NLB 1312D User manual

Revision 12

1312D, 1012D, 812D, 612D,

512D, 412D, 3.512D, 312D,

1060D, 860D, & 760D

Diesel Engine Driven,

High Pressure Water Jetting Units

OPERATION,

MAINTENANCE &

PARTS MANUAL

NLB

Cor

.

29830 BECK ROAD

WIXOM, Ml 48393-2824

(248) 624-5555

FAX (248) 624-0538

PARTS

1-800-227-7652

© Copyright October, 2005 NLB Corporation

Revision o

GENERAL INFORMATION

Every effort has been made to include the most up-to-date information at the time

of

publication

of

this manual. However, the possibility exists that subsequent product changes

made by NLB Corporation may cause the information in this manual to be rendered

inaccurate. In the event that an information conflict is found to exist between this manual,

other publications or the condition and function of your equipment, NLB must be contacted

for clarification prior to operating or servicing the equipment.

Caution:

The

information

contained

in

this

manual

may

be

rendered inaccurate

if

the

equipment

described

herein

is

modified

in

any

way,

without

the authorization

of

NLB,

or

that

said

equipment

is

not

maintained

or

operated

in

a

proper

manner

as

instructed

in

this

manual. NLB

assumes

no

responsibility

or

liability

for

equipment

that

has

been modified,

for

equipment

that

incorporates

any

non-NLB

manufactured

parts

as

components

or

for

equipment

that

has

not

been

maintained

or

used

in

the

manner

set

forth

in

this

manual. In

that

event,

all

NLB

warranties,

either

express

or

implied, are

void.

WARNING:

THE EQUIPMENTDESCRIBED

IN

THIS MANUAL

AND

THE INFORMATION

CONTAINED

IN

THIS MANUAL SHOULD ONLY

BE

USED

BY

PERSONS

WHO

ARE

KNOWLEDGEABLE

AND

HAVEBEEN TRAINED

IN

THE OPERATION

AND/OR MAINTENANCE

OF

EQUIPMENT

OF

THE TYPE DESCRIBED HEREIN.

THE EQUIPMENT OWNER AND/OR USER SHOULD INSPECT THE EQUIPMENT

PRIOR

TO

ITS USE OR SERVICE

IN

ORDER

TO

MAKE

CERTAIN THAT

IT

IS

IN

GOOD WORKING ORDER

AND

FREE FROM DEFECT.

ALL

APPLICABLE

OPERATION, USE

AND

SERVICEMANUALS DESCRIBING THE FORESEEABLE

USES

OF

THE EQUIPMENTMUST

BE

READ

AND

UNDERSTOOD. THE

EQUIPMENTMUSTONLY

BE

USED IN THE MANNER SETFORTH

IN

THIS

MANUAL,

AS

SUPPLEMENTED

BY

ALL

APPLICABLEFEDERAL, STATE

AND

LOCAL LAWS, ORDERS

AND

REGULATIONS THATPERTAIN

TO

THE

OPERATION

AND

USE

OF

THE EQUIPMENT.

IF

THIS EQUIPMENT

JS

OPERATED BEYOND ITS INTENDED CAPACITYOR FORESEEABLE

USE,

IS

MISUSED, MODIFIED OR ABUSED

IN

ANY

WAY

WHATSOEVER, OR

IF

IT

IS

NOTMAINTAINED

IN

ACCORDANCE WITH THE INSTRUCTIONS CONTAINED

IN

THIS MANUAL, WITH

NLB

APPROVED PARTS; DEATH, SEVERE PERSONAL

INJURYOR EQUIPMENT DAMAGE MAYRESULT.

NLB

WARRANTY WILL

BE

VOIDED

IF

NON-NLB

MANUFACTURED

REPLACEMENTPARTS

ARE

USED. NLB'S WARRANTYIS VOID

AS

TO

ANY

DAMAGES CAUSED

TO

THE EQUIPMENT OR

BY

THE EQUIPMENTAND

TO

EXCLUDE

ANY

LIABILITY

AS

A RESULT

OF

INJURY,

IF

SUCH DAMAGEOR

INJURYCAN

BE

LINKED

TO

THE SUBSTANDARD REPLACEMENT

PART.

© Copyright September, 1999 NLB Corporation 0-1

Revision

11

MASTER

TABLE

OF

CONTENTS

1312D,

1012D, 812D, 612D, 512D, 412D, 3.512D, 312D, 1060D,

8600,

& 760D

Diesel Engine Driven,

High Pressure

Water

Jetting Units

DESCRIPTION PAGE NUMBER

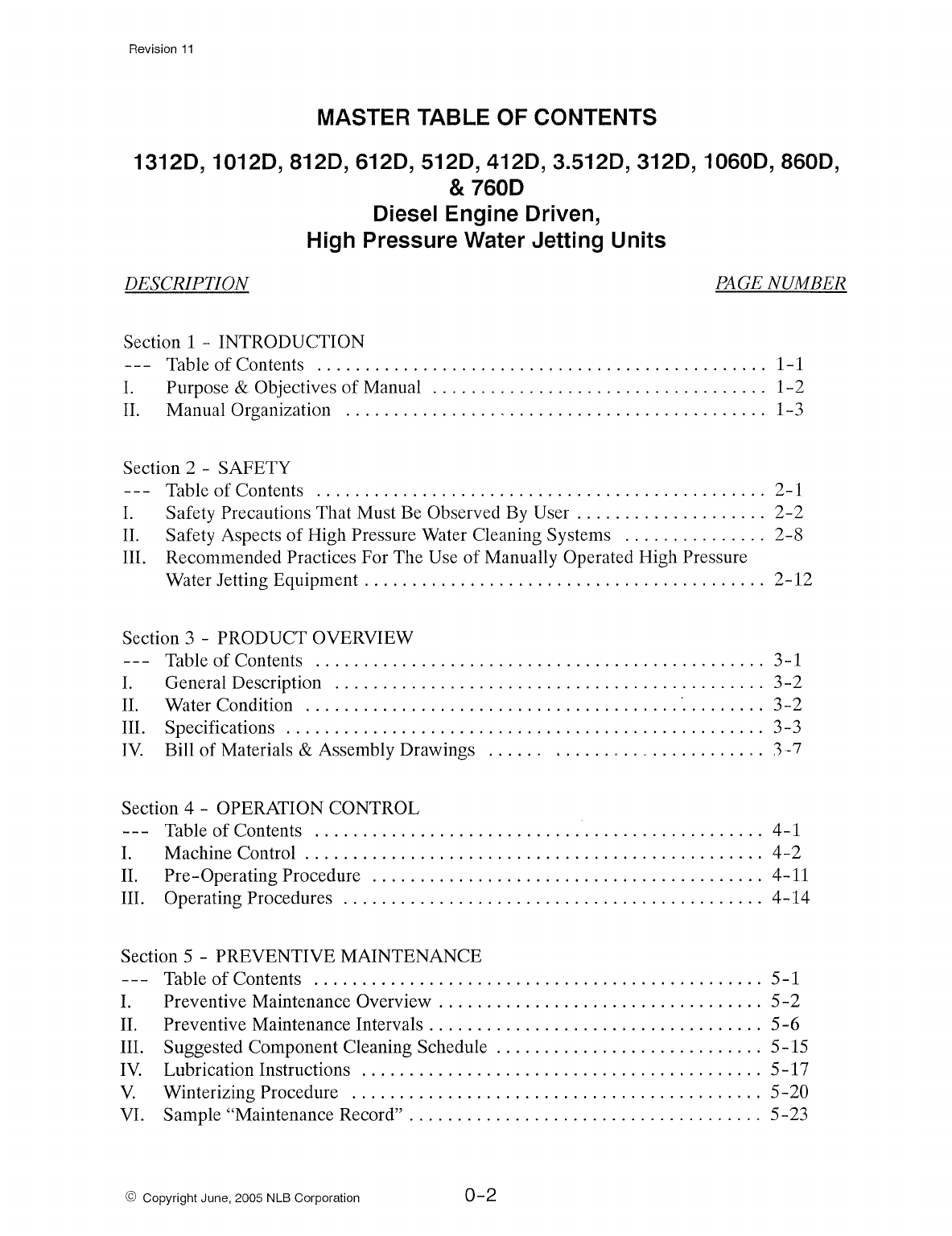

Section 1 - INTRODUCTION

Table

of

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

I. Purpose & Objectives

of

Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

II.

Manual Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3

Section 2 - SAFETY

Table of Contents 2-1

I. Safety Precautions That Must Be Observed

By

User

....................

2-2

II.

Safety Aspects of High Pressure Water Cleaning Systems

...............

2-8

III. Recommended Practices For The Use of Manually Operated High Pressure

Water Jetting Equipment

..........................................

2-12

Section 3 - PRODUCT OVERVIEW

I.

II.

Table of Contents

...............................................

3-1

General Description

.............................................

3-2

Water Condition

.......................................

'.

........

3-2

III. Specifications

..................................................

3-3

IV.

Bill of Materials & Assembly Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Section 4 - OPERATION CONTROL

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

I.

Machine Control

................................................

4-2

II.

Pre-Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

III. Operating Procedures

............................................

4-14

Section 5 - PREVENTIVE MAINTENANCE

Table

of

Contents

...............................................

5-1

I.

Preventive Maintenance Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2

II. Preventive Maintenance Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6

III. Suggested Component Cleaning Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

IV.

Lubrication Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-17

V.

Winterizing Procedure

...........................................

5-20

VI. Sample "Maintenance Record"

.....................................

5-23

© Copyright June, 2005 NLB Corporation

0-2

Revision

11

MASTER TABLE OF CONTENTS (Cont.)

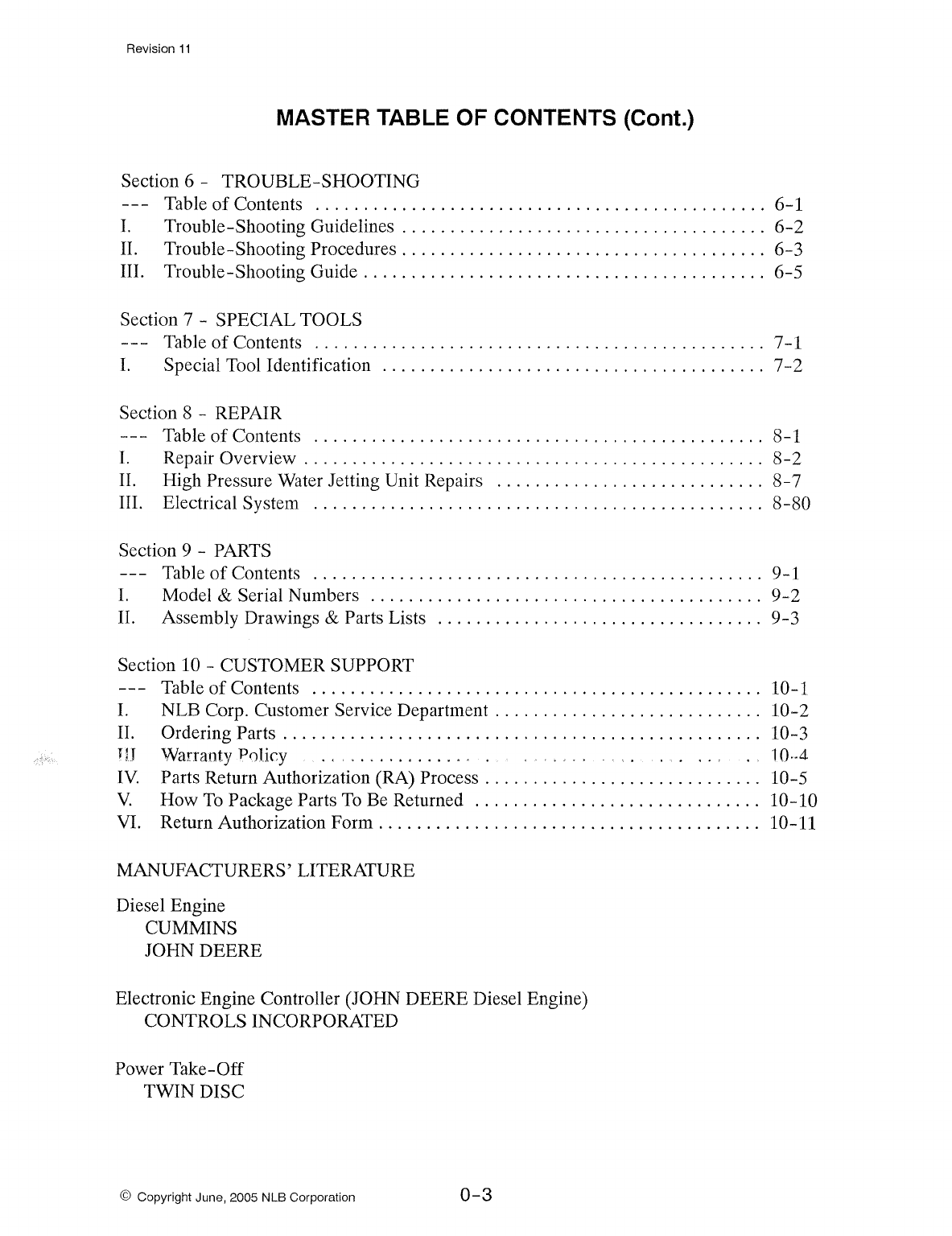

Section 6 - TROUBLE-SHOOTING

Table

of

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1

I. Trouble-Shooting Guidelines

......................................

6-2

II. Trouble-Shooting Procedures

......................................

6-3

III. Trouble-Shooting Guide

..........................................

6-5

Section 7 - SPECIAL TOOLS

Table

of

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1

I. Special Tool Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

-2

Section 8 - REPAIR

Table

of

Contents

...............................................

8-1

I. Repair Overview

................................................

8-2

II.

High Pressure Water Jetting Unit Repairs

............................

8-

7

III. Electrical System

...............................................

8-80

Section 9 - PARTS

Table

of

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

I. Model & Serial Numbers

.........................................

9-2

II. Assembly Drawings & Parts Lists

..................................

9-3

Section 10 -CUSTOMER SUPPORT

Table

of

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

I. NLB Corp. Customer Service Department

............................

10-2

II.

Ordering Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-3

HJ

Warranty Policy . . .

..

. . . . . . . . . . . . . . . . .

10--4.

IV.

Parts Return Authorization (RA) Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

V.

How

To

Package Parts

To

Be Returned

..............................

10-10

VI. Return Authorization Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

MANUFACTURERS' LITERATURE

Diesel Engine

CUMMINS

JOHN DEERE

Electronic Engine Controller (JOHN DEERE Diesel Engine)

CONTROLS INCORPORATED

Power Take-Off

TWIN DISC

© Copyright June, 2005 NLB Corporation

0-3

Revision

11

MASTER TABLE OF CONTENTS (Cont.)

MANUFACTURERS' LITERATURE (Cont.)

Water Inlet Bag Filter Assembly (Optional) -FSP85

FSI

© Copyright June, 2005 NLB Corporation

0-4

Revision

11

NLB

Cor

Manufacturer

of

the National Liquid Blaster

CALIFORNIA

Proposition 65 Warning

29830 BECK ROAD

WIXOM,

Ml

48393-2824

(248)

624-5555

FAX(248)624-0538

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects and

other reproductive harm.

© Copyright June, 2005 NLB Corporation

0-5

Revision O

TABLE OF CONTENTS

SECTION 1

INTRODUCTION

DESCRIPTION PAGE NUMBER

I.

Purpose & Objectives of Manual.

...................................

1-2

II.

Manual Organization

............................................

1-3

A.

Terminology

................................................

1-3

B. Illustrations & Photographs

....................................

1-4

C.

Revisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4

© Copyright September, 1999 NLB Corporation 1

-1

Revision O

I.

Purposes & Objectives

of

Manual

This manual is mandatory reading for all personnel who will be operating or performing

maintenance and/or repairs on the NLB high pressure water jetting equipment. The manual

must also be distributed to maintenance supervisors responsible for work planning,

scheduling, training, performance evaluating, and reporting. While some sections will be

of

more interest to equipment operators, others are for the use

of

the maintenance personnel.

It

is specifically developed to assist operating and maintenance personnel and is not intended

as

a replacement or substitution for customer developed maintenance criteria. The manual

describes safety features, start-up procedures, recommended preventive maintenance

agendas, troubleshooting activities, special tool descriptions, and repair procedures. As

further assistance to maintenance personnel, there are recommended spare parts lists,

photographically reproduced drawings, bills

of

materials, and assembly drawings which may

list other drawings that can be consulted as reference. The information contained in this

manual supplements instructions preferred by the customer.

There is also a section on safety, located in this binder, intended to point out certain safety

precautions and procedures applicable to high pressure water jetting equipment. The safety

section contains NLB's instructions concerning safe operation and service

of

the equipment.

Certain governmental regulations and industry practices may also apply to the operation and

service

of

the equipment.

If

an information conflict is found to exist between NLB's

instructions and other regulations or practices, NLB must be contacted for clarification prior

to operation or service

of

the equipment.

Insure that all persons involved with the operation and service

of

the equipment have

thorough knowledge

of

that equipment and are familiar with the location and operation

of

all

stopping devices. Except

in

cases

of

extreme emergency, permit only authorized personnel

to start or stop any equipment in the system. Confine operation

of

the equipment to

authorized operators. Leave repair functions

to

trained maintenance personnel.

Be alert to hazardous conditions such as sharp edges and protruding objects, and replace any

broken parts causing these conditions

as

soon

as

possible. Maintain good housekeeping

practices. Clean up all spilled lubricants and other material as promptly as possible. Report

all accidents resulting in damage to equipment and any irregularities in equipment operation

to the proper authority.

Reliability

of

mechanical equipment depends largely on sound maintenance procedures. All

NLB high pressure water jetting equipment should be thoroughly inspected at regular

intervals and corrective measures must be taken to prevent major breakdowns and a loss

of

valuable operation time.

A well organized program should be part

of

any maintenance plans.

If

a log is maintained

with sufficient information, a multi-purpose will be accomplished: first, a record

of

trouble

and responsibility is available; secondly, the log can be reviewed periodically for equipment

© Copyright September, 1999 NLB Corporation

"1

-2

Revision O

evaluation; and lastly, as a historical record. From the information collected, frequency

of

inspection and performance change methods could be made. This would then, over a period

of

time, make the maintenance program more effective. The PREVENTIVE

MAINTENANCE section includes a suggested maintenance record form to accomplish these

tasks.

Factors

of

significant importance that must also be considered are adjustment procedures,

lubrication instructions, troubleshooting, and replacement

of

parts. These factors are

thoroughly discussed in other sections

of

this manual.

Note:

Do notattempt to perform maintenance

or

make adjustments on any equipment

without first consulting this manual.

Note:

Replacementparts mustbe genuine NLB parts. The use

of

anyotherparts could

create a hazardous situation. Also, the use

of

any

otherparts will void all warranties

on this equipment.

To

order replacement parts call toll-free 1-800-227-7652.

II.

Manual Organization

A standard section arrangement has been adopted for the instructional sections

of

this

manual. Each section has at least one page in each

of

the following categories:

a,

Table

of

contents

b.

Body

of

the section

A.

Terminology

The following describes the usage

of

Note, Caution and Warning terms in this manual:

Note:

Key Information: "Note" is used to give special emphasis to instructions or additional

information concerning a function, step, or action to be taken.

Caution:

Minor Personal Injury and/or Equipment Damage: "Caution" is used to indicate the

presence

of

a hazard which can or will cause minor personal injury or equipment damage if

the caution is ignored.

© Copyright September, 1999 NLB Corporation 1

-3

Revision O

WARNING:

Severe Personal Injury and/or EquipmentDamage: "WARNING" is used to indicate the

presence

of

a hazard which can or will cause severe personal injury, death, or substantial

equipment damage ifthe warning

is

ignored.

B.

Illustrations &Photographs

Use the illustrations and photographs in this manual as a guide to perform the action,

maintenance, or repair described. Many illustrations are generic and will not look exactly

like the high pressure water jetting equipment or the parts used in your unit. In order to

provide clarity to illustrations and photographs, some illustrations and photographs show

parts removed that are not related

to

the specific parts given

in

the text.

C.

Revisions

This manual is a living document.

It

is revised whenever there are changes to the high

pressure water jetting equipment embodied in this manual.

In the upper left hand corner

of

each page

is

a revision record, listing the number

of

revisions

that have occurred to that page or section from the initial establishment

of

this manual

to

the

present time. When contacting NLB for clarification

of

information contained in this

manual, please indicate the revision number of the page in question.

© Copyright September, 1999 NLB Corporation

1-4

Revision 1

TABLE OF CONTENTS

SECTION 2

SAFETY

IMPORTANT:

PLEASE READ THIS SECTION COMPLETELYBEFORE OPERATING

ANY

OF

THE HIGH PRESSURE

WATER

JETTING EQUIPMENT.

DESCRIPTION PAGE NUMBER

Table

of

Contents

I. Safety Precautions That Must

Be

Observed By The User

...............

.

A. Operator Safety Equipment

...................................

.

B. Pre-Service Safety Check List

.................................

.

C. Recommended Safety Procedures Decal

.........................

.

II. Safety Aspects

of

High Pressure Water Cleaning Systems

..............

.

A. Equipment

.................................................

.

B. Personal Protective Equipment

.................................

.

C.

Pre-Operational Procedures

...................................

.

D. Operational Procedures

.......................................

.

E. Training . . . . . . . . . . . . . . . .

...................................

.

III. Recommended Practices For The Use

of

Manually Operated

High Pressure Water Jetting Equipment

.............................

.

A. Introduction

................................................

.

B. Scope

.....................................................

.

C.

Definition

of

Terms

..........................................

.

D. Equipment Definition and Standards

............................

.

E. Care and Maintenance

of

Equipment

............................

.

F.

Protective Clothing and Personnel Protection

.....................

.

G.

Pre-Operating Procedures

....................................

.

H. Operational Procedures

.......................................

.

I. Use

of

Lances and Nozzles

....................................

.

J.

Operational & Training Requirements

...........................

.

K. Permanent Cleaning Areas

....................................

.

L.

Freeze Precautions

..........................................

.

M. Accidents

..................................................

.

N.

Responsibility

..............................................

.

© Copyright January,

2001

NLB Corporation

2-1

2-1

2-2

2-2

2-4

2-6

2-8

2-8

2-9

2-10

2-11

2-11

2-12

2-12

2-12

2-13

2-14

2-17

2-19

2-20

2-21

2-26

2-27

2-28

2-28

2-29

2-29

Revision 3

WARNING:

NLB

WARRANTY WILL

BE

VOIDED

IF

NON-NLB

MANUFACTURED

REPLACEMENTPARTS

ARE

USED.

NLB'S

WARRANTYIS VOID

AS

TO

ANY

DAMAGES CAUSED

TO

THE EQUIPMENTOR

BY

THE EQUIPMENT

AND

TO

EXCLUDE

ANY

LIABILITY

AS

A RESULT

OF

INJURY,

IF

SUCH DAMAGEOR

INJURYCAN

BE

LINKED

TO

THE SUBSTANDARD REPLACEMENT

PART.

I.

Safety Precautions That Must Be Observed

By

User

Refer to the SAFETYsection before operating any high pressure water jetting components.

Do

not

operate this or any high pressure water jetting component or system without first

reading and understanding the SAFETYsection.

If

the SAFETYsection is missing from this

binder, call NLB at

1-800-226-7652

for a free copy.

Safety Signs:

All NLB high pressure water jetting equipment have safety signs strategically placed on the

equipment.

If

any become marred, painted over, or in any manner unreadable, contact NLB

for free replacements. These signs are furnished as an aid to training employees and as a

reminder to operators and their fellow employees. The safety signs are not intended to be

used as a substitute for a specific company training program covering the operation and

safety

of

the equipment. It is supervision's responsibility to call these signs to the attention

of

all personnel.

A. Operator Safety Equipment

NLB offers complete operator safety suits for high pressure waterblasting operations and

recommends the use

of

all operator and jobsite safety equipment that is available. NLB also

offers operation, maintenance & parts manuals and jobsite barrier marking tape.

Caution:

The use

of

hearing

protection

is

advised

when

operating

this

equipment.

© Copyright September, 2003 NLB Corporation

2-2

Revision 2

TURTLESKIN1!t

WATERARMORTM

© Copyright April, 2003 NLB Corporation

2-3

Revision 1

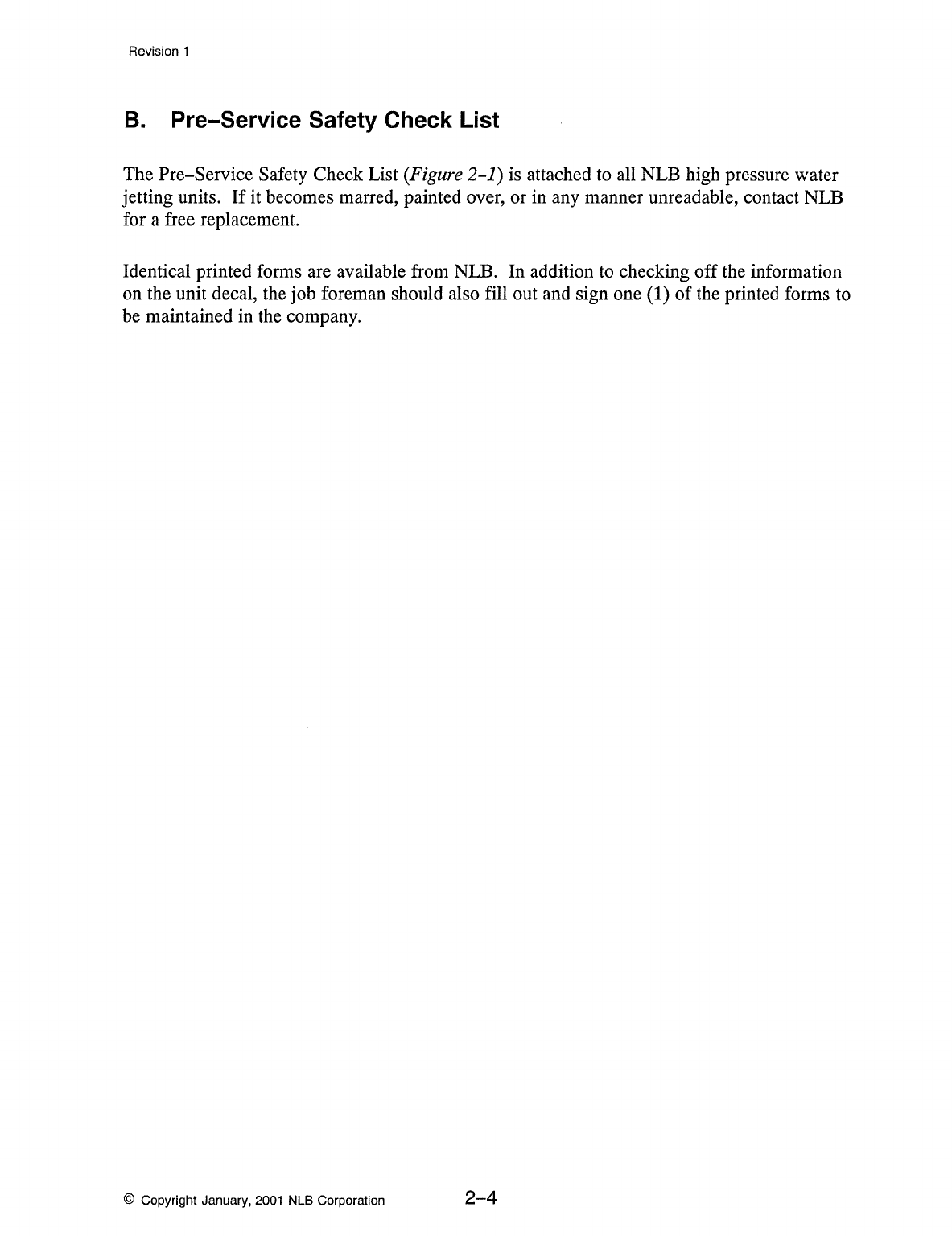

B.

Pre-Service Safety Check List

The Pre-Service Safety Check List (Figure

2-1)

is attached to all NLB high pressure water

jetting units.

If

it becomes marred, painted over, or in any manner unreadable, contact NLB

for a free replacement.

Identical printed forms are available from NLB.

In

addition

to

checking off the information

on the unit decal, the job foreman should also fill out and sign one (1) of the printed forms

to

be maintained in the company.

© Copyright January,

2001

NLB Corporation

2-4

Revision 1

PRE-SERVICE SAFETY CHECK LIST -HIGH PRESSURE WATER CLEANING

DATE: LOCATION:

_____________________

_

EQUIPMENT BEING SERVICED:

_________________________

_

1 IN

THE

AREA, INCLUDING OTHER END OF UNIT BEING SERVICED,

CLEAN, ROPED OFF, AND PROPER SAFETY SIGNS POSTED?

2 HAVE PRECAUTIONS BEEN TAKEN TO PROTECT ELECTRICAL

EQUIPMENT FROM WATER?

3 IS THERE ANY HAZARD TO PERSONNEL FROM POSSIBLE DAMAGE

TO

EQUIPMENT SUCH AS RELEASE

OF

CORROSIVE CHEMICALS,

FLAMMABLE LIQUIDS OR GASES, ETC.?

4

ARE

ALL FITTINGS

OF

THE CORRECT PRESSURE RATING?

5 ARE ALL HOSES OF THE CORRECT PRESSURE RATING?

6 ARE

ALL

HOSES IN GOOD OPERATING CONDITION?

7

ARE

ALL FITTINGS IN GOOD OPERATING CONDITION?

8 ARE ALL NOZZLES FREE FROM PLUGGING? AND

IN

GOOD

OPERATING CONDITION?

9 HAVE PRECAUTIONS BEEN TAKEN

TO

PREVENTLINEMOLE

REVERSAL?

10 IS THE FILTER ON THE PUMP SUCTION CLEAN AND IN GOOD

OPERATING CONDITION?

11

IS THERE A MINIMUM 20 PSIG FRESH CLEAN WATER SUPPLY AT

PUMP SUCTION?

12

HAVE

PRECAUTIONS BEEN TAKEN AGAINST FREEZING?

13

DO

ALL PERSONNEL HAVE THE PROPER SAFETY EQUIPMENT FOR

THIS JOB?

14

DO

ALL PERSONNEL HAVE THE PROPER SAFETY TRAINING FOR THIS

JOB?

15

ARE

ALL MEN QUALIFIED TO PERFORM THIS WORK?

16

ARE

EXPLOSIVE OR FLAMMABLE VAPORS POSSIBLE AND ARE

MONITORING PROVISIONS ESTABLISHED?

17 IF ANSWER

TO

16 IS "YES", DO NOT USE DEMINERALIZED WATER OR

CONDESATE AND GROUND LANCE EQUIPMENT BEING CLEANED.

·18 IS THERE ANY DANGER FROM THE WASTE WATER OR FROM THE

REACTION OF THE SCALE AND WATER?

19 IF ANSWER

TO

18 "YES", HAS PROPER PERSONAL PROTECTIVE

EQUIPMENT BEEN SUPPLIED

TO

PREVENT INJURY, AND HAS

PERSONNEL BEEN INFORMED

OF

THIS ADDITIONAL HAZARD?

20 HAS COMPLETE HOOK-UP BEEN FINISHED PRIOR TO INSTALLING

NOZZLES?

21

HAS HOOK-UP, INCLUDING PIPES, HOSES AND CONNECTIONS, BEEN

PRESSURE TESTED WITH WATER AT MAXIMUM OPERATING

PRESSURE?

22 IS DUMP SYSTEM OPERATING PROPERLY? (WILL IT DUMP WHEN

RELEASED)?

23 ARE SAFETY SYSTEMS OPERATIONAL?

Figure 2-1. Pre-Service Safety Check List.

© Copyright January,

2001

NLB Corporation

2-5

YES NO N/A

Revision 1

C.

Recommended Safety Procedures Decal

The recommended Safety Procedures Decal (Figure

2-2)

is attached

to

all NLB high

pressure water jetting units.

If

it becomes marred, painted over or in any manner unreadable,

contact NLB for a free replacement.

© Copyright January,

2001

NLB Corporation

2-6

Revision 1

IMPORTANT RECOMMENDED SAFETY PROCEDURES

AS

WITH ALL POWER

TOOLS,

THE NATIONAL LIQUID BLASTER MUST BE USED

IN

ACCORDANCE WITH SPECIFIED SAFETY PROCEDURES AND COMMON SAFETY SENSE. TO

AID IN INSURING

THAT

THIS

EQUIPMENT

IS

OPERATED WITH A MAXIMUM AMOUNT OF

SAFETY.

WE

HAVE PREPARED THE FOLLOWING LIST

OF

RECOMMENDATIONS. THIS LIST

IS

NOT

INTENDED

TO

BE ALL INCLUSIVE AND ADDITIONAL SAFETY PRECAUTIONS SHOULD BE

FOLLOWED. AS

THEY

ARE DICTATED BY THE APPLICATION. PLANT SAFETY PROCEDURES

AND

PARTICULAR WORKING CONDITIONS.

1. SAFETY EQUIPMENT

TO

BE WORN BY OPERATORS.

A. GOGGLES

B. HARD HELMET WITH EAR PROTECTION

C.

STEEL TOED SHOES

D. HEAVY-DUTY RUBBER UNIFORMS AND GLOVES

2. THE LANCE

MUST

ALWAYS BE DIRECTLY POINTED AT THE WORK AREA.

3. THE OPERATOR MUST MAINTAIN GOOD FOOTING.

4. NON OPERATORS MUST REMAIN A SAFE DISTANCE FROM THE OPERATOR. THE

DISTANCE SHOULD BE A MINIMUM

OF

25 FEET.

5. NON OPERATORS SHOULD NEVER APPROACH THE OPERATOR WITHOUT FIRST

TURNING THE SAFETY ELECTRICAL SWITCH OFF

AT

THE

UNIT.

6. THE OPERATING PRESSURE SHOULD NEVER EXCEED

THAT

WHICH IS NECESSARY

TO

ACCOMPl.,ISH

THE

JOB.

7. NO UNAUTHORIZED ATTACHMENTS OR MODIFICATIONS SHOULD BE MADE

TO

THE UNIT.

THE

CLEANING GUN,

OR

THE

ACCESSORIES.

8. OPERATORS SHOULD BE CHANGED ON FREQUENT INTERVALS

TO

AVOID FATIGUE.

9. OPERATORS AND ALL PERSONS WITHIN THE OPERATING AREA SHOULD NOT ENGAGE IN

"GOOFINGOFF" PRACTICES.

10. EQUIPMENT SHOULD BE PROPERLY MAINTAINED AS OUTLINED IN THE MAINTENANCE

MANUAL.

11. ALL OPERATORS SHOULD BE PROPERLY TRAINED AS OUTLINED

IN

THE MAINTENANCE

MANUAL.

12. EQUIPMENT SHOULD BE CLEANED OFTEN

TO

PREVENT DIRT AND OTHER BUILD-UPS.

Figure 2-2. Recommended Safety Procedures Decal.

© Copyright January,

2001

NLB Corporation

2-7

Revision 1

II. Safety Aspects of High Pressure Water Cleaning Systems

For maximum operational safety, the following equipment and manual procedures must be

used where applicable:

A.

Equipment

High Pressure Pump

The principal component

of

the high pressure water jetting cleaning system is usually a

positive displacement high pressure pump which discharges water into a common manifold

to

which flexible hoses or lances with nozzles or other cleaningor cutting accessories are

attached. The pumps are appropriately powered and can be either mobile or permanently

mounted. They shall never be operated above NLB's recommended operating pressure.

ReliefSystem

The system shall be equipped with an automatic relief device on the discharge side

of

the

pump, adjusted so that the maximum allowable working pressure of the system is not

exceeded by more than 3%.

Pressure Gauge

The system shall be equipped with a gauge

to

indicate the pressure being developed.

Filter

or

Strainer

The water system shall be equipped with a filter or strainer to prevent particles from entering

the high pressure pump and damaging the plungers.

Dump System

The system shall be equipped with a device which will by-pass the flow or dump the

discharge pressure

to

a safe level immediately when actuated.

An

operator shall control this

dump system.

Hose Assembly

Hose assemblies used on the discharge side of the pump shall have a safety factor

of

3.0

based on the manufacturer's rated minimum burst pressure.

Fittings/Valves

All fittings and valves used in the discharge side

of

the pump shall have a safety factor

of

3.0

based on the tensile strength

of

the materials.

Electrical Controls

All electrical controls handled by personnel shall be either fail safe, low voltage or protected

with an approved ground fault circuit interrupter.

© Copyright January,

2001

NLB Corporation

2-8

Revision 1

B.

Personal Protective Equipment

It

is essential that each operator wear the appropriate protective equipment

to

accomplish the

job safely. The following is a list of NLB recommended safety equipment:

Body Protection

Liquid resistant suits

Head Protection

Head protection equipment -hard hats

Eye

and

Face Protection

Protective eye and face equipment -face shields

Foot Protection

Steel-toed boots

Hand Protection

NLB safety gloves

Ear

Protection

Ear plugs or other suitable protection shall be worn when noise level exceeds OSHA

recommended levels.

Recommendation

The safety engineer or someone thoroughly familiar with the potential hazards to be found at

the location where the work is being performed should be consulted prior to starting work to

determine potential environmental and/or personal problems peculiar

to

that specific task.

If

any are determined

to

exist, appropriate action must be taken prior

to

starting the job.

© Copyright January,

2001

NLB Corporation

2-9

Revision 1

C.

Pre-Operational Procedures

Planning

Pre-job planning shall take place prior

to

start of any job. Personnel familiar with the

equipment to be cleaned and the environment of the work area shall meet with the personnel

who will be doing the cleaning or cutting and outline the potential hazards of the work area,

environmental problems and safety standards.

Check

List

A safety and equipment check list shall be used.

Barricades

Barricades shall be erected to enclose hazardous areas. Barricades may be rope, safety tapes,

barrels, etc.,

as

long as an effective visible barrier is provided.

Hook-Up

Inspect all hoses and fittings for evidence

of

excessive wear and damage prior

to

installing.

Hoses should be laid out in a safe and orderly manner.

Hoses, pipes and fittings shall be supported

to

prevent excessive sway, vibration or stress on

end connections. Hoses should be protected

to

prevent kinking or excessive wear.

Nozzles

Before installing the nozzle, the system shall be completely flushed with sufficient water

to

remove air and foreign particles.

Inspect all nozzles for damage and/or plugged orifices before installing. The high pressure

water jetting unit should be shut off and disconnected before installing nozzles.

© Copyright January,

2001

NLB Corporation

2-10

This manual suits for next models

10

Table of contents

Popular Water Pump manuals by other brands

Eckerle

Eckerle EE 400M installation instructions

LEYBOLD

LEYBOLD SOGEVAC SV25 FP operating instructions

Ceco

Ceco Sethco P90S quick start guide

Wilo

Wilo Rexa UNI Installation and operating instructions

Torishima Pump

Torishima Pump CAL manual

Grundfos

Grundfos PS.R.05-17 Installation and operating instructions

AITECS

AITECS 2015 Service manual

LMI

LMI ROYTRONIC EXCEL AD9 series Programming guide

Hydromatic

Hydromatic HP33 owner's manual

Graco

Graco Therm-O-Flow C03508 Instructions and parts

BLACKMER

BLACKMER TRANSMAX TX206A Installation, operation and maintenance instructions

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 02K31-X2 1P Installation, operation, and maintenance manual with parts list