-2-(3) Aligning with Punch Mark for attaching the lock screw.

2. How to detach the handle Ass’y

- The handleAss’y can be detached by pulling the sleeve of the handle Ass’y toward the handle.

Pinion Shaft

Sleeve

Lock screw

Handle Ass’y

(Fig. 13) (Fig. 14)

●Match the appropriate Pilot Pin to the cutter which is

to be used. (Fig. 15)

HBO 12 to 17mm dia.

Depth 25 mm

HBO

17.5 to 27mm

dia.

Depth 25 mm

06025 PN : TK01167

08025 PN : TJ12696

Pilot Pin HI-BROACH Cutters

81 mm

5 dia.

8 dia.

76 mm

6.35 dia.

08035 PN : TJ15859 JBO

17.5 to 27mm

dia.

Depth 35 mm

91 mm

8 dia.

Pilot Pin JETBROACH Cutters

6.35 dia.

JBO 12 to 17mm dia.

Depth 25 mm

06025 PN : TK01167

81 mm

5 dia.

(Fig. 15)

●Pilot Pins differ according to the type, diameter and

length (depth) of the cutter. If the cutter and Pilot Pin

combination is wrong, the cutter will be damaged due

to failure to eject the slag (metal chip) or poor Cutting

Oil supply.

15.+/2+..]AJ?+050.]C,glbb/0 /2,7,/.28.682.NK

14

・May cause inflammation if it enters the eyes.

Protective eye-wear should be used when handling to

prevent entry into the eyes.

・Skin contact may cause inflammation. Protective

gloves should be worn when handling to prevent

contact with the skin.

・May cause discomfort if mist or vapor is inhaled.

Breathing apparatus should be used when handling so

that mist or vapor should not be inhaled.

・Dilution should be carried out in accordance with the

Instruction Manuals.

・Keep it out of reach of children.

・Do not drink it.

(3) Emergency Treatment

・If it has entered eyes, immediately open the eyelids as

wide as possible and wash thoroughly with water for

at least 15 minutes. If there is inflammation, consult a

physician and follow the instructions.

・If it has contacted the skin, wash immediately with

soap and water. Soiled clothing should be removed

and laundered thoroughly before re-use. If there is

inflammation, consult a physician and follow the

instructions.

・If mist or vapor has been inhaled, immediately transfer

the patient to fresh air, cover his/her body with a

blanket and keep warm and quiet. Consult a physician

and follow the instructions.

・If it has been ingested, immediately give copious water

and induce vomiting. Consult a physician and follow

the instructions. If the patient is unconscious, do not

administer water or induce vomiting.

(4) In Case of Fire

・For a fire in the vicinity, wear protective equipment and

extinguish the fire approaching from the windward side

with foam, powder or CO2fire extinguishers.

(5) Method of Storage

・Seal after use to prevent admixture with dirt and/or

water.

・Store in a cool dark place away from direct sunlight

and rain.

(6) Method of Disposal

・Disposal of undiluted and diluted fluid should be

handled as waste fluid in accordance with the law by

a waste disposal specialist.

・Wash water should be treated by pH adjustment,

flocculation and settling, activated sludge treatment,

activated carbon absorption, etc., and discharged in

accordance with municipal standards.

・Since empty containers contain dregs, they should be

handled with care.

(7) Other

・If transferred to other containers for use, the names

of chemicals used in the workplace and the labeled

contents should be displayed and kept together with

the Instruction Manuals ready for immediate perusal.

・Anyone wishing to have further details may request

product safety data sheets from manufacturer.

・The inscribed details are based on currently available

information and data and updated by new knowledge.

・Items to be noted are aimed at normal handling.

Where special handling is involved, safety measures

appropriate to the application and method of handling

should be implemented.

・The inscribed details are submitted for your information

and do not imply assurances or acceptance of

responsibility.

CAUTION

(1) Use Nitto genuine blue Cutting Oil.

Cutting performance and life may be reduced when other

Cutting Oils are used.

(2) Dilute the Cutting Oil in the proportion of eight to ten

times with tap water.

Do not use well water for dilution.

(3) Put the cutting oil in the supplied jet oiler and connect

to the universal elbow of the machine using a tube of 4 ×

7 × 1000. (Fig. 21)

Jet Oiler

Tube

(Fig. 21)

Universal elbow

Tube

15.+/2+..]AJ?+050.]C,glbb/2 /2,7,/.28.6831NK

19

8 TROUBLESHOOTING

WARNING

●Do not attempt to repair the tool by yourself.

This will cause damage to the tool and danger to

yourself when you use it again.

●If any of the following, or other symptoms occur,

or if there are other matters concerning usage

that you do not understand, please consult the

sales agent from whom you purchased the tool or

an authorized dealer.

Various errors are indicated by LED with this

machine in which the contents of error can be

identified by the color of LED.

Refer to “4-4 Various Safety Functions and

Error Detection Functions” for details including

countermeasures for various errors.

9 MAINTENANCE AND INSPECTION

WARNING

●When performing maintenance or inspection work,

turn the magnet switch off and remove the battery

pack from the machine. Furthermore, unplug the

power supply plug of the charger from the electric

outlet.

●Periodically check for looseness of screws

fastened at each part. Tighten the screw if it is

loose.

●After work, store at a dry area where the

temperature is less than 50°C and is out of reach

of children.

●After work, do not store at an area where volatile

that has possibility of ignition or explosion is kept.

●Do not put conductive items such as chips, nails

and copper wires in the storage case.

●Attach a terminal cover to the battery pack when

storing.

9-1 Greasing of sliding surfaces

From time to time, the sliding surfaces between the

body and the Slide Board should be greased.

9-2 Loose Slide Board adjustment

●When adjusting looseness of the slide board,

check that the slide board is located at the slide

board adjustment screw position before

tightening.

Any looseness between the body and the Slide

Board will adversely affect drilling precision, leading

to premature wear on the cutter. When looseness is

encountered, eliminate it by uniformly re-tightening

the four Slide Board adjustment screws on the

lateral side of the body to the extent that the Drill

Motor will not fall under its dead weight. The screws

are designed to work as a double-lock, so they

should be securely tightened by turning the nuts.

9-3 Sharpening of Pilot Pin tip

If the Pilot Pin tip is dull, the pin will not be able to fit

itself into the punching hole, causing poor drilling

precision. It should be inspected from time to time,

and , if the Pilot Pin tip is found to be dull, sharpen the

tip or replace with a new one. Exercise caution during

the sharpening operation as any rough grinding

softens the tip due to annealing, even to the point of

disabling it in some cases. (Fig. 34)

Pilot Pin

Sharpen

the tip

Optimal angle 70°

(Fig. 34)

9-4 Loosen a tight Pilot Pin

When the cutter needs to be replaced, pull out and

change the Pilot Pin which acts as a guide. However, if

Metal chips are caught between the cutter and the pin,

the pin may be difficult to be pulled out. Tap the end of

the pin gently with a wooden mallet as you pull it out.

(Fig. 35)

Pilot Pin

Cutter

Metal chips

Wooden mallet

(Fig. 35)

9-5 Cutter grinding

When the cutter needs re-grinding, consult the sales

agent from whom you purchased the tool or an authorized

dealer.

9-6 Inspection and Replacement of Carbon Brush

Periodically inspect the abrasion condition of the

carbon brush.

Replace the carbon brush with a new carbon brush

when the remaining length of the carbon brush is 8 to

9 mm since the rectification will deteriorate and may

cause machine failure when left unreplaced. (Fig. 36)

15.+/2+..]AJ?+050.]C,glbb/7 /2,7,/.28//8.7NK

Table of contents

Other Nitto Drill manuals