GB - 6

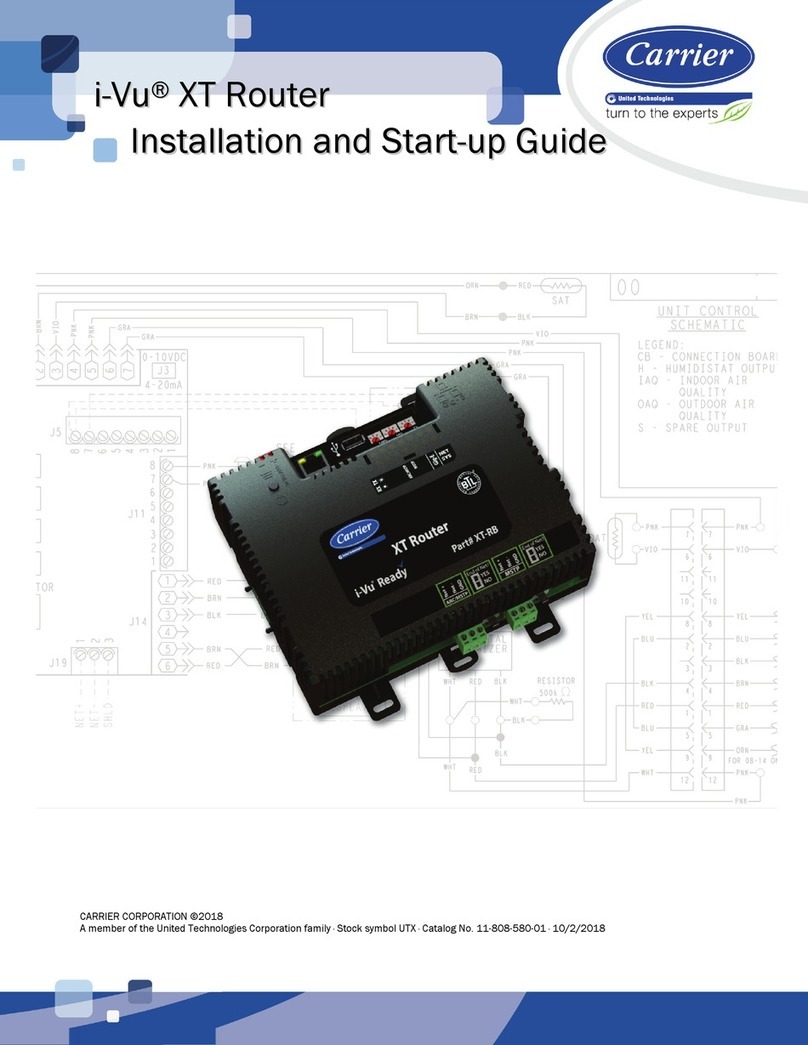

ZoneManager

Electrical connections

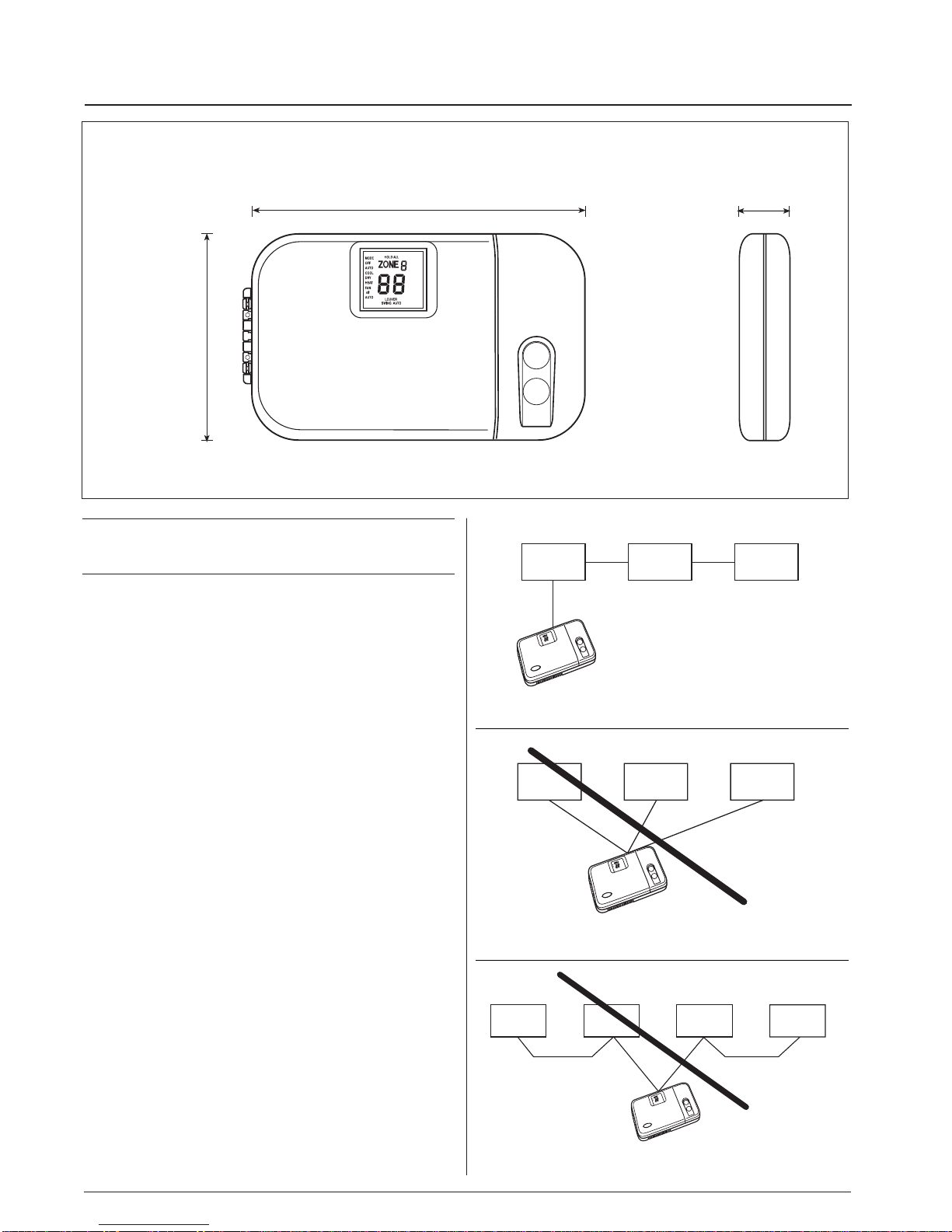

Diagram 1: wiring for Zone manager

Communication Board Zone Manager

To the unit

Ground post

BAC

Gnd 12 V

GND

+12

BK

WH

RD

P1

BK

RD BK RD

Wiring Zone Manager to master unit

The Zone Manager has the ability to control up to 32 units.

To insure the correct operation of this system the wiring must

be installed using the following guidelines.

WARNING:

Before connecting any wiring to the Zone Manager , turn off all

power to the unit that will supply power to the Zone Manager.

Electrical shock can cause personal injury or death.

The Zone Manager is connected to the master unit using the

following instructions. Reference Diagram 1 when making these

connections.

POWER CABLE CONNECTIONS

(2 conductor, double insulated cable)

• In the Zone Manager, loosen the screws on the terminals

labled +12V and GND.

• Insert the RED wire into the terminal labled +12V. Tighten the screw.

• Insert the BLACK wire into the terminal labled GND.

Tighten the screw.

• At the communications board in the master unit product,

loosen the screws on the terminals labled +12V and GND.

• Insert the RED wire into the terminal labled +12V.

Tighten the screw.

• Insert the BLACK wire into the terminal labled GND.

Tighten the screw.

• Power cable installation complete.

COMMUNICATION CABLE CONNECTIONS

(3 conductor, double insulated, shielded cable)

• In the Zone Manager, loosen the screws on the terminals

labled A, B, and C.

• Insert the RED wire into the terminal labled A. Tighten the screw.

• Insert the BLACK wire into the terminal labled B. Tighten the screw.

• Insert the WHITE wire into the terminal labled C. Tighten the screw.

• At the communications board in the master unit product,

loosen the screws on the terminals labled A, B, and C.

• Insert the RED wire into the terminal labled A. Tighten the screw.

• Insert the BLACK wire into the terminal labled B. Tighten the screw.

• Insert the WHITE wire into the terminal labled C. Tighten the screw.

• Connect the shield of the cable to the master unit GND post.

Communication cable installation complete.

B

C

A

BK Black

RD Red

WH White

aZone Manager

bUnit

NOTE:

The shield for the communications cable is not connected at

the Zone Manager.

Terminate the shield in such a manner that it will not short with

anything in the Zone Manager.

Wiring Materials required

(supplied by installer)

• 1 small screwdriver

• 3 x 0,5 and 2 x 0,5 mm2multiple cables, double insulated.

Suggested type: H03VV-F.