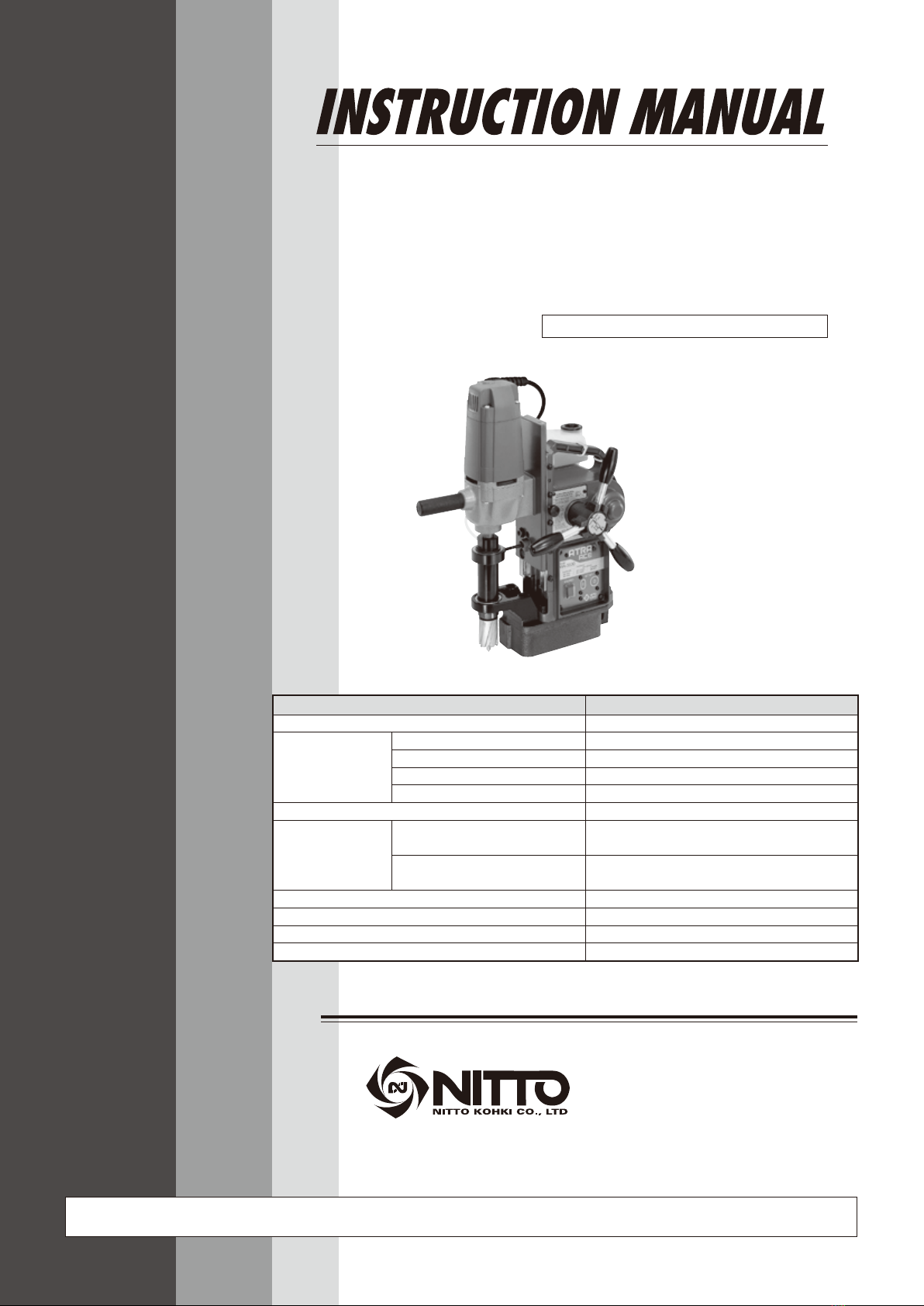

Nitto ATRA ACE WA-3500 User manual

ehT specifications and configurations contained in this document are subject to

change without prior notice due to improvements we are making day in, day out.

Manufactured by :

NITTO KOHKI Co., Ltd.

2-9-4, Nakaikegami, Ohta-ku,

Tokyo, 146-8555, Japan

Tel : (81)-3-3755-1111

Fax : (81)-3-3753-8791

E-mail : overseas@nitto-kohki.co.jp

URL : www.nitto-kohki.co.jp

Keep the manual handy – so you can use it whenever necessary.

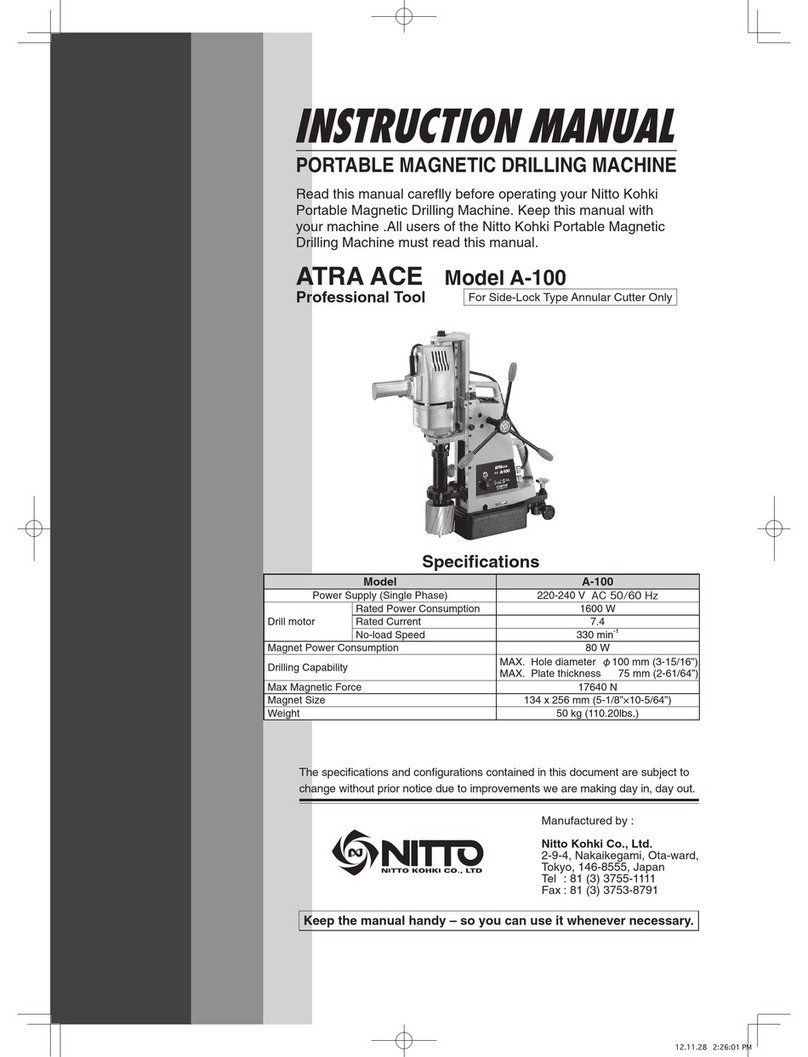

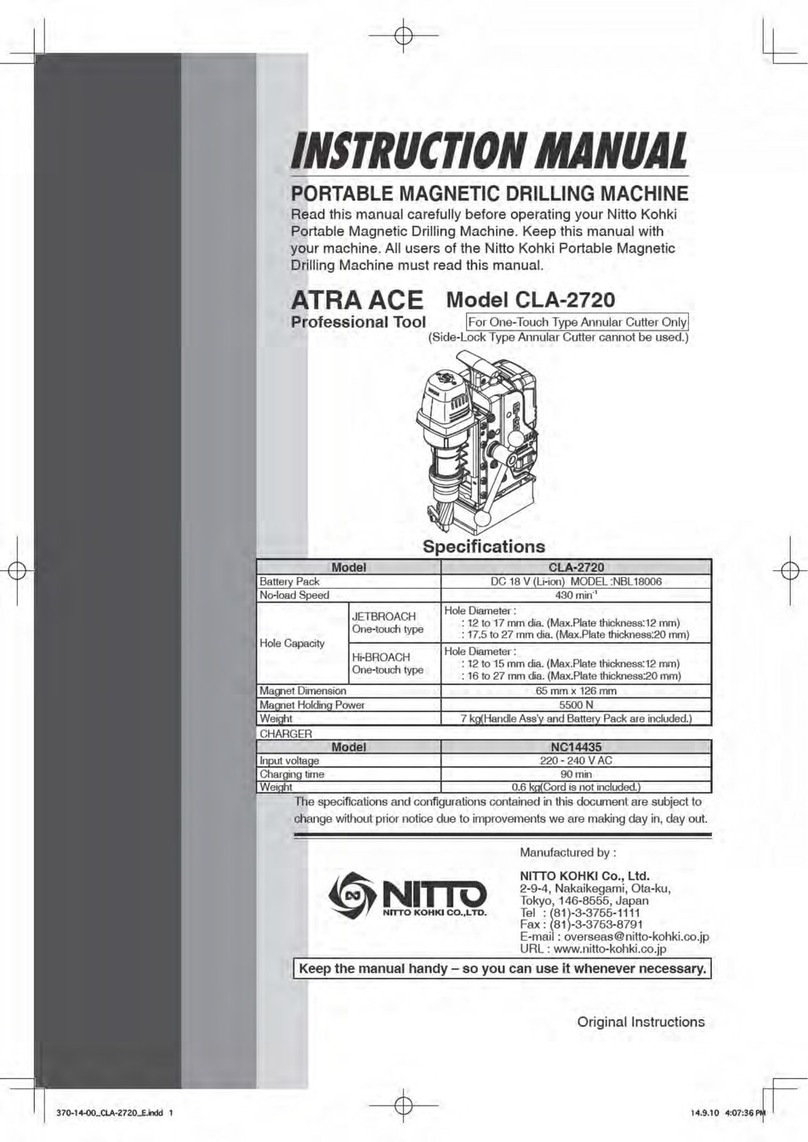

PORTABLE MAGNETIC DRILLING MACHINE

Read this manual carefully before operating your Nitto Kohki

Portable Magnetic Drilling Machine. Keep this manual with

your machine. All users of the Nitto Kohki Portable Magnetic

Drilling Machine must read this manual.

ATRA ACE Model WA-3500

Professional Tool For One-Touch Type Annular Cutter Only

(Side-Lock Type Annular Cutter cannot be used.)

Specifications

Model WA-3500

Power Supply (Single Phase) 220-240 V 〜50/60 Hz

Drill Motor

Rated Power Consumption 1100 W

Rated Current 5.1 A

No-load Speed 950 min-1

Load Speed 580 min-1

Magnet Power Consumption 34 W

Hole Capacity

JETBROACH One-touch type φ17.5 〜φ 35mm

Plate thickness 35mm(50mm)

HI-BROACH One-touch type φ14 〜φ 35mm

Plate thickness 25mm(50mm)

Magnet Holding Power 7,056N

Magnet Dimensions 92mm ×213mm

Weight 20kg

Short-Circuit Current Rating 5kA

Original Instructions

TQ12846-6

1

Thank you very much for your purchase of Nitto

Kohki product.

Before using your machine, please read this

manual carefully so that you may use it properly

to get the most out of it.

Please keep the manual handy - so you can

use it whenever necessary.

・English :Please ask your dealer or

distributor for instruction manual

in local language(s).

・German :Bitte fragen Sie lhren Händler

nach eine Betriebsanleitung in

Landessprache.

・French :S'il vous plait, veuillez demandez

á votre foumisseur de manuel

instruction en langue locale.

・Spanish :Por favor, cantacte con su

distribuidor para el manual de

instrucciones en español.

・Portuguese :Por favor pessa ao seo agente

ou distribuidor o manual de

instrucces ih linguagen local.

・Italian :Per Manuale lstruzioni in lingua

locale Vi preghiamo di rivolgervi

al rivenditore o distributore.

・Dutch :Vraag uw handelaar

om een nederladstalige

gebruiksaanwijzing.

・Swedish :Be er lokala Åtreförsäljare eller

distributör om manualer pá

svenska.

・Danish :Venligst henvend Dem til den

danske distributør for instructions

manualer.

・Polish :Prosze pytac swojego dealera

lub dystrybutora o instrukcje

obslugi w jezyku localnym.

・中文 :

CONTENTS

GENERAL SAFETY RULES ………………………………… 2

POWER TOOL SAFETY……………………………………… 3

ABOUT YOUR NITTO PORTABLE MAGNETIC

DRILLING MACHINE ………………………………………… 4

1. APPLICATION …………………………………………… 7

2. RECEIVING INSPECTION ……………………………… 7

3. PART NAME ……………………………………………… 8

4. FUNCTIONS OF ELECTRONIC CONTROL ………… 9

5. MACHINE SETUP ……………………………………… 9

6. MACHINE OPERATION ……………………………… 11

7. TROUBLESHOOTING………………………………… 14

8. MAINTENANCE/SERVICE…………………………… 15

9. OPTIONAL PARTS …………………………………… 16

PICTOGRAM

・Sound Pressure Level :Maximum 85dB(A) according

to Clause 1.7.4(f), Annex I,

Machinery Directive.

・Sound Power Level :Maximum 98dB(A)

・Operating Temperature :5˚C 〜40˚C

・Operating Humidity :Maximum 90% at 25˚C

・Over-voltage Category :Category Ⅱaccording to

IEC664-1

・Pollution Degree :Degree 3 according to IEC664-1

・Wiring Diagram No. :TZW0055

The following Safety notations are used throughout the manual to highlight safety precautions for the user and for the machine.

DANGER: Indicates an imminently hazardous situation which, if not avoided by following the

instructions given, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided by following the

instructions given, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided by following the

instructions given, could result in injury or material damage.

Caution: Important precautions for machine or tool setup, operation and maintenance.

2

WARNING

Some dust created by power sanding, sawing,

grinding, drilling and other construction activities

contains chemicals known [to the State of California]

to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are;

・Lead from lead-based paints.

・

Crystalline silica from bricks and cement and

other masonry products.

・

Arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals; work in a well ventilated

area, and work within approved safety equipment,

such as those dust masks that are specially designed

to filter out microscopic particles.

GENERAL SAFETY RULES

TO OPERATORS

Always Wear Proper Clothing

●Do not wear loose clothing. Loose clothing can

become caught in the drilling machine. This could

cause severe injuries. Be careful that loose clothing

does not come into contact with the machine.

●Wear non-skid footwear. If you lose your footing,

you could contact moving portions of the machine.

This could cause severe injuries. Always wear non-

skid footwear and remain balanced when using the

drilling machine.

●Be careful of long hair. Wear a hat or a hair net to

contain long hair. Long hair can become caught in

the drilling machine. This will cause severe injuries.

Be careful that long hair does not come into contact

with the drilling machine.

Always Wear Suitable eyeprotection

●Always wear Suitable eyeprotection. The operation

of your drilling machine will cause flying chips and

particles. These will cause severe eye injuries. You

must always wear Suitable eyeprotection.

●Not all glasses are Suitable eyeprotection. Wear

only Suitable eyeprotection that comply with ANSI

standards. Not all of the lenses are shock resistant.

Ordinary glasses will not provide sufficient eye

protection.

Always Wear Suitable Hearing Protection

●Always wear Suitable hearing protection. The

operation of your drilling machine will cause big sound

occurs. These will cause severe hearing loss injuries.

You must always wear Suitable hearing protection.

Wear respiratory protective equipment (PPE)

●Wear respiratory protective equipment (PPE) when

working in an environment where dust particles are

generated in operation.

Maintain Good Posture

●Always wear non-skid footwear and maintain good

posture. Do not use the drilling machine when you

are tired. Fatigue or loss of balance could cause

you to lose control of the machine. This could cause

severe injuries. Always stay balanced. Always keep

good posture. Stop using the machine if you are

tired.

Never Touch the Cutting Tip

●Never touch the moving or cutting tip. Contact with

the moving tip will cause severe injuries. Always

keep all parts of your body away from the cutting tip.

Always keep your hand and clothing away from the

cutting tip.

ABOUT THE WORK AREA

Keep Work Area Clean

●Always keep your work area clean. Cluttered work

areas cause accidents. Always keep clear of other

objects.

●Never use the magnetic drilling machine when it is

wet. Always use the drilling machine in a dry area.

Do not use the drilling machine in the rain. If you

use the machine when it is wet you can get electric

shock. If you use the machine in the rain you can

get an electric shock.

●Always use the drilling machine in a well-lighted

area. Do not use the drilling machine in the dark.

●Avoid all flammable materials. Use of the drilling

machine may cause a spark that could ignite a fire

or an explosion. Never use the machine near any

flammable material.

●Keep away from children. Always keep the drilling

machine away from children. Do not operate drilling

machine when children are present.

BEFORE OPERATION

Make sure that all parts are free from damage

● Make sure that the drilling machine is in good

operating condition. Operation of a damaged

machine could result in severe injuries. If there

is any damage to the machine, do not use the

machine. If there is any damage to the machine,

take it to an authorized Nitto dealer for repair.

● Do not attempt service or repair of the drilling

machine. All service or repair should be done by an

authorized Nitto dealer.

Secure Your Work

● Always secure your work piece. Improperly mounted

3

work can become loose. This can cause severe

injuries. Always secure all work.

●Always use a vice or a clamp. Do not attempt to

hold any work piece with your hand. Attempting to

hold a work piece with your hand may cause severe

injuries. Always use a vice or clamp to hold the work

piece.

●Always secure your drilling machine. Improperly

mounted drilling machine can come loose. This can

cause severe injuries. Always secure the drilling

machine.

Avoid Clutter

●Always stay clear of other objects. Cluttered work

areas cause accidents. Always keep a clean work

area and stay away from other objects.

Always Remove S panner W renches and

Adjustment Tools

●Always remove spanner wrenches and adjustment

tools after adjustments have been made to the

drilling machine. Always remove all adjustment tools

before using the drilling machine.

Always Use a Cutter that is Appropriate for Your

Work

●Always use a cutter that is appropriate for your

work. Avoid heavy-duty work that is the beyond the

capacity of your drilling machine. If the work exceeds

the capacity of your drilling machine, this can cause

accidents and severe injuries. Always use the

drilling machine in accordance with its performance

specifications.

SAFE HANDLING

●Never leave the magnetic drilling machine

unattended while it is running. When the machine

is unattended, disconnect the power source. Do

not leave the work area until the machine comes to

a complete stop. Operating the machine while it is

unattended can case accidents that may result in

severe injuries.

HOW TO STORE YOUR MAGNETIC DRILLING

MACHINE

●Always store the machine in a dry area.

●Always keep the machine out of the reach of

children.

HOW TO CARRY YOUR MAGNETIC DRILLING

MACHINE

●Disconnect the power and turn off the machine

whenever you carry the machine.

MAINTENANCE

Do not take apart or modify your magnetic drilling

machine.

●Do not attempt to disassemble or modify your

magnetic drilling machine.

●Do not modify your magnetic drilling machine.

Modifications can cause accident and severe

injuries.

●All service and repairs must be performed by an

authorized Nitto dealer. Any attempt to service or

repair the machine yourself may result in an accident

and severe injuries.

Check all Parts for Damage.

●Always inspect the magnetic drilling machine before

use.

●Always check that the pilot pin and cutter are in

good condition. Use of the machine with worn pilot

pins or worn cutter can cause accidents and severe

injuries.

●Inspect all cutter before you put them on the

magnetic drilling machine.

●Do not operate the magnetic drilling machine with a

damaged or worn cutter. Do not operate the machine

with a damaged or worn pilot pin. Do not operate the

machine with any damaged accessory. Operating

the machine with any damaged part or accessory

can cause accidents and severe injuries. If there is

any damage to the magnetic drilling machine do not

operate the machine. Take it to an authorized Nitto

Dealer for repair.

●Always have the magnetic drilling machine repaired

at an authorized Nitto dealer. Always take the

magnetic drilling machine to an authorized Nitto

dealer for service, repair and replacement parts. If

you cannot locate an authorized Nitto dealer near

you, please contact your sales representative.

●Always use Nitto genuine parts. The use of improper

or non-Nitto parts can cause accidents and severe

injuries. Never use unauthorized parts. To obtain

genuine Nitto parts, contact your sales agent.

●Do not remove any nameplate from your magnetic

drilling machine. Do not remove any labels from

your magnetic drilling machine. If any label or

nameplate is damaged contact your sales agent for

a replacement.

POWER TOOL SAFETY

WARNING

● Always make sure that the machine is properly

grounded. If the machine is not properly grounded,

someone can get an electric shock.

●If you have any doubt about the grounding of

the magnetic drilling machine, contact a licensed

electrician.

●Never connect the grounding conductor to a gas

4

pipe. This will result in an explosion and severe

injuries or death.

●Always check the grounding conductor. If you have

any doubts about the grounding conductor contact a

licensed electrician.

●Wiring connections to a grounding rod require the

expertise of a licensed electrician. Do not attempt

the wire connections yourself. Always contact a

licensed electrician.

●Do not abuse the power cord. A damaged power

cord can cause an electrocution. A damaged power

cord can cause fires. Always inspect the cord. If the

cord is damaged, do not use the magnetic drilling

machine.

●Do not carry the machine by the cord. Do not pull

the cord to disconnect it from a socket.

●The cord can become damaged from heat, contact

with sharp objects or from being twisted. Always

inspect the cord. Do not use the machine if the cord

is damaged.

●Always use a ground fault circuit interrupter. The use

of a ground fault circuit interrupter may be required

by government regulations. The failure to use a

ground fault circuit interrupter may result in electric

shock.

●Avoid starting the magnetic drilling machine abruptly

or unintentionally.

●Always make sure that the switch is turned off before

connecting the power source.

●Always disconnect the power source and turn off

the switch before setting up for work operations.

Always disconnect the power and turn off the

switch when inspecting work. Always disconnect

the power and turn off the switch before attempting

any maintenance. Failure to disconnect the power

and turn off the switch during set up, inspection

or maintenance can cause accidents and severe

injuries.

ABOUT YOUR NITTO PORTABLE MAGNETIC

DRILLING MACHINE

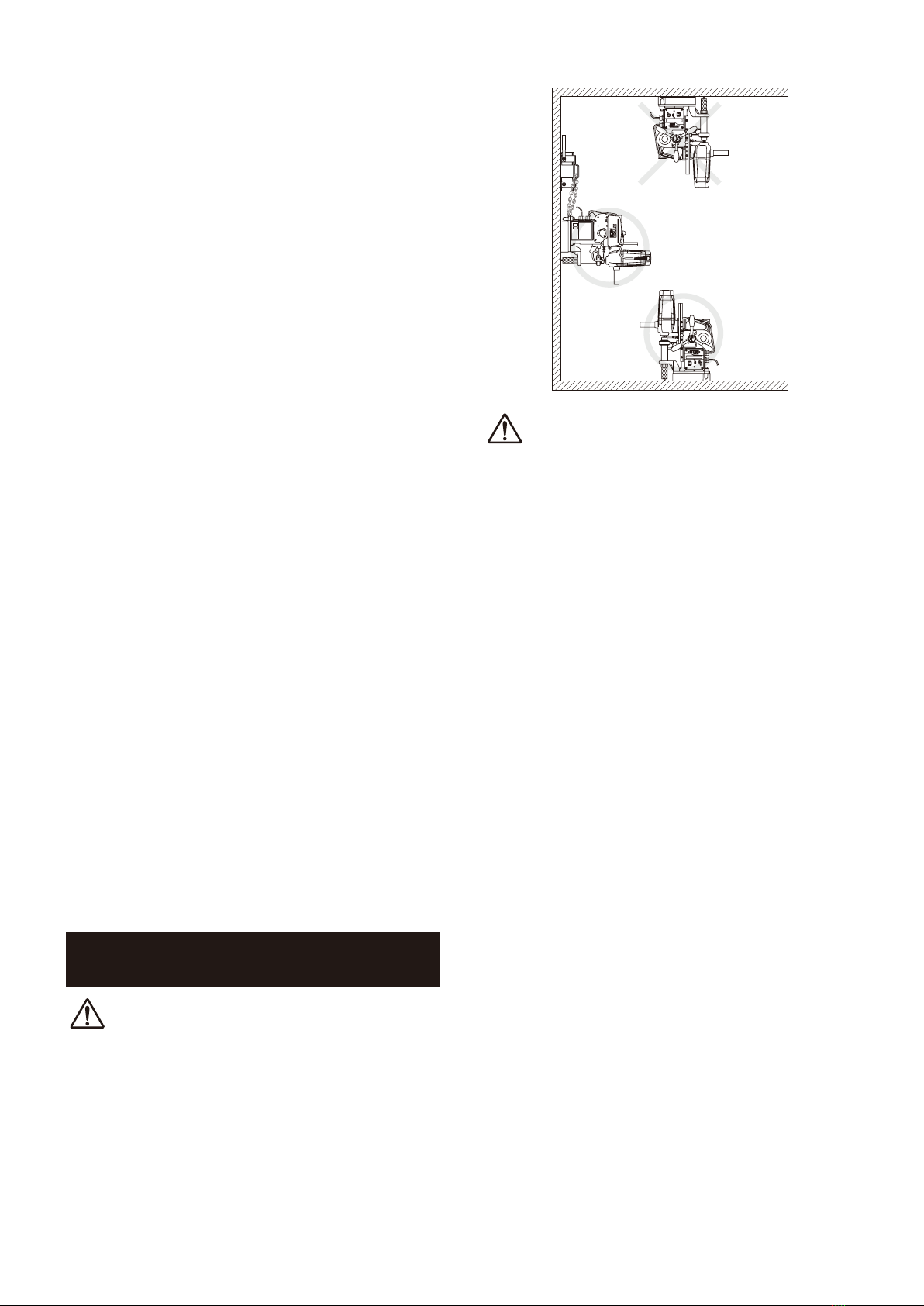

DANGER

Do not use your portable drilling machine on the

ceiling.

●Use of the portable drilling machine on the ceiling

is dangerous. The machine could fall. The falling

machine could cause severe injuries or death. (Fig.1)

Fig. 1

WARNING

Do not use the Magnet for more than five hours.

●More than five hours of uninterrupted operation may

cause a fire. Five hours of uninterrupted operation

generates extreme heat in the Magnet. This heat

can cause a fire. Do not touch the Magnet. When

the Magnet is hot, touching it will cause a severe

burn injury. Never use the Magnet for more than

five continuous hours. When you are not using the

Magnet, turn the switch to the "OFF” position and

pull the plug out of the power source.

Do not use the Drill Motor for over 30 minutes.

●Uninterrupted operation of the Drill Motor for over 30

minutes generates heat. This heat can cause a fire.

Never use the Drill Motor for over 30 minutes. When

you are not using the Drill Motor, turn the switch to

the "OFF' position and pull the plug from the power

source.

Use only on magnetic materials.

●Your portable drilling machine cannot be used

on non-magnetic materials, such as aluminum,

stainless steel, copper or alloys. The Magnet will not

work on non-magnetic materials. Attempting to use

the Magnet on non-magnetic materials could cause

an accident.

Use caution during wall operation.

●When using your portable magnetic drilling machine

on a magnetic wall, always use caution.

●Never stand under the machine.

* Never allow anyone to stand under the machine.

* Never put any part of your body under the

machine.

* If the machine falls, it could result in severe injury

or death.

●Always remove cutting oil from the tank before using

the machine on a wall. You must manually apply

cutting oil to the cutting tool.

5

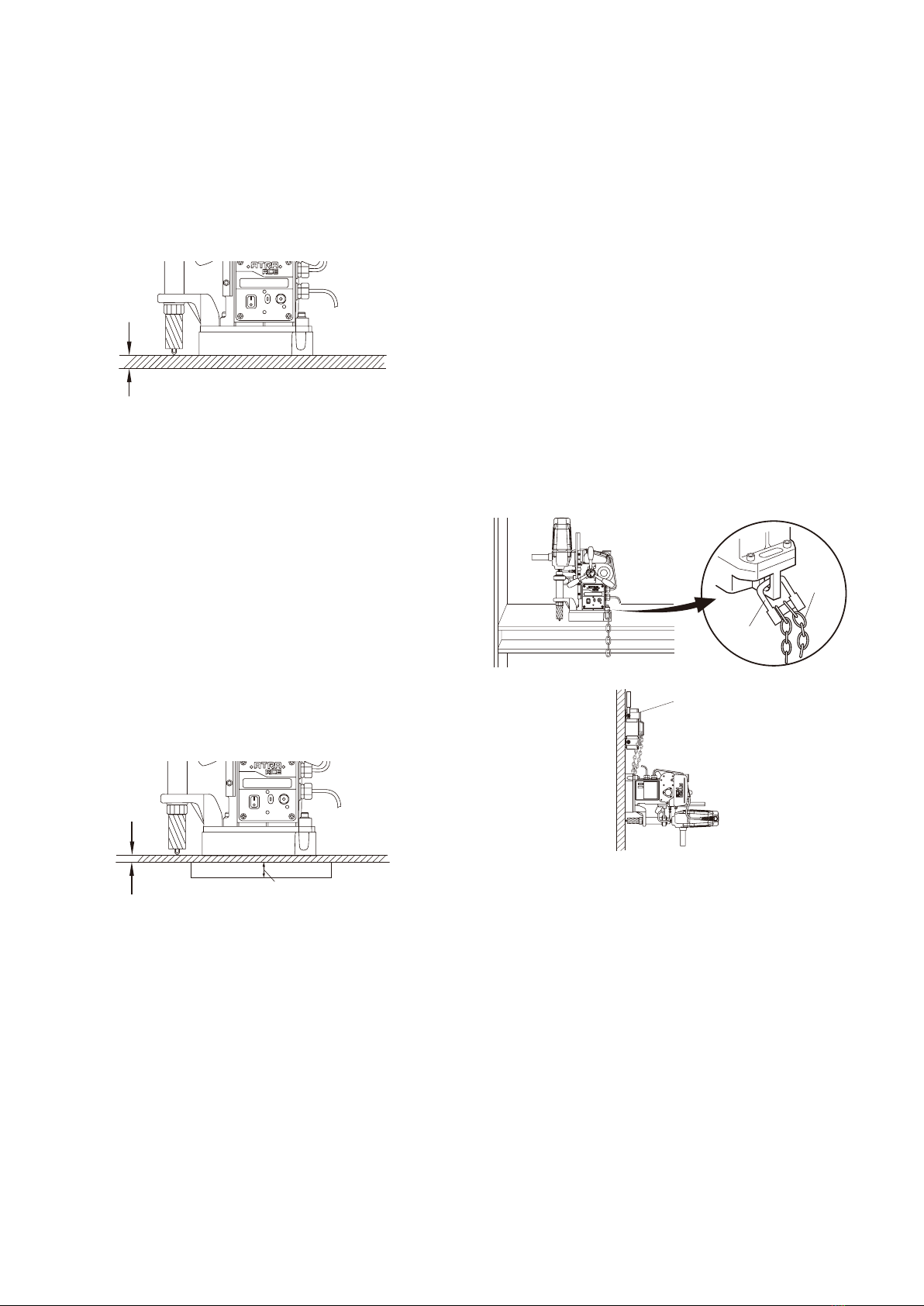

Always use a work piece that is at least 3/8” (9

mm) thick.

●The work piece must be at least 3/8” (9 mm) thick. If

a work piece is too thin, the magnetic power of your

machine will decrease. This will cause the machine

to move during operation. This could result in an

accident. (Fig.3)

Not less than 3/8" (9mm)

Fig. 3

Use an iron back-up plate.

●If the work piece is less than 3/8” (9 mm) thick, you

must use an iron back-up plate that is more than

13/32”(10 mm ) in thickness. The surface area of the

iron back-up plate must he greater than the surface

area of the Magnet. An appropriate back-up plate is

necessary to boost the holding power of the Magnet.

(Fig.3)

Use of an inappropriate back-up plate can result in

an accident, If the back-up plate is not thick enough

or big enough, the machine will come loose during

operation. This can result in an accident and severe

injuries.

Less than 3/8" (9mm)

Plate 13/32" (10mm) or

more thick piece iron

Fig. 3

Always keep surfaces clean.

●Always keep the Magnet surface clean. Always keep

the work piece surface clean. If there are any foreign

objects between the Magnet and the work piece

surfaces, this will reduce magnetic power. This could

cause the machine to move during operation. This

can result in an accident. Keep all surfaces clean of

rust, chips or other foreign material.

Do not place the machine over a hole.

●Do not attempt to position the Magnet over a hole.

Attempting to straddle a hole will reduce the power

of the Magnet. This will cause the work piece to

come loose during operation and can cause an

accident.

Always use a Chain to secure the machine.

●If the machine falls, it can cause severe injuries.

There is always a possibility that magnetic power

can be lost or reduced because of a power failure.

Magnetic power can be lost on rough surfaces. You

must take precautions to prevent the machine from

falling.

●This machine comes with the Chain. The Chain is

to be used to fasten the machine to the work piece.

If you do not use the Chain, it is possible that the

machine may fall. (Fig.4)

●If use of the Chain is not possible because of the

size of the work piece, you must use another method

of securing the machine. Use a Supporting Magnet

Assʼy to prevent the machine from falling.

●The use of a Supporting Magnet Assʼy is shown

below. (Fig.5)

Fig. 4

Supporting Magnet Assy

Fig. 5

Always set the Magnet in the proper position.

●Always set the Magnet parallel to the longitudinal

direction of the material. Failure to set the Magnet in

the proper position may result in reduced magnetic

power. This can cause the machine to move in

operation. This can cause an accident resulting in

severe injuries.

●When using on H-section steel, as shown in the

figure below, set the Magnet in a direction parallel

to the longitudinal direction of the material. This will

ensure that the Magnet is in the best position for

magnetic attraction.(Fig.6)

●Poor magnetic power may result in damage to the

cutter or damage to the work piece.

Shackle

Chain

6

Fig. 6

Be careful about chips.

●Keep your hands away from the cutting area at all

times. During drilling, there will be chips. The chips

are sharp. The chips are rotating with the cutter. Any

contact with the chips can cause severe injuries.

Do not touch the slug.

●Do not touch the slug. The slug is very hot. It will

cause severe burns. Make sure that no one touches

the slug. Make sure that there is no one below the

work area during operation. Hot slugs will fall. Hot

slugs can cause severe burns, other severe injuries,

or even death. Always wear protective equipment,

including protective headgear, eye protection,

hearing protection, and gloves. Do not allow any

person without protective equipment to come near

the machine.

Do not use your hands to remove chips.

●Chips have sharp edges. Use a screwdriver to

remove chips. If you use your hands to remove

chips, you can be injured, even if you are wearing

gloves. Do not use your hands to remove chips

under any circumstances.

The cutting edge is sharp.

●The cutting edge is sharp. If you do not wear gloves,

you will be cut. Attempting to change the cutter can

result in severe injuries.

Do not use Cutting Oil for other purposes.

●Cutting Oil should be used only for drilling. Please

refer to Section 5-5 of this manual for further

warnings and instructions about Cutting Oil.

The Drill Motor will stop automatically when

drilling operation is completed. If the Drill Motor

fails to stop automatically, turn off the Motor

Switch to stop it and then contact sales agent

from which you have purchased your machine or

an authorized dealer near you for repair.

CAUTION

Do not use power that is generated by an engine-

driven welder.

●The use of an engine-driven welder as a power

source may cause your magnetic driven machine to

malfunction, Power from an engine-driven welder

can damage the electronic circuits in your portable

drilling machine.

Use a Proper extension cord.

●Do not use an extension cord that is too thin. Do

not use an extension cord that is too long. Do not

use an extension cord that is wound on a drum.

Do not share an extension cord with other motor-

driven tools. These uses can cause voltage to drop

and can reduce the holding power of the magnet,

causing the machine to move during operation. This

can decrease performance and may cause damage

to the machine. (Fig.7)

Extension Cord

Max length Size (nominal cross-section

area of the conductor)

10 m (32.8ft) Min 1.25 mm2 (AWG16)

20 m (65.6ft) Min 2 mm2(AWG14)

30 m (98.4ft) Min 3.5 mm2(AWG12)

Fig. 7

Do not use this machine on the steel material

being electrically welded.

●When the electric welder is not properly grounded,

electricity will run through the Atra Ace machine

via its Magnet, causing possible failure or

malfunctioning, which in turn may cause accident.

Do not force to feed cutter when drilling manually.

●Because the Hi-Broach and Jet-Broach have

rather thin cutting edges with less cutting pressure

resistance as compared to twist drill, do not force to

feed the cutter when drilling manually.

If you feed it with too much force, the cutter may

break or end up with shorter life than otherwise.

Always use a compatible Pilot Pin.

●The Pilot Pin must be compatible with the cutter. An

improper Pilot Pin may result in an accident. See

Section 5-3 to identify compatible Pilot Pins and

cutters. The proper Pilot Pin to be used will vary,

depending on the type of cutter, the diameter of the

cutter, and the length of the cutter.

Do not switch to auto while drilling in manual mode.

●When you want automatic drilling, set the machine

7

to auto mode first and then start drilling.

Do not switch overto auto mode in the middle of

manual drilling operation: the Drill Motor may come

to a stop if you do so.

Do not apply manual force when feeding in auto

mode.

●Do not apply force to the Rod Handle when feeding

in auto mode (with the Rod Handle pushed toward

the machine).

Do not start drilling with manual feed.

●Do not start drillingwith manualfeed.Once you

have started with manualfeed, however, you must

not change mode to automatic feed half way through

the operation because the Drill Motor may come to a

stop making it impossible to complete the hole.

Leaving the machine alone in a subzero C˚

environment for many hours may cause Drill Motor

start-up failure at the initial startup. This is nothing

unusual. Set the auto-feed switch to OFF (with

the Rod Handle pulled out toward the operator)

and run the machine idly for a few minutes. That

should take care of initial startup failure.

1. APPLICATION

Thisis a portable drillingmachine with a Magnet,

geared to drilling mild steel (or equivalent) using One-

Touch type Jet-Broach orHi-Broach.The machine

willbe mounted on the workpiece to be drilled with

the Magnet securely fasteningthe machine to the

workpiece while drilling takes place.

2. RECEIVING INSPECTION

Upon unpacking, check to see that the shipment is

complete without damage or oil leakage in transport.

Should you find any damage orshort-shipment,

please contact salesagent through which you have

purchased your machine or an authorized dealer near

you for corrective actions.

Package Contents Q ty Check

ATRA ACE 1set

Pilot Pin 08035 1

Hex. Socket Screw Key 3 1

Spanner 8X10 1

Cutting Oil 0.5ℓ

Can 1

Side Handle 1

Chain 1

Guard 1

Instruction Manual 1

8

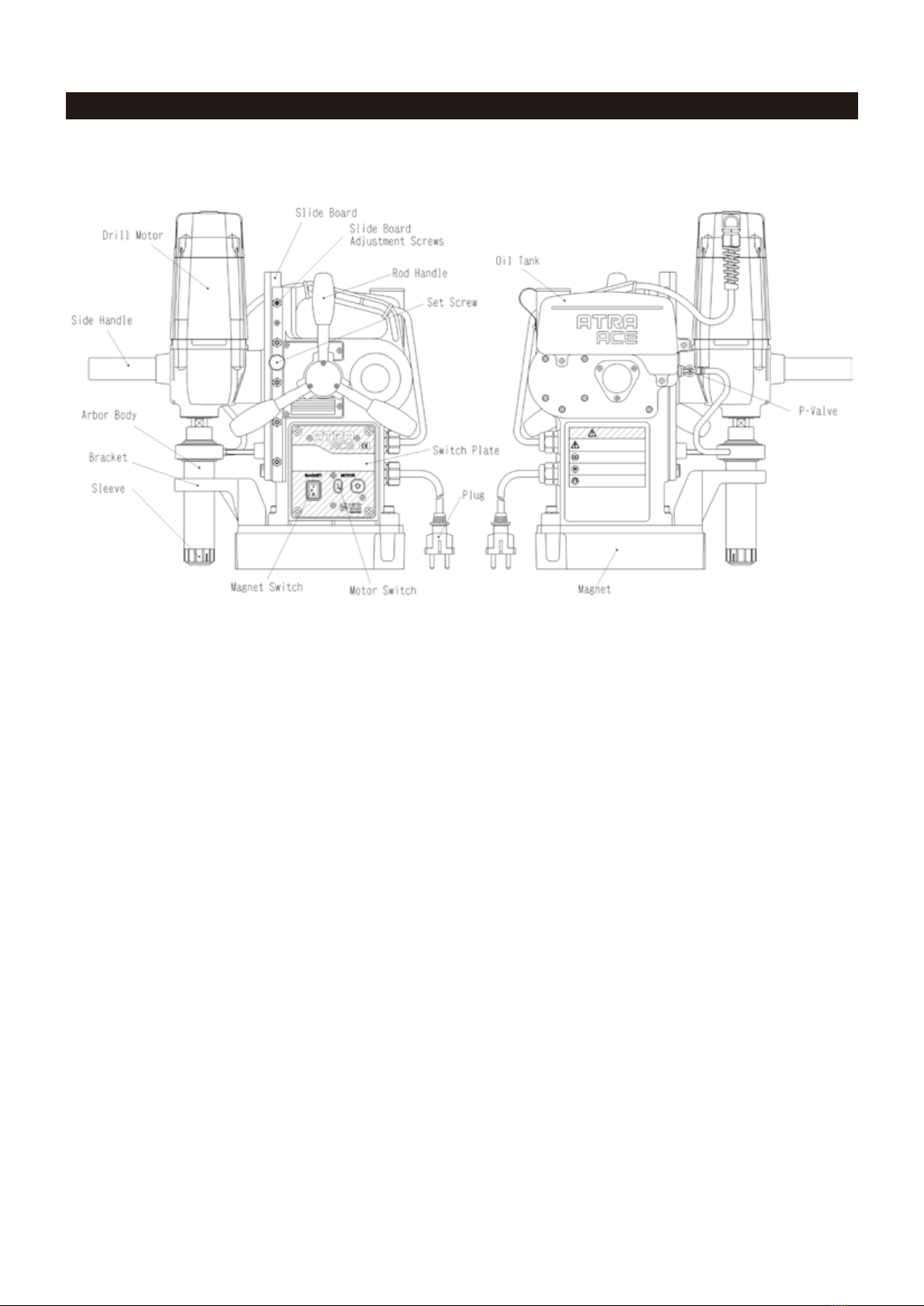

3. PART NAME

Fig. 8

9

4. FUNCTIONS OF ELECTRONIC

CONTROL

4-1. Overload Detecting Function

When overload occurs during drilling operation,

the overload detector puts the following functions

to work. Please note, however, that there may be

cases where the overload detector does not work

properly if power is drawn from an engine generator

with fluctuating output voltage, sometime tool high

and sometime too low.

●Automatic Feed Rate Control Function

Automatic drill feed starts slowly for the first few

seconds and then it picks up speed automatically to

an appropriate level in terms of cutting load applied

to the cutter. In addition, a cutter diameter factor

is also taken into account for automatic feed rate

control.

●Automatic Stop Function

Overload to the Drill Motor or feed motor

automatically stops the drill and ongoing feed,

preventing possible damage to the machine and

cutter. However, if a worn or blunt cutter is being

used, it may break.

4-2. Automatic Cycle Stop Function

When drilling operation is complete with the machine

relieved of cutting load, the Drill Motor stops

automatically.

4-3. Limit Switch Function

Even if the automatic cycle stop function fails to

operate and the drill continues to feed down, the

Limit Switch will stop the down-feed near the lower

limit of the stroke and the Drill Motor.

4-4. Lateral-Shifting Detection Function

This function stops drill feed and the Drill Motor

when lateral shifting of the Magnet is detected.

4-5. Re-Start Prevention Function

The re-start prevention function comes into play

when power failure is restored that has occurred

during operation.

Thanks to this feature, when a plug that has been

disconnected during operation is re-plugged into the

receptacle or when power failure is restored that has

occurred during operation, the Drill Motor will NOT

restart automatically preventing possible accident --

although Magnet lamp will come on and magnetic

power restored.

To resume operation, turn ON the Motor Switch on

the side of the machine to start the Drill Motor.

4-6. Magnet Interlocking Function

When the Magnet fails the Drill Motor will not start

revolving. To repair defective Magnet, please contact

sales agent through which you have purchased your

machine or an authorized dealer near you.

5. MACHINE SETUP

WARNING

●When setting up machine, turn off the Magnet

Switch and disconnect the power supply plug

from power source.

5-1. Mounting Parts

Mount the Side Handle on the Drill Motor.

5-2. Using Cutter

CAUTION

●Use One-Touch type cutters only.

●

For better workability and safety, do not use

worn or damaged cutters.

5-3. Combination of Cutter and Pilot Pin

CAUTION

●

Do not use any other combinations than those

shown in the compatibility table.

Use a Pilot Pin appropriate for the cutter. (Fig.9)

A Pilot Pin to be used varies depending on the cutter

type, diameter, length (depth). A wrong combination

of cutter and Pilot Pin would not allow slug to be

ejected at the end of drilling and/or prevent Cutting

Oil from reaching the cutting point, resulting in

cutting tool damage.

06025PN:TK01167

08025PN:TJ12696

06050PN:TK01166

0850 PN:TK00802

HBO 14 - 17 dia.

Depth 25 mm

HBO 17.5 - 35 dia.

Depth 25 mm

HBO 14 - 18 dia.

Depth 50 mm

JBO 17.5 - 35 dia.

Depth 35 mm

JBO 17.5 - 35 dia.

Depth 50 mm

JBO 17.5 - 35 dia.

Depth 75 mm

HBO 19 - 35 dia.

Depth 50 mm

PILOT PIN HI-BROACH Cutters

PILOT PIN JETBROACH Cutters

08050PN:TJ16019

08035PN:TJ15859

08050PN:TJ16019

08075PN:TJ17436

6.35 dia.

6.35 dia.

8 dia.

100mm

7 dia.

112 mm

8 dia.

91 mm

8 dia.

112 mm

8 dia.

5 dia.

8 dia.

81 mm

76 mm

5 dia.

112 mm

133mm

8 dia.

Fig. 9

10

5-4. Mounting/Removing Cutter

WARNING

●Do not use any other combinations of Pilot

Pin and cutter than those shown in the

compatibility table.

●Wear safety gloves when replacing cutter.

(1) Bring the Drill Motor up by turning the Rod Handle

clockwise. (Fig. 10)

Fig. 10

(2) Insert a Pilot Pin,

appropriate for the cutter

size, into the cutter.

(Fig.11)

(3) Align the depression in

the cutter with the white

line on the Sleeve, and

then insert the cutter.

When you insert the

cutte r f a r enough

the Sleeve will turn

clockwise and lock with

a clicking sound..

* W h e n you f ind i t

hard t o insert t h e

cutter, turn the Sleeve

counterclockwise and do

over. (Fig.12)

(4) To remove the cutter,

turn t h e S leeve

counterclockwise.

The cutter will come off.

(Fig.13)

5-5. Preparation of Cutting Oil

Cutting Oil Safety Precautions

WARNING

(1) Use

●Use Cutting Oil for cutting purpose only. Do not use

it for household purposes

(2) Handling Precautions

●The Cutting Oil contains amine. Do not mix it up

with rust inhibitor, etc. containing nitrite.

●Wear safety glasses for eye protection when

handling Cutting Oil: eye injury may results if it gets

into your eyes.

●Wear protective gloves for hand protection when

handling Cutting Oil: skin injury may result if it

comes into contact with your skin.

●Wear respirator when exposure to respiratory

hazards with oil mist or vapor is anticipated.

Inhalation of oil mist or vapor may make you feel

sick.

●When diluting Cutting Oil, follow the instructions per

the Operation Manual.

●Keep Cutting Oil out of reach of children.

●Do not drink Cutting Oil.

(3) First Aid

●If Cutting Oil gets into your eyes, immediately open

your eyelids with your fingers and wash your eyes

with plenty of water for at least 15 minutes. If your

eyes feel irritated, consult with a medical doctor and

follow his/her instructions.

●If Cutting Oil comes into contact with your skin,

immediately wash it away with plenty of water and

soap. Take off contaminated clothes. Clean the

clothes if you need to wear it again. If your skin

feels irritated, consult with a medical doctor for

medical instructions.

●If someone inhales oil mist or vapor, immediately

take him/her to an area where fresh air is abundant

and wrap up his/her body with a blanket, etc. to

keep body temperature. Have him/her take a

rest and consult with a medical doctor for medical

instructions.

●If someone drinks Cutting Oil, immediately make

him/her drink plenty of water and vomit it. Consult

with a medical doctor for medical instructions. When

unconscious, do not pour water into his/her mouth

nor induce him/her to vomit.

(4) Instructions in Case of Fire

●If fire breaks out in the vicinity, wear PPE (personal

protective equipment) and use foam, powder or

CO2fire extinguisher to put the fire out from the

windward.

Rod Handle

Downward Upward

Pull down out of the body

Fig. 11

Fig. 12

Fig. 13

Pilot pin

Cutter

Spindle Arbor

Turn the Sleeve

to the left

Spindle Arbor

Pull out

Sleeve

White line

Depression

Align

Sleeve

11

(5) Storage

●When storing Cutting Oil after use, put it into a

container and put a lid on for tight sealing so

that dust or moisture, which is a catalyst for

contamination, may not get in.

●Avoid direct sunlight, rainwater or the like and store

Cutting Oil in a dim cool area.

(6) Disposal

●For disposal of concentrate solution and used fluid,

request a waste-disposal company to dispose them

as industrial waste in accordance with the local laws

and regulations.

●Treat flushing water through pH adjustment,

condensation/sedimentation, activated sludge

process, activated carbon adsorption, etc., and

discharge it in accordance with the regulations of

your local municipal bylaw.

●Residual dross will remain in an emptied container:

be careful when handling an empty container.

(7) Others

●When Cutting Oil is poured into another container

for use, post chemical and label information at the

site where it is kept. At the same time, keep the

Operation Manual handy so that it can be referred to

whenever necessary.

●For further details, contact us for product safety data

sheet.

●All the information and descriptions that have been

provided are based on the currently available

documents and information, which may be revised

upon our new recognition and/or discovery.

●The precautions provided apply to regular handling.

If special handling method is used, take safety

measures that are suitable for your applications and

usage.

●The information contained herein is for your

reference purpose only, to which we make no

warranty of any kind and for which we shall not be

held responsible.

Preparation of Cutting Oil

(1-1)

Use our genuine-product Cutting Oil (blue).

If other Cutting Oil is used, the cutting

performance and service life of cutter would be

decreased.

(1-2)

Use tap water to dilute Cutting Oil by 8- to

10-fold. Do not use well water.

(1-3)

The oil tank is of the stationary type.

Remove the rubber cap and pour Cutting Oil

from the Oil Tank inlet. Do not spill Cutting Oil

on the machine.

5-6. Connecting the Power Supply Plug to Power

Source

●Before connecting the power supply plug to power

source, turn off the switch.

Always use the correct voltage for power source.

6. MACHINE OPERATION

WARNING

●Always Wear Safety Glasses.

●Always Wear Hearing Protection.

●Wear respiratory protective equipment.

●Never touch the mounted cutter and the rotating

parts of the machine such as the Spindle Arbor

after the power cable is connected to power

source.

CAUTION

●Do not use hard material such as a screwdriver,

to operate the Motor Switch. This may damage

the panel and switch, which would lead to

machine failure.

6-1 Start and Stop

(1) Magnet On

Set the Magnet Switch to On the Magnet will

activate.

(Fig. 14)

MAGNET

push

Fig. 14

(2) Drill Motor On

Set the Motor Switch to On . The Drill Motor will

start.(Fig. 15)

MOTOR

push

Fig. 15

(3) All Stop

When the Motor Switch is set to off, the Motor

will stop. When the Magnet Switch is set to the

Off position, the magnet will be deactivated and all

functions will stop.

12

6-2. Drilling Procedure

(1) Punch Marking

Put a rather large punch mark in the workpiece by

driving a punch down with a hammer. The punch

mark will be used as a guide for drilling operation

that follows, so it must be made in accurate position.

(Fig.16)

Punch Mark

Fig. 16

(2) Keep the Magnet and Workpiece Contacting

Surfaces Clean.

WARNING

●Always keep surfaces clean.

Always keep the Magnet surface clean. Always keep

the work piece surface clean. If there are any foreign

objects between the Magnet and the work piece

surfaces, this will reduce magnetic power. This could

cause the machine to move during operation. This

can result in an accident. Keep all surfaces clean of

rust, chips or other foreign material.

(3) Aligning with Punch Mark.

Turn the Rod Handle counterclockwise to slightly

lower the cutter and align the tip of Pilot Pin to the

punch mark. (Fig.17)

Fig. 17

(4) Magnet ON

CAUTION

Make sure the magnetis clinging to the workpiece.

Set the Magnet Switch to On and the magnet will be

activated. (Fig. 18)

push

MAGNET

(Fig. 18)

WARNING

●Check to see that Magnetic power is at work.

Turn on the Magnet Switch. The switch lamp will

glow and magnetic power will come on.

(5) Controlling Cutting Oil Flow.

Open the P-Valve and turn the Rod Handle. The

Pilot Pin will move up allowing Cutting Oil to flow.

(6) Mounting the Guard

Mounting the Guard as shown. (Fig.19)

Guard

Fig. 19

(7) Drill Motor ON

CAUTION

Do not touch the rotating parts.

Set the Motor Switch to On . The Drill Motor will

start. (Fig. 20)

(Fig. 20)

WARNING

●Do not touch revolving parts.

Press the Drill Motor ON Switch to start the Drill

Motor

(8) Drilling

Automatic Feed

CAUTION

●Once drilling feed has started, do not touch the

Rod Handle until drilling cycle is complete.

To start automatic feed, push the Rod Handle toward

the machine. As the cutter will be fed at low speed

at the start you do not have to use manual feed.

(Fig.21)

Automatic feed

Fig. 21

Punch Mark

ON OFF

Rod Handle

MOTOR

push

13

CAUTION

●Do not use automatic feed when the workpiece

has a tapered bottom surface through which a

hole is to be drilled.

When putting a hole through workpiece with a

tapered bottom surface or bottom surface with a

radius, such as angle, channel, H-section steel,

etc., use low feed rate at the start as well as toward

the end of drilling operation where the likelihood of

tool chipping is high. (Fig.22)

R

Fig. 22

(9) Finishing Drilling Operation

WARNING

●

When drilling cycle is complete, the Drill Motor

will stop automatically. If it does not, it is a

machine failure. Turn off the Motor Switch and

contact sales agent through which you have

purchase your machine or an authorized dealer

near you for repair.

●

Be alert at the end of drilling operation when

slug will automatically pop out. Do not touch

slug: it is very hot and has sharp edges.

When drilling cycle is complete, the Drill Motor will

come to a complete stop automatically. Once it

has come to a stop, pull the Rod Handle outward

away from the machine and turn off the automatic

feed switch. Turn the Rod Handle clockwise to raise

the Drill Motor. Then promptly turn off the Magnet

Switch. If a Magnet is left alone with its switch

turned on for many hours, electric current will keep

flowing through the Magnet at the cost of shortened

service life.

(10) Removing Slug

Do not proceed to the next operation without

removing the slug from the operation just finished.

At the end of drilling operation slug will pop out

automatically ejected by the spring-operated Pilot

Pin. Should a slug left in the hold sticking, remove it

from the hole by tapping the collar of the slug with a

needle stick or something. (Fig.23)

Fig. 23

6-3. Drilling Oblong Hole

CAUTION

●

Always drill oblong hole manually and slowly.

Drill oblong hole in the order of ①,②,③. For the

steps ②and ③, use manual feed and take care so

that the cutter may not be fed into the workpiece with

too much force. If automatic feed is used, damage to

the cutter or unexpected accident may result. Use a

file to take off any sock that is left unmachined.

Spacing between each step of drilling operations

should be so arranged that the Pilot Pin will always hit

the sold material yet to be machined. (Fig.24)

Fig. 24

6-4. Drilling Stacked Plates

CAUTION

●

Remove slug as each plated is finished:

otherwise, being blocked by the slug left

unremoved, the cutter cannot cut into the next

layer of plate, which results in the Magnet base

being pushed up possibly causing accident.

●

For stacked plates drilling, always use manual

feed and drill slowly and carefully.

●

Before drilling stacked plates, securely clamp

the plates together in place.

●

When drilling stacked plates, retract the cutter as

each layer of plate is finished in order to remove

slug from the drilling area, then put another hole

in the next layer of plate.

File away any excesses

14

7. TROUBLESHOOTING

WARNING

●

Never attempt to repair machine yourself: injury or damage to equipment may result.

●

Please feel free to consult the sales agent through which you have purchase your machine or an

authorized dealer, when the following symptoms appear or when you have any questions about our

products.

This machine is electronically controlled. It will stop when it picks up noise from power source or when malfunction

occurs to the electronic control. When you notice the following symptoms, pull the Rod Handle outward away

from the machine to turn OFF automatic feed and raise the Drill Motor to ensure safety and conduct inspection.

Problem Causes Solutions

Switch lamp does not come

on when Magnet Switch is

turned on.

Power supply plug is not connected to

socket.

Connect power supply plug to socket.

Drill Motor does not start

when Motor Switch is turned

on.

Magnet is disconnected. Request for repair.

Limit switch is activated near the lower

limit of drill stroke.

Slightly raise Drill Motor and release

limit switch.

Drill Motor stops during

drilling. (Magnet is not

working with Magnet lamp not

illuminating.)

Power failure has occurred or power

supply plug is disconnected.

After power failure is restored or power

supply plug is re-connected, turn on

Motor Switch again.

Drill Motor stops completely

in th e middle o f drilling

operation.

No Cutting Oil or insufficient Cutting Oil Increase flow rate of Cutting Oil.

Cutting edges jammed and stuck with

cutting chips.

Remove.

Worn cutting edge. Regrind or replace with new one.

Using cutter of other make Use Nitto brand cutter.

Using Cutting Oil of other made. Use Nitto brand Cutting Oil.

Switching over to auto feed in the

middle of operation that started with

manual feed.

Use the automatic feed from the

beginning.

Temporal glitch with electronic control. Restart .

Overload protection triggered Restart .

Lateral shifting of Magnet is

detected by lateral position

sensor, bringing machine to a

compete stop.

Workpiece too thin. Use back-up plate: thickness 13/32” (10

mm) or more.

Chips under Magnet base. Clean it up.

Worn cutting edge. Regrind or replace with new one.

Effective Magnetic force too weak. Ask for repair.

Drill Motor doesnot come to a

stop when drilling operation is

complete.

Near-exit restarting Normal.

Motor Switch OFF

Almost no cutting pressure throughout

drilling operation

(workpiece too thin.)

Normal.

Motor Switch OFF

No lubrication to Arbor Body or needle

bearing.

Lubricate.

Drill Motor stops within

several seconds after Motor

Switch is turned on.

Frozen machine Turn on and off the switch several times

to warm up machine.

15

8. MAINTENANCE/SERVICE

WARNING

●

Always disconnect the power and turn off the

switch before attempting any maintenance.

Failure to disconnect the power and turn off the

switch during set up, inspection or maintenance

can cause accidents and severe injuries.

●

Check to see periodically that mounting screws

are tight. If you find them loose, retighten.

8-1. Tighten Set Screw When Machine is Not Used

For the purpose of safety, when you do not use

the machine temporally or on a long-term basis,

raise the Drill Motor and set it in position with the

Set Screw so that it will not come down on its own

weight. If you leave the machine alone with the

Drill Motor in a lowered position, the Pilot Pin and/

or cutter may be damaged when the machine is

relocated. (Fig.25)

8-2. Grease the Sliding Surfaces from Time to Time

Grease the machine body and Slide Board from time

to time. (Fig.25)

8-3. Slide Board Clearance Adjustment

Excessive clearance between the machine body

and Slide Board would deteriorate not only drilling

performance but also cutting tool life to a substantial

degree. If you find excessive clearance, make

adjustment by tightening 5 slide board adjusting

screws on the side of the machine using the same

torque all round so that the Drill Motor will not come

down on its own weight. (Fig.25)

8-4. Bracket Inspection and Oiling

Among other things, drilling accuracy hinges on the

Bracket that supports the Arbor Body. See that the

(three Hexagon Socket) Bracket mounting bolts are

tight, from time to time. (Fig.25)

Fig. 25

8-5. Keep the Tip of Pilot Pin Sharp

When the tip of Pilot Pin gets dull, it sometimes fails

to seat into punched hole, causing drilling accuracy

to deteriorate. See that the tip is sharp from time to

time.

If you find it too dull, regrind or replace as required.

When regrinding do so carefully, for grinding with too

much force may cause the tip to get dull or soften

the material to such a degree that it is no longer

usable. (Fig.26)

Fig. 26

8-6. Recovery Measures When Pilot Pin Gets

Jammed

When you change cutting tool you also change

Pilot Pin, which acts as a guide for the cutting tool.

However there are times when the pin does not

come off easy with cutting chips in the clearance

between the cutting tool and pin, causing jamming.

In such case, tap the tip of Pilot Pin with a wooden

hammer, etc., and pull it off. (Fig.27)

Sharpen

the tip

Optimal angle 70°

Pilot Pin

16

Fig. 27

8-7. Cutter Regrinding

When you need to regrind cutter, please contact

sales agent through which you have purchased your

machine or an authorized dealer near you.

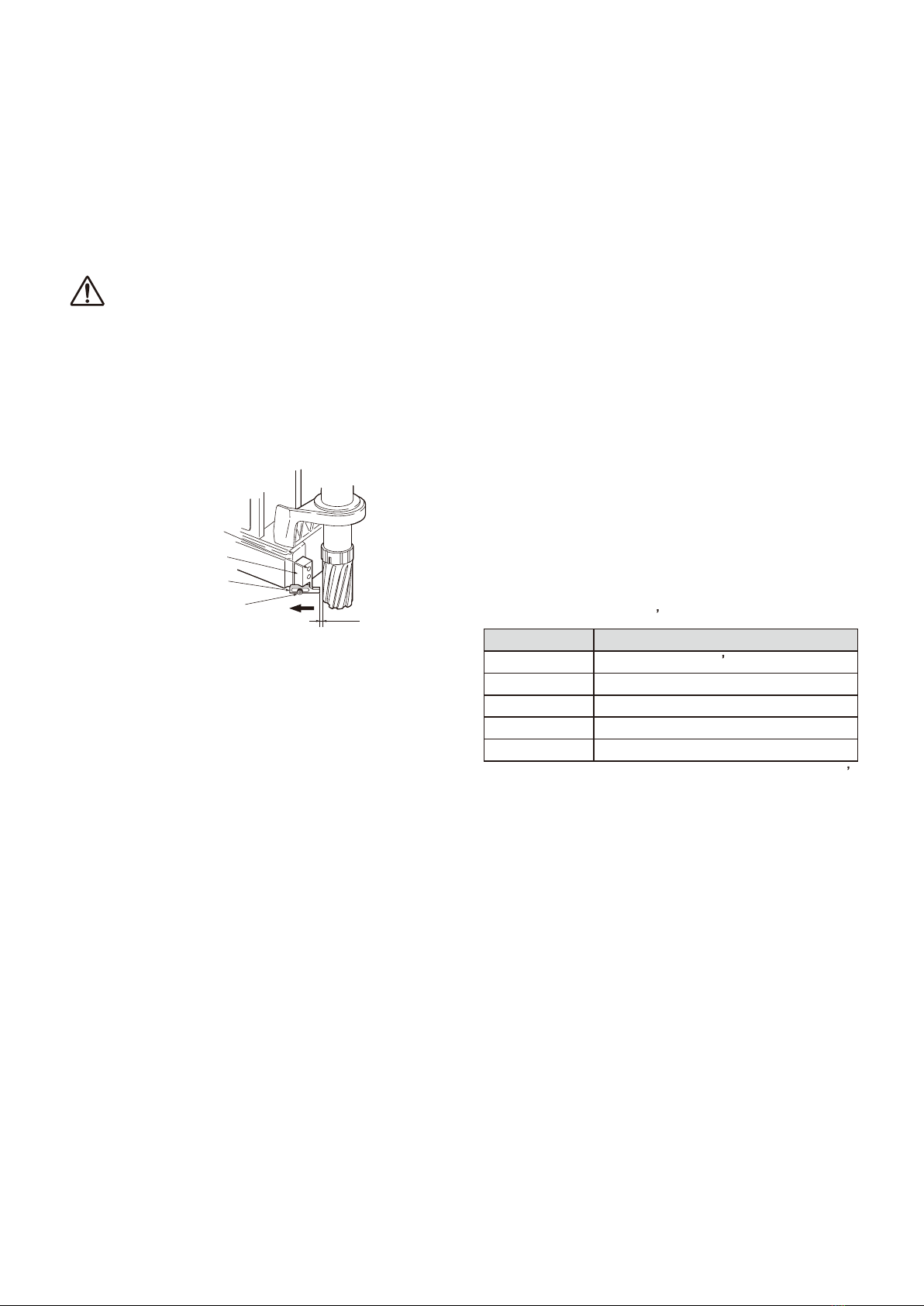

8-8. Carbon Brushes Inspection and Replacement

Check Carbon Brushes for wear periodically.

When the length of Carbon Brushes gets as short

as 5/16” (8 mm), replace it with a new one, for, if you

do not, chances are that you will have a rectification

problem which may cause machine failure. (Fig.28)

(1) Loosen the tap screws to remove the cap.

(2)

Take out the Carbon Brush and replace it with a

new one.

(3)

Put the cover on and securely tighten the tap

screws. When tightening the tap screws, see

that the tap screws are screwed in along the

existing screw threads – without cutting new

threads.

(4)

After replacement, run the machine with no load

for approx. 10 minutes.

Fig. 28

Fig. 29

9. OPTIONAL PARTS

9-1. Nitto-Brand Cutting Oil

CAUTION

Use Nitto-brand Cutting Oil for Atra Ace.

Part No. Part Name

TB01507 Cutting Oil 2ℓ(Light Blue)

9-2. Pilot Pin

(metric sizes)

Part No. Part Name

Depth(mm)

Applicable cutter (mm)

TK01167

Pilot Pin 06025

25

Hi-broach 14 - 17 dia.

TJ12696

Pilot Pin 08025

Hi-broach 17.5 - 35 dia.

TJ15859

Pilot Pin 08035

35

Jetbroach 17.5 - 35 dia.

TK01166

Pilot Pin 06050

50

Hi-broach 14 - 18 dia.

TJ16019

Pilot Pin 08050

Hi-broach 19 - 35 dia.

(TK00802)

Pilot Pin 0850

Jetbroach 17.5 - 35 dia.

※( ):Special Order

9-3. Supporting Magnet Assʼy

Part No. Part Name

TB04374 Supporting Magnet Assy

9-4. Sleeve 6.5 Assʼy for Twist Drills (Fig.30)

Part No. Part Name

TB02536 Sleeve 6.5 Assy

Sleeve 6.5

Hex. Socket Set Screw

with Cup Point 6X5

Fig. 30

Cutting Chips

Pilot Pin

Cutter

17

9-5. Chip Breaker

When chips are not smoothly discharged during

drilling, the overload detection will be frequently

triggered to stop the Drill Motor, particularly when

plate thickness is 1-3/8” (25 mm) or thicker. In such

case, an optional Chip Breaker may be used to ease

chip congestion.

9-5-1. Mounting Chip Breaker

CAUTION

●

When setting Chip Breaker, see that the tip of

blade may not come into contact with cutting

tool.

Chip Breaker breaks cutting chips formed in drilling

into small pieces and facilitates chip discharging.

Hex. Socket Head

Cap Screw 5X12

Hex. Socket Head

Cap Screw 6X10

Blade Base

Blade

0.5-0.8mm

Fig. 31

(1)

Mount Blade Base. (Fig.31)

●Use two Hex. Socket head Cap Screws 6 X 10

to mount the Blade Base on the front face of

Magnet.

Here, see that the bottom face of the Blade

Base is flush with the bottom face of Magnet.

When the bottom face of the Blade Base sticks

out from the bottom face of the Magnet, the

magnetic force it sends out can not be made

fully use of for secure fastening.

●Use the Hex. Socket head Cap Screws 5 ×

12 to mount a blade to the Blade Base in the

direction as shown in the figure.

(2)

Mount cutter.

Loosen the Hex. Socket head Cap Screws 5 ×12

and pull the Blade in the direction as shown by the

arrow until it no longer moves. And then, mount a

cutter.

(3)

Set the blade.

Set the Blade in the way that the cutter and the

blade will have a clearance of 0.5 mm - 0.8mm

and fasten it securely to the Blade Base with Hex.

Socket head Cap Screws 5 ×12.

9-5-2. Chip Breaker Assy

Part No. Part Name

TB05186 Chip Breaker Assy

(TQ04949) Blade

(TQ04950) Blade Base

(TP14178)

Hex. Socket Head Cap Screw 6

×

10

(TP01945) Hex. Socket Head Cap Screw 5×12

The part number with ( )are include in the Ass y

parts written above them.

18

TK00355 31 ×25

TK00356 32 ×25

TK00357 33 ×25

TK00358 33.5 ×25

TK00359 34 ×25

TK00360 34.5 ×25

TK00361 35 ×25

TK00347 24.5 ×25

TK00348 25 ×25

TK00349 26 ×25

TK00350 26.5 ×25

TK00351 27 ×25

TK00352 28 ×25

TK00353 29 ×25

TK00354 30 ×25

TK00339 20 ×25

TK00340 21 ×25

TK00341 21.5 ×25

TK00342 22 ×25

TK00343 22.5 ×25

TK00344 23 ×25

TK00345 23.5 ×25

TK00346 24 ×25

Part No.

Diameter×Depth

Part No.

Diameter ×Depth

Part No.

Diameter ×Depth

Part No.

Diameter ×Depth

TK00700 14 ×25

TK00701 15 ×25

TK00702 16 ×25

TK00703 17 ×25

TK00335 17.5 ×25

TK00336 18 ×25

TK00337 19 ×25

TK00338 19.5 ×25

9-6 Ordering parts

Hi-Broach One-touch Type (metric sizes)

Jetbroach One-touch Type (metric sizes)

Jetbroach One-touch Type (metric sizes)

TK00325 33 ×35

TK00326 34 ×35

TK00327 34.5 ×35

TK00328 35 ×35

Part No.

Diameter×Depth

Part No.

Diameter ×Depth

Part No.

Diameter ×Depth

Part No.

Diameter ×Depth

TK00317 26 ×35

TK00318 26.5 ×35

TK00319 27 ×35

TK00320 28 ×35

TK00321 29 ×35

TK00322 30 ×35

TK00323 31 ×35

TK00324 32 ×35

TK00309 21.5 ×35

TK00310 22 ×35

TK00311 22.5 ×35

TK00312 23 ×35

TK00313 23.5 ×35

TK00314 24 ×35

TK00315 24.5 ×35

TK00316 25 ×35

TK00301 17.5 ×35

TK00302 18 ×35

TK00303 18.5 ×35

TK00304 19 ×35

TK00305 19.5 ×35

TK00306 20 ×35

TK00307 20.5 ×35

TK00308 21 ×35

TK00387 21.5 ×50

TK00388 22 ×50

TK00389 22.5 ×50

TK00390 23 ×50

TK00391 23.5 ×50

TK00392 24 ×50

TK00393 24.5 ×50

TK00380 17.5 ×50

TK00381 18 ×50

TK00382 19 ×50

TK00383 19.5 ×50

TK00384 20 ×50

TK00385 20.5 ×50

TK00386 21 ×50

Part No.

Diameter×Depth

Part No.

Diameter ×Depth

Part No.

Diameter ×Depth

Part No.

Diameter ×Depth

TK00394 25 ×50

TK00395 26 ×50

TK00396 26.5 ×50

TK00397 27 ×50

TK00398 28 ×50

TK00399 29 ×50

TK00400 30 ×50

TK00401 31 ×50

TK00402 32 ×50

TK00403 33 ×50

TK00404 34 ×50

TK00405 35 ×50

OverseasAffiliates/Offices

NIT

TOKOHKIU.S.A.,Inc.

4525

TurnberryDrive,HanoverPark,IL60133,U.S.A

T

el:(1)-630-924-9323 Fax:( 1)-630-924-0303

http

://www.nittokohki.com/index.html

NIT

TOKOHKIEUROPECo.,Ltd.

Unit21

,EmpireCentre,ImperialWay,

W

atfordHertfordshire,WD244TS,UnitedKingdom

T

el:( 44)-01923-239668 Fax:( 44)-01923-248815

http

://www.nitto.co.uk/

NIT

TOKOHKIDEUTSCHLANDGmbH

Lerchenst

r.47,D-71144Steinenbronn,Germany

T

el:( 49)-7157-22436 Fax:(49)-7157-22437

http

://www.nitto-kohki.de/

NIT

TOKOHKIAUSTRALIAPty.Ltd.

77Brandl

Street,EightMilePlainsQLD4113,

Au

stralia

T

el:( 61)-7-3340-4600 Fax:( 61)-7-3340-4640

http

://www.nitto-australia.com.au/

NITTOKOHKICo.,Ltd. SingaporeBranch

10UbiCrescent#01-62,UbiTechparkLobbyD,

Singapore408564

Tel: (65)-6227-5360 Fax:(65)-6227-0192

http://www.nitto-kohki.co.jp/e/nksb/

NITTOKOHKICo.,Ltd. ShanghaiRepresentativeOffice

#1117RuijingBuilding,MaomingSouthRoad,

Shanghai200020China

Tel: (86)-21-6415-3935 Fax:(86)-21-6472-6957

http://www.nitto-kohki.cn/

NITTOKOHKICo.,Ltd. ShenzhenRepresentativeOffice

#0726InternationalCultureBuilding,3039,Shennan

ZhongRd.,FutianDistrict,Shenzhen,518003China

Tel:(86)-755-8375-2185Fax:(86)-755-8375-2187

http://www.nitto-kohki.cn/

NITTOKOHKICo.,Ltd. BangkokRepresentativeOffice

38Q,HouseConventBldg,7thFloor,Unit7A,

ConventRd,Silom,Bangkok,10500Thailand

Tel: (66)-2-632-0307 Fax:(66)-2-632-0308

http://www.nittobkk.com/engindex.htm

ECDECLARATION OF CONFORMITY

Weherebydeclarethatthefollowingourproductconformswiththeessential healthandsafetyrequirementsofECDirectives.

Product PORTABLEMAGNETICDRILLINGMACHINE

Model ATRAACE WA-3500

SerialNo XXXXXX XXXX Christianera

Consecutivenumbers(00001 99999)

Christianeraʼslastdigit(0 9)

Manufacturer NITTOKOHKICo.,Ltd.

2-9-4, Nakaikegami, Ohta-ku,Tokyo,146-8555,Japan

AuthorisedCompilerintheCommunity

MasatoshiOgue

President

NITTOKOHKIEUROPECo.,Ltd.

Unit21,Empire Centre,ImperialWay,WatfordHertfordshire,WD24 4TS,UK

Tel:(44)-01923-239668 Fax:(44)-01923-248815

Directive 98/37/ECand2006/42/ECMachineryDirective

2006/95/ECLowVoltageDirective

2004/108/ECEMCDirective

Theaboveproducthasbeenevaluatedforconformitywithabove directivesusingthefollowingEuropeanstandards.

Thetechnicalconstructionfile(TCF)forthisproductisretainedandcompliedattheabovemanufacturerʼslocation.

MachineryDirective/LowVoltageDirective

ENISO12100-1:2003,ENISO12100-2:2003,ENISO14121-1:2007,EN60204-1:2006,others

EMCDirective EMI EMS

EN55014-1:2006 EN55014-2:1997+A1:2001:Category

EN61000-3-2:2006 EN61000-4-2:1995+A1:1998+A2:2001

EN61000-3-3:1995/A1:2001+A2:2005 EN61000-4-4:2004

EN61000-4-5:1995+A1:2001

EN61000-4-6:1996+A1:2001

EN61000-4-11:2004

Name K.Kishi

Title: GENERALMANAGERMACHINETOOLS DIV.

Beingtheresponsiblepersonappointedandemployedthemanufacturer.

PrintedinJAPAN TQ12846-0

Printed in JAPAN TQ12846-6

Table of contents

Other Nitto Drill manuals

Popular Drill manuals by other brands

Bosch

Bosch 38636-01 - 36V Cordless Litheon Brute Tough... Operating/safety instructions

Bosch

Bosch GBM 10 operating instructions

Panasonic

Panasonic EY6803 - HAMMER DRILL DRIVER 12V operating instructions

Kernlochbohrer

Kernlochbohrer DKB Series operating instructions

Skil

Skil 6271 Original instructions

Craftsman

Craftsman 315.101532 Operator's manual