Nitto ASH-800 User manual

Due to continuous product development/improvement the specifications and configurations in this

document are subject to change without prior notice.

Manufactured by :

NITTO KOHKI Co., Ltd.

2-9-4, Nakaikegami, Ohta-ku,

Tokyo, 146-8555, Japan

TEL : (81)-3-3755-1111

FAX : (81)-3-3753-8791

URL : www.nitto-kohki.co.jp

Keep the manual handy – so you can use it whenever necessary.

AIR FILE

Please read this manual carefully before you attempt to use

your tool so that you may use it properly and safely.

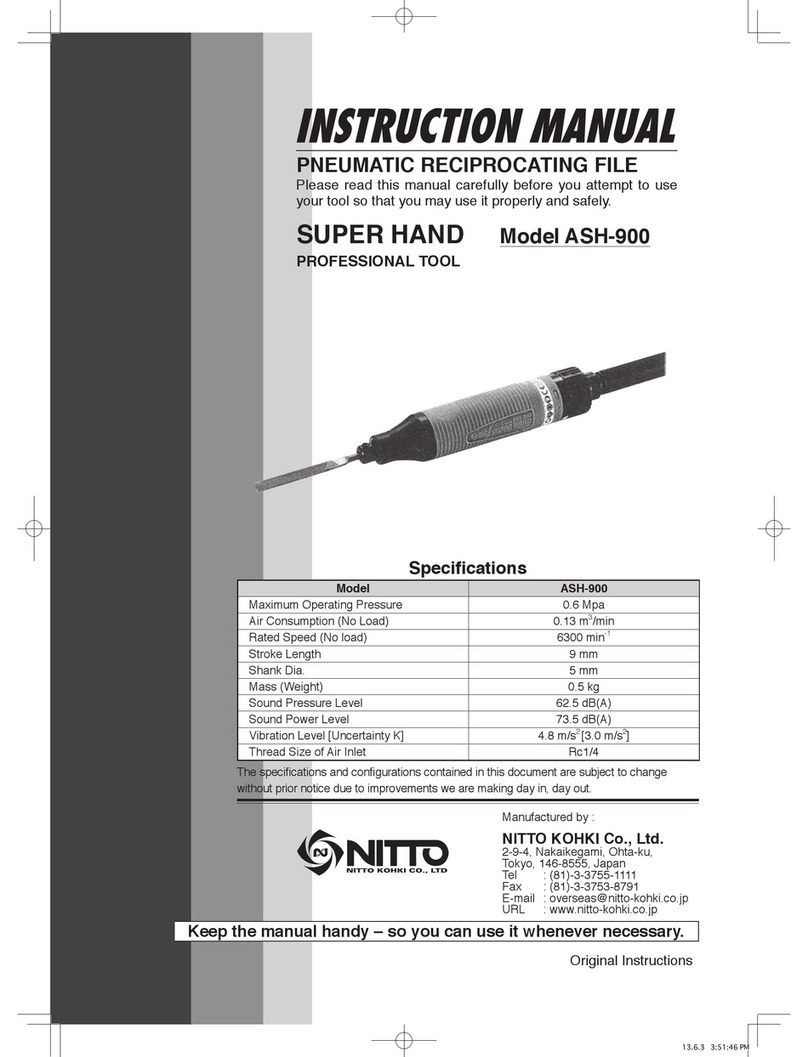

SUPER HAND

Model ASH-800

PROFESSIONAL TOOL

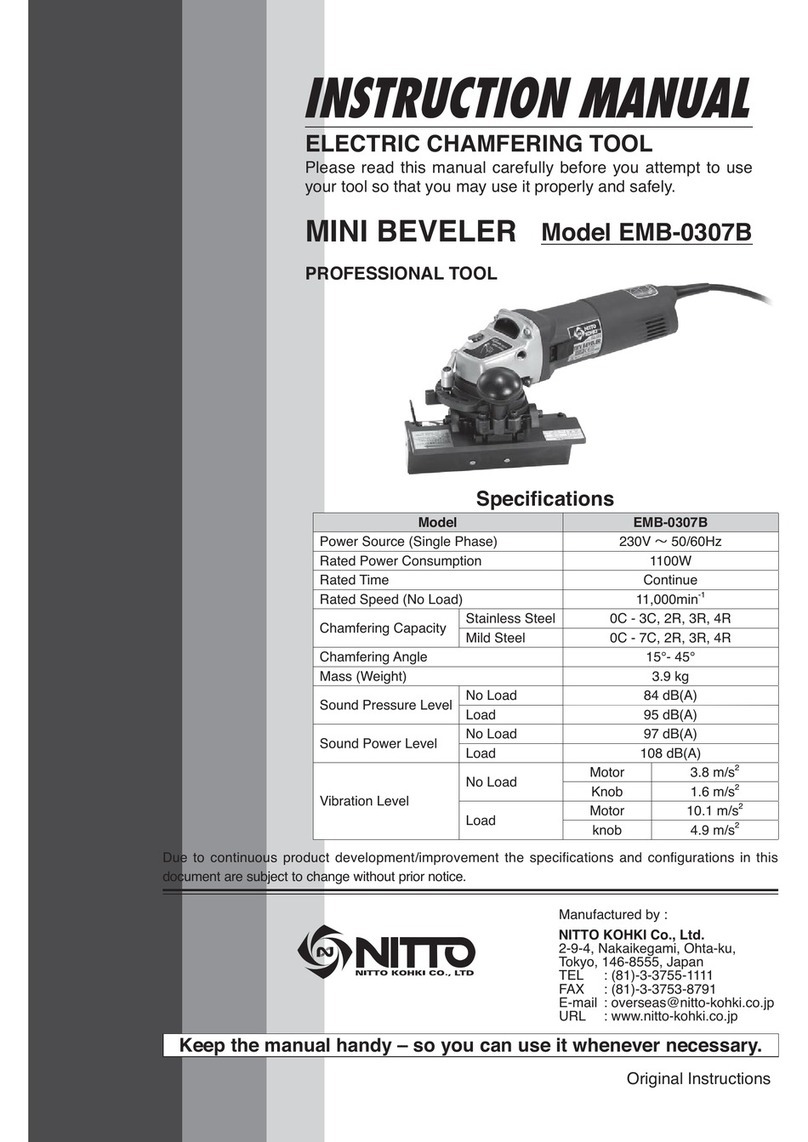

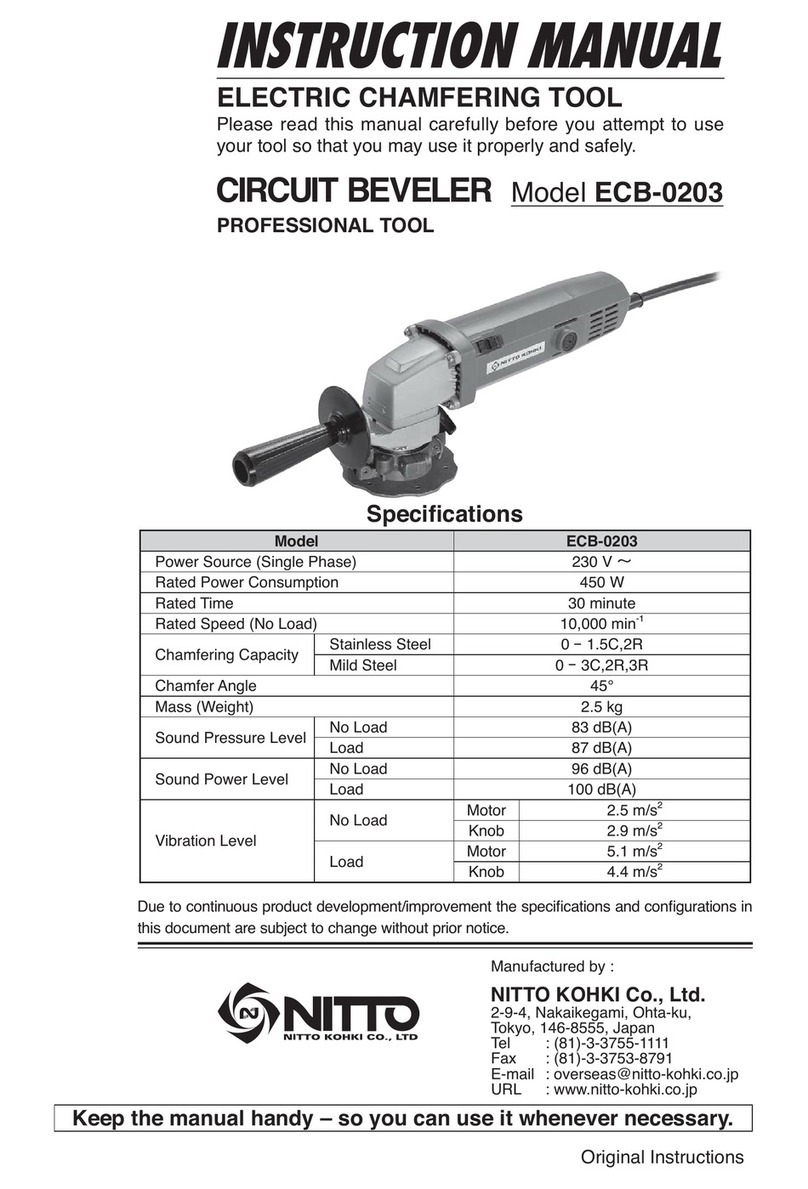

Specifications

Model ASH-800

Rated Air Pressure 0.6MPa(6kgf/cm2)

Air Consumption at Free Speed 0.23m3/min

Stroke Speed 6500min-1

Stroke Length 8mm

MAX.Shank Dia. of Points φ5.5mm

Maximum Weight of Applications 0.02kg

Sound Pressure Level (ISO 15744) 73dB(A)

Sound Power Level 84dB(A)

Vibration Level (ISO 8662-12) 8.1m/s2

Mass (Weight) 0.52kg

Thread Size of Air Inlet Rc1/4(PT1/4)

1

The following Safety notations are used throughout the manual to highlight safety precautions for the user and for

the machine.

Warning: Indicates a potentially hazardous situation which, if not avoided by following the

instructions given, could result in death or serious injury.

Caution: Indicates a potentially hazardous situation which, if not avoided by following the

instructions given, could result in injury or material damage.

Please note, however, that failure to observe safety precautions under the “ Caution” category could result in a

serious occurrence depending on the situation: please observe all safety precautions in the manual.

Caution: Important precautions for machine or tool setup, operation and maintenance.

Thank you very much for your purchase of Nitto Kohki products. Before using your tool, please read this manual

carefully so that you may use it properly to get the most out of it. Please keep the manual handy - so you can use it

whenever necessary.

CONTENTS page

IMPORTANT SAFETY INSTRUCTIONS ……………………………………… 2

GENERAL: TOOLS ……………………………………………………………… 2

GENERAL: PNEUMATIC TOOLS ……………………………………………… 3

INSTRUCTIONS FOR THIS TOOL …………………………………………… 4

1. APPLICATION ………………………………………………………………… 4

2. RECEIVING INSPECTION …………………………………………………… 4

3. AIR SUPPLY …………………………………………………………………… 4

4. OPERATION …………………………………………………………………… 5

5. THREAD SIZE OF HOSE FITTING ………………………………………… 5

6. OPTIONAL PARTS …………………………………………………………… 5

7. ORDERING PARTS …………………………………………………………… 5

8. EXPLODED DIAGRAM : ASH-800 PARTS LIST ………………………… 6

2

IMPORTANT SAFETY

INSTRUCTIONS

When using the tool, please take the basic safety

precautions as described below to prevent possible

injury.

GENERAL: TOOLS

Warning

To Operators

●Wear proper clothing for the type of work being

done.

No loose clothing nor adornments when at work: you

will be pulled into the tool if you’re unlucky. Wear

nonskid footwear. If you have long hair, wear a

safety hat that can cover up your hair completely.

●Always wear safety glasses.

Remember, regular glasses are no safety glasses.

The lenses are only shock resistant, which will not

give you sufficient eye protection you may need in

your working environment.

●Wear respiratory protective equipment (PPE).

Wear respiratory protective equipment (PPE) when

working in an environment where dust particles are

generated in operation.

●Avoid working posture that is too stressful.

Secure good footing, work in a well-balanced

posture.

●Do not operate the machine if you are too tired.

●Never touch any moving member on the tip of

machine when running.

About Work Area

●Keep the work area clean.

Cluttered work areas (e.g. workbench) invite

accidents.

●Carefully select the work area.

Do not expose tool to rain. Do not use tool in a wet

or soaked area.

See that the work area is adequately illuminated.

●Never work near inflammable liquid or in a

potentially explosive atmosphere.

●Keep children off the work area.

Keep children and unauthorized persons off the

work area.

Before Operation

●Inspect tool before use.

Before using, check that screws are securely

tightened, that a protective cover and other parts

are free from damage, and that the tool runs as it

should.

Check that moving members are properly adjusted

for positioning and tightened, that parts are free from

damage and properly mounted, and that all other

parts are in good condition for normal operation.

Should you find any damage to the protective cover

or other part, replace it in accordance with the

Operation Manual. If there are no instructions in the

Manual, please contact sales agent through which

you have purchased your tool or an authorized

dealer near you for repair.

Likewise, if a switch failure occurs, contact sales

agent through which you have purchased your tool

or an authorized dealer near you for repair.

Do not use the tool -- if it does not start or stop with

the start/stop switch.

●Securely mount File

Improperly mounted File may fly out, causing

possible damage to the machine or injury to the

operator, etc.

●Always remove spanner, wrench, etc., once

adjustment is made with them.

●Use a tool appropriate for the application.

Avoid heavy-duty application that is beyond the

capacity of tool.

Do not use tool for other purposes than is geared to.

●Do not abuse tool.

Use tool in accordance with the specifications: you’ll

get the most out of it while ensuring safely.

●Securely fasten workpiece in place.

Use a vice or clamp to securely fasten the workpiece

in place. It is much safer this way than holding it in

your hand, allowing you to operate the tool with both

hands.

About Handling

●How to store tool.

When the tool is not used, store it in a dry area and

out of reach of children.

●How to carry tool.

Do not touch the start switch while the tool is being

carried.

●Do not leave the tool unattended while it is

running.

Turn off the start switch and disconnect the tool from

power source. Do not leave the work area until the

tool comes to a complete stop.

3

Maintenance/service

●Do not take apart or modify tool.

Disassembling or modification carried out without

the supervision by a qualified or authorized service

engineer might cause accident.

●Inspect cutting tool and accessories, etc.

Always check to see that Lapping tool and

accessories, etc. are in good operating condition

without damage or deterioration -- before you

mount them on the power tool. Should you find any

damage to an accessory or part, please contact

sales agent through which you have purchased your

tool or an authorized dealer near you for repair.

●Check parts for damage.

When you have found damage to accessory or other

part, carefully check the damaged part to determine

the extent of influence it has upon the functions of

the power tool – that is, determine whether it can

still perform its normal functions. Check to see that

the linkage of the moving members is OK, that all

parts are OK without damage, that they are properly

mounted, and that the power tool functions normally.

Should you find any damage to an accessory or

part that may hamper proper functioning of the tool,

please contact sales agent through which you have

purchased your tool or an authorized dealer near

you for repair.

●Have your tool repaired at Nitto service station

For repair or parts replacement please contact sales

agent through which you have purchased your tool

or an authorized dealer near you.

●Use Nitto genuine parts.

Use of improper parts may result in serious

occurrence.

To obtain a Nitto genuine part, consult this Manual or

contact sales agent from which you have purchased

your tool directly.

●Do not detach label or nameplate from tool.

When a label or nameplate gets scratched or peeled

off, contact sales agent through which you have

purchased your tool or Nitto Koki Co., Ltd. directly

for a replacement.

GENERAL:PNEUMATIC

TOOLS

Warning

●Use appropriate air pressure.

Excessively high air pressure will increase the

number of revolutions or strokes, causing not only

premature failure or breakage but also unexpected

accident.

●Connect only pneumatic air supply lines.

Never attempt to connect the Air Lapping Tool to

any supply line other than a pneumatic air supply

line. There are other kinds of supply lines and pipes,

such as oxygen supply lines, nitrogen supply lines or

gas pipes.

Never attempt to connect the Air Lapping Tool to any

of these other types of supply lines.

Attempting to connect the Air Lapping Tool to any

supply line other than a pneumatic air supply line

can result in accidents and/or severe injury.

●Start tool properly.

Turn the start switch OFF before connecting the tool

to the hose leading to air supply line.

●Always disconnect the tool from the connecting

hose leading to air supply line before putting on

or taking off accessories or before getting down

to maintenance work.

●Avoid exposure to exhaust air.

Exhaust air contains from pneumatic tool contains oil

and contaminated moisture. Make sure that exhaust

air will not be directed to your face or anyone else

who may be around.

●Keep tool off electricity.

The pneumatic tool is not insulated against

electricity. You may get electric shock if your

pneumatic tool comes into contact with running

electricity: keep it off electricity.

Caution

●Handle tool carefully.

Abusive use of tool would invite failure or accident.

Do not throw or drop; don’t give tool a shock.

●Handle connecting hose carefully.

Don’t hold the tool by the connecting hose when

carrying it; don’t pull the connecting hose to

disconnect.

4

INSTRUCTIONS FOR

THIS TOOL

Warning

●Wear protective glasses and a dustproof mask

Operation generates chips and dust particles,

etc. which may cause eye and/or respiratory

injury: Always use PPE (Personal Protective

Equipment) for eye and respiratory protection.

●If discomfort or pain is encountered during use,

you should cease operations and check with

your physician.

●Be sure to keep hands clear of moving parts.

●Always turn off the air supply and disconnect

the air supply hose before replacing or adjusting

a file and a part on the tool.

Caution

●Use NITTO genuine parts files and pads.

●Use of the ones other than NITTO genuine parts

may cause abnormal vibration or defective

finishing surface.

●The weight of the accessory for this tool should

be 12~15g.

1. APPLICATION

This tool is for filing the workpieces using the exclusive

file.

2. RECEIVING INSPECTION

Upon unpacking, check to see that the shipment is

complete without damage or oil leakage in transport.

Should you find any damage or short-shipment,

please contact sales agent through which you have

purchased your machine or an authorized dealer

near you for corrective actions.

Package Content Q’ty

SUPER HAND ASH-800 1set

Rat Tail File SF-10 1

Triangular Taper File SF-11 1

Half Round File (Rat Tail / Double

Cut) SF-12 1

Flat Bastard File SF-13 1

Hex. Wrench Key 2.5 1

Bushing PT1/4×NPT1/4 1

Instruction Manual 1

3. AIR SUPPLY

3-1. Air Pressure

Adjust air pressure with the air regulator to the level

appropriate for the pneumatic tool used.

Air pressure that is too low fails the tool to operate at

full capacity.

Air pressure that is too high may cause damage to

the tool.

3-2. Air Line (Fig. 1)

Use a 9.5 mm (3/8”) connecting hose between the

compressor and the tool.

Drained water, etc., if flown into the tool, could

cause tool failure. Install an air filter. between the

compressor and the tool.

Air Regulator Oiler

Air Filter

C

o

m

p

r

e

s

s

o

r

TOOL 9.5mm (3/8 in)

Hose

Fig. 1

3-3. Lubrication

Caution

●Always lubricate with a few drops of oil (ISO

VG-10), 2 to 3 times a day.

Install an oiler between the compressor and the

tool. Use Machine Oil #10. Failure to lubricate

causes damage to the tool. Lubricating oil with high

viscosity degrades tool performance.

5

4. OPERATION

4-1. Mounting / Removing the file (Fig. 2)

Warning

●Always turn off the air supply and disconnect

the air supply hose.

Mounting

Insert the file shaft into the Holder and tighten the Hex.

Socket Set Screw with the Hex. Wrench Key until the

file is securely fixed.

Removing

Loosen the Hex Socket Set Screw with the Hex.

Wrench Key and take it out.

File

Holder

Hex.SocketSetScrew

Hex.WrenchKey

Fig. 2

4-2. Start and Stop (Fig. 3)

Warning

To start : Turn the Valve Ring clockwise a and match

“▲” to “

■

” on the Housing.

To stop : Turn the Valve Ring counterclockwise and

match “ ▲” to “ ●” on the Housing.

Housing

Valvering

Fig. 3

4-3. Operation

Warning

●Always wear eye protection during operations.

●Start the operation and press the tool slightly to

the workpiece. Even if the tool is strongly pressed,

the filing efficiency cannnot be improved.

4-4. How to use the Sanding Pad (Optional

Accessories) (Fig. 4)

(1) Attach the Abrasive Paper on the sponge of

Sanding Pad and fix it with the Paper Clamp as

shown on the figure 4.

(2) Mount the Sanding Pad in the same menner as the

one for the file and carry out operation.

(3) Cut the locally available the Abrasive Paper into

20mm × 190mm size and use it.

Note: The Sanding Pad may cause the larger vibration

of the tool than the one caused by the file.

Sponge Abrasivepaper

HangtheApointof

PaperClamptotheShaft

Hangittotheshaft

PaperClamp

A

FixtheAbrasivepaper

onthesponge

Fig. 4

4-5. Storing Tool

Warning

●When tool is not used, store it out of reach of

children.

When the tool is not used, store it in a dry area.

If the tool is left alone as it has been used without

preparation for storage, ambient moisture will remain

inside the tool, which will leave it susceptible to

rusting. After finishing your work, add the machine oil

#10 through the Air Hose and run the tool for a while

before storage.

5. THREAD SIZE OF HOSE FITTING

The product comes with a metal fitting with PT

thread. Connect the Bushing PT thread X NPT thread

containing standard accessories. If you would like to

have American NPT thread.

6. OPTIONAL PARTS

In addition to standard accessory parts, the following

parts are available for your application and needs.

Part No. Part Name Q’ty

TA9A222 Rat Tail File SF-10 5pcs.

TA9A223 Triangular Taper File SF-11 5pcs.

TA9A224 Half Round File (Rat Tail /

Double Cut) SF-12 5pcs.

TA9A225 Flat Bastard File SF-13 5pcs.

TB03887 Sanding pad Ass’y 1set.

7. ORDERING PARTS

When ordering parts from our agency, plesase be sure

to give them part number, part name and quantities.

6

37

36 39

8. EXPLODED DIAGRAM : ASH-800 PARTS LIST

Warning

This diagram is for refrence only. Do not attempt to service or repair the Nitto Air Lapping Tool. Do not take the Tool

apart. Contact an authorized Nitto dealer for all service and repair of the Tool.

Improper service and repair can cause accidents and severe injuries.

Never attempt to modify the Tool.

Never attempt to service or repair the Tool yourself.

7

The part numbers with ( ) are included in the Ass’y parts written above them.

No. Part No. Part Name Q’ty Price

1 TQ04988 Collar 1

2 TQ00485 Hex. Socket Set Screw with

Flat Point 5×6 1

3 CQ03877 Internal Retaining Ring

IRTW-18 1

4 TQ04986 Guide 1

5 TP00639 Hex. Socket Set Screw with

Flat Point 4×3 1

6 TQ04984 Front Case 1

7 TQ04987 Holder 1

8 TB03853 Front End Cap Ass’y 1set

9 (TP03978) Oil Seal G10×14×13 1set

10 (TA9A101) U Seal Ass’y 1set

11 (TQ01971) Bushing 1

12 (CP24319) O-Ring JASO-1018 1

13 TB03854 Front Piston Ass’y 1set

14 TB03928 Piston Ring Ass’y 2sets

15 TP02152 Washer M5 1

16 TP00126 Hex. Socket Head Cap

Screw 5×16 1

17 TQ04994 Spring 0.8×13.5×40 1

18 TB03856 Rear Piston Ass’y 1set

19 TQ05000 Partition 2

20 TQ05007 O-Ring S-63 2

21 TQ04999 Cylinder 1

22 TB03918 Housing Ass’y 1set

23 (TQ05069) Label Warning 1

24 (TQ05010) Label Model Number 1

25 TB03857 Rear End Cap Ass’y 1set

26 (CP24319) O-Ring JASO-1018 3

28 TP11994 O-Ring P-4 2

29 TB03878 Hose Nipple Ass’y 1set

30 (TP07006) Spring Pin 2×8

31 TQ05002 Shim 1

32 TQ13162 Lock Plate 1

33 CP25822 O-Ring JASO-2018 1

34 TB03861 Valve Ring Ass’y 1set

35 (TQ05012) Label Serial Number 1

36 TB08131 Air Hose K Ass’y 1set

39 (TQ11519) Label Lubrication 1

37 CP25581 O-Ring JASO-1015 1

38 TQ1125 Exhaust Hose 1

40 TQ05009 External Retaining Ring STW-7 1

41 TQ05353 Spacer 7.1×12.2×6 1

Part list of accessories

No. Part No. Part Name Q’ty Price

TP00700 Rat Tail File SF-10 1

TP00701 Triangular Taper File SF-11 1

TP00702 Half Round File (Rat Tail

/ Double Cut) SF-12 1

TP00703 Flat Bastard File SF-13 1

TP04305 Hex. Wrench Key 2.5 1

TQ05087 Instruction Manual 1

TP02236 Bushing PT1/4×NPT1/4 1

Printed in JAPAN

TQ05087-5

SUPER HAND Model ASH-800

PROFESSIONAL TOOL

Table of contents

Other Nitto Power Tools manuals

Popular Power Tools manuals by other brands

Stanley

Stanley Fatmax FMC608 Original instructions

Gage Bilt

Gage Bilt GB713 Original instructions

Daewoo

Daewoo DALMT18-1 user manual

Atlas Copco

Atlas Copco LTV38 R Series Original product instructions

Black & Decker

Black & Decker Speedy Roller Original instructions

Hougen

Hougen HMD914 series instruction manual