Nivis ER-550 Installation manual

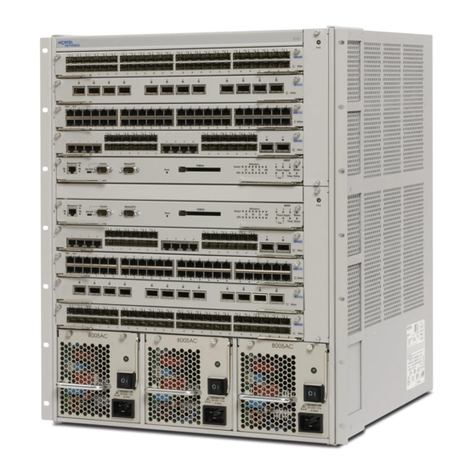

Acuity Edge Router ER-550

Hardware User Guide

(ER-550 Rev. C)

Version 1.0

Created: Mar. 4, 2008

Proprietary & Confidential – NIVIS LLC

Page 1 - V1.0

Revision History

Date Revision Description Author

03.03.2008 1.0 Create Document – Initial Draft Dan Cornescu

Proprietary & Confidential – NIVIS LLC

Page 2 - V1.0

Table of Contents

1. Scope ......................................................................................................................... 3

2. Introduction ............................................................................................................... 3

3. Mechanical View........................................................................................................ 3

4. Block Diagram ........................................................................................................... 4

5. User Configuration & Connections.......................................................................... 7

6. Internal Connections............................................................................................... 10

7. Start-Up Procedure ................................................................................................. 13

8. RF and Compliance................................................................................................. 14

Appendix 1................................................................................................................... 15

Proprietary & Confidential – NIVIS LLC

Page 3 - V1.0

1. Scope

The present document describes the Acuity Edger Router ER-550 hardware features.

2. Introduction

•The Acuity Edge Router ER-550 is designed to fulfill communications and data

acquisition requirement and use multiple communication channels (GPRS/EDGE

WAN + 10/100Base-T Ethernet port) and gather data via the 2.4GHz mesh

network radio link.

•The board is configured as intelligent LAN to WAN gateway for mesh sensor

networks applications. Data is stored and forwarded based on firmware

application.

•Board is operated continuously powered and includes circuitry that allows control

of power for sections of the board.

•Hardware includes a powerful ARM9 (@200MHz) and utilize a USB hub structure

and internal USB to serial converters in order to achieve communication

channels functionality

•Hardware includes a second MSP430 microcontroller that fulfills watchdog and

wake-up and monitoring duties for different modes of operation available.

•Communication modules are installed on a pluggable communication board on

top of the main board

•There are few connection available to user and include antenna connections,

Ethernet port and AC power connection, all other connections are internal in the

enclosure and are not directly accessible form outside.

•Design is AC powered and support an operating voltage range of 100-240VAC

•Hardware support operation temperatures range: -40C...+85C with up to 95%

non condensing humidity

3. Mechanical View

•Mechanical outline was designed to fit requirements

•Dimensions are presented in Appendix 1

Proprietary & Confidential – NIVIS LLC

Page 4 - V1.0

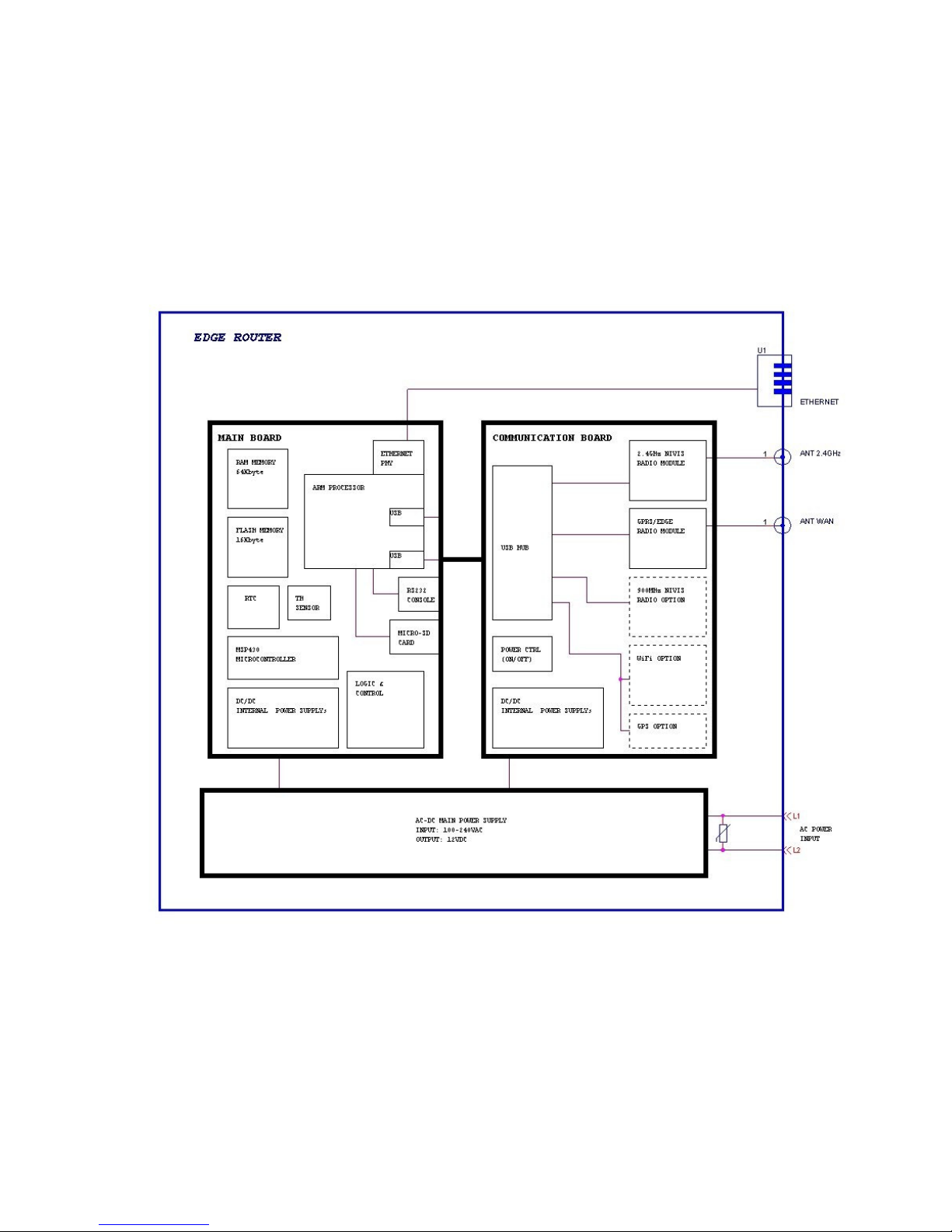

4. Block Diagram

Block diagram present the most important subsystems of the board.

Proprietary & Confidential – NIVIS LLC

Page 5 - V1.0

The Edge Router includes an ARM9 processor as the main processing entity that

controls most of the system features (some features are integrated internally into chip).

Subsystems controlled by the ARM processor are:

•Two directly connected serial channels. First channel is used for serial console

port used for factory programming and as debug console and is available on the

as RS232 connection. Second channel is used for intercommunication

(watchdog, commands, control and BSL mode) with the MSP430 microcontroller

that ensure system level watchdog and low power modes of operation. Also the

second channel is used for remote firmware upgrade of MSP430 code by using

the BSL mode programming mode.

•Two directly connected USB host channels. First channel is used for uplink USB

to a 4 port USB hub situated on the communication board in order to extend the

number of channels to necessary slot ports. Second channel is used for

providing the front panel USB user channel for administration via serial interface

and configuration purposes or as general USB host port for further applications.

•One Ethernet port (twisted pair port - 10/100Base-T). ARM processor implements

the Ethernet MAC internally and connects via the external PHY IC to RJ45

available connector on the main board.

•One 16-bit Data Address and Control bus for easy interfacing the memory

subsystem. Multiple chip select signals allow simple interface and multiple

methods for booting the system.

•Hardware SPI bus multiplexed for use with 2K Boot EEPROM option, micro-SD

card slot on main board for boot or storage or optional installed LCD panel.

•A large number of I/O grouped for internal control of board subsystems, for

control of power signals latch, for control of BSL programming mode of MSP430,

for implementing the I2C buses on the board. Two signals drive the Red and

Green on board LED’s.

The ARM memory subsystem is situated on the main board and includes the FLASH

memory (implemented 16Kbyte) and the two RAM memory chips (implement 2 x

32Kbyte). No buffering is included between memory and ARM processor. Boot of

system is realized from FLASH image programmed at factory. Also FLASH

accommodates the file system, application code and space for data storage. The RAM

memory is used to run the live system after boot, as temporary storage file system and

as memory allocated for system.

A set of 4 USB ports present on communication board are connected to USB-to-Serial

converters (internally) and supplemental circuitry that allow creation of slots

(communication slots) for the OEM installed communication modules. Slot powering is

controlled internally via a latch. This ensure a lot of flexibility for available power on/off

modes used in firmware.

The power supply subsystem include a 3.3V permanent power supply with low

quiescent current for MSP430 low power modes, a set of two power supply for 3.3V and

1.8V for the ARM, a 5V power supply for the USB hub and serial to USB converters and

level shifters of the communication board, one high current (up to 4A) switched power

supply for powering the OEM radio modules installed. Some extra linear regulators are

Proprietary & Confidential – NIVIS LLC

Page 6 - V1.0

present in order to efficiently provide the voltages for OEM modules and control the

power. Power supply can be switched ON/OFF under ARM control (separate for each

OEM module installed), the ARM power and USB hub power can be switched ON/OFF

under MSP430 control in order to support fine power management and a large

combination of modes of operation.

The main internal voltage is 12V and is provided by the AC-DC converter module

installed together with the main and communication board into the internal metallic

enclosure (for shielding purposes). Input voltage is AC trough installed power cord and

screw connections of the AC-DC power module.

Some auxiliary subsystems are present for internal management and include:

•Temperature and humidity sensor for environment management and alarms if

unit is exposed to values outside the specified range

•Precision hardware RTC used for applications that need precise time keeping,

also this is the 32KHz reference for the ARM processor internal RTC. The RTC

selected should allow drifts of no more than 3-4 seconds/month under normal

conditions and better if calibration trimmed at factory.

•Analog measurements via ARM analog input pins for on board voltages in order

to allow alarms when on board circuitry present anomaly in usage or onboard

components are faulty affecting the correct range for voltages.

Whole boards are installed stacked into the inside metallic enclosure and include the

power supply (in order to minimize the RF emissions). The external connections for

antennas and Ethernet are routed outside the metallic enclosure to proper connectors

on the IP-65 certified external plastic enclosure.

Proprietary & Confidential – NIVIS LLC

Page 7 - V1.0

5. User Configuration & Connections

5.1 Power Connection

•Power is connected trough grummet situated on the right side of the unit

•Recommended connection via PVC or Teflon insulated power cable with minimal

AWG #24 conductor size.

•Please check installation manual for other available connection types

Ethernet

GPRS

Antenna 2.4GHz

Antenna

AC Power Input

Proprietary & Confidential – NIVIS LLC

Page 8 - V1.0

5.2 External Ethernet Port Connection (10/100Base-T, RJ45)

•Ethernet port connects externally trough an RJ-45 type water proof connection

on top of the enclosure

•Proper cabling need to be used according to specifications for network cabling.

(PC use cross cable, connection via Hub use straight cable, or as specified)

•Ethernet subsystem can be power down under firmware control using board

internal control I/O pins in order to avoid extra consumption (when not used)

•Pin usage for Ethernet (10/100Base-T, RJ45 connection) are presented below:

Pin

Signal

Description

Direction

1 TD+ Transmit Data (+) Line Output

2 TD- Transmit Data (-) Line Output

3 RD+ Receive Data (+) Line Input

4 Not Used

5 Not Used

6 RD- Receive Data (-) Line Input

7 Not Used

8 Not Used

•Usage of a Lightening Protection device between Ethernet port and actual

connection cable is recommended for exterior installations. We recommend

usage of a device similar to http://www.hyperlinktech.com/web/al-cat5w.php .

Pin1

Proprietary & Confidential – NIVIS LLC

Page 9 - V1.0

5.4 Antenna Ports

•Antenna ports are situated on the sides of the enclosure.

•Antennas used have been specified in accordance to FCC certifications for the

device.

•On the left side of enclosure (the pedal shaped antenna) is the WAN connection

antenna. This is a quad band antenna specifically designed for GSM/GPRS

operation.

GPRS/EDGE – WAN ANTENNA

Description ANTENNA RUBBR DUCK MULT-BAND SMA

Model T6140AM-AGDPU-S

Manufacturer Nearson Inc.

Vendor Digi-Key Corporation

Vendor P/N 730-1016-ND

Gain [dBi] 2.0

Connection Type SMA (Male), Swivel

•On the right side of enclosure (the ring marked) is the mesh LAN connection

antenna. This is a 2.4GHz antenna specifically designed for ISM band operation.

2.4GHz – MESH LAN ANTENNA

Description ANTENNA 2.4GHZ 1/2 WAVE RP/SMA

Model ANT-2.4-CW-RCT-RP

Manufacturer Antenna Factor

Vendor Digi-Key Corporation

Vendor P/N ANT-2.4-CW-RCT-RP-ND

Gain [dBi] 2.2

Connection Type SMA Reverse (Female), Swivel

GPRS/EDGE

Antenna

2.4GHz Mesh

LAN Antenna

Proprietary & Confidential – NIVIS LLC

Page 10 - V1.0

6. Internal Connections

6.1 Connectors and cables

•Internal Connections are used for engineering diagnostics and factory

configuration of the unit.

•Usage and access to those connection are described in separate documents

•Those connections are internal and accessible only if unit is opened

•WARNING: Unit can be damaged by improper use of internal connections

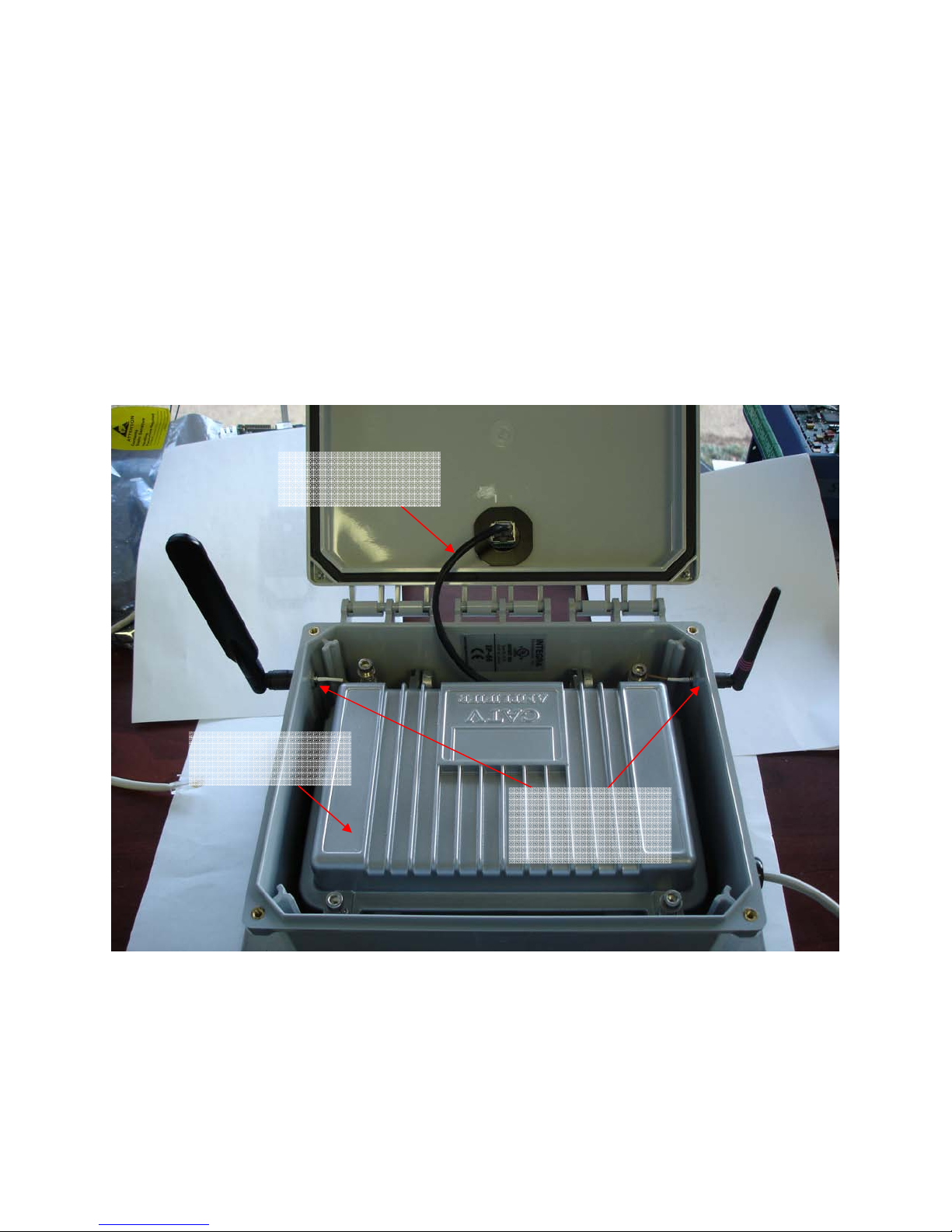

•Enclosure View

Internal Metallic

Enclosure

Internal Ethernet

Cable

Bulkhead

Antenna

Connections

Proprietary & Confidential – NIVIS LLC

Page 11 - V1.0

•Communication Board View

•Main Board View

GPRS/EDGE

Module

2.4GHz Module

SIM CARD

LED’s

AC-DC

Power Supply

AC Input

12V DC Input

Ethernet

RS232

Console

USB

ALARM S

Micro-SD

LCD

Expansion

ARM Processor

EXPANSION

CONN

Proprietary & Confidential – NIVIS LLC

Page 12 - V1.0

6.2 RTC Back-up Battery

•The device contain a coin cell battery socket to accommodate battery for RTC

•Socket should be populated with a coin cell CR2032 battery type

•Follow indicated polarity for battery installation, (+) on bottom.

•Anticipated battery life based on theoretical calculations is 10 years.

•Battery should be replaced as needed based on unit usage

•Inspection for corrosion is recommended when battery change is done

•WARNING: Unit can be damaged by polarity reverse battery installation

•Default Factory Configuration: CR2032 Lithium Battery Installed (10 year life)

RTC

CR2132 Coin

Cell Battery

Proprietary & Confidential – NIVIS LLC

Page 13 - V1.0

7. Start-Up Procedure

7.1 Quick Power-On

•System is factory preconfigured with firmware to support intended application

•First Install mechanically the Edge Router according to Installation Manual

•Verify proper installation and positioning of the external antennas.

•Install power connection and apply AC power to the system.

•Wait about 1-2 minutes for the system to boot and connect to NOC

•Verify with NOC specialists if system has registered and all subsystems are

running properly

•Coordinate tests and actions with NOC personnel if issues appear at installation

•There are no field accessible configuration elements on the hardware of the

device, configuration changes are solely achieved under firmware control

Note: The Ethernet port can be used for field configuration and debug according

to documentation provided. For direct PC or PDA connection use appropriate

crossed type cable.

Proprietary & Confidential – NIVIS LLC

Page 14 - V1.0

8. RF and Compliance

8.1 RF Exposure Limits WARNING

To comply with FCC’s RF exposure limits for general population / uncontrolled

exposure, the antenna(s) used for this transmitter must be installed to provide a

separation distance of at least 20cm from all persons and must not be collocated or

operating in conjunction with any other antenna or transmitter.

8.2 Compliance Statement (Part 15.19)

This Device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

•This device may not cause harmful interference.

•This device must accept any interference received, including interference that

may cause undesired operation.

8.3 Information to the user (Part 15.105)

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver.

•Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

•Consult the dealer or an experienced radio/TV technician for help.

8.4 WARNING (Part 15.21)

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Proprietary & Confidential – NIVIS LLC

Page 15 - V1.0

Appendix 1

•Mechanical outline and dimensions:

Table of contents

Other Nivis Network Router manuals

Popular Network Router manuals by other brands

Vista

Vista QSW8 user manual

DataRemote

DataRemote CDS-9010 quick start guide

Vimar

Vimar Well-contact Plus manual

TP-Link

TP-Link SafeStream TL-ER5120 installation guide

DIGITAL FORECAST

DIGITAL FORECAST Bridge RS16x16 instruction manual

Cyclades

Cyclades Access Router Cyclades-PR2000 Quick installation manual