JEI AIRBEAST 35 ATEX User manual

AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

2

Contents

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

1.2. Technical data............................................................................................................ 3

1.3. Design ....................................................................................................................... 4

1.4. Equipment included ................................................................................................... 4

1.5. Air preparation unit (optional)..................................................................................... 5

2. SAFETY PRECAUTIONS.................................................................................................. 5

3. STARTUP AND OPERATION........................................................................................... 7

3.1. Mounting and operation of annular cutter................................................................... 7

3.2. Preparation................................................................................................................ 9

3.3. Drilling.......................................................................................................................12

3.4. Maintenance of air preparation unit...........................................................................13

4. DECLARATION OF CONFORMITY.................................................................................14

5. QUALITY CERTIFICATE..................................................................................................15

6. WARRANTY CARD..........................................................................................................16

JEI GroupLtd AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

3

1. GENERAL INFORMATION

1.1. Application

The AIRBEAST 35 ATEX air drilling machine with magnetic base is designed to drill

holes with diameters of up to 35 mm (1.38’’) to the maximum depth of 25 mm (0.98’’)

through the use of annular cutters. The machine is ATEX II 2G/D cIIC T6/T4 certified,

which allows for working in explosive environments.

The magnetic base allows the drilling machine to be fixed to ferromagnetic surfaces

with aforce that ensures user safety and proper machine operation. A safety chain

protects the machine from dropping in case of a pressure loss.

1.2. Technical data

Pressure

6 bar

Air connection

GZ 3/8’’ BSPT

Power

800 W

Air consumption

1400 l/min (50 CFM)

Cutter holder

19 mm Weldon (0.75’’)

Maximum drilling diameter

35 mm (1.38’’)

Maximum drilling depth

25 mm (0.98’’)

Magnetic base holding force

(surface with the thickness of 22 mm and roughness Ra= 1.25)

6 500 N

Magnetic base dimensions

80 mm × 80 mm × 143 mm

3.1’’ × 3.1’’ × 5.6’’

Spindle stroke

39 mm (1.54’’)

Rotational speed under load

240 min-1

Minimum workpiece thickness

10 mm (0.39’’)

Noise level

over 70 dB

Required ambient temperature

0–40°C (32–104°F)

Weight

17 kg (37 lbs)

460 mm (18.1’’)

183 mm (7.2’’)

191 mm (7.5’’)

JEI GroupLtd AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

4

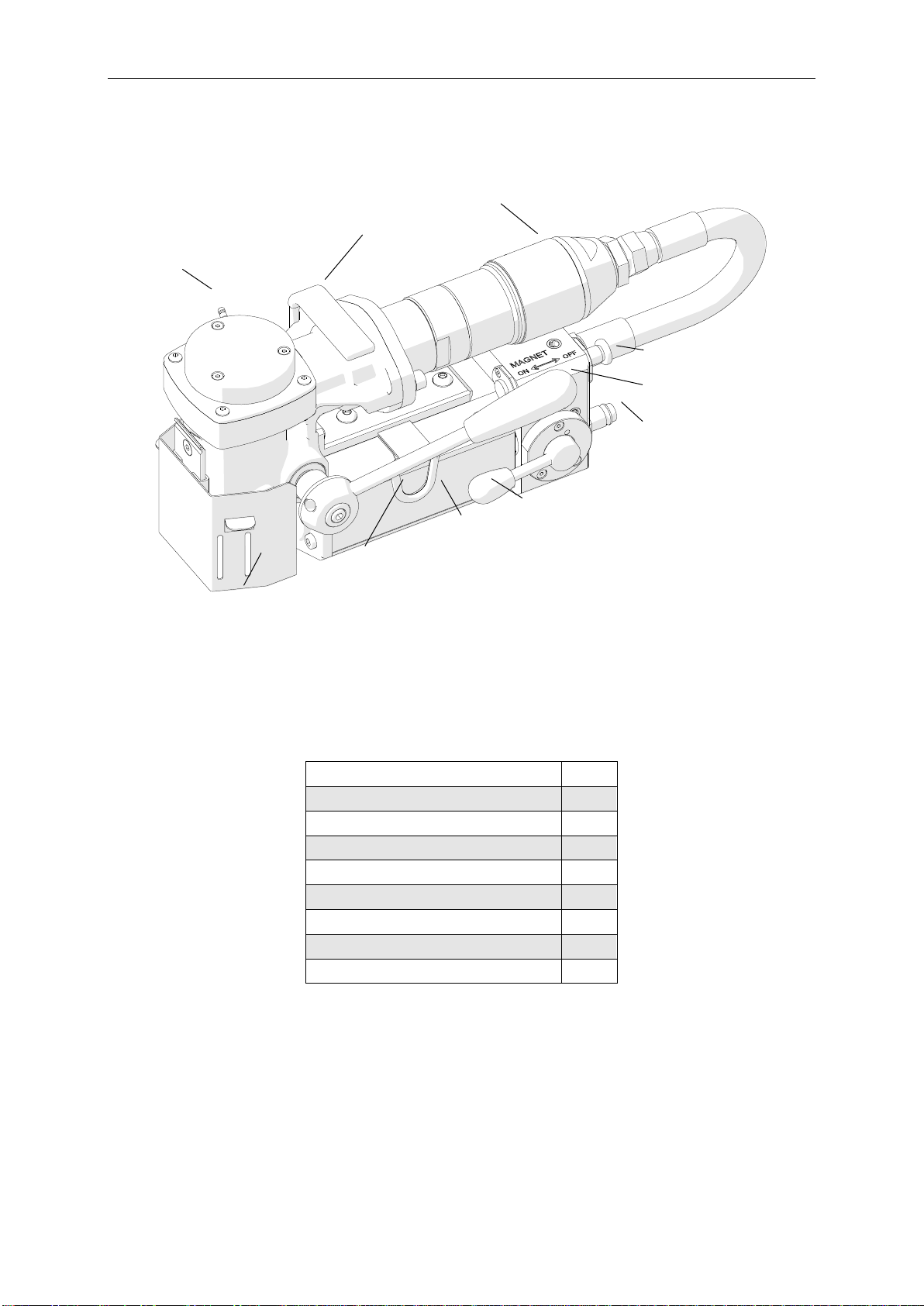

1.3. Design

Figure 1. AIRBEAST 35 ATEX design

1.4. Equipment included

The AIRBEAST 35 ATEX drilling machine is supplied in a metal box with complete

standard equipment. The included equipment consists of:

•pneumatic drilling machine

1 unit

•metal box

1 unit

•feed lever

1 unit

•cooling system bottle 0.5 l

1 unit

•pilot pin

1 unit

•safety chain

1 unit

•4 mm hex wrench

1 unit

•5 mm hex wrench

1 unit

•Operator’s Manual

1 unit

lug for safety chain

chip guard

magnetic base

ON/OFF switch

air connection

carrying handle

coupling for

cooling system bottle

magnetic base

feed lever

MOTOR lever

air motor

JEI GroupLtd AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

5

1.5. Air preparation unit (optional)

2. SAFETY PRECAUTIONS

1. Before beginning, read this Operator’s Manual and complete proper occupational

safety and health training.

2. The machine must be used only in applications specified in this Operator’s Manual.

3. The machine must be complete and all parts must be genuine and fully operational.

4. Thesupplyspecificationsmustconformtothosespecifiedontheratingplate.

5. Supply the machine only with clean and lubricated air. The air installation must be

equipped with filter, regulator, and lubricator.

6. Never carry the machine by the motor hose, nor yank the supply hose to

disconnect the connector.

7. Transport and position the machine using the carrying handle, with the magnet

switch set to position OFF.

8. Untrained bystanders must not be present in the vicinity of the machine.

9. Before beginning, check the condition of the machine and air supply, including the

supply hose, connector, and cutters.

10. Keep the machine dry. Exposing it to rain, snow, or frost is prohibited.

11. Never stay below the machine placed at heights.

12. Keep the work area well lit, clean, and free of obstacles.

13. Mount the annular cutter securely using the set screws. Remove adjusting keys

and wrenches from the work area before connecting the machine to the supply.

14. Never use dull or damaged cutters.

15. Mount and dismount cutters using protective gloves and with the machine

unplugged from the supply.

16. Never use annular cutters without the pilot pin except for establishing incomplete

through holes.

Part number (filter, regulator, lubricator):

ZST-000021

JEI GroupLtd AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

6

17. Mount only annular cutters with the maximum drilling diameter and drilling depth

of 35 mm (1.38’’).

18. Using the machine on surfaces that are rusty, covered with a thick paint layer,

uneven, or not stiff is prohibited.

19. Use the safety chain in all operating positions. The chain must not be loose and

must be fastened to a securely fixed element.

20. Before every use, inspect the machine to ensure it is not damaged. Check

whether any part is cracked or improperly fitted. Make sure to maintain proper

conditions that may affect the operation of the machine.

21. Always use eye and hearing protection and protective clothing during operation.

Do not wear loose clothing.

22. The whole surface of the magnetic base bottom must stick to the workpiece.

Before every positioning, wipe the workpiece with coarse-grained sandpaper.

23. Do not touch moving parts or chips formed during milling. Prevent objects from

being caught in moving parts.

24. After every use, remove metal chips and coolant remainder from the machine. Do

not remove chips with bare hands.

25. Maintain the machine and tools with care. Cover steel parts with a thin grease

layer to protect them against rust when not in use for a longer period.

26. Perform maintenance only with the machine unplugged from the supply.

27. Perform repairs only in a service center appointed by the seller.

28. If the machine falls on a hard surface, from height, is wet, or has any other

damage that could affect the technical state of the machine, stop the operation

and immediately send the machine to the service center for inspection and repair.

29. Never leave the machine unattended during operation.

30. Remove from the worksite and store in an isolated and dry location when not in

use, previously removing the cutter from the arbor.

JEI GroupLtd AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

7

3. STARTUP AND OPERATION

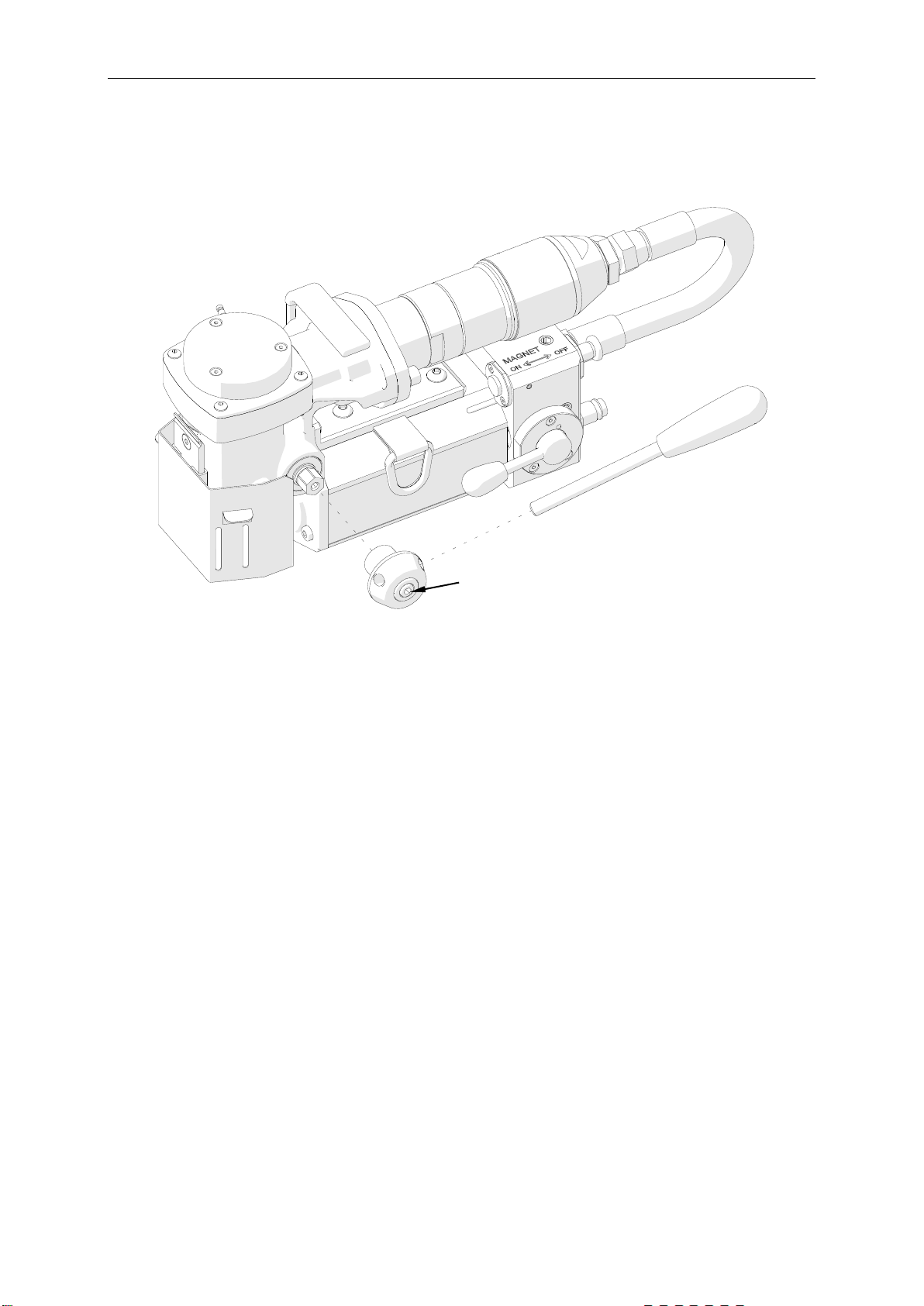

3.1. Mounting and operation of annular cutter

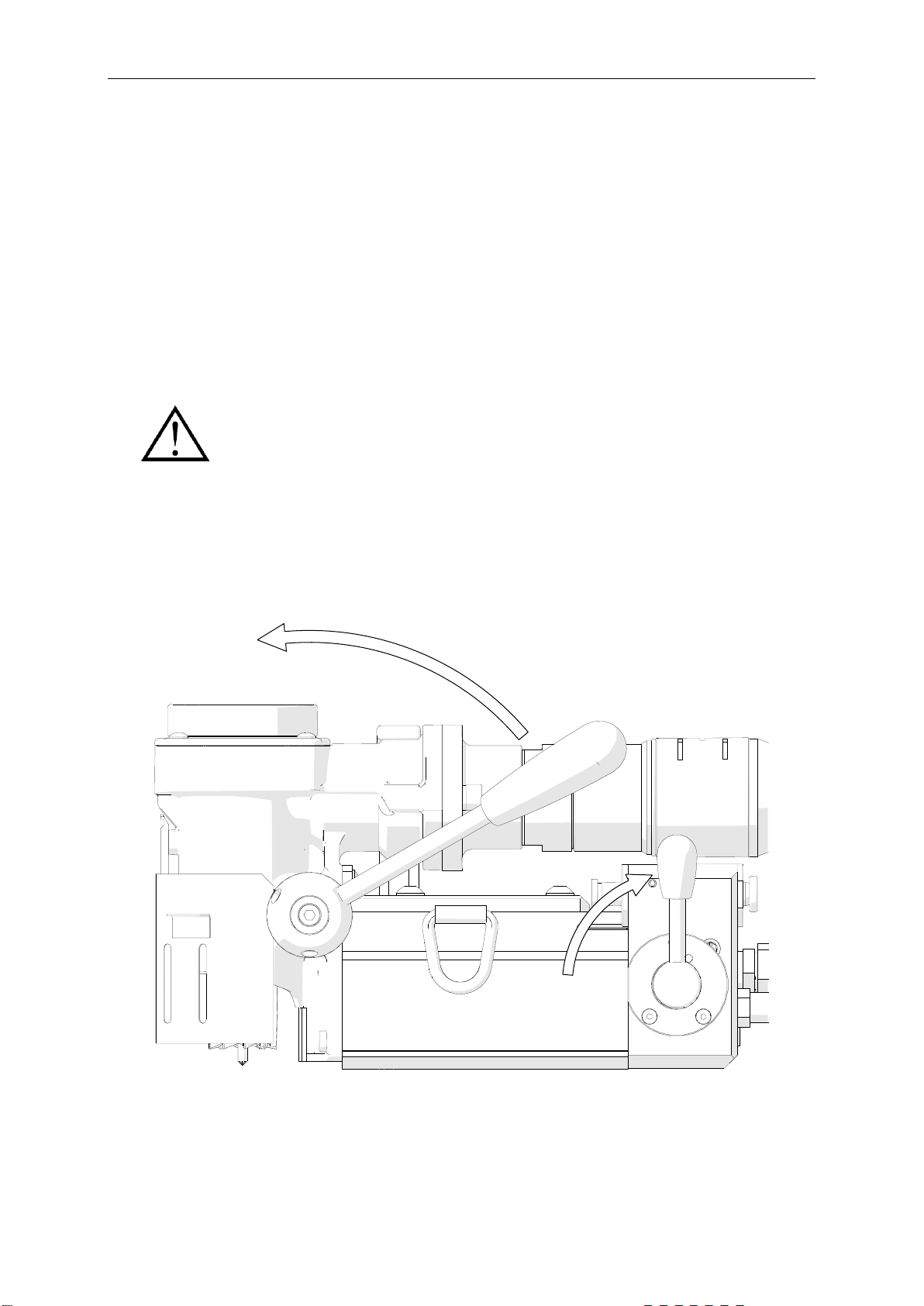

With the machine unplugged from the supply, proceed as follows. Maximally raise the

chip guard (1, Figure 2) and rotate the feed lever counterclockwise (2) to access the

set screws 3.Then, insert the proper pilot pin into the annular cutter (4), after which

wear protective gloves and place the cutter into the arbor (5)in such away to align the

flats 6with the set screws 3.Finally, tighten both set screws with 4 mm hex wrench. To

dismount the cutter, proceed in reverse order.

All safety precautions must be closely observed.

JEI GroupLtd AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

8

Figure 2. Method of mounting the annular cutter

Figure 3 shows how annular cutters operate. As the cutter penetrates the workpiece,

the pilot pin recesses into the arbor and tightens the spring. As a result, after the cutter

goes through the entire thickness, the slug core is expelled from the cutter.

4

5

3

6

1

2

JEI GroupLtd AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

9

Figure 3. Annular cutters operation

Annular cutters are designed to establish only through holes shown in Figure 4.

Establishing incomplete through holes requires not using the pilot pin.

Figure 4. Types of holes to establish with annular cutters

3.2. Preparation

Before beginning, clean steel parts, especially the Weldon shank, from grease used

to preserve the machine for storage and transport.

complete through holes

incomplete through holes

slug core

spring

pilot pin

annular cutter

arbor

JEI GroupLtd AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

10

Then, screw in the feed lever (1,Figure 5).To mount the lever at the opposite side of

the machine, use 5 mm hex wrench to loosen the screw 2mounting the head and

reposition the head to the other side, and tighten the screw.

Figure 5. Method of mounting the feed lever

Mount the annular cutter into the arbor in the manner described before.

Connect the machine to a correctly prepared air supply of sufficient purity using

a hose with the internal diameter of at least 10 mm (0.4’’). The air installation must be

equipped with an air preparation unit: filter, regulator, and lubricator.

Position the machine on a flat ferromagnetic surface (some types of stainless and

acid-proof steel do not conduct magnetic flux) with thickness of at least 10 mm (0.4’’).

The workpiece must be clean, without rust or paint that decrease the holding force of

the magnetic base.

With the MOTOR lever set in the position from Figure 6, enable the magnetic base by

toggling the MAGNET switch to position ON.

2

1

JEI GroupLtd AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

11

Figure 6. Method of enabling the magnetic base

Protect the machine using the safety chain to prevent possible injury if the machine

loses magnetic adhesion in case of a pressure loss.

Figure 7. Method of protecting the machine using the safety chain

a)

b)

c)

JEI GroupLtd AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

12

To do this, attach the end links of the chain to the snap hooks and grasp the hooks to

the lugs located on both sides of the machine (Figure 7). The chain must not be

loose. Wrap the chain around the workpiece if possible.

When working in the position from Figure 7a and 7c, fill the cooling system bottle with

acutting fluid and attach the bottle hose to the coupling (Figure 1). Do not use pure

water as the cutting fluid, however, using emulsions formed from mixing water and

drilling oil is also satisfactory. Then, press the lever of the bottle several times, after

which rotate the feed lever to initially apply pressure on the pilot pin. The fluid will fill

the system and will begin flowing from the inside of the cutter.

3.3. Drilling

Start the motor by positioning the MOTOR lever vertically (1, Figure 8). Rotate the

feed lever counterclockwise (2) to bring the cutter close to the workpiece and gently

begin drilling. Maintain constant pressure on the lever. Accomplish the hole in one pass.

Figure 8. Method of starting the motor

Use a cooling paste when working in inverted positions

(Figure 7b).

1

2

JEI GroupLtd AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

13

Once the hole is accomplished, retract the cutter from the workpiece and stop the

motor by rotating the MOTOR lever counterclockwise to the horizontal position. To

move the machine to another drilling spot, first disable the magnetic base by positioning

the MAGNET switch in position OFF.

Once the work is finished, unplug the machine from the supply, clean chips and

coolant remainder from the machine and cutter, after which remove the machine from

the worksite.

Press the pilot to expel the coolant remaining within the system. Before inserting the

drilling machine into the toolbox, disassemble the cooling system bottle and remove

the cutter from the arbor using protective gloves.

3.4. Maintenance of air preparation unit

Maintain the air preparation unit as required to keep the water trap drained, filter

cleaned, and the lubricator oil reservoir filled so that there is a drop of oil every 2–5

seconds. Use only oil which ignition temperature exceeds 260°C (500°F). If the

machine is to be left idle for at least 24 hours, increase the delivery of oil and run the

motor for 2–3 seconds, which will prevent rusting and degrading of the rotor vanes.

When the cutter goes through the material, the slug core

is expelled from the tool with a significant force.

JEI GroupLtd AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

14

4. DECLARATION OF CONFORMITY

EC Declaration of Conformity

We

JEI GROUP LTD

Unit 21 Empire Business Park

Enterprise Way, Burnley

Lancashire BB12 6LT

Declare with full responsibility that product:

AIRBEAST 35 ATEX AIR DRILLING MACHINE

WITH MAGNETIC BASE

ATEX group II category 2 G/D

Which the declaration applies to is in accordance with the following standards:

•EN ISO 12100

•EN 1127-1

•EN 1127-2+A1

•EN 13463-1

•EN 13463-5

and satisfies safety regulations of the guidelines: 2006/42/EC, 94/9/EC.

Burnley, 1ST December 2017 ___________________________

David McFadden

Managing Director

JEI GroupLtd AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

15

5. QUALITY CERTIFICATE

Machine control card

AIRBEAST 35 ATEX Air Drilling Machine with Magnetic

Base

Serial number................................................................................................................

Spindle radial runout......................................................................................................

Spindle to base travel perpendicularity..........................................................................

Spindle axis to base perpendicularity ............................................................................

Base holding force.........................................................................................................

(surface with the minimum thickness of 22 mm and roughness Ra≤1.25)

Quality control ................................................

Adjustments, inspections

Quality control .................................................

JEI GroupLtd AIRBEAST 35 ATEX

AIRBEAST 35 ATEX Operator’s Manual

16

6. WARRANTY CARD

WARRANTY CARD No.............

..................................................................... in the name of Manufacturer warrants the

AIRBEAST 35 ATEX Air Drilling Machine with Magnetic Base to be free of defects in

material and workmanship under normal use for a period of 12 months from date

of sale.

This warranty does not cover cutters, damage or wear that arise from misuse,

accident, tempering or any other causes not related to defects in workmanship or

material.

Date of production.........................................................................................................

Serial number................................................................................................................

Date of sale ...................................................................................................................

Signature of seller..........................................................................................................

1.02 / 21 November 2016

WE RESERVE THE RIGHT TO MAKE CORRECTIONS

AND MODIFICATIONS IN THIS MANUAL WITHOUT PRIOR NOTICE

Table of contents

Other JEI Drill manuals