Nivetec UNICONT PMM-500 Owner's manual

pmm5111a0600p_01

1 / 32

UNICONT

PMM-500

Universal process controller and

display unit

User's and Programming manual

1 edition

st

2 / 32

pmm5111a0600p_01

TABLE OF CONTENTS

1. GENERAL DESCRIPTION........................................................................................................................3

2. ORDER CODE...........................................................................................................................................4

3. TECHNICAL DATA ...................................................................................................................................5

4. DIMENSIONS ............................................................................................................................................6

5. MOUNTING ...............................................................................................................................................6

6. WIRING......................................................................................................................................................6

6.1 WIRING INSTRUCTIONS ..........................................................................................................................6

6.2 WIRING CHART OF THE OUTPUT VERSIONS ...............................................................................................7

7. FRONT PANEL, KEYPAD, DISPLAYS ....................................................................................................8

8. ERROR MESSAGES AND INDICATIONS ...............................................................................................9

9. PROGRAMMING SEQUENCE................................................................................................................10

9.1 POWERING UP FOR THE FIRST TIME .......................................................................................................10

9.2 SELECT MODE ....................................................................................................................................10

9.2.1 Mode Selection sequence for programming............................................................................10

9.2.2 Unlock code.............................................................................................................................11

10. OPERATION MODES, PROGRAMMING .............................................................................................11

10.1 INFORMATION MODE..........................................................................................................................12

10.2 CONFIGURATION MODE......................................................................................................................12

10.3 SET-UP MODE...................................................................................................................................21

10.4 AUTO-TUNING (AT) MODE .................................................................................................................25

10.5 MANUAL SETTING OF PID PARAMETERS...............................................................................................25

10.6 MANUAL FINE TUNING OF PID PARAMETERS ........................................................................................26

10.7 OPERATOR MODE .............................................................................................................................27

10.7.1 Display modes.......................................................................................................................27

10.7.2 Manual Mode.........................................................................................................................29

11. COMMUNICATION................................................................................................................................29

11.1 GENERAL DATA .................................................................................................................................29

11.2 MODBUS COMMUNICATION .................................................................................................................30

11.3 COMMUNICATION PARAMETERS ..........................................................................................................30

11.3.1 Bit Parameters.......................................................................................................................30

11.3.2 Word Parameters ..................................................................................................................31

pmm5111a0600p_01

3 / 32

Thank you for choosing a NIVELCO instrument.

We are sure that you will be satisfied throughout its use!

1. GENERAL DESCRIPTION

The UNICONT PMM-500 universal display and controller instruments are 1/16 DIN (48x48mm) size, panel

mountable, modern, easy of use microprocessor based devices supporting versatile functions. EEPROM

memory ensures data- and program protection during power outages.

The universal input can be connected with wide range of temperature sensors (Pt-100 RTD-s and most type

of thermocouples), or standard analogue current and voltage signals (mA, mV, V).

The instrument operates its control outputs in accordance to selected control algorithm generated from the

measured input values of various physical parameters.

The control algorithm can be ON-OFF, or PID, therefore it can provide differential control, or can realize

multiple control characteristics.

Using the Auto Tuning mode, the instrument provides optimal settings without entering any P-I-D

parameters.

The controller has multiple outputs: relay, SSR-driver, analogue current-, or voltage output, RS485

communication. The modular structure provides wide selection of output variations. In accordance to the

mechanical structure of the output boards (plug-in PCB-s) there is a possibility to order special (differing

from the standard) variations.

Inputs Outputs

Thermocouple

Voltage signal

PMM-500

Universal

controller

Relay

SSR driver

RS485 communication

Power supply for

transmitters

ON-OFF

PID

Heat / Cool

operation

Manual

mode

Controls

The RS485 Modbus RTU serial output provides digital communication interface with PC and remote

programming possibility.

Some models have 24V DC output performing power supply for transmitters.

The large bi-coloured 2-line, 7-segmented, 4-digit LED display provides easy reading even from far distance.

It indicates the Process (PV) and a Set-point (SV) Value, as well the programming steps or other settings.

Operation modes and alarm signals are indicated with LED-s. The 4 push-buttons provide easy

programming.

4 / 32

pmm5111a0600p_01

2. ORDER CODE

UNICONT PMM-500 series:

UNICONT PMM-5 –*

INPUT CODE POWER SUPPLY CODE

Universal 100-240 V AC 1

(sensor or analogue)

1 20-48 V AC

22-65 V DC 2

OUTPUT* CODE

R1, R2, analogue OUT 1 OUTPUT DESCRIPTION

R1, R2, Ut2 R1, R2, R3 SPDT relay outputs

R1, analogue OUT, Ut3analogue OUT Analogue current- or voltage outputs

R1, R2, R3 4 SSR1, SSR2 Solid State Relay driver output

SSR1, SSR2, analogue OUT 5 UtTransmitter power supply 24 V DC/ 22 mA

SSR1, SSR2, Ut6 RS485 Serial communication line

SSR1, analogue OUT, Ut7

SSR1, R1, analogue OUT 8 Accessories:

R1, R2, analogue OUT, RS485 A NAME ORDER CODE

R1, R2, Ut, RS485 B Mounting accessory pmm5111m00001

R1, analogue OUT, Ut, RS485 C Front plate sealing pmm5111m00002

R1, R2, R3, RS485 D Front plate size adapter

SSR1,SSR2, analogue OUT, RS485 E from 96x48 mm cut-off PAM-500-0

SSR1, SSR2, Ut, RS485 Fsize to 48x48 mm

SSR1, analogue OUT, Ut, RS485 G

SSR1, R1, analogue OUT, RS485 H

* Special output versions differing from the above code-variations are available to order.

pmm5111a0600p_01

5 / 32

3. TECHNICAL DATA

Type PMM-5--

Pt100 RTD: -199 ºC...+800 ºC

Thermocouple: J, T, K, L, N, B, R, S, C, Pt Rh

-240 ºC...+2320 ºC

Current: (DC) 4-20 mA, 0-20 mA

Sensor,

or analogue input

Voltage: (DC) 0-50 mV, 10-50 mV,

0-5 V, 1-5 V, 0-10 V, 2-10 V

Input resistance

Pt100 RTD: >10 MOhm,

Current input (20 mA): 5 Ohm

Voltage input (10 V): 47 kOhm

Input

Other data

Input Sampling rate: 4 / sec

Digital Input Filter time constant: 0.5...100 sec

Pt100 Sensor Current: 150 µA

Isolated from all outputs (except SSR driver)

Relay Max. 3 pcs., SPDT (Single pole double throw) 240 V AC, 2A, AC11

SSR Max. 2 pcs., SSR (Solid State Relay) driver, 0-10 V DC / 20 mA

Analogue DC

4-20 mA, 0-20 mA / 500 Ohm max.

0-5 V, 0-10 V, 2-10 V/500 Ohm min.

Short-circuit protected

Accuracy: ±0.25 %

Reinforced safety isolation from the input and other outputs

Transmitter power

supply

19-28 V DC not regulated, Nominal value: 24 V DC / 22mA,

Reinforced safety isolation from the input and other outputs

Outputs

Serial communication RS485 MODBUS RTU, Address range: 1-255, Bit rate: 1200-19200 Baud

Features Operation range Resolution

Proportional Bands (P) 0.5-999.9% 0.1 %

Derivative Time Constant (D) 0 - 100 min 1 sec

Integral Time Constant (I) 1 sec - 100 min 1 sec

Cycle Times 0.5 sec - 512 sec binary steps

ON/OFF Differential 0.1% - 10 % of input span 0.1 %

Controls:

ON / OFF

P, PD, PI, PID, Dual PID

AT

AUTO / MANUAL

Cooling / Heating Deadband/Overlap -20 % ...+20 % of input span 0.1 %

Process Value (PV): 4 digit, red, height of characters: 10 mm7-segment LED

display Set Value (SV): 4 digit, green, height of characters: 8 mm

Indication

LED

Operation modes:

Select mode, configuration

Automatic Tune

Alarms

Over-range indication

Under-range indication

Configuration With press buttons of the front panel from -1999 to +9999 range

Measurement accuracy ±0.1% of range ±1LSD, Thermocouple: ±0.1% of full range span ±1LSD

Linearization accuracy Better than ±0.2°C any point, any 0.1°C range ( ±0.05°C typical). Better than ±0.5°C any point,

any 1 °C range

Temperature stability 0.01% of range/°C change in ambient temperature

Sensor break protection Process Control outputs turn OFF within two seconds

In case of analogue input: applicable for 4 to 20mA, 1 to 5V and 2 to 10V ranges only

Cold junction compensation > ±1 ºC

Wire compensation 3-wire Pt100, automatic

100-240 V AC 50/60 Hz 7.5 VA

Power supply 20-48 V AC 50/60 HZ 7.5 VA; 22-65 V DC 5 W

Electrical connection Screw type terminals

Memory protection Data stored in EEPROM

Electrical protection Class II.

Ingress protection Front panel: IP66 Back panel: IP20

Ambient temperature 0 ºC…+55 ºC

Storage temperature -20 º…+80 ºC

Relative humidity Max. 85%

Dimensions 48 x 48 x 110 mm

Mass ~0.25 kg

6 / 32

pmm5111a0600p_01

4. DIMENSIONS

The unit can be mounted into a

suitable 1/16DIN (48x48 mm) cut-

out place. Insertion length of the

unit is 110mm, the additional

dimensions can be seen on the

drawing below.

48

48 10 110

5. MOUNTING

The unit can be mounted with the help of the

attached mounting accessory to the suitable cut-out

hole. Be careful with the sealing, which provides

proper sealing from the front panel. Suitable

distances between multiple units should be taken

into consideration.

The cut-out dimensions in case of single, or multiple

units should be the following, and width of the

mounting-plate is Lv=3-9 mm.

Using the optional PAM-500-0 front plate size

adapter the 48x48mm sized unit can be mounted to

an existing 96x48mm cut-out hole. In case of using

the front plate size adapter, the width of the

mounting-plate is Lv=3-5 mm

62

55

45

+0,5

+0,2

45

+0,5

+0,2

6. WIRING

6.1 WIRING INSTRUCTIONS

POWER SUPPLY

PMM-5□□ -1 PMM-5□□ -2

100-240 V AC 20-48 V AC

22-65 V DC

T1A T365 mA

Notes:

Connect the line voltage (live and neutral) as illustrated via a

two-pole isolating switch (preferably located near the equipment)

and an anti-surge fuse.

All analogue and communication signals must use shielded

cable. The shield should be grounded at one end only.

Two wire RTDs leads should be less than 3 metres long,

resistive leg and the common legs of the RTD (4-5 points) should

be connected.

Four wire RTDs can be used, provided that the fourth wire is left

unconnected.

+

-

Fuse

Power supply

OUT A

OUT 2.

OUT 3.

Thermo-

couple

Analogue

mA V/mV

IN

+

-

+

+

--

-

1

2

3

4

5

6

7

8

9

10

11

12

16 17 18

13 14 15

TOP

OUT 1.

Pt100

pmm5111a0600p_01

7 / 32

6.2 WIRING CHART OF THE OUTPUT VERSIONS

Outputs

OUT1 OUT2 OUT3 OUTA

Type

1

2

3

13

14

15

16

17

18

11

12

PMM-511-□

R1

N

O

N

C

C

R2

N

O

N

C

C

Analogue

PMM-512-□

R1

N

O

N

C

C

R2

N

O

N

C

C

24V DC / 22mA

PMM-513-□

R1

N

O

N

C

C

Analogue

24V DC / 22mA

PMM-514-□

R1

N

O

N

C

C

R2

N

O

N

C

C

R3

NON

C

C

PMM-515-□

SSR1

10V DC / 20mA

SSR2

10V DC / 20mA

Analogue

PMM-516-□SSR1

10V DC / 20mA

SSR2

10V DC / 20mA

24V DC / 22mA

PMM-517-□SSR1

10V DC / 20mA

Analogue

24V DC / 22mA

PMM-518-□

SSR1

10V DC / 20mA

R2

N

O

N

C

C

Analogue

RS485

PMM-51A-□

R1

N

O

N

C

C

R2

N

O

N

C

C

Analogue

B A

RS485

PMM-51B-□

R1

N

O

N

C

C

R2

N

O

N

C

C

24V DC / 22mA

B A

RS485

PMM-51C-□

R1

N

O

N

C

C

Analogue

24V DC / 22mA

B A

RS485

PMM-51D-□

R1

N

O

N

C

C

R2

N

O

N

C

C

R3

NON

C

C

B A

RS485

PMM-51E-□SSR1

10V DC / 20mA

SSR2

10V DC / 20mA

Analogue

B A

RS485

PMM-51F-□SSR1

10V DC / 20mA

SSR2

10V DC / 20mA

24V DC / 22mA

B A

RS485

PMM-51G-□

SSR1

10V DC / 20mA

Analogue

24V DC / 22mA

B A

RS485

PMM-51H-□

SSR1

10V DC / 20mA

R2

NO N

C

C

Analogue

B A

8 / 32

pmm5111a0600p_01

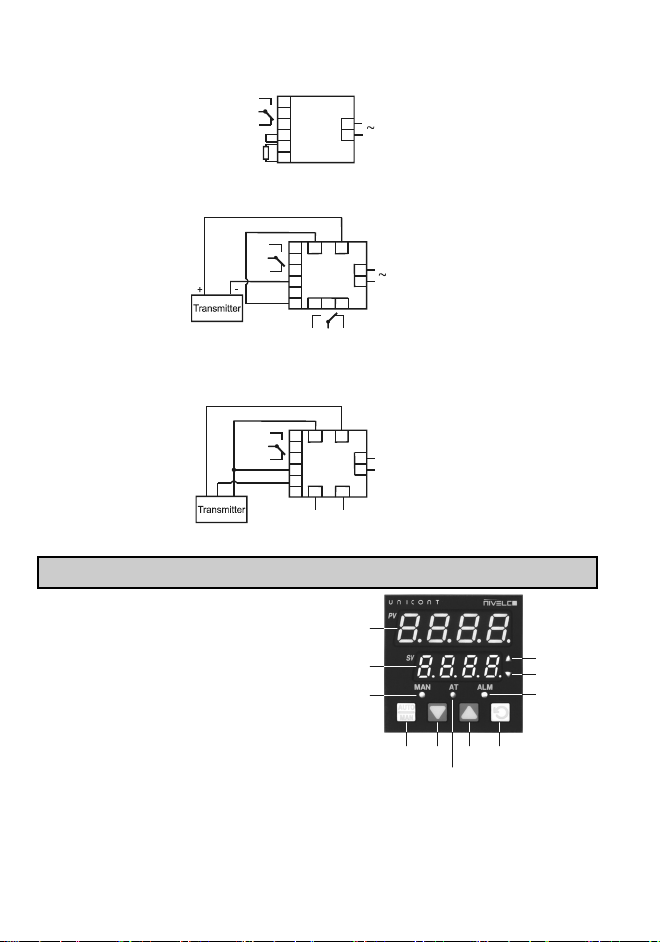

Wiring examples:

2-wire Pt 100 RTD, 1 relay output.

1

2

3

4

5

6

9

10 100-240V AC

Pt100

NO

NC

C

OUT 1.

2-wire 4-20 mA transmitter, power supply for transmitter, 2 pcs. relay output.

1

2

3

4

5

6

9

10

16 18

13

14 15

OUT 1. NO

NC

C

100-240V AC

NO NC

C

24VDC

+

-

+

-

4-20mA

OUT 2.

OUT 3.

3-wire voltage output transmitter, power supply for transmitter, 1 relay output, 1 analogue output.

1

2

3

4

5

6

9

10

16 18

13 15

NO

NC

C

pl. 22- 65V DC

24VDC

+

-

+

-

U

-

+

-

+

OUT

+

-

Analogue OUT

OUT 2.

OUT 1.

OUT 3.

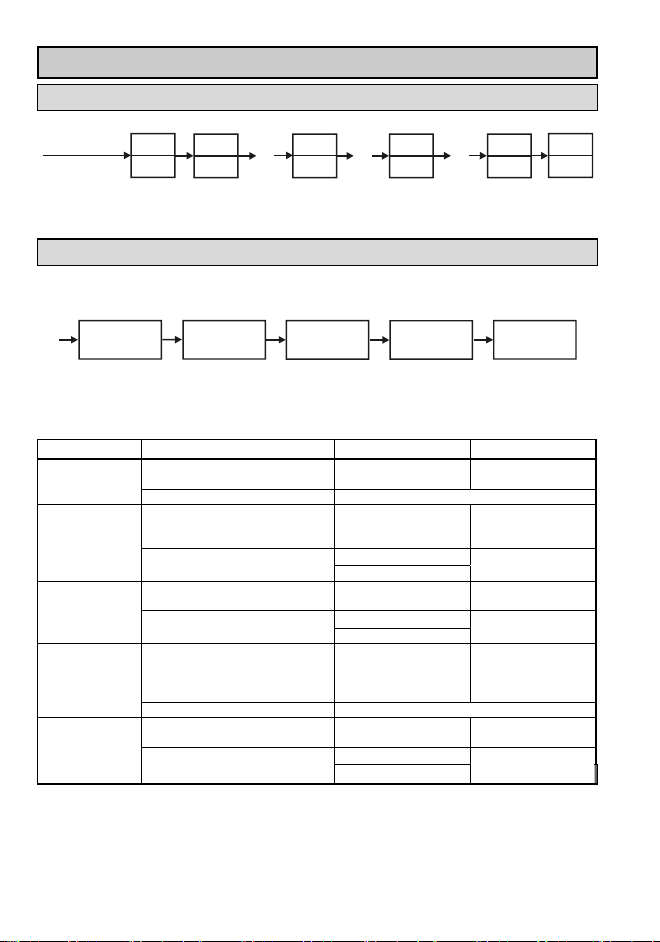

7. FRONT PANEL, KEYPAD, DISPLAYS

The 7-segmented displays show the measured and

set process values (Process Value-PV, Set Value-

SV) in normal operation, and show text signals and

values in accordance to the actual state of

programming and configuration. With the 4 push-

buttons the menu-system can be handled and

programming can be performed.

Process Value

Set Value

Manual mode

Auto Tuning

Toggle between

Automatic /

Manual control

and acknowledge

Down Up Function

Primary output

Secondary output

Alarm indication

pmm5111a0600p_01

9 / 32

Operation

LED LIGHTS FLASHES

MAN Setup mode Manual mode

Auto tuning mode

AT Self-Tune mode Pre-Tune mode

ALM - Alarm condition is present

▲

For Current Proportioned outputs, ON indicates

primary power is >0%

It turns ON when the stored Max. PV value is

displayed on indicators

FLASHES in unison with Time Proportioning

Primary outputs

▼

For Current Proportioned outputs, ON secondary

power is >0%

It turns ON when the stored Min. PV value is

displayed on indicators

FLASHES in unison with Time Proportioning

Secondary outputs,

After powering ON the unit performs an automatic self-test and flashes all front-plate LEDs for a moment. At

first turning ON, or after replacing an output module indication can be seen on the

display, which means that the unit should be configured in Configuration Mode (see 9.1, 10.2. points).

In all other cases after the self-test the unit returns to normal operation mode.

8. ERROR MESSAGES AND INDICATIONS

ERROR DESCRIPTION PV DISPLAY SV DISPLAY

Configuration & Setup is required at first turn ON or if

hardware configuration changed!

Press button to enter configuration mode, then press ,

or button to unlock code number, then press button to

proceed. Configuration should be completed according to the

configuration menu points.

Input more than 5% over-range 1 Normal display

Input more than 5% under-range 2 Normal display

Sensor Break. Break detected in the input sensor or wiring Normal display

OUTPUT 1 error

OUTPUT 2 error

OUTPUT 3 error

OUTPUT A error

1 If the PV display exceeds 9999 before 5% over-range is reached, an over-range indication is given.

2Indicators will allow up to 10% under-range on non-zero based Linear ranges. If the PV display is less than

-1999 before the 5% under-range is reached, an under-range indication is given.

10 / 32

pmm5111a0600p_01

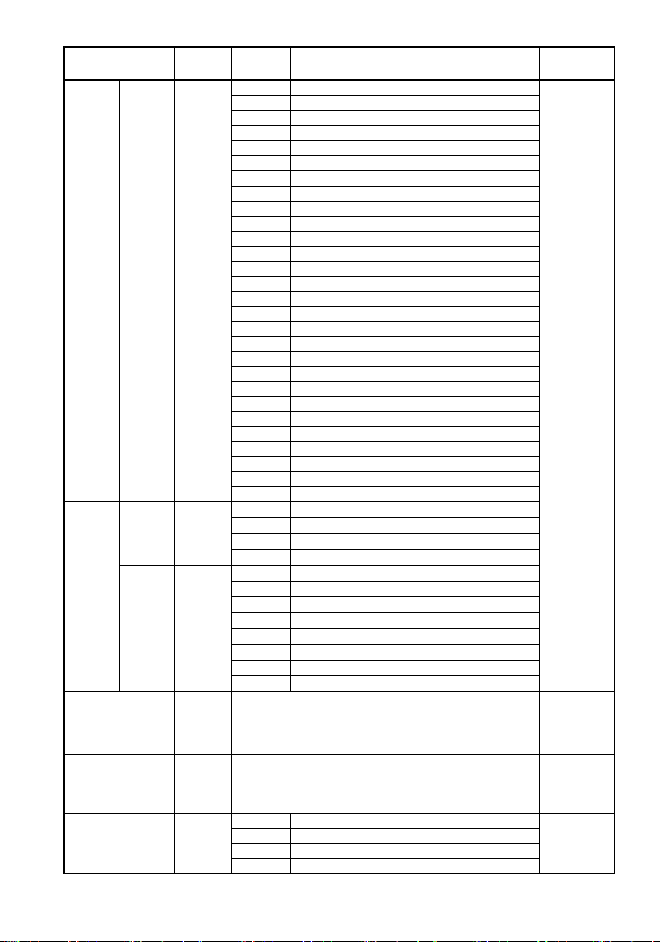

9. PROGRAMMING SEQUENCE

9.1 POWERING UP FOR THE FIRST TIME

Self-test

First turn ON

Turn ON

after replacing

an output

module

Automatic

hardware test

Entering

unlock code

Selecting the value of

unclock code

Configuration

menu

Normal

operation

Wait 2 minutes

Self-test

9.2 SELECT MODE

9.2.1 MODE SELECTION SEQUENCE FOR PROGRAMMING

Information

mode

Configuration

mode

Set-up

mode

Auto-tuning

mode

Operator

mode

Hold down button and press button in any mode to enter Select Mode. Once in Select Mode, press

or to select the required mode, then press to enter the chosen mode.

MODE FUNCTION PV DISPLAY SV DISPLAY

The Default Mode on power up used

for normal operation

Operator mode

Unlock code none

Used to tailor the instrument to the

application, adjustment of tuning

terms etc.

Set-up mode

Unlock code Default value: 5

Used to configure the instrument for

first time use or on re-installation.

Configuration

mode Unlock code Default value: 5

Used to check the hardware, firmware

and

manufacturing information of the

instrument

Production

Information mode

Unlock code none

Used to invoke pre-tune or self-tune

on controllers.

Auto Tuning mode

Unlock code Default value: O

If there is no key activity for 2 minutes the controller automatically returns to operator mode!

pmm5111a0600p_01

11 / 32

9.2.2 UNLOCK CODE

To enter a required menu point press button then select the corresponding unlock code with and

buttons. This procedure can prevent unauthorised entry to Configuration, Setup and Automatic Tuning

modes. Entering an incorrect unlock code will result to return to Select Mode. The value of the lock codes

only can be changed from within the modes that they apply to.

In the event that a lock code is not known or forgotten, the instrument lock code values can be seen in the

lock code view. In this view the codes are read only, the codes can be changed from the mode to which they

apply.

Turn OFF the device. Press and together whilst the instrument is powering up until the display is

shown. Once in this mode press to step between lock codes.

LOCK CODE NAME PV DISPLAY SV DISPLAY

Configuration Lock Code Max. 4 digit value, DEFAULT VALUE: 5

Setup Lock Code Max. 4 digit value, DEFAULT VALUE: 5

Automatic Tune Lock Code Max. 4 digit value, DEFAULT VALUE: 0

If there is no key activity for 2 minutes the controller automatically returns to operator mode!

10. OPERATION MODES, PROGRAMMING

Self

Tes t

+

Turn ON

+

Operation mode Normal operation

Normal

operation

Automatic

hardware test

Entering unlock code

Entering

set-up

mode

+

Set-up

mode

+

+

Entering

unlock code

Toggle

menu points

Entering

configuration

mode

-Entering an incorrect unlock code

results in a return to Select Mode.

-If there is no key activity for 2 minutes

the controller autamtically returns to

normal operation.

Warning!

Configuration

mode

To gg l e

menu points

Entering

information

mode

To gg l e

menu points

Information

mode

+

To gg l e

menu points

Entering

auto-tuning

mode

Entering

unlock code

Auto-tuning

mode

12 / 32

pmm5111a0600p_01

10.1 INFORMATION MODE

This mode describes the instrument and the options fitted to it. It is advised to start Select Mode procedure

with this point because toggling in the menu, hardware configuration, manufacturing data can be seen about

the given instrument.

+

+

Toggle menu points

Exit from Select Mode

Parameters are read only!

If there is no key activity for 2 minutes the controller automatically returns to operator mode!

PARAMETER POSSIBLE VALUES PV DISPLAY SV DISPLAY

Input type Universal input

No option fitted

R1 Relay

Option 1 module type

SSR1 drive

No option fitted

R2 Relay

SSR2 drive

Option 2 module type

Linear voltage / current output

No option fitted

R3 Relay

Linear voltage / current output

Option 3 module type

24V Transmitter power supply

No option fitted

Auxiliary option A module type RS485

Type number 4 characters

Firmware Issue number 2 characters

Product Rev Level Interior code 4 characters

Date of manufacture Interior code 4 characters

Serial number Interior code

4 characters

4 characters

4 characters

10.2 CONFIGURATION MODE

This mode is normally used only when the instrument is configured for the first time or when a major change

is made to the instruments characteristics.The Configuration Mode parameters must be set as required

before adjusting parameters in Setup Mode, or attempting to use the instrument in an application.

Navigating in Configuration Mode

+

Select

mode

Toggle to the

next parameter

+

Return to

Select Mode

Configuration

mode

Entering unlock code

Default value: 5

Entering configuration

mode menu

Default value:

Toggle

menupoints

Setting the value of the

parameter as required Accept

Caution:

Entering an incorrect unlock code will result to return to Select Mode. Only parameters that are

applicable to the hardware options chosen will be displayed.

Once the value is changed, the display will flash to indicate that confirmation of the change is required.

The value will revert back if not confirmed within 10 seconds.

If there is no key activity for 2 minutes the controller automatically returns to operator mode!

pmm5111a0600p_01

13 / 32

PARAMETER SV-

DISPLAY

PV-

DISPLAY ADJUSTMENT RANGE DEFAULT

VALUE

B tip. 100…1824 °C

B tip. 211…3315 °F

C tip. 0…2320 °C

C tip. 32…4208 °F

J tip. -200…120 °C

J tip.-328…2192 ° F

J tip. -188,8…537,7 °C

J tip. -199,9…999,9 °F

K tip.-240…1373 °C

K tip. -400…2503 °F

K tip. -128,8…537,7 °C

K tip. -199,9…999,9 °F

L tip. 0…762 °C

L tip. 32…1403 °F

L tip.0,0…537,7 °C

L tip. 32,0…999,9 °F

N tip. 0…1399 °C

N tip. 32…2551 °F

R tip. 0…1759 °C

R tip.32…3198 °F

S tip. 0…1762 °C

S tip. 32…3204 °F

T tip. -240…400 °C

T tip. -400…752 ° F

T tip. -128,8…400,0 °C

T tip. -199,9…752,0 °F

PtRh tip. 0…1850 °C

Input type and

Range

Thermocouple

PtRh tip. 32…3362 °F

Pt100: -199…800 °C

Pt100: -328…1472 °F

Pt100: -128,8…537,7 °C

Pt100

Pt100: -199,9…999,9 °F

0-20 mA DC

4-20 mA DC

0-50 mV DC

10-50 mV DC

0-5V DC

1-5 V DC

0-10 V DC

Input type and

Range

Analogue

2-10 V DC

Scale Range

Upper Limit

Scale Range Lower Limit +100 to Range Max

Between -1999…+9999

Linear inputs

= 1000 (°C/°F

inputs = max

range)

Scale Range

Lower Limit

Range Min. to Scale range Upper Limit -100

Between -1999…+9999 Linear =

(°C/°F = min

range):

No decimal point

XXX.X

XX.XX

Decimal point position

(Only for analogue

input)

X.XXX

14 / 32

pmm5111a0600p_01

PARAMETER SV-

DISPLAY

PV-

DISPLAY ADJUSTMENT RANGE DEFAULT

VALUE

Single outputs can drive the PV in one direction only (e.g.

heat only, cool only, increase humidity etc)

Control Type

Dual outputs can force the PV to increase or decrease

(e.g heat & cool, humidify and dehumidify etc)

Reverse action is typically used with heating applications;

On-Off reverse outputs will turn off when the process

variable exceeds setpoint. Proportional reverse outputs

will decrease the percentage of output as the process

value increases within the proportional band. The

Secondary Output will be direct whenever the Primary

Output is selected as reverse.

Primary Output

Control Action

Direct action is typically used with cooling applications;

On-Off direct outputs will turn on when the process

variable exceeds setpoint. Proportional direct outputs will

increase the percentage of output as the process value

increases within the proportional band. The Secondary

Output will be reverse whenever the Primary Output is

selected as direct.

Process High Alarm

Reverse action

OFF

ON

OFF ON

OUT

ALM

Alarm PV

Direct action

OFF

ON

OFF ON

OUT

ALM

Alarm PV

Alarm 1 Type

Process Low Alarm

Reverse action

OFF

ON

OFF

ON

OUT

ALM

Alarm PV

Direct action

OFF

ON

OFF

ON

OUT

ALM

Alarm PV

pmm5111a0600p_01

15 / 32

PARAMETER SV-

DISPLAY

PV-

DISPLAY ADJUSTMENT RANGE DEFAULT

VALUE

Deviation Alarm

Up

Reverse action

OFF

ON

OFF ON

OUT

ALM

Alarm

PV

+

Direct action

OFF ON

OFF ON

OUT

ALM

Alarm

PV

+

Down

Reverse action

OFF

ON

OFF

ON

OUT

ALM

Alarm PV

-

Direct action

OFF

ON

OFF

ON

OUT

ALM

Alarm PV

-

Band Alarm

Reverse action

OFF

ON

OFF

ON

OUT

ALM

Alarm

PV

-

OFF

ON

+

==

Direct action

OFF

ON

OFF

ON

OUT

ALM

PV

Alarm

-+

==

ON

ON

No alarm

Process High

Alarm 1 value

Only visible when

= set

Parameter is repeated

in Set-up Mode

Range Min. to Range Max. Range

Max.

Process Low

Alarm 1 value

Only visible when

= set

Parameter is repeated

in Set-up Mode

Range Min. to Range Max. Range

Min.

16 / 32

pmm5111a0600p_01

PARAMETER SV-

DISPLAY

PV-

DISPLAY ADJUSTMENT RANGE DEFAULT

VALUE

Deviation

Alarm 1 Value

Only visible when

= set

Parameter is repeated

in Set-up Mode

±span from setpoint 5

Band Alarm 1 Value

Only visible when

= set

Parameter is repeated

in Set-up Mode

1 LSD to full span from setpoint 5

Alarm 1 Hysteresis

Parameter is repeated

in Set-up Mode

Up to

100% of

span

Alarm hysteresis

Process High Alarm or Deviation Alarm

OFF ON OFF

Alarm Hysteresis

Value

Alarm Value

or Deviation

Alarm value

PV

Process Low Alarm or Deviation Alarm

PV OFF ON OFF

Alarm or

Deviation value

Alarm Hysteresis

Value

Band Alarm

Setpoint

OFF OFF

ON ON OFF

PV

Alarm

band

Alarm Hysteresis

Value

Alarm Hysteresis

Value

1

As for Alarm 1.

As for Alarm 1.

As for Alarm 1.

As for Alarm 1.

Alarm 2 Type

As for Alarm 1.

Process High

Alarm 2 Value

Only visible when

= set

Parameter is repeated

in Set-up Mode

Range Min. to Range Max Range

max.

Process Low

Alarm 2 Value

Only visible when

= set

Parameter is repeated

in Set-up Mode

Range Min. to Range Max Range

min.

pmm5111a0600p_01

17 / 32

PARAMETER SV-

DISPLAY

PV-

DISPLAY ADJUSTMENT RANGE DEFAULT

VALUE

Deviation

Alarm 2 Value

Only visible when

= set

Parameter is repeated

in Set-up Mode

±span from setpoint 5

Band Alarm 2 Value

Only visible when

= set

Parameter is repeated

in Set-up Mode

1 LSD to full span from setpoint 5

Alarm 2

Hysteresis

Parameter is repeated

in Set-up Mode

1 LSD to

100% of

span (in

display

units) on

“safe” side

of alarm

point

As for Alarm 1. 1

Disabled:

Loop Alarm Enable

Enabled:

Loop Alarm

A loop alarm is a special alarm, which detects faults in

the control feedback loop, by continuously monitoring

process variable response to the control output(s). The

loop alarm can be tied to any suitable output. When

enabled, the loop alarm repeatedly checks if the control

output(s) are at the maximum or minimum limit. If an

output is at the limit, an internal timer is started:

thereafter, if the high output has not caused the process

variable to be corrected by a predetermined amount 'V'

after time 'T' has elapsed, the loop alarm becomes

active. Subsequently, the loop alarm mode repeatedly

checks the process variable and the control output(s).

When the process variable starts to change value in the

correct sense or when the output is no longer at the limit,

the loop alarm is deactivated. For PID control, the loop

alarm time 'T' is always twice the Automatic Reset

parameter value. For On-Off control, a user defined

value for the Loop Alarm Time parameter is used. The

value of 'V' is dependent upon the input type. For

Temperature inputs, V = 2°C or 3°F. For Linear inputs, V

= 10 least significant display units.

Control output limits are:

0% for Single output (Primary only)

controllers

-100% for Dual output (Primary and

Secondary) controllers

Correct operation of the loop alarm depends upon

reasonably accurate PID tuning. The loop alarm is

automatically disabled during manual control mode and

during execution of the Pre-Tune mode. Upon exit from

manual mode or after completion of the Pre-Tune

routine, the loop alarm is automatically re-enabled.

18 / 32

pmm5111a0600p_01

PARAMETER SV-

DISPLAY

PV-

DISPLAY ADJUSTMENT RANGE DEFAULT

VALUE

Loop Alarm Time

Only visible when

= set

Parameter is repeated

in Set-up Mode

1 sec to 99 mins. 59secs

Only applies if primary proportional band =0

99.59

No alarms Inhibited

Alarm 1 inhibited

Alarm 2 inhibited

Alarm Inhibit

Alarm 1 and alarm 2 inhibited

Primary Power

Secondary Power if =

Alarm 1, Direct Acting

Alarm 1, Reverse Acting

Alarm 2, Direct Acting

Alarm 2, Reverse Acting

Loop Alarm, Direct Acting

Loop Alarm Reverse

Loop Alarm, Reverse Acting

Alarm 1. OR Alarm 2.

Logical combinations of Alarms

Direct Reverse

Alarm 1.

OR Alarm

2.

Direct Alarm

1

Alarm

2

OUT

1

Alarm

1

Alarm

2

OUT1

.

OFF OFF OFF OFF OFF ON

ON OFF ON ON OFF OFF

OFF ON ON OFF ON OFF

Alarm1

OR Alarm

2.

Reverse

ON ON ON ON ON OFF

A

larm1. AND Ala

r

m 2.

Direct Reverse

Alarm

1

Alarm

2

OUT

1

Alarm

1

Alarm

2

OUT1

.

Alarm1.

AND

Alarm 2.

Direct

OFF OFF OFF OFF OFF ON

ON OFF OFF ON OFF ON

OFF ON OFF OFF ON ON

Output 1 Usage

Only visible when

≠

Alarm 1.

AND

Alarm 2.

Reverse

ON ON ON ON ON OFF

Primary Power

Secondary Power if =

Alarm 1, Direct Acting

Alarm 1, Reverse Acting

Alarm 2, Direct Acting

Alarm 2, Reverse Acting

Loop Alarm Direct Acting

Loop Alarm Reverse Acting

Logical combinations of Alarms

Alarm 1. OR Alarm 2.

Direct Reverse

Alarm1

OR

Alarm2

Direct

Alarm

1

Alarm

2

OUT

2

Alarm

1

Alarm

2

OUT2

OFF OFF OFF OFF OFF ON

ON OFF ON ON OFF OFF

OFF ON ON OFF ON OFF

Output 2 Usage

Only visible when

≠

Alarm1

OR

Alarm2

Reverse

ON ON ON ON ON OFF

pmm5111a0600p_01

19 / 32

PARAMETER SV-

DISPLAY

PV-

DISPLAY ADJUSTMENT RANGE DEFAULT

VALUE

Alarm1. és (AND) Alarm 2.

Direct Reverse

Alarm

1

Alarm

1

OUT

2

Alarm

1

Alarm

1

OUT2

Alarm1

AND

Alarm2

Direct OFF OFF OFF OFF OFF OFF

ON ON ON ON ON ON

OFF OFF OFF OFF OFF OFF

Alarm1

AND

Alarm2

Reverse

ON ON ON ON ON ON

Retransmit SP or PV Output if

=

0-5V DC OUT2.

0-10V DC OUT2.

2-10V DC OUT2.

0-20 mA DC OUT2.

Linear Output 2 Range

Only visible when

=

4-20 mA DC OUT2.

0-10

Retransmit Output 2

Scale maximum

Only visible when

=

or

It may be adjusted within the range -1999 to 9999; the decimal position

is always the same as that for the process variable input. If <

, the relationship between the process variable/setpoint value and

the retransmission output is reversed.

Range

max.

Retransmit Output 2

Scale minimum

Only visible when

=

or

It may be adjusted within the range -1999 to 9999; the decimal position

is always the same as that for the process variable input. If >

, the relationship between the process variable/setpoint value and

the retransmission output is reversed.

Range

min.

Primary Power

Secondary Power if =

Alarm 1, Direct Acting

Alarm 1, Reverse Acting

Alarm 2. Direct Acting

Alarm 2 Reverse Acting

Loop Alarm Direct Acting

Loop Alarm Reverse Acting

Logical combinations of Alarms

Alarm 1. OR Alarm 2.

Direct Reverse

Alarm1

OR

Alarm2

Direct Alarm

1

Alarm

2

OUT

3

Alarm

2

Alarm

1

OUT3

OFF OFF OFF OFF OFF ON

ON OFF ON ON OFF OFF

OFF ON ON OFF ON OFF

Alarm1

OR

Alarm2

Reverse

ON ON ON ON ON OFF

Alarm1. AND Alarm 2.

Direct Reverse

Alarm

1

Alarm

2

OUT

3

Alarm

1

Alarm

2

OUT3

Alarm1

AND

Alarm2

Direct

OFF OFF OFF OFF OFF OFF

ON ON ON ON ON ON

OFF OFF OFF OFF OFF OFF

Output 3 Usage

Only visible when

≠

Alarm1

AND

Alarm2

Reverse

ON ON ON ON ON ON

20 / 32

pmm5111a0600p_01

PARAMETER SV-

DISPLAY

PV-

DISPLAY ADJUSTMENT RANGE DEFAULT

VALUE

Retransmit SP or PV Output if

=

0-5 V DC OUT3

0-10 V DC OUT3

2-10 V DC OUT3

0-20 mA DC OUT3

Output 3 PV

Retransmit Type

Only visible when

=

4-20 mA DC OUT3

0-10

Retransmit Output 3

Scale maximum

Only visible when

= or

It may be adjusted within the range -1999 to 9999; the decimal position

is always the same as that for the process variable input. If <

, the relationship between the process variable/setpoint value and

the retransmission output is reversed.

Range

max.

Retransmit Output 3

Scale minimum Only

visible when

= or

It may be adjusted within the range -1999 to 9999; the decimal position

is always the same as that for the process variable input. If >

, the relationship between the process variable/setpoint value and

the retransmission output is reversed.

Range

min.

Display Strategy 1, 2, 3, 4,

5, 6

see Operator Mode for details 1

Modbus with no parity

Modbus with Even Parity

Communication

Protocol

Configured for OUT A

Only visible when

=

Modbus with Odd Parity

1.2 1200 Baud

2.4 2400 Baud

4.8 4800 Baud

9.6 9600 Baud

Bit rate

Only visible when

=

19.2 19200 Baud

4.8

Communication

Address

1 A unique address for each instrument between 1 to 255 1

Read / Write. Writing via Comms is possible

Communications Write

Enable

Read only. Comms writes ignored

Configuration Mode

Lock Code

Selectable between 0….9999 5

Table of contents